ASTM D3825-90(2005)

(Test Method)Standard Test Method for Dynamic Surface Tension by the Fast-Bubble Technique

Standard Test Method for Dynamic Surface Tension by the Fast-Bubble Technique

SIGNIFICANCE AND USE

While this test method can be applied to pure liquids, it is especially designed for use with mixtures in which one or more components migrate to the surface.

Data of this type are needed for the design of equipment for processing mixed liquids, such as in distillation towers.

SCOPE

1.1 This test method covers the determination of the specific free energy of a liquid-gas surface a short time after formation of the surface.

1.2 It is applicable to liquids with vapor pressures up to 30.0 kPa (225 torr) and kinematic viscosities up to 4.0 mm /s (4.0 cSt) at the test temperature. Higher viscosities have not yet been investigated.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see 7.3, 7.4, and 7.5.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D3825–90(Reapproved 2005)

Standard Test Method for

Dynamic Surface Tension by the Fast-Bubble Technique

This standard is issued under the fixed designation D3825; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Definitions of Terms Specific to This Standard:

−1

3.2.1 bubble frequency (S)—bubbling rate, s .

1.1 Thistestmethodcoversthedeterminationofthespecific

3.2.2 bubble pressure (DP)—difference between maximum

free energy of a liquid-gas surface a short time after formation

pressures for the wide capillary (P ) and the narrow capillary

of the surface. 1

(P ), Pa.

1.2 Itisapplicabletoliquidswithvaporpressuresupto30.0

3.2.3 dead time (t )—timerequiredfromstarttocompletion

kPa (225 torr) and kinematic viscosities up to 4.0 mm/s (4.0 o

of a bubble, ms.

cSt) at the test temperature. Higher viscosities have not yet

2 3.2.4 dead time %—fraction of a cycle (t+ t ) in the dead

been investigated. o

state,%.

1.3 The values stated in SI units are to be regarded as

3.2.5 surface age (t)—time required to start a new bubble,

standard. The values given in parentheses are for information

ms.

only.

3.3 Symbols:

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to consult and

g = surface tension, millinewtons per metre (dynes/cm)

−1

establish appropriate safety and health practices and deter-

S = bubble frequency, s

mine the applicability of regulatory limitations prior to use.

t = dead time, ms

o

For specific warning statements, see 7.3, 7.4, and 7.5.

t = surface age, ms

D = density, kg/m

2. Referenced Documents

r = radius, mm

2.1 ASTM Standards: DP = difference between maximum pressures, Pa

D1193 Specification for Reagent Water P = maximum pressure for the wide capillary, Pa

P = maximum pressure for the narrow capillary, Pa

D1331 Test Methods for Surface and Interfacial Tension of

Solutions of Surface-Active Agents

4. Summary of Test Method

E1 Specification for ASTM Liquid-in-Glass Thermometers

4.1 Thepressurerequiredforbubbleformationatacapillary

3. Terminology

tip immersed in the liquid is measured at gas flow rates that

provide a series of bubble frequencies. The pressure and a

3.1 Definitions:

calibration constant are used to calculate the dynamic surface

3.1.1 surface tension (g)—the specific surface free energy

tension at various surface ages.

of a liquid gas interface, millinewton per metre (ergs/cm ).

5. Significance and Use

This test method is under the jurisdiction of ASTM Committee D02 on

5.1 While this test method can be applied to pure liquids, it

PetroleumProductsandLubricantsandisthedirectresponsibilityofSubcommittee

is especially designed for use with mixtures in which one or

D02.11 on Engineering Sciences of High Performance Fluids and Solids.

Current edition approved June 1, 2005. Published August 2005. Originally more components migrate to the surface.

approved in 1990. Last previous edition approved in 2000 as D3825–90(2000).

5.2 Dataofthistypeareneededforthedesignofequipment

DOI: 10.1520/D3825-90R05.

for processing mixed liquids, such as in distillation towers.

Kloubek, J., “Measurement of the Dynamic Surface Tension by the Maximum

Bubble Pressure Method, III,” Journal of Colloid and Interface Science, Vol. 41,

6. Apparatus

October 1972, pp. 7–16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1 Bubbler Unit, water-jacketed, as shown in Fig. 1.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.2 Thermostat, circulating water, to hold bubbler at speci-

Standards volume information, refer to the standard’s Document Summary page on

fied temperature.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3825–90 (2005)

Tips of b and b8 shall be cut squarely at exactly the same level, and finely

ground (for example, 44 µm S;C (320 mesh S;C).

FIG. 1 Bubbler Unit

6.3 Oven, adjustable to 378 K (105°C), explosion-proof. on Analytical Reagents of the American Chemical Society,

6.4 Pressure Transducer, diaphragm-resistive unbonded where such specifications are available. Other grades may be

straingage,timeconstant25msorless,0to2000Pa,accuracy used, provided it is first ascertained that the reagent is of

,

62%. sufficiently high purity to permit its use without lessening the

6.5 Bridge Power Supply, for the strain gage. accuracy of the determination.

6.6 Oscilloscope, capable of sweep times down to 0.020 s. 7.2 Purity of Water—Unlessotherwiseindicated,references

6.7 Filtered (5-µm) Air Supply, with pressure regulator towatershallbeunderstoodtomeanreagentwaterconforming

capable of 0 to 724 kPa (0 to 105 psig) above ambient. to Specification D1193, Type III.

7.3 Calibration Liquids, reagent grade, covering a wide

NOTE 1—Nitrogen shall be used in place of air if there is any problem

rangeofsurfacetension.Acetone,toluene,ethanol,andmetha-

of oxidizing the liquid.

nol have been found satisfactory for this purpose.

6.8 Thermometer, appropriate range, conforming to Speci-

7.3.1 Acetone—(Warning—Extremely flammable. Vapors

fication E1.

may cause flash fire. See Annex A1.1.)

7.3.2 Toluene—(Warning—Flammable. Vapor harmful.

7. Reagents and Materials

See Annex A1.6.)

7.1 Purity of Reagents—Reagent grade chemicals shall be

7.3.3 Methanol—(Warning—Flammable. Vapor harmful.

used in all tests. Unless otherwise indicated, it is intended that

See Annex A1.5.)

allreagentsshallconformtothespecificationoftheCommittee

Reagent Chemicals, American Chemical Society Specifications, American

Razouk, R. “Surface Tension of Propellants,” JPLQuarterly Technical Review Chemical Society, Washington, DC. For suggestions on the testing of reagents not

Vol 2, 1972, pp. 123–133. listed by the American Chemical Society, see Analar Standards for Laboratory

Razouk, R. and Walmsley, D., “Surface Tension Measurement by the Differ- Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

entialMaximumBubblePressureMethodUsingaPressureTransducer,” Journal of and National Formulary,U.S.PharmaceuticalConvention,Inc.(USPC),Rockville,

Colloid and Interface Science, Vol. 47, 1974, pp. 515–519. MD.

D3825–90 (2005)

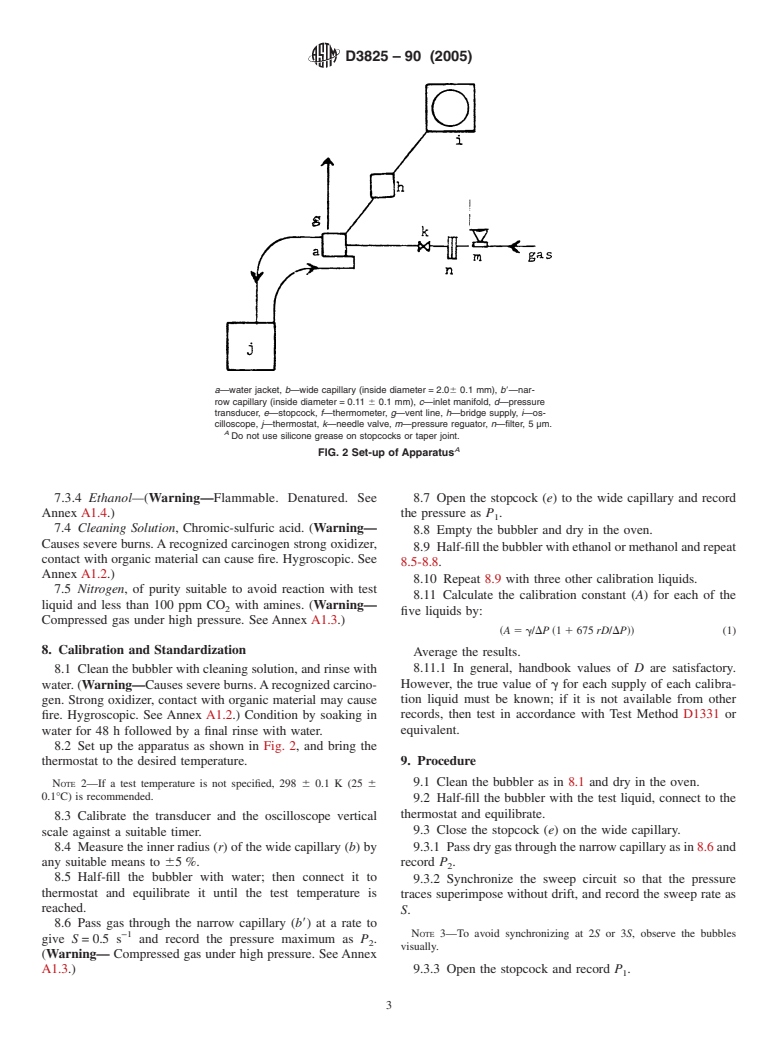

a—water jacket, b—wide capillary (inside diameter = 2.06 0.1 mm), b8—nar-

row capillary (inside diameter = 0.11 6 0.1 mm), c—inlet manifold, d—pressure

transducer, e—stopcock, f—thermometer, g—vent line, h—bridge supply, i—os-

cilloscope, j—thermostat, k—needle valve, m—pressure reguator, n—filter, 5 µm.

A

Do not use silicone grease on stopcocks or taper joint.

A

FIG. 2 Set-up of Apparatus

7.3.4 Ethanol—(Warning—Flammable. Denatured. See 8.7 Open the stopcock (e) to the wide capillary and record

Annex A1.4.) the pressure as P .

7.4 Cleaning Solution, Chromic-sulfuric acid. (Warning—

8.8 Empty the bubbler and dry in the oven.

Causes severe burns.Arecognized carcinogen strong oxidizer,

8.9 Half-fillthebubblerwithethanolormethanolandrepeat

contact with organic material can cause fire. Hygroscopic. See

8.5-8.8.

Annex A1.2.)

8.10 Repeat 8.9 with three other calibration liquids.

7.5 Nitrogen, of purity suitable to avoid reaction with test

8.11 Calculate the calibration constant (A) for each of the

liquid and less than 100 ppm CO with amines. (Warning—

five liquids by:

Compressed gas under high pressure. See Annex A1.3.)

~A5g/DP ~1 1675 rD/DP!! (1)

8. Calibration and Standardization

Average the results.

8.11.1 In general, handbook values of D are satisfactory.

8.1 Cleanthebubblerwithcleaningsolution,andrinsewith

However, the true value of g for each supply of each calibra-

water.(Warning—Causessevereburns.Arecognizedcarcino-

tion liquid must be known; if it is not available from other

gen. Strong oxidizer, contact with organic ma

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.