ASTM D6698-01

(Test Method)Standard Test Method for On-Line Measurement of Turbidity Below 5 NTU in Water

Standard Test Method for On-Line Measurement of Turbidity Below 5 NTU in Water

SCOPE

1.1 This test method is applicable to the on-line measurement of turbidity under 5 nephelometric turbidity units (NTU) in water.

1.2 It is the user's responsibility to ensure the validity of this test method for waters of untested matrices.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6698–01

Standard Test Method for

On-Line Measurement of Turbidity Below 5 NTU in Water

This standard is issued under the fixed designation D 6698; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope US Patent 4,283,143 fromAdvanced Polymer Systems, Inc.,

123 Saginaw Dr., Redwood City, CA 94063

1.1 This test method is applicable to the on-line measure-

US Patent 4,291,980 fromAdvanced Polymer Systems, Inc.,

ment of turbidity under 5 nephelometric turbidity units (NTU)

123 Saginaw Dr., Redwood City, CA

in water.

US Patent 5,777,011 from Hach Company, 5600 Lindbergh

1.2 Itistheuser’sresponsibilitytoensurethevalidityofthis

Drive, Loveland, CO 80537

test method for waters of untested matrices.

1.3 This standard does not purport to address all of the

3. Terminology

safety concerns, if any, associated with its use. It is the

3.1 Definitions—For definitions of terms used in this

responsibility of the user of this standard to establish appro-

method refer to Terminology D 1129.

priate safety and health practices and determine the applica-

3.2 Definitions of Terms Specific to This Standard:

bility of regulatory limitations prior to use.

3.2.1 calibration turbidity standard—a turbidity standard

2. Referenced Documents that is traceable and equivalent to the reference turbidity

standard to within statistical errors, including commercially

2.1 ASTM Standards:

prepared 4000 NTU Formazin, stabilized formazin, and sty-

D 1129 Terminology Relating to Water

renedivinylbenzene (SDVB). These standards may be used to

D 1193 Specification for Reagent Water

calibrate the instrument.

D 1889 Test Method for Turbidity in Water

D 2777 Practice for Determination of Precision and Bias of

NOTE 1—Calibration standards may be instrument specific.

Applicable Methods of Committee D19 on Water

3.2.2 calibration verification standards—defined standards

D 3370 Practices for SamplingWater from Closed Conduits

used to verify the accuracy of a calibration in the measurement

D 3864 Guide for Continual On-line Monitoring for Water

range of interest. These standards may not be used to perform

Analysis

calibrations, only calibration verifications. Included standards

2.2

are opto-mechanical light scatter devices, gel-like standards, or

EPA 180.1 Methods for Chemical Analysis of Water and

any other type of stable liquid standard.

Wastes, Turbidity

NOTE 2—Calibration verification standards may be instrument specific.

Standard Methods for the Examination of Water and Waste-

water 2130B, 19th edition

3.2.3 in-situ nephelometer—a turbidimeter that determines

ISO 7027 (The International Organization for Standardiza-

the turbidity of a sample using a sensor that is placed directly

tion) for the Determination of Turbidity

in the sample. This turbidimeter does not require transport of

Hach Method 8195

the sample to or from the sensor.

GLI Method 2

3.2.4 nephelometric turbidity measurement—the measure-

ment of light scatter from a sample in a direction that is at 90°

with respect to the centerline of the incident light path. Units

This test method is under the jurisdiction of ASTM Committee D19 on Water

are NTU (Nephelometric Turbidity Units); when ISO 7027

and is the direct responsibility of Subcommittee D19.03 on Sampling Water and

technology is employed, units are FNU (Formazin Nephelom-

Water-Formed Deposits, Analysis of Water for Power Generation and Process Use,

On-Line Water Analysis, and Surveillance of Water.

etric Units).

Current edition approved July 10, 2001. Published November 2001.

3.2.5 ratio turbidity measurement—the measurement de-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

rived through the use of a nephelometric detector that serves as

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on the primary detector and one or more other detectors used to

the ASTM website.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

D6698–01

compensate for variation in incident light fluctuation, stray causes negative interference. Dissolved material that imparts a

light, instrument noise, or sample color. color to the water may cause errors in pure photoelectric

3.2.6 reference turbidity standard—a standard that is syn- nephelometric readings (versus ratio photoelectric nephelom-

thesized reproducibly from traceable raw materials by the user. etric readings) unless the instrument has special compensating

All other standards are traced back to this standard. The features.Certainturbulentmotionsalsocreateunstablereading

reference standard for turbidity is formazin. conditions of nephelometers.

3.2.7 seasoning—the process of conditioning labware with 6.2 Scratches, finger marks, or dirt on any part of an optical

the standard that will be diluted to a lower value. The process component through which light must travel to reach the

reduces contamination and dilution errors. See Appendix X2 sample, or through which scattered light leaves the sample to a

for suggested procedure. detector, may give erroneous readings. Keep these surfaces

3.2.8 slip stream nephelometer—an on-line turbidimeter scrupulously clean and replace damaged (etched or scratched)

that determines the turbidity of a sample as the sample flows components.

through a sampling chamber. The sample is drawn from the

7. Apparatus

source into the turbidimeter, analyzed and then transported to

7.1 The sensor used for the on-line monitoring of turbidity

drain.

is designed for continuous monitoring of the turbidity of the

3.2.9 stray light—all light reaching the detector other than

sample stream.

that contributed by the sample. For example: ambient light

7.2 The instrument design should eliminate signal spikes

leakage and divergent light in optical systems.

resulting from bubbles present in samples through the use of

3.2.10 turbidimeter—an instrument that measures light

either internal or external bubble rejection chambers (traps),

scatter using a nephelometric detector. Examples include

sample pressurization, and/or electronic rejection methods.

photoelectric nephelometers and ratio photoelectric nephelom-

7.3 The sensor must be designed to be calibrated. The

eters.

calibration should be performed by following the manufactur-

3.2.11 turbidity—anexpressionoftheopticalpropertiesofa

er’s recommended procedures. If a calibration algorithm for

sample that causes light rays to be scattered and absorbed

the instrument is used, it should be derived through the use of

rather than transmitted in straight lines through the sample.

a reference or calibration turbidity standard.

(Turbidity of water is caused by the presence of matter such as

7.4 Theresolutionoftheinstrumentshouldpermitdetection

clay, silt, finely divided organic matter, plankton, other micro-

of turbidity differences of 0.01 NTU or less in waters having

scopic organisms, organic acids, and dyes.)

turbidities of less than 1.00 NTU. The instrument should

4. Significance and Use

permit detection of turbidity differences of 0.10 NTU or less in

4.1 Turbidity is undesirable in drinking water, plant effluent

waters with turbidity between 1.0 and 5.0 NTU.

waters, water for food and beverage processing, and for a large 7.5 Instrument Types—Two types of instruments are avail-

number of other water-dependent manufacturing processes.

able for the nephelometric turbidity method, the nephelometer

Removal of suspended matter is accomplished by coagulation, and ratio nephelometer.

settling, and filtration. Measurement of turbidity provides a

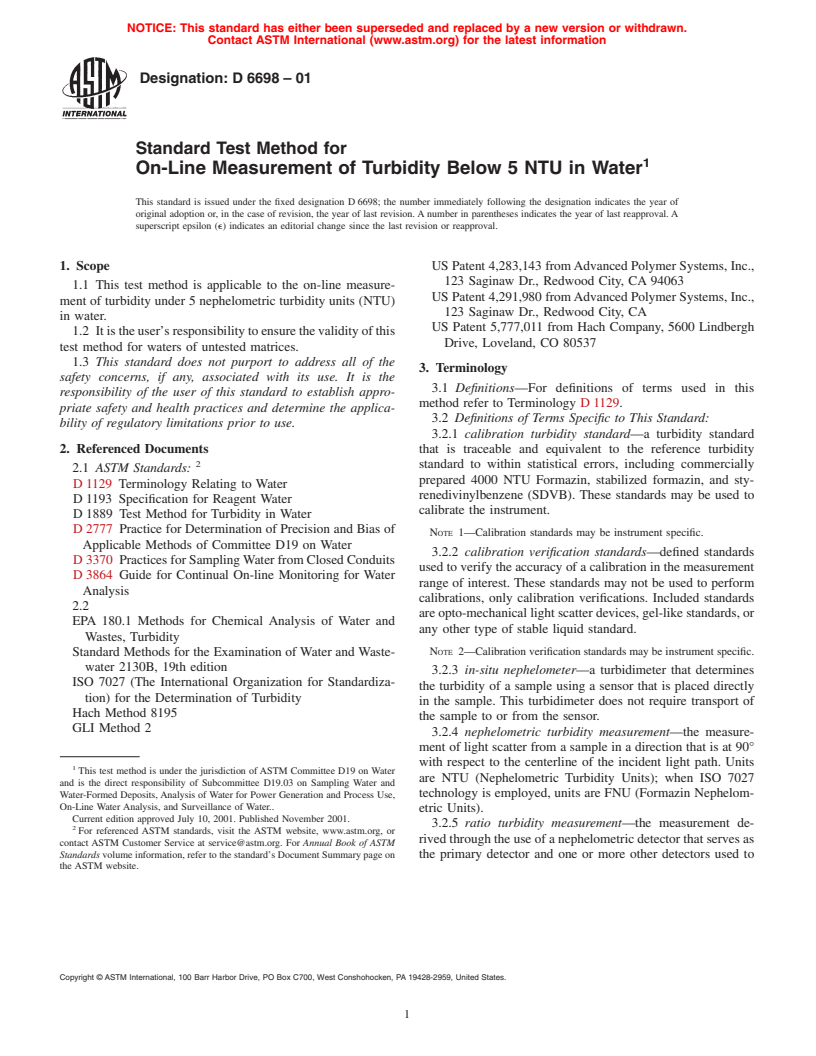

7.5.1 The Photoelectric Nephelometer—(see Fig. 1). This

rapid means of process control to determine when, how, and to instrument uses a light source for illuminating the sample and

what extent the water must be treated to meet specifications.

a single photo-detector with a readout device to indicate the

4.2 Thistestmethodissuitablefortheon-linemonitoringof intensityoflightscatteredat90°tothecenterlineofthepathof

turbidity such as that found in drinking water, process water,

the incident light.The photoelectric nephelometer should be so

and high purity industrial waters. designed that minimal stray light reaches the detector in the

4.3 The instrumentation used must allow for the continuous

absence of turbidity and should be free from significant drift

on-line monitoring of a sample stream. after a short warm-up period. The light source should be a

Tungsten lamp operated at a color temperature between 2200

NOTE 3—See 7.2 for discussion on signal spikes resulting from

and 3000 K. Light Emitting Diodes (LEDs) and laser diodes in

bubbles.

defined wavelengths ranging from 400-900 nm may also be

5. Safety

used. If LEDs or laser diodes are used, then the LED or laser

diode should be coupled with a monitor detection device to

5.1 Wear appropriate personal protection equipment at all

achieve a consistent output. The total distance traversed by

times.

incident light and scattered light within the sample is not to

5.2 Follow all relevant safety guidelines.

exceed 10 cm. Angle of light acceptance to the detector:

5.3 Refer to instrument manuals for safety guidelines when

centered at 90° to the centerline of the incident light path and

installing, calibrating, measuring or performing maintenance

not to exceed 610° from the 90° scatter path center line. The

with any of the respective instrumentation.

detector must have a spectral response that is sensitive to the

5.4 Refer to all Material Safety Data Sheets (MSDSs) prior

spectral output of the incident light used.

to preparing or using standards and before calibrating or

7.5.1.1 Differences in physical design of photoelectric

performing instrument maintenance.

nephelometers will cause slight differences in measured values

6. Interferences

for turbidity even though the same suspension is used for

6.1 Bubbles, color, and large suspended particles may result calibrations. Comparability of measurements made using in-

in interferences. Bubbles cause positive interference and color struments differing in optical and physical design is not

D6698–01

FIG. 1 Photoelectric Nephelometer

recommended. To minimize initial differences, observe the should not exceed 610° from the scatter path center line. The

following design criteria: detector must have a spectral response that is sensitive to the

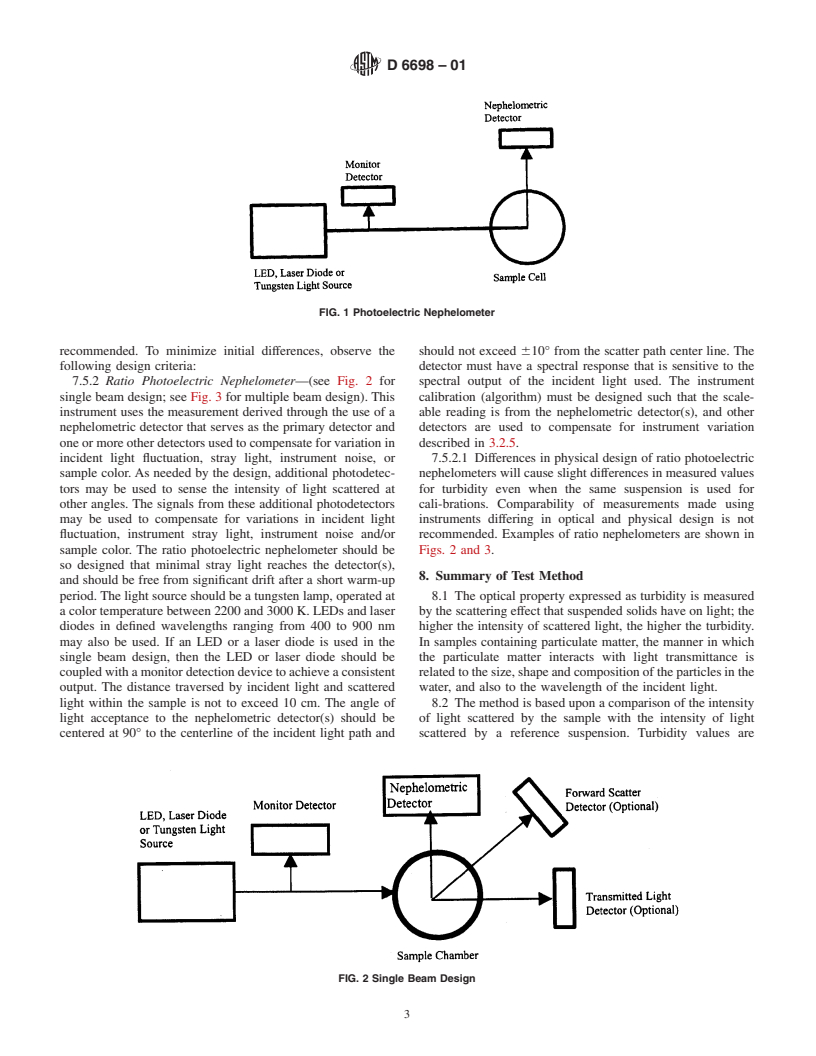

7.5.2 Ratio Photoelectric Nephelometer—(see Fig. 2 for spectral output of the incident light used. The instrument

single beam design; see Fig. 3 for multiple beam design). This calibration (algorithm) must be designed such that the scale-

instrument uses the measurement derived through the use of a able reading is from the nephelometric detector(s), and other

nephelometric detector that serves as the primary detector and detectors are used to compensate for instrument variation

oneormoreotherdetectorsusedtocompensateforvariationin described in 3.2.5.

incident light fluctuation, stray light, instrument noise, or 7.5.2.1 Differences in physical design of ratio photoelectric

sample color. As needed by the design, additional photodetec- nephelometers will cause slight differences in measured values

tors may be used to sense the intensity of light scattered at for turbidity even when the same suspension is used for

other angles. The signals from these additional photodetectors cali-brations. Comparability of measurements made using

may be used to compensate for variations in incident light instruments differing in optical and physical design is not

fluctuation, instrument stray light, instrument noise and/or recommended. Examples of ratio nephelometers are shown in

sample color. The ratio photoelectric nephelometer should be Figs. 2 and 3.

so designed that minimal stray light reaches the detector(s),

8. Summary of Test Method

and should be free from significant drift after a short warm-up

period.The light source should be a tungsten lamp, operated at 8.1 The optical property expressed as turbidity is measured

a color temperature between 2200 and 3000 K. LEDs and laser by the scattering effect that suspended solids have on light; the

diodes in defined wavelengths ranging from 400 to 900 nm higher the intensity of scattered light, the higher the turbidity.

may also be used. If an LED or a laser diode is used in the In samples containing particulate matter, the manner in which

single beam design, then the LED or laser diode should be the particulate matter interacts with light transmittance is

coupledwithamonitordetectiondevicetoachieveaconsistent relatedtothesize,shapeandcompositionoftheparticlesinthe

output. The distance traversed by incident light and scattered water, and also to the wavelength of the incident light.

light within the sample is not to exceed 10 cm. The angle of 8.2 The method is based upon a comparison of the intensity

light acceptance to the nephelometric detector(s) should be of light scattered by the sample with the intensity of light

scattered by a reference suspension. Turbidity values are

centered at 90° to the centerline of the incident light path and

FIG. 2 Single Beam Design

D6698–01

FIG. 3 Multiple Beam Design

NOTE 6—All volumetric glassware must be scrupulously clean. The

determined by a nephelometer, which measures light scatter

necessary level of cleanliness can be achieved by performing all of the

from a sample in a direction that is at 90 degrees with respect

following steps: washing glassware with laboratory detergent followed by

to the centerline of the incident light path.

3 tap water rinses; then rinse with portions of 1:4 HCl followed by at least

3 tap water rinses; finally, rinse 3 times with rinse water as defined in 9.2.

9. Purity of Reagents

Reference FormazinTurbidity Standard (4000 NTU) is synthesized on the

9.1 ACS grade chemicals of high purity (99+ %) shall be

bench.

used in all tests. Unless otherwise indicated, it is intended that

10.2.1.1 Dissolve 5.000 grams of ACS grade hydrazine

all reagents shall conform to the specifications of the Commit-

sulfate (99.5 % + purity) (N H·H SO into approximately

2 4 2 4

tee onAnalytical Reagents of theAmerican Chemical Society,

400 mL of dilution water (see 9.2) contained in a 1-liter Class

where such specifications are available. Other grades may be

A volumetric flask.

used providing it is first ascertained that the reagent is of

10.2.1.2 Dissolve 50.000 grams of ACS grad

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.