ASTM D6544-00(2007)

(Practice)Standard Practice for Preparation of Textiles Prior to Ultraviolet (UV) Transmission Testing

Standard Practice for Preparation of Textiles Prior to Ultraviolet (UV) Transmission Testing

SIGNIFICANCE AND USE

The significance of this practice is that cloth, labeled as UV-protective, which will ultimately be submitted for UV transmittance testing will be in a state that simulates their condition at the end of two years of normal seasonal use. Therefore, the UV-protection level ultimately placed on a label estimates the maximum UV transmittance of the garment fabric during a two-year life cycle.

SCOPE

1.1 This practice covers standardized exposures to laundering, simulated sunlight, and chlorinated pool water to which cloth, labeled as ultraviolet-(UV) protective, must be exposed prior to testing for UV transmission.

1.2 This practice leads to measurement of the residual level of UV-protection in fabrics or garments labeled as sun- or UV-protective, after exposure to conditions that relate to about two years of seasonal use. The UV transmission measurements may be done in accordance with AATCC Test Method 183 using fabrics prepared in accordance with this practice. This measurement may be used in support of a label statement regarding UV protection.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6544–00 (Reapproved 2007)

Standard Practice for

Preparation of Textiles Prior to Ultraviolet (UV)

Transmission Testing

This standard is issued under the fixed designation D6544; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 AATCC Test Methods and Documents:

AATCC 16[E] Colorfastness to Light

1.1 This practice covers standardized exposures to launder-

AATCC 135 Dimensional Changes in Automatic Home

ing, simulated sunlight, and chlorinated pool water to which

Laundering of Woven or Knit Fabric

cloth, labeled as ultraviolet-(UV) protective, must be exposed

AATCC 162 Colorfastness to Water: Chlorinated Pool

prior to testing for UV transmission.

AATCC172 ColorfastnesstoNon-chlorineBleachinHome

1.2 This practice leads to measurement of the residual level

Laundering

of UV-protection in fabrics or garments labeled as sun- or

AATCC 183 Transmittance or Blocking of Erythemally

UV-protective, after exposure to conditions that relate to about

Weighted Ultraviolet Radiation through Fabrics

two years of seasonal use. The UV transmission measurements

Glossary of AATCC Standard Terminology

may be done in accordance with AATCC Test Method 183

using fabrics prepared in accordance with this practice. This

3. Terminology

measurement may be used in support of a label statement

3.1 Definitions—For definitions of other textile terms used

regarding UV protection.

in this practice, refer toTerminology D123 and the Glossary of

1.3 The values stated in SI units are to be regarded as the

AATCC Standard Terminology.

standard. The values given in parentheses are for information

only.

4. Summary of Practice

1.4 This standard does not purport to address the safety

4.1 This practice directs the exposure of cloth, labeled as

concerns, if any, associated with its use. It is the responsibility

UV-protective, to conditions of laundering, simulated sunlight,

of the user of this standard to establish appropriate safety and

and chlorinated pool water generally known to affect UV

health practices and determine the applicability of regulatory

transmittance.

limitations prior to use.

4.2 This practice directs selection and sequencing of expo-

sure conditions for UV-protective fabrics and garments.

2. Referenced Documents

2.1 ASTM Standards:

5. Significance and Use

D123 Terminology Relating to Textiles

5.1 The significance of this practice is that cloth, labeled as

D2905 PracticeforStatementsonNumberofSpecimensfor

3 UV-protective, which will ultimately be submitted for UV

Textiles

transmittance testing will be in a state that simulates their

D3938 Guide for Determining or Confirming Care Instruc-

condition at the end of two years of normal seasonal use.

tions for Apparel and Other Textile Products

Therefore, the UV-protection level ultimately placed on a label

E122 Practice for Calculating Sample Size to Estimate,

estimates the maximum UV transmittance of the garment

With Specified Precision, the Average for a Characteristic

fabric during a two-year life cycle.

of a Lot or Process

6. Sampling and Test Specimens

6.1 Primary Sampling Unit—Consider rolls or bolts of

ThispracticeisunderthejurisdictionofASTMCommitteeD13onTextilesand

is the direct responsibility of Subcommittee D13.65 on UV Protective Fabrics and

fabric, or cartons of garments to be the primary sampling unit,

Clothing.

as applicable.

Current edition Jan. 1, 2007. Published January 2007. Originally approved in

6.1.1 Take the number of primary sampling units from each

2000. Last previous edition approved in 2000 as D6544 – 00. DOI: 10.1520/D6544-

lot, shipment, or production run in accordance with Practice

00R07.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

E122.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Available from American Association of Textile Chemists and Colorists

Withdrawn. The last approved version of this historical standard is referenced (AATCC), P.O. Box 12215, Research Triangle Park, NC 27709, http://

on www.astm.org. www.aatcc.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

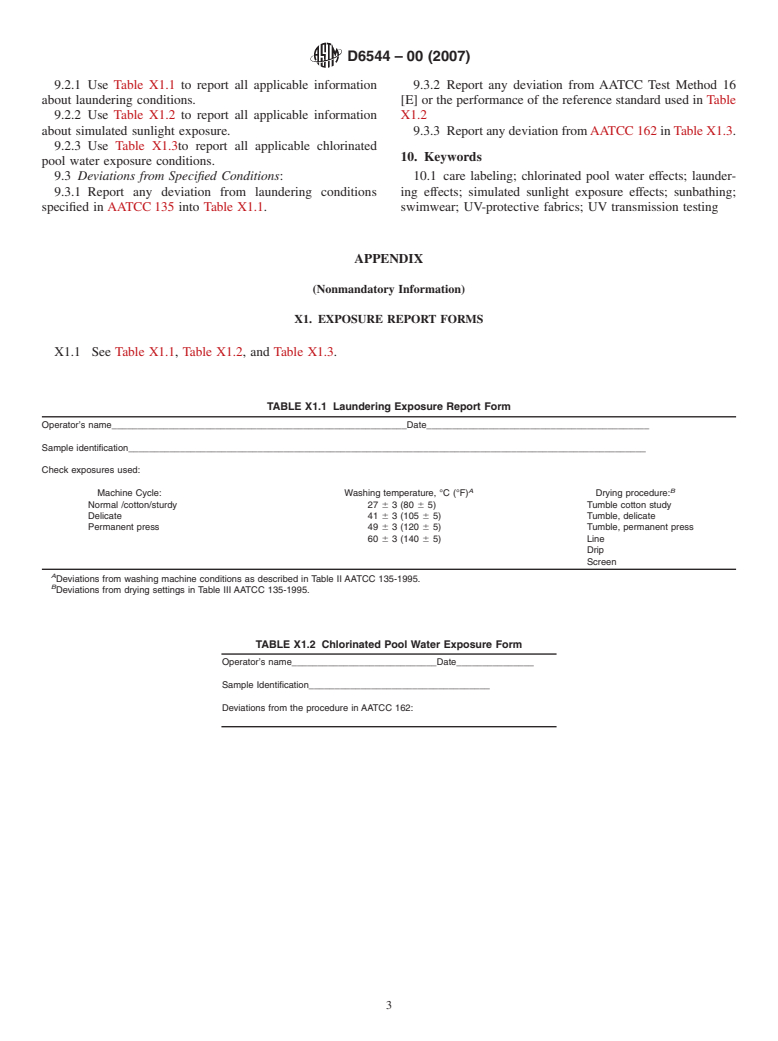

D6544–00 (2007)

6.2 Laboratory Sampling Unit: described in 8.1. Then take specimens from the laundered

6.2.1 Takethenumberoflaboratorysamplingunitsfromthe fabricsorgarmentsandexposethosespecimensto100AATCC

primary sampling unit in accordance with Practice E122. Fading Units of simulated sunlight in accordance with the

6.2.2 Rolls or Bolts of Fabric—Take from each primary conditions described in 8.2 and then to chlorinated water in

sampling unit one full-width piece of fabric that is about 1 m accordance with the conditions described in 8.3.

(1 yd) in length along the selvage (machine direction), after 7.3 Garments and fabrics intended for use in garments other

removing a first 1-mm length. For narrow fabrics, a longer than swimsuits that are sold with the expectation they will not

sample length may be required to meet the test specimen be laundered (such as disposable or limited-use garments for

requirements. pesticide application) need only be exposed to simulated

6.2.3 Garments—Take from each primary sampling unit sunlight.

one entire garment. For small garments, such as children’s,

where sufficient material is not available to meet the three test 8. Exposure Conditions

specimensrequirement,takeapairofgarmentsandtreatasone

8.1 Laundering:

sampling unit.

8.1.1 Conditions of Exposure—Hand washing or automatic

6.3 Laundering—Unless exempt from laundering, launder

machine washing, wash water temperature, agitation cycle in

thelaboratorysamplingunitorasectionofitthatisatleast380

automatic laundering, drying method and temperature if ma-

by 380 mm (15 by 15 in.) using exposure conditions as

chine drying, and use of bleach must be those that will be

described in 8.1. If the laboratory sampling unit does not have

conveyed to the consumer on the care label attached to the

the minimum 380-mm dimension, then take a section that is at

fabric/garment.Those conditions should have been determined

2 2

least 1450 cm (225 in. ). For small samples, it may be

by following Guide D3938.

necessary to seal the edges to prevent raveling during launder-

8.1.1.1 Care procedures determined in accordance with

ing.

GuideD3938maybemodifiedwhenitisestablishedthatthose

6.4 Test Specimens—As test specimens, take from each

procedures increase the UV-transmittance of the fabric.

laboratory sampling unit at least three specimens of each fabric

8.1.1.2 Follow one of the washing and drying procedures in

type in accordance with Practice D2905.

AATCC 135 orAATCC 172 that matches the care instructions

6.4.1 For simulated sunlight and chlorinated water testing,

of the fabric or garment.

cut test specimens 125 by 180 mm (5 by 7 in.).

8.1.2 The specimens to be laundered may be garments,

6.4.2 Cut specimens representing a broad distribution di-

one-yard lengths of fabric, or areas of fabric having minimum

agonally across the width of the laboratory sampling unit.

dimensions of 380 by 380 mm (15 by 15 in.) or when

Ensure specimens are free of folds, creases, or wrinkles.Avoid 2 2

applicable 1450 cm (225 in. ).

getting oil water, gr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.