ASTM D3353-04

(Test Method)Standard Test Methods for Fibrous-Insulated Magnet Wire

Standard Test Methods for Fibrous-Insulated Magnet Wire

ABSTRACT

These test methods cover the testing of fibrous-insulated electrical conductors, commonly referred to as magnet wire, which are used in electrical apparatus. The test methods are intended primarily for evaluation of the electrical insulating materials used. It is intended that these test methods be used, except where modified by individual specifications for particular applications. This elongation testing method covers the determination of the elongation of fibrous insulated magnet wire that results in a fracture of the conductor. The electrical resistance testing method covers the determination of the electrical resistance of fibrous insulated magnet wire conductors. The fibrous coverage testing method covers the determination of the quality of fibrous servings on round magnet wire or bare conductor. The measurement of dimensions test methods determine the dimensions of the bare or film insulated conductor and the fibrous-insulated magnet wire. The adhesion and flexibility test method covers the evaluation of the flexibility and adherence of varnished fibrous glass, and varnished or unvarnished fibrous polyester-glass insulating material on either bare conductor, or film-insulated magnet wire. The dielectric breakdown voltage test method covers the determination of the dielectric breakdown voltage in air of insulation on round, rectangular, and square wires at commercial power frequencies.

SCOPE

1.1 These test methods cover the testing of fibrous-insulated electrical conductors, commonly referred to as magnet wire, which are used in electrical apparatus. The test methods are intended primarily for evaluation of the electrical insulating materials used. It is intended that these test methods be used, except where modified by individual specifications for particular applications.

1.1.1 These test methods apply to those magnet wires that are fiber-covered and in which the substrate is bare conductor or is coated with an underlying insulating film as covered by Test Methods D 1676. Fiber-covered wires are produced by serving helically or wrapping fibers or fibrous-tape insulation uniformly around the wire in single and multiple layers. The served or wrapped materials are bonded or not bonded to the underlying wire.

1.2 The values stated in inch-pound units are the standard. The SI equivalents of inch-pound units are provided for reference.

1.3 The test methods appear in the following sections:ProcedureSectionMeasurement of Dimensions7Electrical Resistance of Conductors 5Elongation4Adhesion and Flexibility8Fibrous Coverage6Dielectric Breakdown Voltage9

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.See and for specific caution statements.

1.4 This standard and IEC 60851 are similar if not equivalent in technical content.

1.5 This standard and NEMA, MW 1000 are similar if not equivalent in technical content.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation:D3353–04

Standard Test Methods for

1

Fibrous-Insulated Magnet Wire

This standard is issued under the fixed designation D3353; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 These test methods cover the testing of fibrous-insulated 2.1 ASTM Standards:

electrical conductors, commonly referred to as magnet wire, B193 Test Method for Resistivity of Electrical Conductor

which are used in electrical apparatus. The test methods are Materials

intended primarily for evaluation of the electrical insulating D149 Test Method for Dielectric Breakdown Voltage and

materials used. It is intended that these test methods be used, Dielectric Strength of Solid Electrical Insulating Materials

except where modified by individual specifications for particu- at Commercial Power Frequencies

lar applications. D1676 Test Methods for Film-Insulated Magnet Wire

1.1.1 These test methods apply to those magnet wires that D1711 Terminology Relating to Electrical Insulation

are fiber-covered and in which the substrate is bare conductor D5423 Specification for Forced-Convection Laboratory

or is coated with an underlying insulating film as covered by Ovens for Evaluation of Electrical Insulation

Test Methods D1676. Fiber-covered wires are produced by E8 Test Methods for Tension Testing of Metallic Materials

serving helically or wrapping fibers or fibrous-tape insulation 2.2 Other Standards:

3

uniformly around the wire in single and multiple layers. The IEC 60851 Methods of Test for Winding Wires

served or wrapped materials are bonded or not bonded to the NEMA Standards Publication No. MW 1000 on Magnet

4

underlying wire. Wire

1.2 The values stated in inch-pound units are the standard.

3. Terminology

The SI equivalents of inch-pound units are provided for

3.1 Definitions:

reference.

1.3 The test methods appear in the following sections: 3.1.1 For definitions of terms used in this test method, refer

to Terminology D1711.

Procedure Section

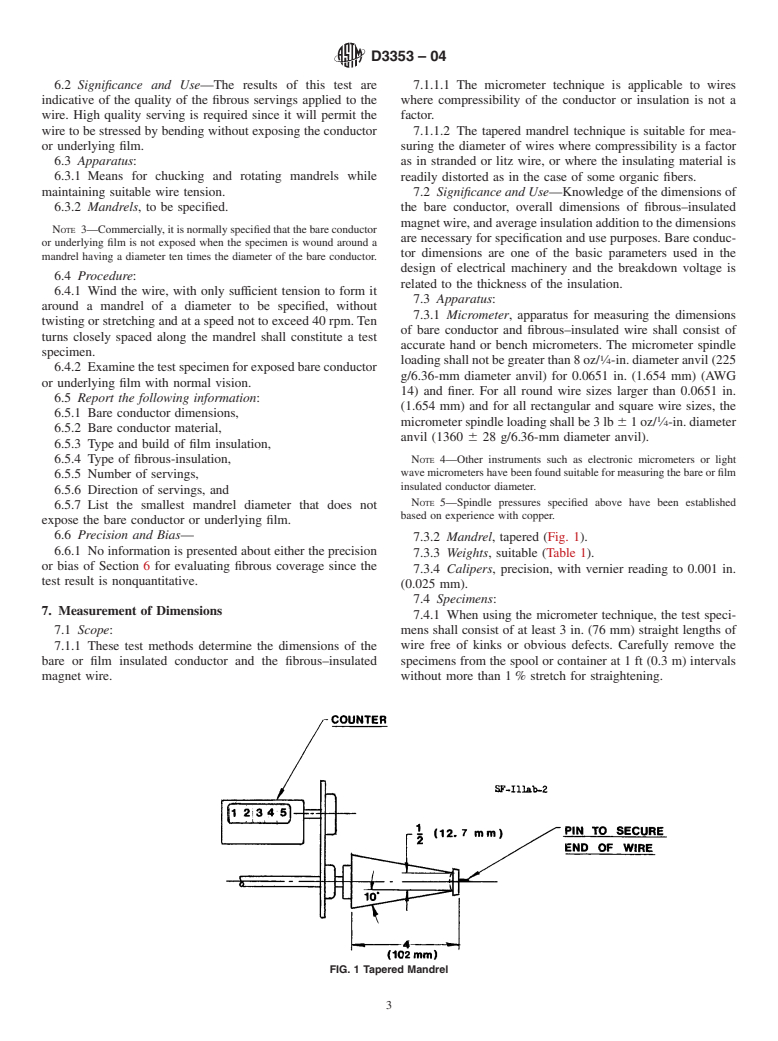

Measurement of Dimensions 7

3.1.2 Definition of Term(s) Specific to this Standard:

Electrical Resistance of Conductors 5

3.1.2.1 serving—a uniform wrapping of fibrous insulation

Elongation 4

around a magnet wire of bare conductor.

Adhesion and Flexibility 8

Fibrous Coverage 6

3.1.2.2 fibrous coverage, of served-magnet wire—that char-

Dielectric Breakdown Voltage 9

acteristic which allows a fibrous served magnet wire to be

1.4 This standard does not purport to address all of the wound around mandrels in a prescribed manner without

safety concerns, if any, associated with its use. It is the causing observable openings in the fibrous coverage.

responsibility of the user of this standard to establish appro-

4. Elongation

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.See 8.4.1 and 9.4.1 4.1 Scope—This test method covers the determination of

for specific caution statements. the elongation of fibrous insulated magnet wire that results in

1.5 This standard and IEC 60851 are similar if not equiva- a fracture of the conductor.

lent in technical content. 4.2 Significance and Use—The elongation determined by

1.6 This standard and NEMA, MW 1000 are similar if not this test method provides a general measure of the ductility of

equivalent in technical content.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

These test methods are under the jurisdiction of ASTM Committee D09 on Standards volume information, refer to the standard’s Document Summary page on

Electrical and Electronic Insulating Materials and are the direct responsibility of the ASTM website.

3

Subcommittee D09.10 on Magnet Wire Insulation. Available from International Engineering Consortium, 549 West Randolph

Current edition approved April 1, 2004. Published May 2004. Originally Street, Suite 600, Chicago IL 60661–2208.

4

approved in 1974. Last previous edition approved in 1998 as D3353 – 98. DOI: Available from National Electrical Manufacturers Association (NEMA), 1300

10.1520/D3353-04. N. 17th St., Suite 1847, Rosslyn, VA 22209.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3353–04

the conductor and the effect of the processing to which it has 4.7 Precision and Bias:

been subjected during the insulating operation.

4.7.1 This test method has been in use for many years, but

4.3 Apparatus—Theequipmen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.