ASTM D1837-17

(Test Method)Standard Test Method for Volatility of Liquefied Petroleum (LP) Gases (Withdrawn 2017)

Standard Test Method for Volatility of Liquefied Petroleum (LP) Gases (Withdrawn 2017)

SIGNIFICANCE AND USE

4.1 Volatility, expressed in terms of the 95 % evaporated temperature of the product, is a measure of the amount of least volatile components present in the product. Coupled with a vapor pressure limit, it serves to ensure essentially single-component products in the cases of commercial grades of propane and butane. When volatility is coupled with a vapor pressure limit which has been related to density, as in the case of the commercial PB-mixture, the combination serves to assure essentially two component mixtures for such fuels. When coupled with a proper vapor pressure limit, this measurement serves to assure that special-duty propane products will be composed chiefly of propane and propylene and that propane will be the major constituent.

SCOPE

1.1 This test method is a measure of the relative purity of the various types of liquefied petroleum (LP) gases and helps to ensure suitable volatility performance. The test results, when properly related to vapor pressure and density of the product, can be used to indicate the presence of butane and heavier components in propane-type LP-gas, and pentane and heavier components in propane-butane and butane-type fuels. The presence of hydrocarbon compounds less volatile than those of which the LP-gas is primarily composed is indicated by an increase in the 95 % evaporated temperature.

1.2 When the type and concentration of higher boiling components is required, chromatographic analysis should be used.

1.3 The values stated in SI units are to be regarded as the standard.

1.3.1 Exception—The non-SI values are provided for information only.

1.4 WARNING—Mercury has been designated by many regulatory agencies as a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Safety Data Sheet (SDS) for details and EPA’s website—http://www.epa.gov/mercury/faq.htm—for additional information. Users should be aware that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.4.1 Note that thallium in a mercury-thallium thermometer is also a hazardous material.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method is a measure of the relative purity of the various types of liquefied petroleum (LP) gases and helps to ensure suitable volatility performance. The test results, when properly related to vapor pressure and density of the product, can be used to indicate the presence of butane and heavier components in propane-type LP-gas, and pentane and heavier components in propane-butane and butane-type fuels. The presence of hydrocarbon compounds less volatile than those of which the LP-gas is primarily composed is indicated by an increase in the 95 % evaporated temperature.

Formerly under the jurisdiction of Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants, this test method was withdrawn in October 2017 because the method is no longer being maintained and updated by a subcommittee.

The following language was added editorially to the withdrawn statement in May 2018:This standard is withdrawn with no replacement. D1837 still references the use of mercury thermometers. Replacement of the armored mercury thermometer currently specified in D1837 is not a simple replacement by a non-mercury liquid-in-glass thermometer or a digital contact thermometer. Some initial test work showed serious discrepancies in temperature measurements, thus a significant work program would have to be carried out to validate a replac...

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1837 −17

Standard Test Method for

1

Volatility of Liquefied Petroleum (LP) Gases

This standard is issued under the fixed designation D1837; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

1.1 This test method is a measure of the relative purity of 2.1 ASTM Standards:

the various types of liquefied petroleum (LP) gases and helps D96Test Method for Water and Sediment in Crude Oil by

3

toensuresuitablevolatilityperformance.Thetestresults,when Centrifuge Method (Field Procedure) (Withdrawn 2000)

properly related to vapor pressure and density of the product, D1796Test Method for Water and Sediment in Fuel Oils by

can be used to indicate the presence of butane and heavier the Centrifuge Method (Laboratory Procedure)

components in propane-type LP-gas, and pentane and heavier E1Specification for ASTM Liquid-in-Glass Thermometers

components in propane-butane and butane-type fuels. The

3. Summary of Test Method

presenceofhydrocarboncompoundslessvolatilethanthoseof

which the LP-gas is primarily composed is indicated by an

3.1 Refrigerate the sample by means of a cooling coil and

increase in the 95% evaporated temperature.

collect 100 mL of liquid in a weathering tube. Allow to

1.2 When the type and concentration of higher boiling evaporate (“weather”) at ambient pressure under specified

conditionsthatapproximateasingleplatedistillation.Measure

components is required, chromatographic analysis should be

used. the observed temperature when 5 mL of liquid test portion

remains. Correct this observed temperature for barometric

1.3 The values stated in SI units are to be regarded as the

pressure and thermometer ice point error, and report as the

standard.

95% evaporation temperature.

1.3.1 Exception—The non-SI values are provided for infor-

mation only.

4. Significance and Use

1.4 WARNING—Mercury has been designated by many

4.1 Volatility, expressed in terms of the 95% evaporated

regulatory agencies as a hazardous material that can cause

temperature of the product, is a measure of the amount of least

central nervous system, kidney and liver damage. Mercury, or

volatile components present in the product. Coupled with a

its vapor, may be hazardous to health and corrosive to

vapor pressure limit, it serves to ensure essentially single-

materials.Cautionshouldbetakenwhenhandlingmercuryand

component products in the cases of commercial grades of

mercurycontainingproducts.SeetheapplicableproductSafety

propane and butane. When volatility is coupled with a vapor

Data Sheet (SDS) for details and EPA’s website—http://

pressure limit which has been related to density, as in the case

www.epa.gov/mercury/faq.htm—for additional information.

of the commercial PB-mixture, the combination serves to

Users should be aware that selling mercury and/or mercury

assure essentially two component mixtures for such fuels.

containing products into your state or country may be prohib-

When coupled with a proper vapor pressure limit, this mea-

ited by law.

surement serves to assure that special-duty propane products

1.4.1 Note that thallium in a mercury-thallium thermometer

will be composed chiefly of propane and propylene and that

is also a hazardous material.

propane will be the major constituent.

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

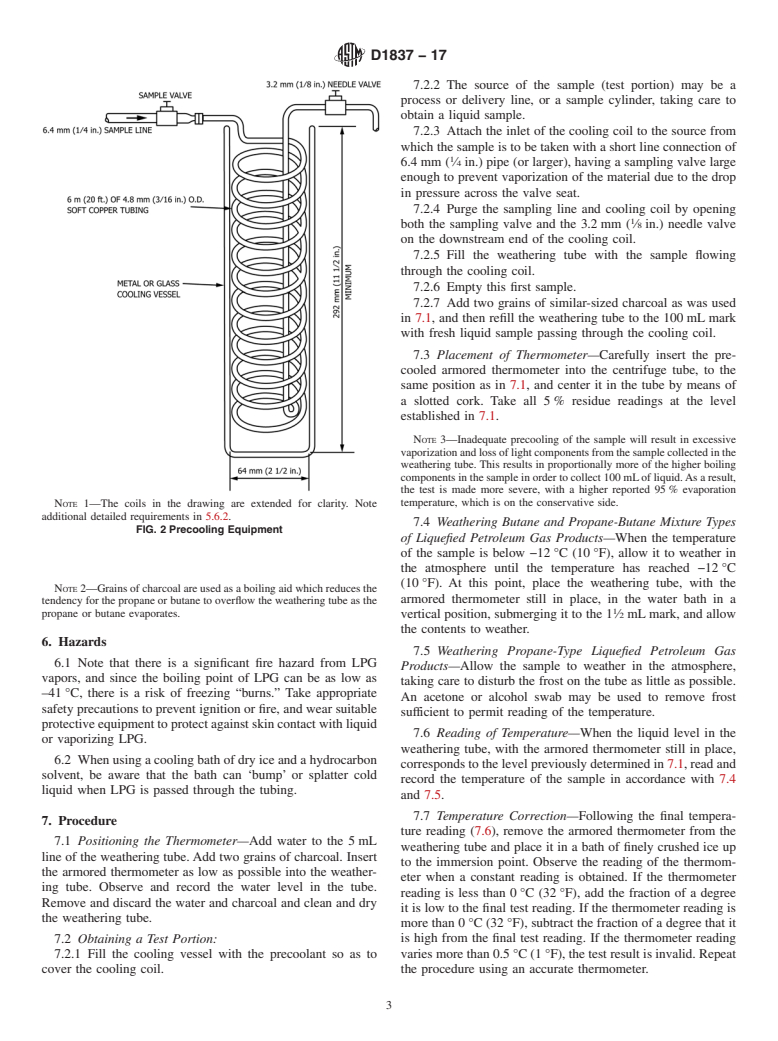

5. Apparatus

responsibility of the user of this standard to establish appro-

5.1 Weathering Tube—Acentrifuge tube, cone-shaped, con-

priate safety and health practices and determine the applica-

forming to the dimensions given in Fig. 1 and made of

bility of regulatory limitations prior to use.

1 2

This test method is under the jurisdiction of ASTM Committee D02 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee D02.H0 on Liquefied Petroleum Gas. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Jan. 1, 2017. Published February 2017. Originally the ASTM website.

3

approved in 1961. Last previous edition approved in 2011 as D1837–11. DOI: The last approved version of this historical standard is referenced on

10.1520/D1837-17. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.