ASTM D3931-93a(2005)

(Test Method)Standard Test Method for Determining Strength of Gap-Filling Adhesive Bonds in Shear by Compression Loading

Standard Test Method for Determining Strength of Gap-Filling Adhesive Bonds in Shear by Compression Loading

SIGNIFICANCE AND USE

Structural design based on strength-of-materials principles requires knowledge of the mechanical properties of the structural components, including adhesives. By nature of their use, the most important property of adhesive is shear strength.

Shear strength measured by this test method is suitable for use in adhesive development, manufacturing quality control, and in materials performance specifications, as well as structural design.

SCOPE

1.1 This test method covers the determination of comparative shear properties of gap-filling adhesives in wood-to-wood joints at specified thicknesses of bondline in the dry condition, when tested on standard specimens under specified conditions of preparation, conditioning, and loading in compression. This test method is intended as an evaluation of gap-filling adhesives such as those used to bond plywood to lumber, lumber to lumber, and other similar materials in building constructions.

1.2 This test method also may be used to determine shear properties of gap-filling adhesives in species of wood and in thicknesses of bondline other than those specified for the comparative tests of shear properties within this test method. All procedures specified herein are applicable, excepting requirements for wood species and specific gravity, and thicknesses of bondlines.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3931–93a(Reapproved2005)

Standard Test Method for

Determining Strength of Gap-Filling Adhesive Bonds in

Shear by Compression Loading

This standard is issued under the fixed designation D 3931; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Bonds in Shear by Compression Loading

D 1151 TestMethodforEffectofMoistureandTemperature

1.1 This test method covers the determination of compara-

on Adhesive Bonds

tive shear properties of gap-filling adhesives in wood-to-wood

E 171 Specification for Standard Atmospheres for Condi-

joints at specified thicknesses of bondline in the dry condition,

tioning and Testing Materials

when tested on standard specimens under specified conditions

of preparation, conditioning, and loading in compression. This

3. Terminology

test method is intended as an evaluation of gap-filling adhe-

3.1 Definitions:

sives such as those used to bond plywood to lumber, lumber to

3.1.1 gap-filling adhesive, n—an adhesive capable of form-

lumber, and other similar materials in building constructions.

ing and maintaining a bond between surfaces that are not

1.2 This test method also may be used to determine shear

close-fitting.

properties of gap-filling adhesives in species of wood and in

3.1.1.1 Discussion—Close-fitting is relative to a given ma-

thicknesses of bondline other than those specified for the

terial and industry; for example, standards in construction

comparative tests of shear properties within this test method.

differ from standards in electronics. Some adhesives will bond

All procedures specified herein are applicable, excepting re-

by bridging without completely filling the gap; others by filling

quirements for wood species and specific gravity, and thick-

the gap completely.

nesses of bondlines.

1.3 The values stated in inch-pound units are to be regarded

4. Significance and Use

as standard. The values given in parentheses are mathematical

4.1 Structural design based on strength-of-materials prin-

conversions to SI units that are provided for information only

ciples requires knowledge of the mechanical properties of the

and are not considered standard.

structural components, including adhesives. By nature of their

1.4 This standard does not purport to address all of the

use, the most important property of adhesive is shear strength.

safety concerns, if any, associated with its use. It is the

4.2 Shear strength measured by this test method is suitable

responsibility of the user of this standard to establish appro-

for use in adhesive development, manufacturing quality con-

priate safety and health practices and determine the applica-

trol, and in materials performance specifications, as well as

bility of regulatory limitations prior to use.

structural design.

2. Referenced Documents

5. Apparatus

2.1 ASTM Standards:

5.1 Testing Machine, having a capacity of about 15 000 lb

D 143 Test Methods for Small Clear Specimens of Timber

(6818 kg) in compression or of sufficient capacity to test the

D 905 Test Method for Strength Properties of Adhesive

adhesive in use. The machine shall be fitted with a shearing

tool containing a self-aligning seat to ensure uniform lateral

distribution of the load. The machine shall be capable of

This test method is under the jurisdiction of ASTM Committee D14 on

maintainingauniformrateofloadingsuchthattheloadmaybe

Adhesives and is the direct responsibility of Subcommittee D14.70 on Construction

applied with a continuous motion of the movable head to

Adhesives.

maximum load at a rate of 9.20 in. (5.0 mm)/min with a

Current edition approved April 1, 2005. Published April 2005. Originally

e 1

approved in 1980. Last previous edition approved in 1999 as D 3931–93a (1999) .

permissible variation of 625 %. The shearing tool shown in

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Fig. 1 of Test Method D 905 has been found satisfactory.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Locate the testing machine in an atmosphere such that the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3931–93a (2005)

moisture content of the specimens, developed under the con- been found to be satisfactory for this purpose. The moisture

ditions prescribed in 7.3, is not noticeably altered during content shall be from 8 to 10 % (conditions prescribed in7.3.1)

testing. based on ovendry weight as determined on representative

samples in accordance with the final measurement section

6. Test Specimen and Sample

under radial and tangential shrinkage and the weighing section

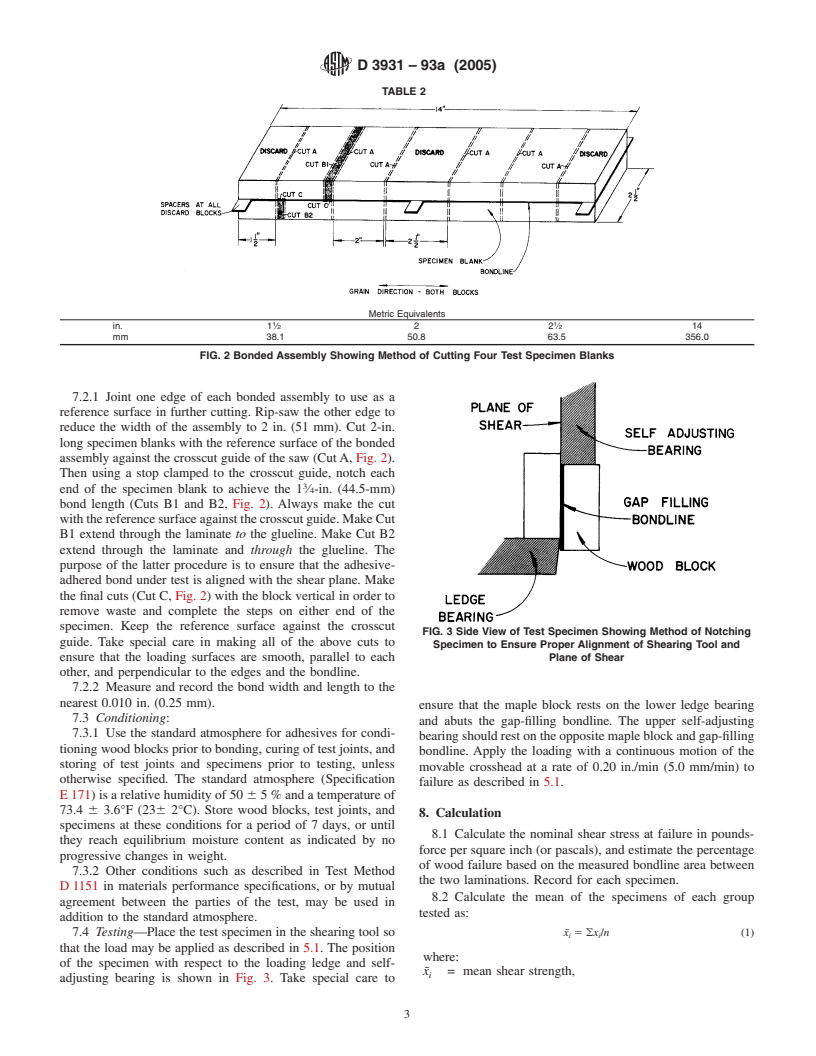

6.1 Test specimens for adhesive bonds shall conform to the under moisture determination in Test Methods D 143. Surface

form and dimensions shown in Fig. 1. Prepare bonded assem- the blocks just prior to gluing, preferably with a hand-feed

blies as described in 7.1. Prepare test specimens for testing as jointer. Make sure the surfaces remain unsanded and free from

described in 7.2. dirt.

6.2 Determine mean shear strengths of bonds at bondline

7.1.2 Use spacer strips to control bondlines to specified

thicknesses of 0.006 and 0.060 in. (0.15 and 1.52 mm). Tests

thicknesses between blocks. Spacers shall be wood veneer or

for strengths of bonds at other thicknesses, in addition to those 1 1

plastic, and measure approximately ⁄2 by 3 ⁄2 in. (13 by 89

specified, shall be optional upon agreement between the

mm)long.Placespacerscrosswiseattheendsandcenterofthe

manufacturer and the user.

lower test joint block. Apply adhesive in sufficient quantity to

6.3 Test a minimum of 28 specimens, representing seven

ensure squeezeout at the ends of the joint when blocks are

differentbondedassemblies,todeterminemeanshearstrengths

under pressure (Note 2).

of bonds at each bondline thickness.

NOTE 2—If the adhesive is to be applied as an extruded bead, the bead

3 1

should be ⁄8 to ⁄2 in. (10 to 13 mm) in diameter to ensure squeezeout in

7. Procedure

bondlinethicknessesnear0.060in.(1.5mm).Useasmallerdiameterbead

7.1 Preparation of Bonded Assemblies:

of adhesive for thinner bondlines.

7.1.1 Prepare bonded assemblies with hard maple blocks

7.1.2.1 Take care to avoid air entrapment in the bondline.

(Acer saccharum or Acer nigrum) conditioned as described in

Do not spread the adhesive closer than ⁄2 in. (13 mm) to any

7.3. The blocks shall have a minimum specific gravity of 0.65,

spacer because adhesive may be entrapped between block and

based on ovendry weight and ovendry volume (Note 1).

spacer, thereby increasing bondline thickness. Assemble the

NOTE 1—A method for selecting maple blocks of satisfactory specific

blocks immediately, unless specified otherwise by agreement

gravity is described in theAppendix of Test Method D 905. For reference

between the manufacturer and user of the adhesive. Apply a

tests, the specific gravity of blocks may be determined in accordance with

15-lb (7.0-kg) load uniformly over the entire bond area to

the Weight and Moisture Content Section under Nail Withdrawal of Test

Methods D 143. ensure firm contact between spacers and blocks of the assem-

bly. Maintain the pressure on test joints at the conditions

7.1.1.1 These blocks shall be straight-grained and free of

prescribed in 7.1.

defects, including knots, splits, birdseye, short grain, decay,

7.1.3 Curing time for bonded assemblies shall be as speci-

and any unusual discoloration within the shearing area. The

fied by the ma

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.