ASTM D7725-17

(Test Method)Standard Test Method for the Continuous Measurement of Turbidity Above 1 Turbidity Unit (TU)

Standard Test Method for the Continuous Measurement of Turbidity Above 1 Turbidity Unit (TU)

SIGNIFICANCE AND USE

4.1 Turbidity is undesirable in drinking water, plant effluent waters, water for food and beverage processing, and for a large number of other water dependent manufacturing processes. Removal of suspended matter is accomplished by coagulation, settling, and filtration. Measurement of turbidity provides a rapid means of process control to determine when, how, and to what extent the water must be treated to meet specifications.

4.2 This test method is suitable for the on-line monitoring of turbidity such as that found in drinking water, process water, and high purity industrial waters.

4.3 The instrumentation used must allow for the continuous on-line monitoring of a sample stream.

4.4 When reporting the measured result, appropriate units should also be reported. The units are reflective of the technology used to generate the result, and if necessary, provide more adequate comparison to historical data sets.

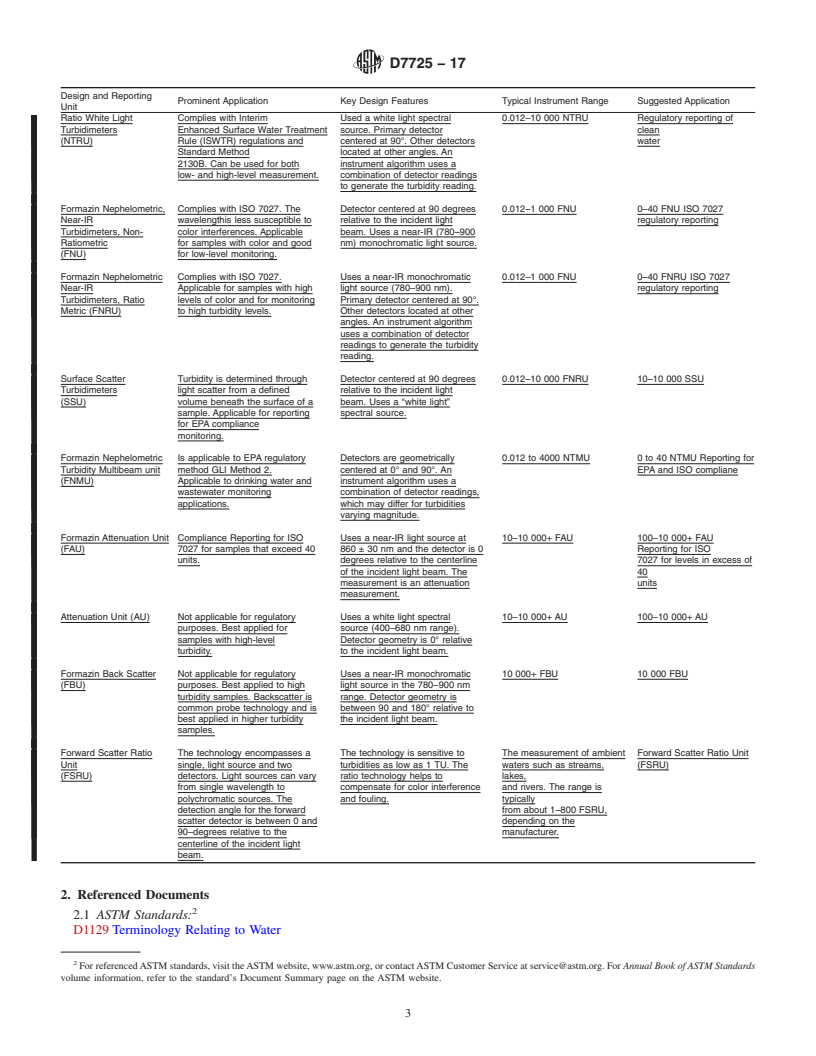

4.4.1 Table 1 describing technologies and reporting results. Those technologies listed are appropriate for the range of measurement prescribed in this test method are mentioned, though others may come available. Fig. X3.1 from Appendix X3 contains a flowchart to assist in technology selection.

4.4.2 For a specific design that falls outside of these reporting ranges, the turbidity should be reported in TU with a subscripted wavelength value to characterize the light source that was used.

4.4.3 Ratio white light turbidimeters are common as bench top instruments but not as a typical process instrument. However, if fitted with a flow-cell they meet the criteria of this test method.

SCOPE

1.1 This test method covers the on-line and in-line determination of high-level turbidity in water that is greater than 1.0 turbidity units (TU) in municipal, industrial and environmental usage.

1.2 In principle, there are three basic applications for on-line measurement set ups. This first is the slipstream (bypass) sample technique. For the slipstream sample technique a portion of sample is transported out of the process and through the measurement apparatus. It is then either transported back to the process or to waste. The second is the in-line measurement where the sensor is brought directly into the process (see Fig. 8). The third basic method is for in-situ monitoring of sample waters. This principle is based on the insertion of a sensor into the sample itself as the sample is being processed. The in-situ use in this test method is intended for the monitoring of water during any step within a processing train, including immediately before or after the process itself.

1.3 This test method is applicable to the measurement of turbidities greater than 1.0 TU. The absolute range is dictated by the technology that is employed.

1.4 The upper end of the measurement range is left undefined because different technologies described in this test method can cover very different ranges of turbidity.

1.5 Many of the turbidity units and instrument designs covered in this test method are numerically equivalent in calibration when a common calibration standard is applied across those designs listed in Table 1. Measurement of a common calibration standard of a defined value will also produce equivalent results across these technologies. This test method prescribes the assignment of a determined turbidity values to the technology used to determine those values. Numerical equivalence to turbidity standards is observed between different technologies but is not expected across a common sample. Improved traceability beyond the scope of this test method may be practiced and would include the listing of the make and model number of the instrument used to determine the turbidity values.

1.5.1 In this test method, calibration standards are often defined in NTU values, but the other assigned turbidity units, such as those in Table 1 are equivalent. For example, a 1 NTU formazin standard is also a 1...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7725 − 17

Standard Test Method for the

Continuous Measurement of Turbidity Above 1 Turbidity

1

Unit (TU)

This standard is issued under the fixed designation D7725; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope values to the technology used to determine those values.

Numerical equivalence to turbidity standards is observed

1.1 This test method covers the on-line and in-line determi-

between different technologies but is not expected across a

nation of high-level turbidity in water that is greater than 1.0

common sample. Improved traceability beyond the scope of

turbidity units (TU) in municipal, industrial and environmental

this test method may be practiced and would include the listing

usage.

of the make and model number of the instrument used to

1.2 Inprinciple,therearethreebasicapplicationsforon-line

determine the turbidity values.

measurement set ups. This first is the slipstream (bypass)

1.5.1 In this test method, calibration standards are often

sample technique. For the slipstream sample technique a

defined in NTU values, but the other assigned turbidity units,

portion of sample is transported out of the process and through

such as those in Table 1 are equivalent. For example,a1NTU

themeasurementapparatus.Itistheneithertransportedbackto

formazin standard is alsoa1FNU,a1FAU,a1BU,andso

the process or to waste. The second is the in-line measurement

forth.

where the sensor is brought directly into the process (see Fig.

1.6 This test method does not purport to cover all available

8). The third basic method is for in-situ monitoring of sample

waters. This principle is based on the insertion of a sensor into technologies for high-level turbidity measurement.

the sample itself as the sample is being processed. The in-situ

1.7 Thistestmethodwastestedondifferentwaters,andwith

use in this test method is intended for the monitoring of water

standards that will serve as surrogates to samples. It is the

during any step within a processing train, including immedi-

user’s responsibility to ensure the validity of this test method

ately before or after the process itself.

for waters of untested matrices.

1.3 This test method is applicable to the measurement of

1.8 Those samples with the highest particle densities typi-

turbidities greater than 1.0 TU. The absolute range is dictated

cally prove to be the most difficult to measure. In these cases,

by the technology that is employed.

the process monitoring method can be considered with ad-

1.4 The upper end of the measurement range is left unde-

equate measurement protocols installed.

fined because different technologies described in this test

1.9 The values stated in SI units are to be regarded as

method can cover very different ranges of turbidity.

standard. No other units of measurement are included in this

1.5 Many of the turbidity units and instrument designs

standard.

covered in this test method are numerically equivalent in

1.10 This standard does not purport to address all of the

calibration when a common calibration standard is applied

safety concerns, if any, associated with its use. It is the

across those designs listed in Table 1. Measurement of a

responsibility of the user of this standard to establish appro-

common calibration standard of a defined value will also

priate safety, health, and environmental practices and deter-

produce equivalent results across these technologies. This test

mine the applicability of regulatory limitations prior to use.

method prescribes the assignment of a determined turbidity

Refer to the MSDSs for all chemicals used in this procedure.

1 1.11 This international standard was developed in accor-

This test method is under the jurisdiction of ASTM Committee D19 on Water

dance with internationally recognized principles on standard-

and is the direct responsibility of Subcommittee D19.03 on Sampling Water and

Water-Formed Deposits, Analysis of Water for Power Generation and Process Use,

ization established in the Decision on Principles for the

On-Line Water Analysis, and Surveillance of Water.

Development of International Standards, Guides and Recom-

Current edition approved Dec. 15, 2017. Published February 2018. Originally

mendations issued by the World Trade Organization Technical

approved in 2012. Last previous edition approved in 2012 as D7725 – 12. DOI:

10.1520/D7725-17. Barriers to Trade (TBT) Committee.

Copyright © ASTM International, 100 Bar

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7725 − 12 D7725 − 17

Standard Test Method for the

Continuous Measurement of Turbidity Above 1 Turbidity

1

Unit (TU)

This standard is issued under the fixed designation D7725; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the onlineon-line and inlinein-line determination of high-level turbidity in water that is greater than

1.0 turbidity units (TU) in municipal, industrial and environmental usage.

1.2 In principle, there are three basic applications for on-line measurement set ups. This first is the slipstream (bypass) sample

technique. For the slipstream sample technique a portion of sample is transported out of the process and through the measurement

apparatus. It is then either transported back to the process or to waste. The second is the in-line measurement where the sensor

is brought directly into the process (see Fig. 8). The third basic method is for in-situ monitoring of sample waters. This principle

is based on the insertion of a sensor into the sample itself as the sample is being processed. The in-situ use in this test method is

intended for the monitoring of water during any step within a processing train, including immediately before or after the process

itself.

1.3 This test method is applicable to the measurement of turbidities greater than 1.0 turbidity unit (TU). TU. The absolute range

is dictated by the technology that is employed.

1.4 The upper end of the measurement range is left undefined because different technologies described in this test method can

cover very different ranges of turbidity.

1.5 Many of the turbidity units and instrument designs covered in this test method are numerically equivalent in calibration

when a common calibration standard is applied across those designs listed in Table 1. Measurement of a common calibration

standard of a defined value will also produce equivalent results across these technologies. This test method prescribes the

assignment of a determined turbidity values to the technology used to determine those values. Numerical equivalence to turbidity

standards is observed between different technologies but is not expected across a common sample. Improved traceability beyond

the scope of this test method may be practiced and would include the listing of the make and model number of the instrument used

to determine the turbidity values.

1.5.1 In this test method, calibration standards are often defined in NTU values, but the other assigned turbidity units, such as

those in Table 1 are equivalent. For example, a 1 NTU formazin standard is also a 1 FNU, a 1 FAU, a 1 BU, and so forth.

1.6 This standard test method does not purport to cover all available technologies for high-level turbidity measurement.

1.7 This test method was tested on different waters, and with standards that will serve as surrogates to samples. It is the

user’suser’s responsibility to ensure the validity of this test method for waters of untested matrices.

1.8 Those samples with the highest particle densities typically prove to be the most difficult to measure. In these cases, the

process monitoring method can be considered with adequate measurement protocols installed.

1.9 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.10 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. Refer to the MSDSs for all chemicals used in this procedure.

1.11 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This test method is under the jurisdiction of ASTM Committee D19 on Water and is the direct responsibility of Subcommittee D19.03 on Sampling Water and

Water-Formed Deposits, Analysis of Water for Power Generation and Process Use, On-Line Water Analysis, and Surveillance of Wat

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7725 − 17

Standard Test Method for the

Continuous Measurement of Turbidity Above 1 Turbidity

1

Unit (TU)

This standard is issued under the fixed designation D7725; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope values to the technology used to determine those values.

Numerical equivalence to turbidity standards is observed

1.1 This test method covers the on-line and in-line determi-

between different technologies but is not expected across a

nation of high-level turbidity in water that is greater than 1.0

common sample. Improved traceability beyond the scope of

turbidity units (TU) in municipal, industrial and environmental

this test method may be practiced and would include the listing

usage.

of the make and model number of the instrument used to

1.2 In principle, there are three basic applications for on-line

determine the turbidity values.

measurement set ups. This first is the slipstream (bypass)

1.5.1 In this test method, calibration standards are often

sample technique. For the slipstream sample technique a

defined in NTU values, but the other assigned turbidity units,

portion of sample is transported out of the process and through

such as those in Table 1 are equivalent. For example, a 1 NTU

the measurement apparatus. It is then either transported back to

formazin standard is also a 1 FNU, a 1 FAU, a 1 BU, and so

the process or to waste. The second is the in-line measurement

forth.

where the sensor is brought directly into the process (see Fig.

8). The third basic method is for in-situ monitoring of sample 1.6 This test method does not purport to cover all available

technologies for high-level turbidity measurement.

waters. This principle is based on the insertion of a sensor into

the sample itself as the sample is being processed. The in-situ

1.7 This test method was tested on different waters, and with

use in this test method is intended for the monitoring of water

standards that will serve as surrogates to samples. It is the

during any step within a processing train, including immedi-

user’s responsibility to ensure the validity of this test method

ately before or after the process itself.

for waters of untested matrices.

1.3 This test method is applicable to the measurement of

1.8 Those samples with the highest particle densities typi-

turbidities greater than 1.0 TU. The absolute range is dictated

cally prove to be the most difficult to measure. In these cases,

by the technology that is employed.

the process monitoring method can be considered with ad-

1.4 The upper end of the measurement range is left unde-

equate measurement protocols installed.

fined because different technologies described in this test

1.9 The values stated in SI units are to be regarded as

method can cover very different ranges of turbidity.

standard. No other units of measurement are included in this

1.5 Many of the turbidity units and instrument designs

standard.

covered in this test method are numerically equivalent in

1.10 This standard does not purport to address all of the

calibration when a common calibration standard is applied

safety concerns, if any, associated with its use. It is the

across those designs listed in Table 1. Measurement of a

responsibility of the user of this standard to establish appro-

common calibration standard of a defined value will also

priate safety, health, and environmental practices and deter-

produce equivalent results across these technologies. This test

mine the applicability of regulatory limitations prior to use.

method prescribes the assignment of a determined turbidity

Refer to the MSDSs for all chemicals used in this procedure.

1.11 This international standard was developed in accor-

1

This test method is under the jurisdiction of ASTM Committee D19 on Water

dance with internationally recognized principles on standard-

and is the direct responsibility of Subcommittee D19.03 on Sampling Water and

Water-Formed Deposits, Analysis of Water for Power Generation and Process Use,

ization established in the Decision on Principles for the

On-Line Water Analysis, and Surveillance of Water.

Development of International Standards, Guides and Recom-

Current edition approved Dec. 15, 2017. Published February 2018. Originally

mendations issued by the World Trade Organization Technical

approved in 2012. Last previous edition approved in 2012 as D7725 – 12. DOI:

Barriers to Trade (TBT) Committee.

10.1520/D7725-17.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.