ASTM D8000-15

(Practice)Standard Practice for Flow Conditioning of Natural Gas and Liquids

Standard Practice for Flow Conditioning of Natural Gas and Liquids

SIGNIFICANCE AND USE

4.1 Flow conditioners are used for the conditioning of the turbulent flow profile of gases or liquids to reduce the ADD (velocity profile distortion) DEL (turbulence), swirl, or irregularities caused by the installation effects of piping elbows, length of pipe, valves, tees, and other such equipment or piping configurations that will affect the reading of flow measurement meters thus inducing measurement errors as a result of the flow profile of the gas or liquid not having a fully developed flow profile at the measurement point.4

SCOPE

1.1 This practice covers flow conditioners that produce a fully developed flow profile for liquid and gas phase fluid flow for circular duct sizes 1- to 60-in. (25.4- to 1525-mm) diameter and Reynolds Number (Re) ranges from transition (100) to 100 000 000. These flow conditioners can be used for any type of flow meter or development of a fully developed flow profile for other uses.

1.2 The central single-hole configuration that is derived using fundamental screen theory is referenced as the flow conditioner described herein.

1.3 Piping lengths upstream and downstream of a flow conditioner are considered a critical component of a flow conditioner and constitute the complete flow conditioner system.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D8000 −15

Standard Practice for

1

Flow Conditioning of Natural Gas and Liquids

This standard is issued under the fixed designation D8000; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This practice covers flow conditioners that produce a 3.1 Refer to Terminology D4150 for general definitions

fully developed flow profile for liquid and gas phase fluid flow related to gaseous fuels. Definitions specific to this standard

for circular duct sizes 1- to 60-in. (25.4- to 1525-mm) diameter follow.

and Reynolds Number (Re) ranges from transition (100) to

3.2 Definitions of Terms Specific to This Standard:

100 000 000. These flow conditioners can be used for any type

3.2.1 annuli, n—ring-shaped object, structure, or region.

of flow meter or development of a fully developed flow profile

3.2.2 axial symmetry, n—symmetry around an axis; an

for other uses.

object is axially symmetric if its appearance is unchanged if

1.2 The central single-hole configuration that is derived

rotated around an axis.

using fundamental screen theory is referenced as the flow

3.2.3 Reynolds number, n—dimensionless number used in

conditioner described herein.

fluid mechanics to indicate whether fluid flow past a body or in

1.3 Piping lengths upstream and downstream of a flow

a duct is steady or turbulent.

conditioner are considered a critical component of a flow

3.2.4 velocity profile, n—variation in velocity along a line at

conditioner and constitute the complete flow conditioner sys-

right angles to the general direction of flow.

tem.

4. Significance and Use

1.4 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

4.1 Flow conditioners are used for the conditioning of the

conversions to SI units that are provided for information only

turbulent flow profile of gases or liquids to reduce the ADD

and are not considered standard.

(velocity profile distortion) DEL (turbulence), swirl, or irregu-

larities caused by the installation effects of piping elbows,

1.5 This standard does not purport to address all of the

lengthofpipe,valves,tees,andothersuchequipmentorpiping

safety concerns, if any, associated with its use. It is the

configurations that will affect the reading of flow measurement

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- meters thus inducing measurement errors as a result of the flow

profile of the gas or liquid not having a fully developed flow

bility of regulatory limitations prior to use.

4

profile at the measurement point.

2. Referenced Documents

5. Flow Conditioner Design Methodology

2

2.1 ASTM Standards:

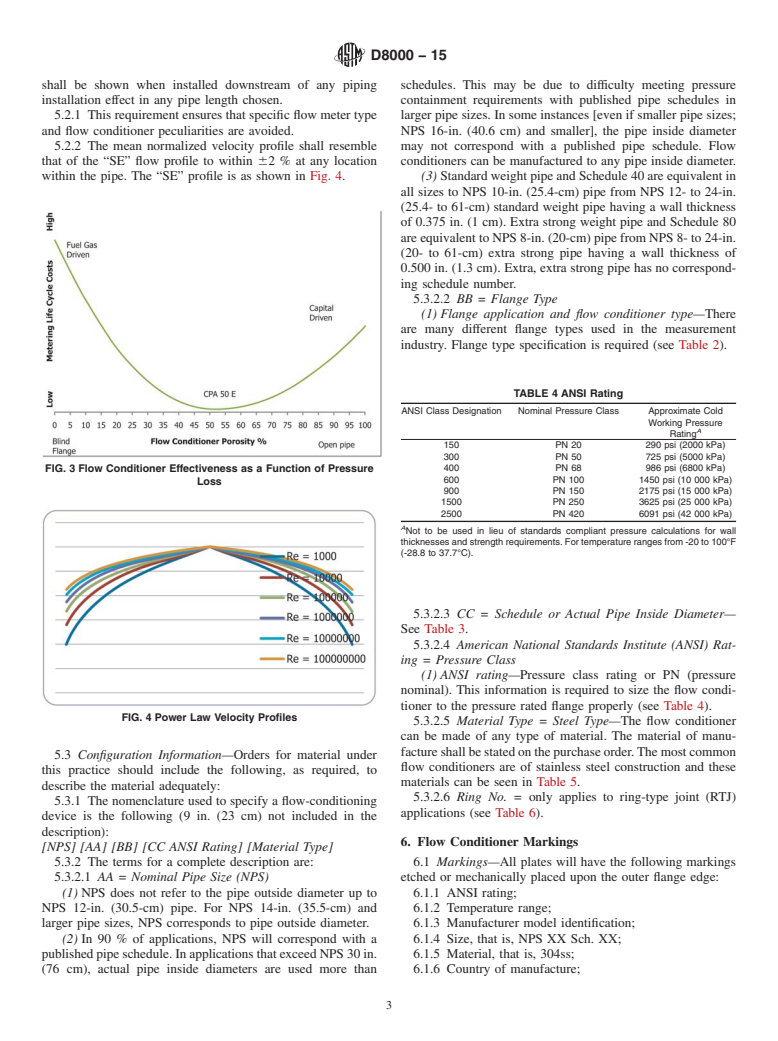

5.1 Pipe Flow Profiles—Almost any description can be

D4150 Terminology Relating to Gaseous Fuels

prescribed by using the perforated plate utilizing screen theory.

3

2.2 AGA Standard:

That is, any upstream velocity profile, U , can be changed to a

1

AGA Report No. 8 Compressibility Factor of Natural Gas

downstream velocity profile, U , with the use of a screen

2

and Related Hydrocarbon Gases

(herein referred to as a flow conditioner) (see Fig. 1).

NOTE 1—The upstream flow profile need not be mathematically defined

or even known.

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD03onGaseous

Fuels and is the direct responsibility of Subcommittee D03.12 on On-Line/At-Line 5.1.1 The intent of the screen theory methodology is to

Analysis of Gaseous Fuels.

suppress or allow flow such that the axi-symmetric distribution

Current edition approved Sept. 15, 2015. Published October 2015. DOI:

of the fluid flow eventually manifests itself into a fully

10.1520/D8000–15.

2 developed state—g(r). Separating the pipe flow into annuli and

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

4

the ASTM website. Per various Coriolis Flow Meter manufacturer statements: A Coriolis Flow

3

Available from the American Gas Association, 400 N. Capital St., NW, Meter reportedly does not require flow conditioning, therefore this ASTM standard

Washington, DC 20001, www.techstreet.com/aga. does not apply.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

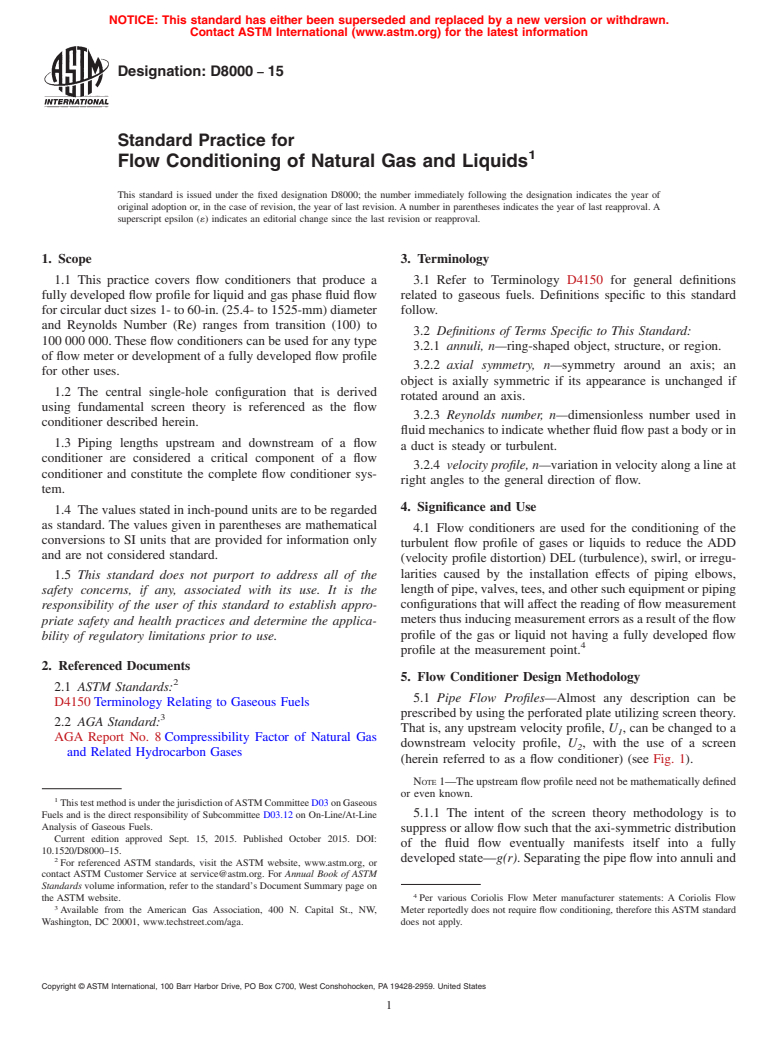

D8000−15

FIG. 1Pipe Flow Profile

2

correlating the openness of each annulus in terms of an 2n

U 5 U (2)

F G

ave max

effective beta ratio of that annulus with respec

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.