ASTM E1208-10

(Practice)Standard Practice for Fluorescent Liquid Penetrant Testing Using the Lipophilic Post-Emulsification Process

Standard Practice for Fluorescent Liquid Penetrant Testing Using the Lipophilic Post-Emulsification Process

SIGNIFICANCE AND USE

Liquid penetrant examination methods indicate the presence, location, and, to a limited extent, the nature and magnitude of the detected discontinuities. This test method is normally used for production examination of critical components or structures when (a) removal of excessive amounts of penetrant from discontinuities using a water-washable process can be a problem and (b) the use of a hydrophilic remover is impractical.

SCOPE

Liquid penetrant examination methods indicate the presence, location, and, to a limited extent, the nature and magnitude of the detected discontinuities. This practice is normally used for production examination of critical components or structures when (a) removal of excessive amounts of penetrant from discontinuities using a water-washable process can be a problem and (b) the use of a hydrophilic remover is impractical.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1208 −10

StandardPractice for

Fluorescent Liquid Penetrant Testing Using the Lipophilic

1

Post-Emulsification Process

This standard is issued under the fixed designation E1208; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

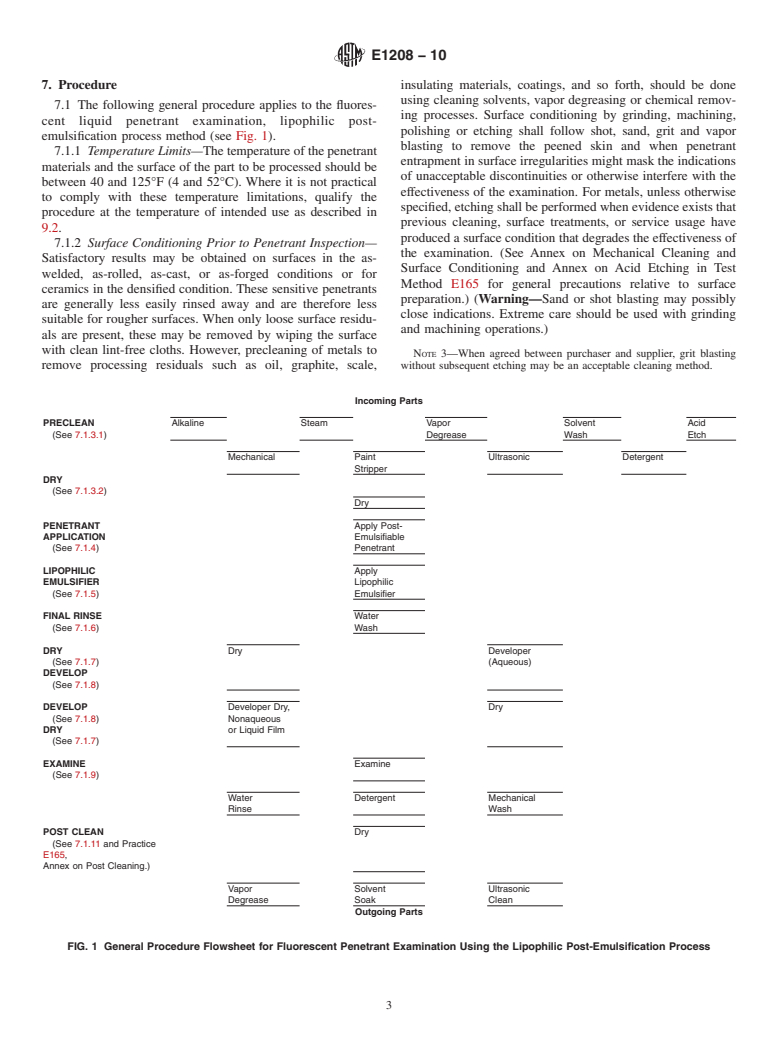

1. Scope 1.5 All areas of this document may be open to agreement

between the cognizant engineering organization and the

1.1 This practice covers procedures for fluorescent liquid

supplier, or specific direction from the cognizant engineering

penetrant examination utilizing the lipophilic post-

organization.

emulsificationprocess.Itisanondestructivetestingmethodfor

1.6 This standard does not purport to address all of the

detecting discontinuities that are open to the surface such as

safety concerns, if any, associated with its use. It is the

cracks, seams, laps, cold shuts, laminations, through leaks, or

responsibility of the user of this standard to establish appro-

lack of fusion and is applicable to in-process, final, and

priate safety and health practices and determine the applica-

maintenance examination. It can be effectively used in the

bility of regulatory limitations prior to use.

examination of nonporous, metallic materials, both ferrous and

of nonmetallic materials such as glazed or fully densified

2. Referenced Documents

ceramics and certain nonporous plastics and glass.

2

2.1 ASTM Standards:

1.2 This practice also provides a reference: D129 Test Method for Sulfur in Petroleum Products (Gen-

eral High Pressure Decomposition Device Method)

1.2.1 By which a fluorescent liquid penetrant examination,

D516 Test Method for Sulfate Ion in Water

lipophilic post-emulsification process recommended or re-

D808 Test Method for Chlorine in New and Used Petroleum

quiredbyindividualorganizationscanbereviewedtoascertain

Products (High Pressure Decomposition Device Method)

its applicability and completeness.

D1552 Test Method for Sulfur in Petroleum Products (High-

1.2.2 For use in the preparation of process specifications

Temperature Method)

dealing with the fluorescent penetrant examination of materials

E165 Practice for Liquid Penetrant Examination for General

and parts using the lipophilic post-emulsification process.

Industry

Agreement by the purchaser and the manufacturer regarding

E433 Reference Photographs for Liquid Penetrant Inspec-

specific techniques is strongly recommended.

tion

1.2.3 For use in the organization of the facilities and

E543 Specification forAgencies Performing Nondestructive

personnel concerned with the liquid penetrant examination.

Testing

E1316 Terminology for Nondestructive Examinations

1.3 This practice does not indicate or suggest standards for

3

2.2 ASNT Documents:

evaluationoftheindicationsobtained.Itshouldbepointedout,

Recommended Practice SNT-TC-1A Personnel Qualifica-

however, that indications must be interpreted or classified and

tion and Certification in Nondestructive Testing

then evaluated. For this purpose there must be a separate code

ANSI/ASNT-CP-189 QualificationandCertificationofNDT

or specification or a specific agreement to define the type, size,

Personnel

location, and direction of indications considered acceptable,

4

2.3 Military Standard:

and those considered unacceptable.

MIL-STD-410 Nondestructive Testing Personnel Qualifica-

1.4 The values stated in inch-pound units are regarded as

tion and Certification

standard.SIunitsgiveninparenthesesareforinformationonly.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This practice is under the jurisdiction of ASTM Committee E07 on Nonde- Standards volume information, refer to the standard’s Document Summary page on

structive Testing and is the direct responsibility of Subcommittee E07.03 on Liquid the ASTM website.

3

Penetrant and Magnetic Particle Methods. Available fromTheAmerican Society for NondestructiveTesting (ASNT), P.O.

Current edition approved Feb. 15, 2010. Published March 2010. Originally Box 28518, 1711 Arlingate Lane, Columbus, OH 43228-0518.

4

approved in 1987. Last previous edition approved in 2005 as E1208 - 05. DOI: AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

10.1520/E1208-10. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1208−10

5

2.4 AIA Standard: family of post-emulsifiable fluorescent penetrant, lipophilic

NAS 410 Certification and Qualification of Nondestructive emulsifier, a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.