ASTM E767-96

(Test Method)Standard Test Method for Shear Strength Properties of Metal Connector Plates

Standard Test Method for Shear Strength Properties of Metal Connector Plates

SCOPE

1.1 This test method provides a basic procedure for evaluating the effective shear resistance of the net section of finished metal connector plates.

1.2 The determination of the tensile properties of metal connector plates is covered in Test Method E489.

1.3 Test Methods D1761 covers the performance of the teeth and nails in the wood members during the use of metal connector plates.

1.4 This test method serves as a basis for determining the comparative performance of different types and sizes of metal connector plates resisting shear forces.

1.5 This test method provides a procedure for quantifying shear strength properties of metal connector plates and is not intended to establish design values for connections fabricated with these plates.

1.6 This test method does not provide for the corrosion testing of metal connector plates exposed to long-term adverse environmental conditions where plate deterioration occurs as a result of exposure. Under such conditions, special provisions shall be introduced for the testing for corrosion resistance.

1.7 In the case of dispute, the inch-pound units, shown in parentheses, shall be governing.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 767 – 96

Standard Test Method for

Shear Strength Properties of Metal Connector Plates

This standard is issued under the fixed designation E 767; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The use of prepunched metal connector plates with or without integral projecting teeth as well as

solid metal connector plates, usually fabricated from structural quality sheet coils, such as described

in Specification A 653/A 653M, to fasten wood members together is a widely accepted practice. In

many applications, these plates must resist shear forces, in one or two planes.

These plates must resist the force to be transferred from the wood member into the plate at the

interface of the connection and wood members. The plate’s resistance to a shear force in this plane is

a measure of the ability of the teeth or nails to transmit forces from the wood member to the plate. This

shear force is developed as the force per unit area of the plate, or force per tooth or nail. The method

for arriving at the unit plate value is described in Test Methods D 1761.

These plates must resist shear forces through their cross sections in a plane perpendicular to the face

of the plate. This resistance to shear is a measure of the ability of the connection to transmit forces

within the connection. This test method is to be used for the determination of unit design values for

pairs of plates (one pair on each side of the connection of the three-member specimen) subject to a

shear force through their cross section.

During manufacture and subsequent loading of these plates, stress concentrations develop around

the teeth and nail holes. Because of these stress concentrations and the difficulty of predicting the path

of failure, design values for plates shall be based on tests rather than analytical methods. The shear

resistance of the perforated plate is compared to the theoretical shear resistance of a solid

metal-coupon control specimen to arrive at the effective shear resistance ratio of the perforated plate

in the orientation tested.

If a given section taken through the length of a plate differs in a geometric character from a section

taken in an alternative orientation, the effective shear resistance ratio of the plate, that is, the ratio of

perforated-plate shear stress and matched solid-section shear stress, shall be a function of the

alternative orientation. If this is the case, the test method presented here requires that the net section

of the plate be evaluated at six different orientations.

If the net cross section of the plate is identical for all orientations, testing only along its length shall

be necessary. The resulting effective shear resistance ratio of the plate is then applicable to all

orientations of the plate.

If the effective shear resistance ratio is desired for any specific angle of plate orientation, it shall be

evaluated by this test method.

If the plate is without prepunched (or predrilled) holes immediately prior to assembly of the wood

members and teeth or nails are not to be located along the shear plane, tests on specimens, following

the manufacturer’s recommended minimum edge spacing, shall be used to determine the effective

shear resistance ratio by this test method.

Since shear tests are difficult to perform on the solid metal-coupon control specimens, tension tests

on these control specimens shall be substituted. Such tests shall be conducted in accordance with Test

Methods E 8.

Tensile values are related to shear values by the Von Mises yield theory which indicates that the

theoretical yielding in shear occurs at a stress equal to 0.577 of the yield stress in tension. For purposes

of this test evaluation, the ultimate shear stress and ultimate tensile stress are in the same ratio.

The test specimens can be used for the evaluation of metal connector plates with integral teeth

projecting from one plate side or both plate sides. In the former case, the plates are located along the

sides of the test specimen. In the latter case, the plates are located along the interfaces of the test

specimen.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 767

An example of determining the shear resistance of metal connector plates is presented in Appendix

X1.

Alternate static (monotonic) and dynamic (cyclic) compression and tension tests on two-member

test specimens are described in Appendix X2. The selection of the type of test specimen and test setup

depends on the specific requirements for test data.

1. Scope Building Constructions, Elements, Connections, and As-

semblies

1.1 This test method provides a basic procedure for evalu-

E 631 Terminology of Building Constructions

ating the effective shear resistance of the net section of finished

F 680 Test Methods for Nails

metal connector plates.

2.2 ANSI Standard:

1.2 The determination of the tensile properties of metal

ANSI/TPI 1—1995 National Design Standard for Metal-

connector plates is covered in Test Method E 489.

Plate-Connected Wood Truss Construction

1.3 Test Methods D 1761 covers the performance of the

2.3 CSA Standard:

teeth and nails in the wood members during the use of metal

S 347-M-1980 Methods of Test for Evaluation of Truss

connector plates.

Plates Used in Lumber Joints

1.4 This test method serves as a basis for determining the

comparative performance of different types and sizes of metal

3. Terminology

connector plates resisting shear forces.

3.1 Definitions—For general definitions of terms used in

1.5 This test method provides a procedure for quantifying

this test method, see Terminology E 631. For specific defini-

shear strength properties of metal connector plates and is not

tions of terms, see the terminology section of Test Method

intended to establish design values for connections fabricated

E 489.

with these plates.

3.2 Symbols Specific to This Standard:

1.6 This test method does not provide for the corrosion

3.2.1 A—base-metal cross-sectional area (width times base-

testing of metal connector plates exposed to long-term adverse

metal thickness) of solid metal-coupon control specimen.

environmental conditions where plate deterioration occurs as a

3.2.2 a—angle of placement for plates tested at a specific

result of exposure. Under such conditions, special provisions

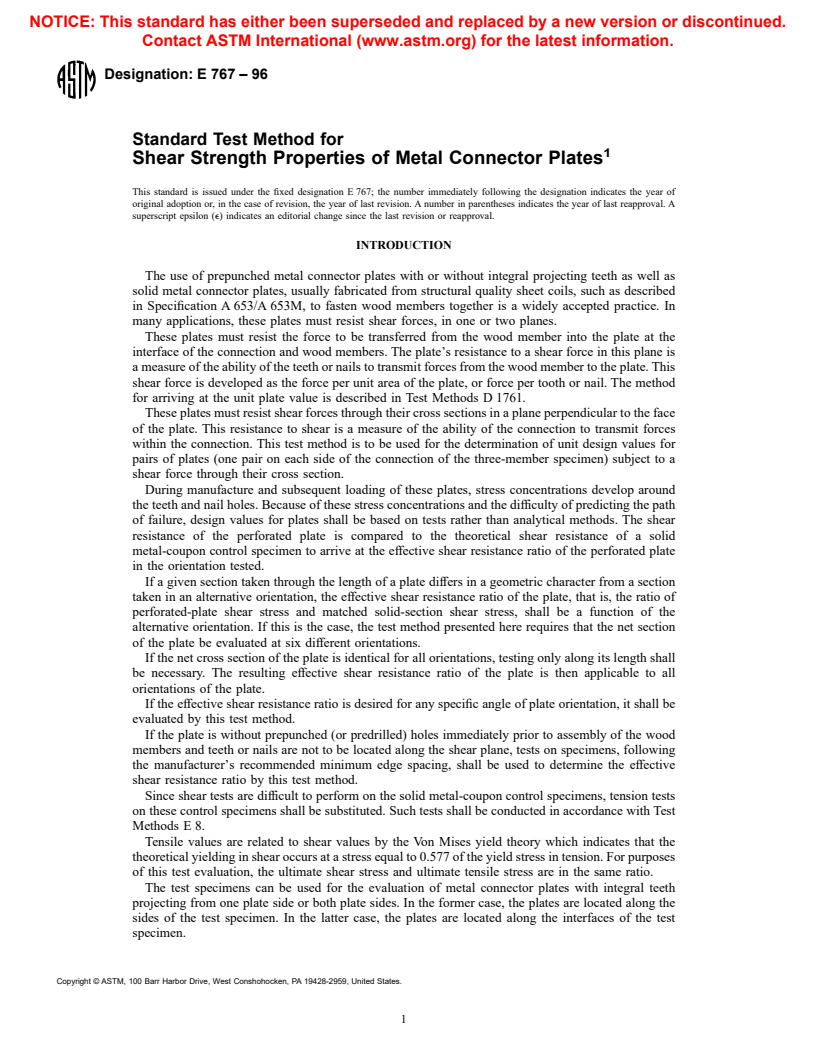

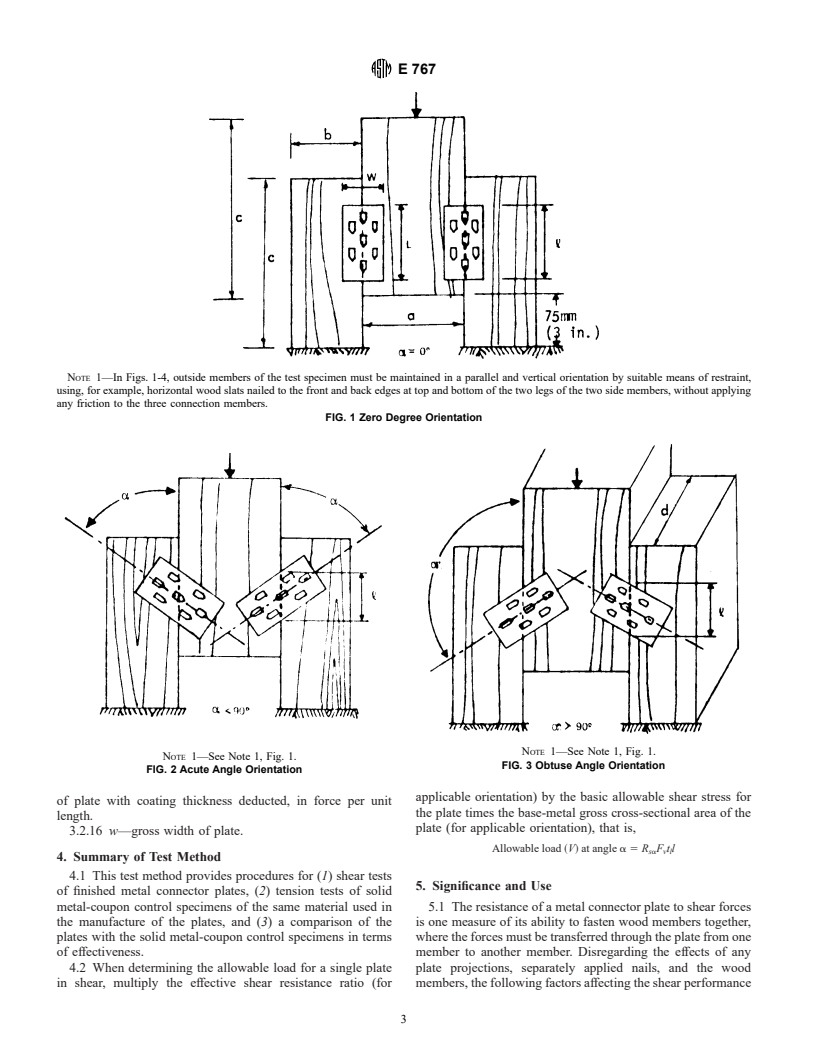

orientation (see 8.3 and Figs. 1-4).

shall be introduced for the testing for corrosion resistance.

3.2.3 F —theoretical ultimate shear stress of the solid

s

1.7 In the case of dispute, the inch-pound units, shown in

metal-coupon control specimen (0.577 F ).

t

parentheses, shall be governing.

3.2.4 F —ultimate tensile stress of solid metal-coupon con-

t

1.8 This standard does not purport to address all of the

trol specimen.

safety concerns, if any, associated with its use. It is the

3.2.5 F —basic allowable shear stress in metal.

v

responsibility of the user of this standard to establish appro-

3.2.6 f —ultimate shear stress of plate at angle a to

sa

priate safety and health practices and determine the applica-

lengthwise axis of plate.

bility of regulatory limitations prior to use.

3.2.7 f —ultimate shear stress of plate at angle a to length-

t

wise axis of plate, based on thickness of plate with coating

2. Referenced Documents

thickness deducted.

2.1 ASTM Standards:

3.2.8 L—gross length of plate.

A 591/A 591M Specification for Steel Sheet, Electrolytic

2 3.2.9 l—calculated shear length of plate oriented at anglea

Zinc-Coated, for Light Coating Mass Applications

to lengthwise axis of plate.

A 653/A 653M Specification for Steel Sheet, Zinc-Coated

3.2.10 P —ultimate shear force resisted by test specimen

a

(Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed)

assembled with plates oriented at angle a to lengthwise axis of

by the Hot-Dip Process

plate.

A 924/A 924M Specification for General Requirements for

3.2.11 R —effective shear resistance ratio at angle a,

sa

Steel Sheet, Metallic-Coated by the Hot-Dip Process

3 f /F .

sa s

D 1761 Test Methods for Mechanical Fasteners in Wood

3.2.12 T—ultimate tensile force resisted by metal-coupon

E 4 Practices for Force Verification of Testing Machines

4 control specimen.

E 8 Test Methods for Tension Testing of Metallic Materials

3.2.13 t—gross thickness of plate and solid metal-coupon

E 489 Test Method for Tensile Strength Properties of Metal

5 control specimen.

Connector Plates

3.2.14 t —base-metal thickness of plate and solid metal-

l

E 575 Practice for Reporting Data from Structural Tests of

coupon control specimen after deducting coating thickness.

3.2.15 V—allowable plate shear design value for single

1 plate at angle a to lengthwise axis of plate, based on thickness

This test method is under the jurisdiction of ASTM Committee E-6 on

Performance of Buildings and is the direct responsibility of Subcommittee E06.13

on Structural Performance of Connections in Building Constructions.

Current edition approved March 10, 1996. Published May 1996. Annual Book of ASTM Standards, Vol 15.08.

2 7

Annual Book of ASTM Standards, Vol 01.06. Available from the American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 04.10. Floor, New York, NY 10036.

4 8

Annual Book of ASTM Standards, Vol 03.01. Available from the Canadian Standard Association, 178 Rexdale Blvd.,

Annual Book of ASTM Standards, Vol 04.07. Rexdale, ON M9W 1R3, Canada.

E 767

NOTE 1—In Figs. 1-4, outside members of the test specimen must be maintained in a parallel and vertical orientation by suitable means of restraint,

using, for example, horizontal wood slats nailed to the front and back edges at top and bottom of the two legs of the two side members, without applying

any friction to the three connection members.

FIG. 1 Zero Degree Orientation

NOTE 1—See Note 1, Fig. 1.

NOTE 1—See Note 1, Fig. 1.

FIG. 3 Obtuse Angle Orientation

FIG. 2 Acute Angle Orientation

applicable orientation) by the basic allowable shear stress for

of plate with coating thickness deducted, in force per unit

the plate times the base-metal gross cross-sectional area of the

length.

plate (for applicable orientation), that is,

3.2.16 w—gross width of plate.

Allowable load ~V! at anglea5 R F t l

sa v l

4. Summary of Test Method

4.1 This test method provides procedures for (1) shear tests

5. Significance and Use

of finished metal connector plates, (2) tension tests of solid

metal-coupon control specimens of the same material used in 5.1 The resistance of a metal connector plate to shear forces

the manufacture of the plates, and (3) a comparison of the is one measure of its ability to fasten wood members together,

plates with the solid metal-coupon control specimens in terms where the forces must be transferred through the plate from one

of effectiveness. member to another member. Disregarding the effects of any

4.2 When determining the allowable load for a single plate plate projections, separately applied nails, and the wood

in shear, multiply the effective shear resistance ratio (for members, the following factors affecting the shear performance

E 767

capability to indicate the displacement throughout the test

range.

7. Test Material

7.1 Metal Connector Plates—The metal connector plates

shall be typical of production and manufactured in accordance

with the design and of materials specified by the plate

manufacturer. The coil metal used for production of metal

connector plates shall meet minimum specified grade proper-

ties, including the elongation for a 50-mm (2.0-in.) gage length

to be at least 16 % for specified Grade C steel with a minimum

275-MPa (40-ksi) yield point and a minimum 380-MPa (55-

ksi) ultimate tensile stress according to Specification A 653/

A 653M.

7.2 Solid Metal-Coupon Control Specimens—The solid

metal-coupon control specimens shall originate from the same

coil from which the metal connector plates were fabricated.

NOTE 1—The centroid of the plate contact area on the outer connection

7.3 Nails—Any nails, used for fastening the plates to the

members shall be above the centroid of the plate contact area on the center

wood members, shall be typical of those used in the field and

connection member to ensure tension shear for orientations with angle a

fully comply with the applicable design provisions for trans-

< 90 deg. To ensure compression shear for orientations with angle a >90

ferring the structural forces from member to member. For the

deg, the centroid of the plate contact area on the outer connection

definition of nails, see Terminology E 631, and for testing of

members shall be below the centroid of the plate area on the center

connection member. nails, see Test Methods F 680.

FIG. 4 90° Orientation

7.4 Wood Members—The wood members of the connection

shall be of such density and moisture content to ensure that

of a plate shall be considered when using this test method: failure occurs in the plates and not in the wood, teeth, or nails.

length, width, and thickness of the plate; location, spacing,

The edges of the wood members shall not be modified from the

orientation, size, and shape of holes in the plate; edge and end dressed surface condition.

distances of holes in the plate; stress concentrations around

8. Sampling

projections and perforations of the plate; basic properties of the

plate metal, and unsupported length of the plate. When using 8.1 Sampling of metal coils and metal connector plates shall

this test method on nail-on plates, their performance is also provide for selection, on an objective and unbiased basis, of

influenced by the type, size, quantity, and quality of the nails representative test specimens, typical of plate production, and

used for load transfer as well as the method of installing the cover the different widths and configuration of plates to be

plates and their fasteners. tested.

8.2 Testing for each of the six required plate orientations

6. Apparatus

requires at least three replicate test specimens. Each three-

6.1 Testing Machine—A testing machine capable of apply- member test specimen shall be made using three pieces of

ing tensile and compressive loads at a specific rate, and having

wood and four identical plates. A total of at least 18 test

an accuracy of 61 % of the applied load, and calibrated in specimens is needed to obtain data for the required plate

accordance with Practices E 4.

orientations of 0°, 30°, 60°, 90°, 120°, and 150°, as defined in

6.2 Grips—For tension tests,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.