ASTM C501-21

(Test Method)Standard Test Method for Relative Resistance to Wear of Unglazed Ceramic Tile by the Taber Abraser

Standard Test Method for Relative Resistance to Wear of Unglazed Ceramic Tile by the Taber Abraser

ABSTRACT

This test method covers the establishment of an abrasive wear index by determination of the loss of weight resulting from abrasion of unglazed ceramic tile by Taber Abraser. The test method consists of mounting the tile specimens in suitable holders, attaching the mounted holders to the spindle of the Taber Abraser, and subjecting the specimens to a prescribed number of revolutions under abrasive wheels of specified coarseness and under a definite applied load. The apparatus consists of Taber abrading machine, vacuum pick-up, revolution counter, wheel refacer, and balance. The procedure of sampling and mounting the test specimen are detailed. The formula for calculating the abrasive wear index from the loss of weight due to abrasion is given.

SIGNIFICANCE AND USE

5.1 This test method provides a means to quantify the abrasion resistance of unglazed ceramic tile and may be related to end-use performance, or used to comparatively rank material performance, or both.

SCOPE

1.1 This test method covers the establishment of an abrasive wear index by determination of the loss of weight resulting from abrasion of unglazed ceramic tile. It is applicable to tile described in Definitions C242.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C501 − 21

Standard Test Method for

Relative Resistance to Wear of Unglazed Ceramic Tile by

1

the Taber Abraser

This standard is issued under the fixed designation C501; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 4. Summary of Test Method

1.1 Thistestmethodcoverstheestablishmentofanabrasive 4.1 A test specimen is abraded using rotary rubbing action

wear index by determination of the loss of weight resulting under controlled conditions of pressure and abrasive action.

from abrasion of unglazed ceramic tile. It is applicable to tile The specimen is mounted on a turntable platform and turns on

described in Definitions C242. a vertical axis, against the sliding rotation of two abrading

wheels of specified coarseness under a defined applied load.

1.2 The values stated in inch-pound units are to be regarded

When resting on the specimen, the wheels have a peripheral

as standard. The values given in parentheses are mathematical

engagement with the surface of the specimen, the direction of

conversions to SI units that are provided for information only

travel of the periphery of the wheels and of the specimen at the

and are not considered standard.

contacting portions being at acute angles, and the angles of

1.3 This standard does not purport to address all of the

travel of one wheel periphery being opposite to that of the

safety concerns, if any, associated with its use. It is the

other. Motion of the abrasive wheels, is provided by rotation of

responsibility of the user of this standard to establish appro-

the specimen and the associated friction therefrom, while a

priate safety, health, and environmental practices and deter-

vacuum system removes wear debris generated during the test.

mine the applicability of regulatory limitations prior to use.

The resulting abrasion marks form a pattern of crossed arcs

1.4 This international standard was developed in accor- 2 2

over an area of approximately 5 in. (30 cm ). From the loss of

dance with internationally recognized principles on standard-

weight due to abrasion, the abrasive wear index is calculated

ization established in the Decision on Principles for the

by a given formula.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

5. Significance and Use

Barriers to Trade (TBT) Committee.

5.1 This test method provides a means to quantify the

abrasionresistanceofunglazedceramictileandmayberelated

2. Referenced Documents

toend-useperformance,orusedtocomparativelyrankmaterial

2

2.1 ASTM Standards:

performance, or both.

C242 Terminology of Ceramic Whitewares and Related

Products

6. Apparatus

G195 Guide for Conducting Wear Tests Using a Rotary

3

6.1 Abraser, as described in Guide G195 with accessory

Platform Abraser

weightsthatprovideaforceof9.8N(1000gf),whenthewheel

3. Terminology

is pressed against the specimen, exclusive of the mass of the

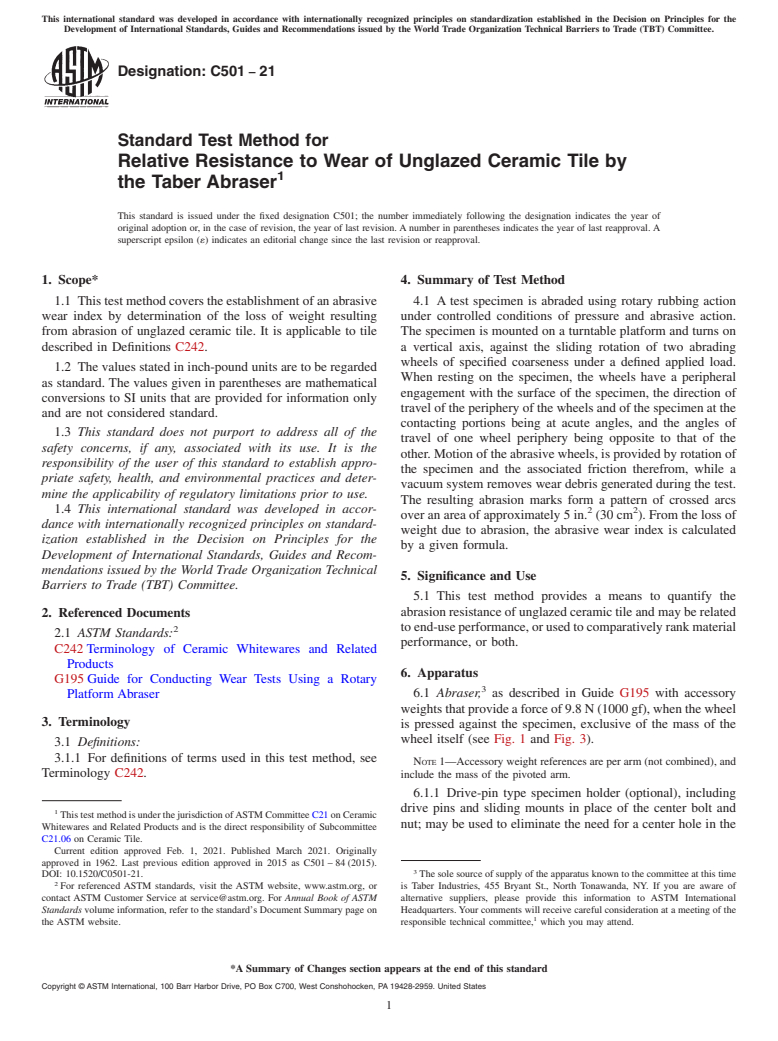

wheel itself (see Fig. 1 and Fig. 3).

3.1 Definitions:

3.1.1 For definitions of terms used in this test method, see

NOTE 1—Accessory weight references are per arm (not combined), and

Terminology C242. include the mass of the pivoted arm.

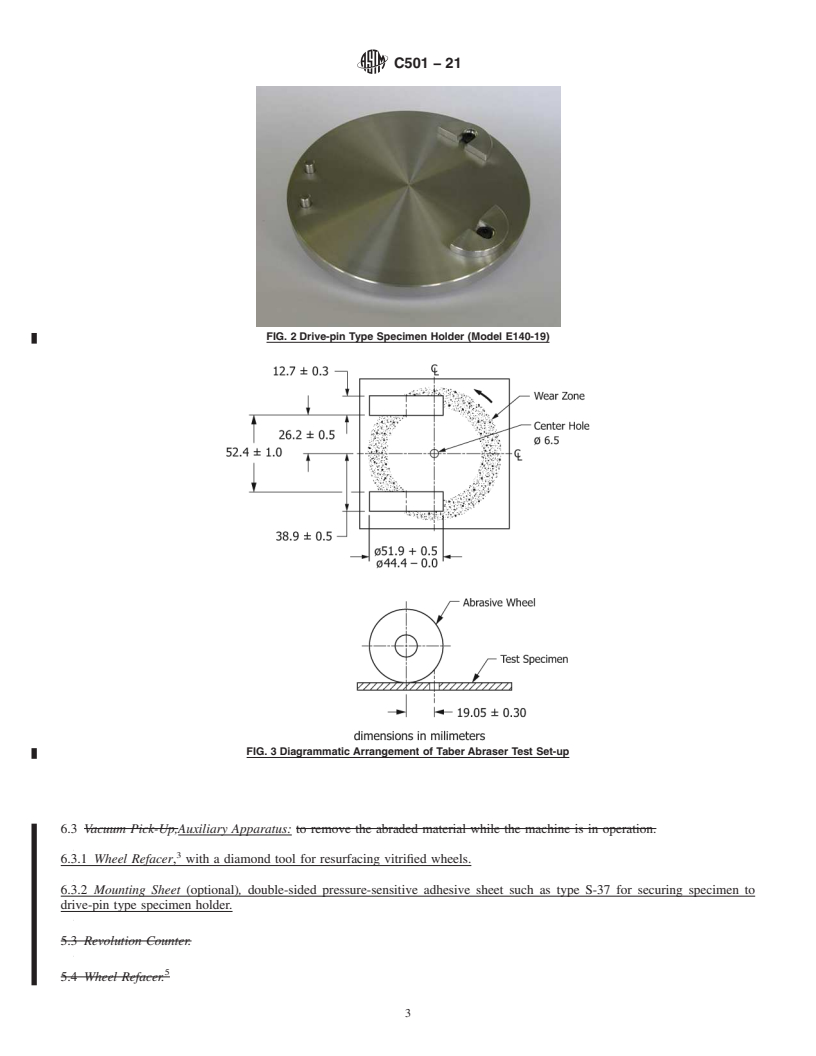

6.1.1 Drive-pin type specimen holder (optional), including

drive pins and sliding mounts in place of the center bolt and

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC21onCeramic

nut; may be used to eliminate the need for a center hole in the

Whitewares and Related Products and is the direct responsibility of Subcommittee

C21.06 on Ceramic Tile.

Current edition approved Feb. 1, 2021. Published March 2021. Originally

approved in 1962. Last previous edition approved in 2015 as C501 – 84 (2015).

3

DOI: 10.1520/C0501-21. The sole source of supply of the apparatus known to the committee at this time

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or is Taber Industries, 455 Bryant St., North Tonawanda, NY. If you are aware of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM alternative suppliers, please provide this information to ASTM International

Standards volume information, refer to the standard’s Document Summary page on Headquarters.Your comments will receive careful consideration at a meeting of the

1

the ASTM website. responsible technical committee, which you may attend.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO B

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C501 − 84 (Reapproved 2015) C501 − 21

Standard Test Method for

Relative Resistance to Wear of Unglazed Ceramic Tile by

1

the Taber Abraser

This standard is issued under the fixed designation C501; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method overscovers the establishment of an abrasive wear index by determination of the loss of weight resulting from

abrasion of unglazed ceramic tile. It is applicable to tile described in Definitions C242. c

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C242 Terminology of Ceramic Whitewares and Related Products

G195 Guide for Conducting Wear Tests Using a Rotary Platform Abraser

2.2 Federal Specification:

4

SS-T–308b Tile, Floor, Wall, and Trim Units, Ceramic

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in this test method, see Terminology C242.

4. Summary of Test Method

4.1 This test method consists of mounting the tile specimens in suitable holders, attaching the mounted holders to the spindle of

the Taber Abraser, and subjecting the specimens to a prescribed number of revolutions under abrasive A test specimen is abraded

1

This test method is under the jurisdiction of ASTM Committee C21 on Ceramic Whitewares and Related Products and is the direct responsibility of Subcommittee C21.06

on Ceramic Tile.

Current edition approved Dec. 15, 2015Feb. 1, 2021. Published December 2015March 2021. Originally published asapproved in C501 – 62.1962. Last previous edition

approved in 20092015 as C501 – 84 (2009).(2015). DOI: 10.1520/C0501-84R15.10.1520/C0501-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C501 − 21

using rotary rubbing action under controlled conditions of pressure and abrasive action. The specimen is mounted on a turntable

platform and turns on a vertical axis, against the sliding rotation of two abrading wheels of specified coarseness and under a definite

applied load. defined applied load. When resting on the specimen, the wheels have a peripheral engagement with the surface of

the specimen, the direction of travel of the periphery of the wheels and of the specimen at the contacting portions being at acute

angles, and the angles of travel of one wheel periphery being opposite to that of the other. Motion of the abrasive wheels, is

provided by rotation of the specimen and the associated friction therefrom, while a vacuum system removes wear debris generated

2 2

during the test. The resulting abrasion marks form a pattern of crossed arcs over an area of approximately 5 in. (30 cm ). From

the loss of weight due to abrasion, the abrasive wear index is calculated by a given formula.

5. Significance and Use

5.1 This test method provides a means to quantify the abrasion resistance of unglazed ceramic tile and may be related to end-use

performance, or used to comparatively rank material performance, or both.

6. Apparatus

3

6.1 Abraser, as described in Guide G195 with accessory weights that provide a force of 9.8 N (1000 gf), when the wheel is

presse

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.