ASTM E1951-14(2019)

(Guide)Standard Guide for Calibrating Reticles and Light Microscope Magnifications

Standard Guide for Calibrating Reticles and Light Microscope Magnifications

SIGNIFICANCE AND USE

4.1 These methods can be used to determine magnifications as viewed through the eyepieces of light microscopes.

4.2 These methods can be used to calibrate microscope magnifications for photography, video systems, and projection stations.

4.3 Reticles may be calibrated as independent articles and as components of a microscope system.

SCOPE

1.1 This guide covers methods for calculating and calibrating microscope magnifications, photographic magnifications, video monitor magnifications, grain size comparison reticles, and other measuring reticles. Reflected light microscopes are used to characterize material microstructures. Many materials engineering decisions may be based on qualitative and quantitative analyses of a microstructure. It is essential that microscope magnifications and reticle dimensions be accurate.

1.2 The calibration using these methods is only as precise as the measuring devices used. It is recommended that the stage micrometer or scale used in the calibration should be traceable to the National Institute of Standards and Technology (NIST) or a similar organization.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:E1951 −14 (Reapproved 2019)

Standard Guide for

Calibrating Reticles and Light Microscope Magnifications

This standard is issued under the fixed designation E1951; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This guide covers methods for calculating and calibrat- 4.1 These methods can be used to determine magnifications

ing microscope magnifications, photographic magnifications, as viewed through the eyepieces of light microscopes.

video monitor magnifications, grain size comparison reticles,

4.2 These methods can be used to calibrate microscope

and other measuring reticles. Reflected light microscopes are

magnifications for photography, video systems, and projection

used to characterize material microstructures. Many materials

stations.

engineering decisions may be based on qualitative and quan-

4.3 Reticlesmaybecalibratedasindependentarticlesandas

titative analyses of a microstructure. It is essential that micro-

components of a microscope system.

scope magnifications and reticle dimensions be accurate.

1.2 Thecalibrationusingthesemethodsisonlyaspreciseas

5. Procedures

the measuring devices used. It is recommended that the stage

5.1 Nominal Magnification Calculations:

micrometer or scale used in the calibration should be traceable

5.1.1 A calculated magnification, using the manufacturer’s

to the National Institute of Standards and Technology (NIST)

or a similar organization. supplied ratings, is only an approximation of the true

magnification, since individual optical components may vary

1.3 This standard does not purport to address all of the

from their marked magnification. For a precise determination

safety concerns, if any, associated with its use. It is the

of the magnification observed through an eyepiece, see the

responsibility of the user of this standard to establish appro-

procedure describe in 5.5.

priate safety, health, and environmental practices and deter-

5.1.2 For a compound microscope, the total magnification

mine the applicability of regulatory limitations prior to use.

(M) of an image through the eyepiece is the product of the

1.4 This international standard was developed in accor- t

objective lens magnification (M ), the eyepiece magnification

o

dance with internationally recognized principles on standard-

(M ), and, if present, a zoom system or other intermediate lens

ization established in the Decision on Principles for the e

magnification (M).An expression for the total magnification is

Development of International Standards, Guides and Recom- i

shown in Eq 1.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

M 5 M 3M 3M (1)

t o e i

5.1.3 Example 1—For a microscope configured with a 10X

2. Referenced Documents

objective, a 10X eyepiece, and a 1.25X intermediate lens, the

2.1 ASTM Standards:

total magnification observed through the eyepiece would be

E7 Terminology Relating to Metallography

calculated as follows.

E112 Test Methods for Determining Average Grain Size

M 5 1031031.25 5 125 (2)

t

3. Terminology

5.2 Calibration for Photomicrography Magnifications:

3.1 Definitions—All terms used in this guide are defined in 5.2.1 The magnification of an image can be determined by

Terminology E7. photographing a calibrated stage micrometer using the desired

optical setup. First, photograph the stage micrometer using the

desired combination of objective, bellows extension, zoom and

ThisguideisunderthejurisdictionofASTMCommitteeE04onMetallography

intermediate lens, and then measure the apparent ruling length

and is the direct responsibility of Subcommittee E04.03 on Light Microscopy.

on the photomicrograph. The measurement should be made

Current edition approved Nov. 1, 2019. Published November 2019. Originally

consistently from an edge or center of one division to the

approved in 1998. Last previous edition approved in 2014 as E1951–14. DOI:

10.1520/E1951-14R19.

corresponding edge or center of another (see Note 1). By

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

dividing this apparent length of ruling by the known dimension

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

of the micrometer, the magnification of the photomicrograph is

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. determined (see Fig. 1). The accuracy of the calibration is

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1951−14 (2019)

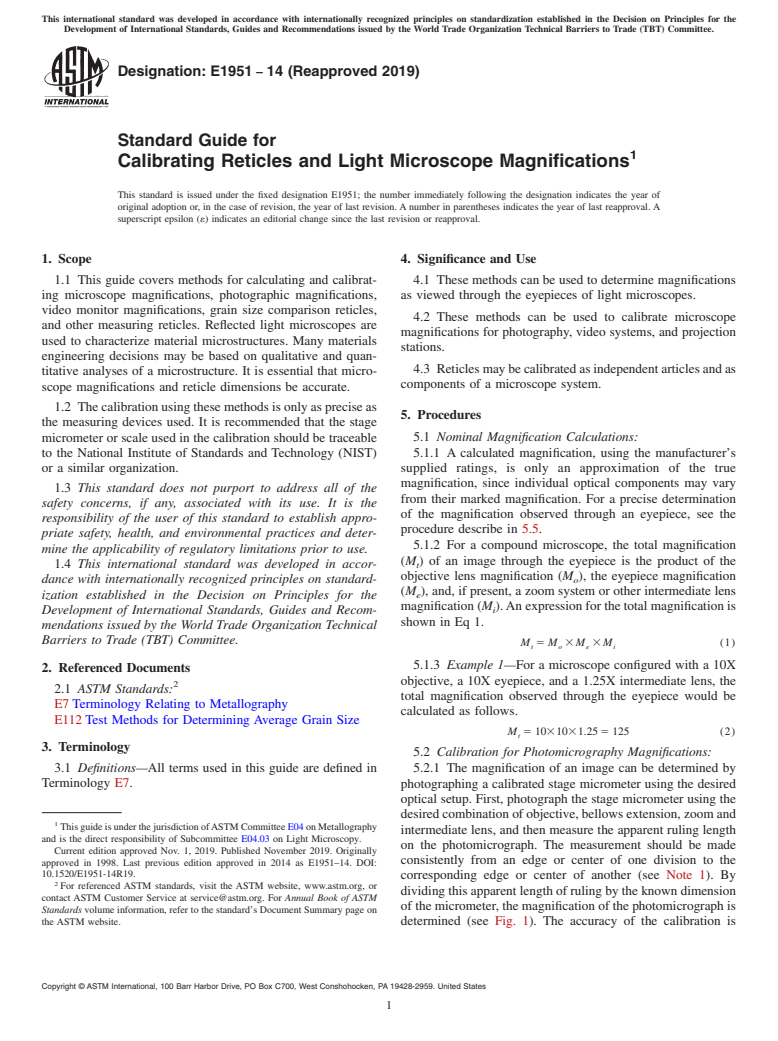

NOTE 1—This schematic shows the procedure used to determine the calibrated magnifications of video screens, video printers, projection screens, and

photographs.

FIG. 1 Procedure for Determining Calibrated Magnifications

dependent on the accuracy of the calibrated stage micrometer directly on the screen, or by transferring the apparent length to

and the scale used to measure the apparent length of the a scale using pinpoint dividers. Virtually all modern computer

photographed ruling.

monitors use square pixels, so the x(horizontal) and y(vertical)

magnifications are the same provided that the monitor is

NOTE1—Thechoiceofusingtheedgeorcenterofareticlelinedepends

displayed in its native resolution. If the monitor screen reso-

on the method of manufacture used to produce the measuring device.

Some devices are calibrated from center to center while others are lution is set to other than its native resolution, the magnifica-

measured from one edge to another. Consult with the manufacturer to

tions may be different between the x and y axes and result in a

determine which method should be employed.

distortedimage.Themeasurementshouldbemadeconsistently

5.2.2 Example 2—For a metallograph with a given configu-

from an edge or center of one division to the corresponding

ration (50X objective), determine the calibrated magnification

edge or center of another. The magnification is calculated by

of a photomicrograph.

dividing the measured apparent length by the known dimen-

5.2.2.1 Aphotograph of a stage micrometer was taken (Fig.

sions of the micrometer (see Example 2 in 5.2.2 and Fig. 1).

1). A rule was overlaid. From one corresponding edge of a

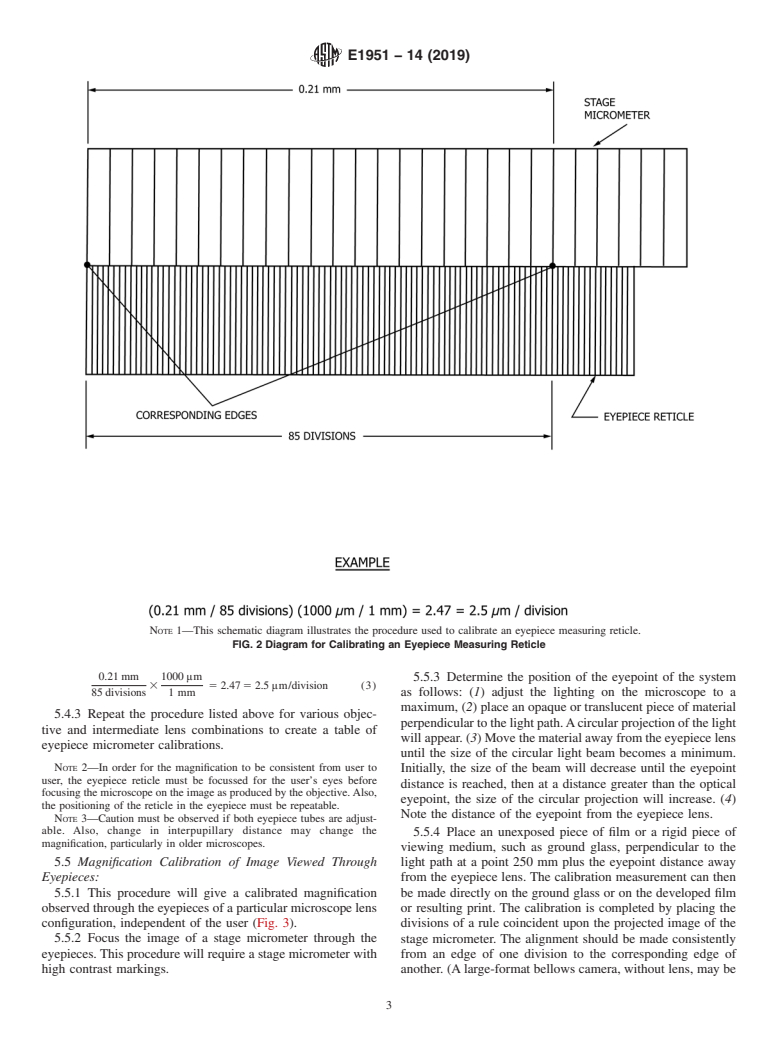

5.4 Eyepiece Micrometer Calibration:

division to another, using the rule, a distance of 62 mm was

measuredoveraknowndistanceof0.12mmonthephotograph 5.4.1 To calibrate an eyepiece micrometer reticle, view

of the stage micrometer. Dividing 62 mm by 0.12 mm yields a through the eyepiece an image of a stage micrometer using a

photographic magnification of 517X.

givenobjectiveandintermediatelenscombination.Overlaythe

5.2.3 By photographing a stage micrometer using various

eyepiece micrometer image on the stage micrometer image,

combinations of objectives, intermediate lenses, zoom and

with one end of each coincident upon one another. The

bellows extensions, a table can be produced which summarizes

measurement should be made consistently from an edge of one

the possible magnifications of a system. Microscopes incor-

division to the corresponding edge of another (Fig. 2). The

porating devices allowing continuous magnification ranges

eyepiece reticle calibration can be determined by dividing the

(zooms) should not be used for critical measurements, except

known length of the stage micrometer by the number of

by including reference photos of traceable reticles taken

overlaid eyepiece micrometer divisions.This calculation yields

concurrently with the measured item. Mechanical play in these

a length per division value of the micrometer for a given

devices can be a significant source of error.

optical setup.

5.3 Calibration for Computer Monitors:

5.4.2 Example 3—For a given microscope configuration

5.3.1 For computer monitors, the magnification can be

(40X objective), determine the length per division value of an

calibrated as follows. Focus an image of a stage micrometer on

eyepiece micrometer.

the screen, and then measure the projected apparent length of

5.4.2.1 The image of the eyepiece micrometer was aligned

the ruling. If convenient, the measurement can be made

with the stage micrometer image (Fig. 2). Eighty-five divisions

were counted over a distance of 0.21 mm on the stage

3 micrometer. The length per division can then be calculated as

Vander Voort, G. F., Metallography, Principles and Practice, McGraw Hill,

follows.

New York, NY, 1984, pp. 279-280.

E1951−14 (2019)

NOTE 1—This schematic diagram illustrates the procedure used to calibrate an eyepiece measuring reticle.

FIG. 2 Diagram for Calibrating an Eyepiece Measuring Reticle

0.21 mm 1000 µm

5.5.3 Determine the position of the eyepoint of the system

3 5 2.47 5 2.5 µm/division (3)

85 divisions 1mm as follows: (1) adjust the lighting on the microscope to a

maximum, (2) place an opaque or translucent piece of material

5.4.3 Repeat the procedure listed above for various objec-

perpendiculartothelightpath.Acircularprojectionofthelight

tive and intermediate lens combinations to create a table of

will appear. (3) Move the material away from the eyepiece lens

eyepiece micrometer calibrations.

until the size of the circular light beam becomes a minimum.

NOTE 2—In order for the magnification to be consistent from user to

Initially, the size of the beam will decrease until the eyepoint

user, the eyepiece reticle must be focussed for the user’s eyes before

distance is reached, then at a distance greater than the optical

focusing the microscope on the image as produced by the objective.Also,

eyepoint, the size of the circular projection will increase. (4)

the positioning of the reticle in the eyepiece must be repeatable.

Note the distance of the eyepoint from the eyepiece lens.

NOTE 3—Caution must be observed if both eyepiece tubes are adjust-

able. Also, change in interpupillary distance may change the

5.5.4 Place an unexposed piece of film or a rigid piece of

magnification, particularly in older microscopes.

viewing medium, such as ground glass, perpendicular to the

5.5 Magnification Calibration of Image Viewed Through light path at a point 250 mm plus the eyepoint distance away

Eyepieces: from the eyepiece lens. The calibration measurement can then

5.5.1 This procedure will give a calibrated magnification be made directly on the ground glass or on the developed film

observed through the eyepieces of a particular microscope lens or resulting print. The calibration is completed by placing the

configuration, independent of the user (Fig. 3). divisions of a rule coincident upon the projected image of the

5.5.2 Focus the image of a stage micrometer through the stage micrometer. The alignment should be made consistently

eyepieces. This procedure will require a stage micrometer with from an edge of one division to the corresponding edge of

high contrast markings. another. (Alarge-format bellows camera, without lens, may be

E1951−14 (2019)

NOTE 1—A schematic diagram illustrating the procedure used to determine the magnification observed through the microscope eyepieces.

FIG. 3 Diagram for Magnification Observed Through Microscope Eyepieces

conveniently used here. If this is done, a film of the image can 5.6 Filar Eyepiece Calibration:

also be exposed, with the calibration then performed on the 5.6.1 The calibration of a filar measuring eyepiece is similar

developed film.) to that of an eyepiece reticle as illustrated in Fig. 2. The

5.5.5 Determine the observed magnification by dividing the moveable cross-hair in the eyepiece is positioned at an extreme

measured length of the projected section of the stage microm- end of a stage micrometer coincident with one micrometer

eter by the known length of that section of the stage microm- division. The measurement should be made consistently from

eter. an edge or the center of one division to another.

5.5.6 Repeat this procedure for various objective and inter- 5.6.2 For a drum filar eyepiece, note the micrometer drum

mediate lens combinations to create a table of observable value. Traverse the cross-hair over as many micrometer divi-

magnifications. sions as possible that are visible in the central region of the

5.5.7 Example 4—Determine the magnification viewed field of view. Note the new micrometer drum value. To obtain

through an eyepiece with a microscope configuration consist- the total drum movement, subtract the final drum value from

ing of a 10X objective and a 10X eyepiece. the initial value. The value of each increment on the filar drum

5.5.7.1 Using an overhead transparency, and a rule placed is determined by dividing the actual length traversed on the

perpendicular to the plane of the eyepiece lens, the eyepoint stage micrometer by the total drum movement. Repeat this

was determined to be at a distance of 18 mm. Next, a distance procedure for each objective of interest. This calculation is

of 268 mm was measured perpendicular from the plane of the similar to that of determining an eyepiece micrometer calibra-

eyepiece. tion ( Example 3 in Section 5.4.2.1).

5.5.7.2 Aviewingmediumwasfixedatthisdistanceparallel 5.6.3 For digital filar eyepieces, a multiplier must be deter-

to the plane of the eyepiece lens. The divisions of a rule were mined for each objective.

placed coincident upon the projected image of the stage 5.6.3.1 To determine the value of the multiplier for a

micrometer consistently from an edge of one division to the specificmicroscopeconfiguration,setthemultipliertoone,and

corresponding edge of another. A distance of 89 mm was traverse a known distance.

measured over a known distance of 0.9 mm on the stage 5.6.3.2 Thevalueofthemultiplierisdeterminedbydividing

micrometer. By dividing the measured length by the known the known distance traversed by the value determined by the

length a calibrated magnification of 99X was determined. filar eyepiece.

E1951−14 (2019)

5.6.3.3 Next, set the instrument to zero, and enter the 5.7.3 All grain size comparison graphics are calibrated for

approximate multiplier into the system. Traverse the stage size by the number of grain sections per unit area. The reticle

micrometer as described in the previous section. If the mea- figure area for a single grain size must be measured, then

sured distance is incorrect, adjust the multiplier according

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.