ASTM F239-81(1987)

(Specification)Specification for Nickel Alloy Cathode Sleeves for Electron Devices (Withdrawn 1992)

Specification for Nickel Alloy Cathode Sleeves for Electron Devices (Withdrawn 1992)

General Information

Standards Content (Sample)

~ ~~

= 9009276 0038225 221

Designation: F 239 - 81 (Reapproved 1987)

ab

Standard Specification for

NICKEL ALLOY CATHODE SLEEVES FOR ELECTRON

DEVICES’

This standard is issued under the fixed designation F 239: the number immediately following the designation indicates the year of

original adoption or. in the case of revision, the year of last revision. A number in parenthaes indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change sina the last revision or reapproval.

1. scope

3.1.6 Bead diameter,

3.1.7 Bead location, and

1.1 This specification covers nickel alloy

3.1.8 Number of cathode sleeves required.

cathode sleeves, seamless, welded-and-drawn,

lockseam, or lapseam, for use as indirectly

4. hlateriaìsandManufacîure

heated oxide-coated cathodes in electron de-

4. i The cathode sleeves shall be of such quai-

vices.

ity, purity, and surface cleanness (Section 10)

1.2 The values sîated in inch-pound units are

that the finished product shali have the properties

to be regarded as the standard. The values in

and characteristics prescribed in this dca-

parentheses are for information only.

tion.

2. Referenced Documents

4.2 The cathode sleeves shali be manufac-

tured by hot working and cold drawing or cold

2.1 ASTM Standards:

roliing, welding and drawing, or seaming as

E39 Methods for Chemical Analysis of

may be required.

Nickel*

E 107 Methods for Chemical Analysis ofElec-

5. Chemicai Composition

tronic Nickel2

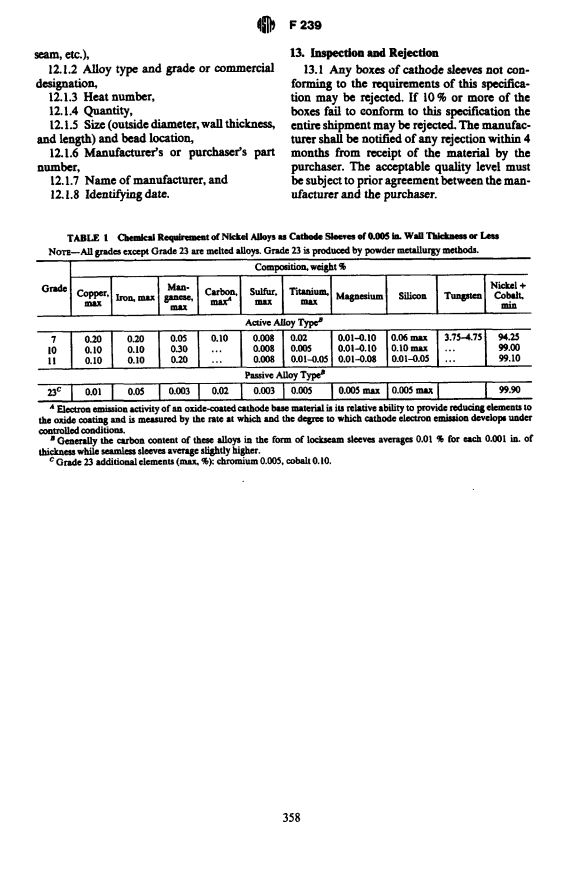

5.1 Chemical Composition-The cathode

E 129 Method for Spectrographic Analysis of

sleeves shall conform to the requirements as to

Thermionic Nickel Alloys by the Powder

chemical composition for the particular grade

Techniques3

ordered, as prescribed in Table 1.

E 383 Method for X-Ray Emission Spectro-

5.2 Cert@cation-The manufacturer of the

metric Determination of Tungsten in

cathode sleeves shall, upon request, furnish a

Nickel-Tungsten Alloys4

certified analysis covering the elements, except

F I28 Methods of Testing Sleeves and Tubing

carbon, listed in Table 1 for the particular grade

for Electron Tube Cathodes)

specified. The carbon content will vary slightly

3. ordering information

from lot to lot of a heat and for different

3.1 Orders for cathode sleeves furnished to

thicknesses of cathode sleeves. The certificate

this specification shall include the following

shail state whether the carbon content is within

information, ali dimensions being expressed in

the limits prescribed for the particular grade

inches and decimal parts with metric equiva-

specified.

lents:

3.1.1 Method of fabrication,

’ This specification is under the jurisdiaion of ASTM Com-

3.1.2 Alloy grade (Table i), mim F-1 on Electronics, and U the direct responsibility of

Subcommittee Foi .O3 on Metallic Materials.

3.1.3 Diameter (either outside diameter or

Current edition approved May 29, 1981. Publied August

inside diameter),

l98i.Onginallypublishedin 1949asB239; rodesignatedF239

in 1955. Last previous edition F 239 - 68.

3.1.4 Wali thickness,

Annual Book ofASTM Standard& Vol 03.05.

3.1.5 Length (expressed in inches and di-

’Annual Book ofASTM Standards. Vol 10.04.

metres), ‘Annual Book ofASTM Standards, Vol 03.06.

356

---------------------- Page: 1 ----------------------

-

~-

~

m 900927b 0038226 Lb8 m

F 239

5.3 Chemical Analyses-A chemical analysis 1.6 Integral Tabs-The basic sizes and tol-

emces for integral tabs are as shown in Table

shall be made for each heat of cathode nickel.

The chemical composition thus determined 6. Special requirements shall be as agreed upon

shali be reported to the purchaser or his rep- between the manufacturer and the purchaser.

7.7 St@ne*The minimum cold collapse

resentative and SU conform to the require-

strength of round seamless and lockseam

ments prescribed in Table 1 for the designated

grade. in the event of disagreement, chemical sleeves, measured in grams of collapsing load

analysis shall be performed in accordance with for a designated span, shall be in accordance

one of the following methods: with the values listed in Table 7.

5.3.1 Methods E 39,

NOn-It is intended that limits for minimum

5.3.2 Methods E 107, collapse strength will be developed.

5.3.3 Method E 129,

7.8 Sem-The seam dimensions shall be in

5.3.4 Method E 383, or

accordance with the values listed in Table 8.

5.3.5 X-ray fluorescent or emission heat

analyses using standards analyzed by Methods

8. NumberofTests

1, 2, or 3.

8.1 When a stiffness test is required, the

number of samples tested shall be as agreed

ó. Heat Approval (sermless or Welded-and-

upon between the manufacturer and the pur-

Dram Cathode Sleeves)

chaser.

6.1 When requested by the purchaser, and

9. Test Methods

agreed to by the manufacturer the litter shall

advise the purchaser each time a new heat is

9.1 The dimensions and physical properties

available. The purchaser shall then advise lhe

prescribed in this

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.