ASTM F2232-03

(Test Method)Standard Test Method for Determining the Longitudinal Load Required to Detach High Heels from Footwear

Standard Test Method for Determining the Longitudinal Load Required to Detach High Heels from Footwear

SIGNIFICANCE AND USE

Since the heel is an integral support element of the shoe, the heel-attaching strength is a significant factor in ensuring the wearer’safety, as well as the longevity and serviceability of the shoe.

This test should be performed on each new style shoe and when any changes are made in the design, material or method of shank or heel area of the shoe, or both, or in the attachment of the heel in an existing shoe.

SCOPE

1.1 This method covers the determination of the force required to detach the heel from footwear through the application of longitudinal tensile force at a constant displacement rate. The longitudinal test force simulates the most common heel failure mode. Heel height of 20 mm (13/16 in.) or larger is needed to perform this test method properly. Most women's medium and high heeled footwear meets this requirement.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2232–03

Standard Test Method for

Determining the Longitudinal Load Required to Detach High

Heels from Footwear

This standard is issued under the fixed designation F 2232; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This method covers the determination of the force 3.1 Definitions:

required to detach the heel from footwear through the appli- 3.1.1 forefoot—the portion of the shoe extending forward

cation of longitudinal tensile force at a constant displacement from the break of the joint to the toe, also called forepart.

rate. The longitudinal test force simulates the most common 3.1.2 heel attachment strength—the force in pounds mea-

heel failure mode. Heel height of 20 mm ( ⁄16 in.) or larger is sured under the testing conditions of Test Method F 2232

needed to perform this test method properly. Most women’s required to detach the heel from the sole/insole assembly.

medium and high heeled footwear meets this requirement. 3.1.3 heel breast—the front face of the shoe heel.

1.2 The values stated in SI units are to be regarded as the 3.1.4 heel height—the vertical distance from the top back

standard. The values given in parentheses are for information edge of the heel to the plane of the tread (wear) surface of the

only. heel.

1.3 This standard does not purport to address all of the 3.1.5 insole—the part of the shoe that is a structural anchor

safety concerns, if any, associated with its use. It is the to which the upper and heel are fastened during manufacture.

responsibility of the user of this standard to establish appro- It may or may not be covered on the foot side by material

priate safety and health practices and determine the applica- referred to as a socklining.

bility of regulatory limitations prior to use. 3.1.6 outsole—the bottom (sole) of the shoe: including the

surface which is exposed to wear.

2. Referenced Documents

3.1.7 seatboard—a reinforcement (if used) of the insole

2.1 ASTM Standards:

where the heel is attached.

E29 Practice for Using Significant Digits in Test Data to 3.1.8 shank—a reinforcement in the arch (instep) of the

Determine Conformance with Specifications

shoe between the insole and outsole made from steel, wood,

E 105 Practice for Probability Sampling of Materials

fiberboard or plastic (individually or in combination).

E 122 Practice for Calculating Sample Size to Estimate, 3.1.9 shankboard—the back part of the insole which is

With a Specified Tolerable Error, the Average for Charac-

fabricated from a firm fiberboard. It is contoured to the arch of

teristic of a Lot or Process the foot for support.

E 456 Terminology for Relating to Quality and Statistics

3.1.10 top piece (toplift)—the bottom layer of a heel (wear

2.2 European Standard: surface) usually made of leather, rubber, plastic, steel, or

EN 12785 Footwear, Test Method for Whole Shoes—Heel

elastomers.

Attachment 3.2 For definitions of other terms relating to footwear, refer

2.3 ANSI Standard:

to the Footwear Products Glossary.

ANSI Z41-1999 American National Standard for Personal

4 4. Significance and Use

Protection—Protective Footwear

4.1 Sincetheheelisanintegralsupportelementoftheshoe,

theheel-attachingstrengthisasignificantfactorinensuringthe

This test method is under the jurisdiction of ASTM Committee F13 on

wearer’s safety, as well as the longevity and serviceability of

Pedestrian/Walkway Safety and Footwear and is the direct responsibility of

the shoe.

Subcommittee F13.30 on Footwear.

4.2 This test should be performed on each new style shoe

Current edition approved Jan. 10, 2003. Published March 2003.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and when any changes are made in the design, material or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

method of shank or heel area of the shoe, or both, or in the

Standards volume information, refer to the standard’s Document Summary page on

attachment of the heel in an existing shoe.

the ASTM website.

Orders for all BSI, International and foreign standards publications should be

addressed to Customer Service.

4 5

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St., Available from American Apparel & Footwear Assoc. (AAFA), 1601 N. Kent

4th Floor, New York, NY 10036. St., Suite 1200, Arlington, VA 22209.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

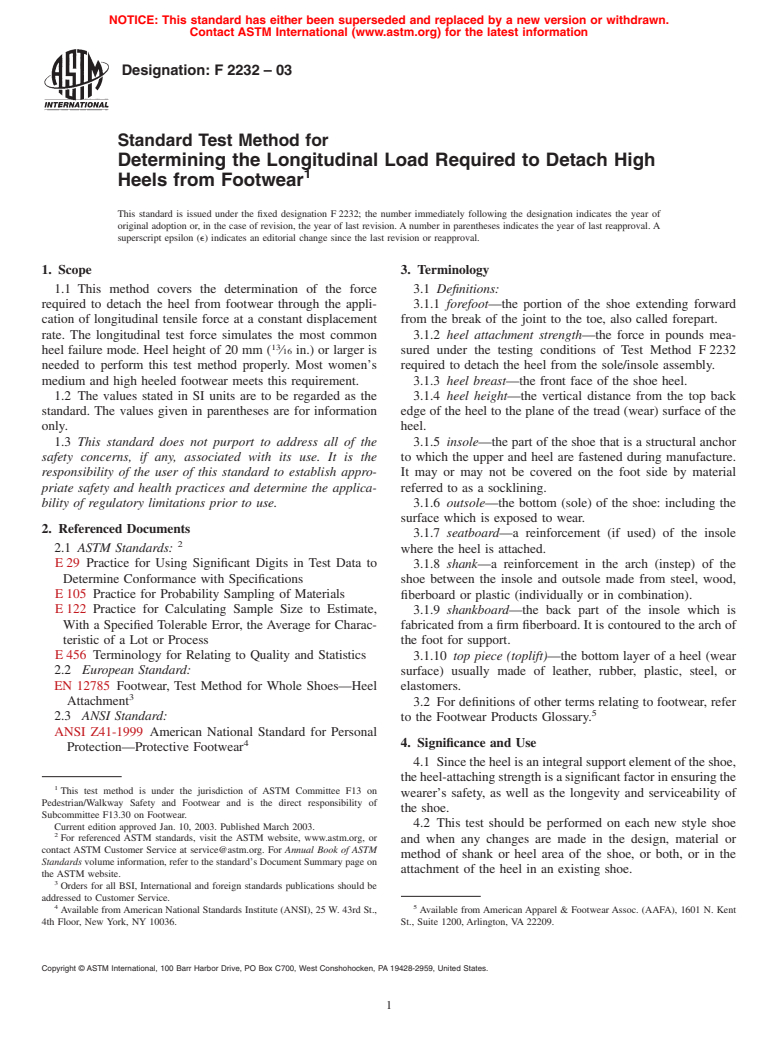

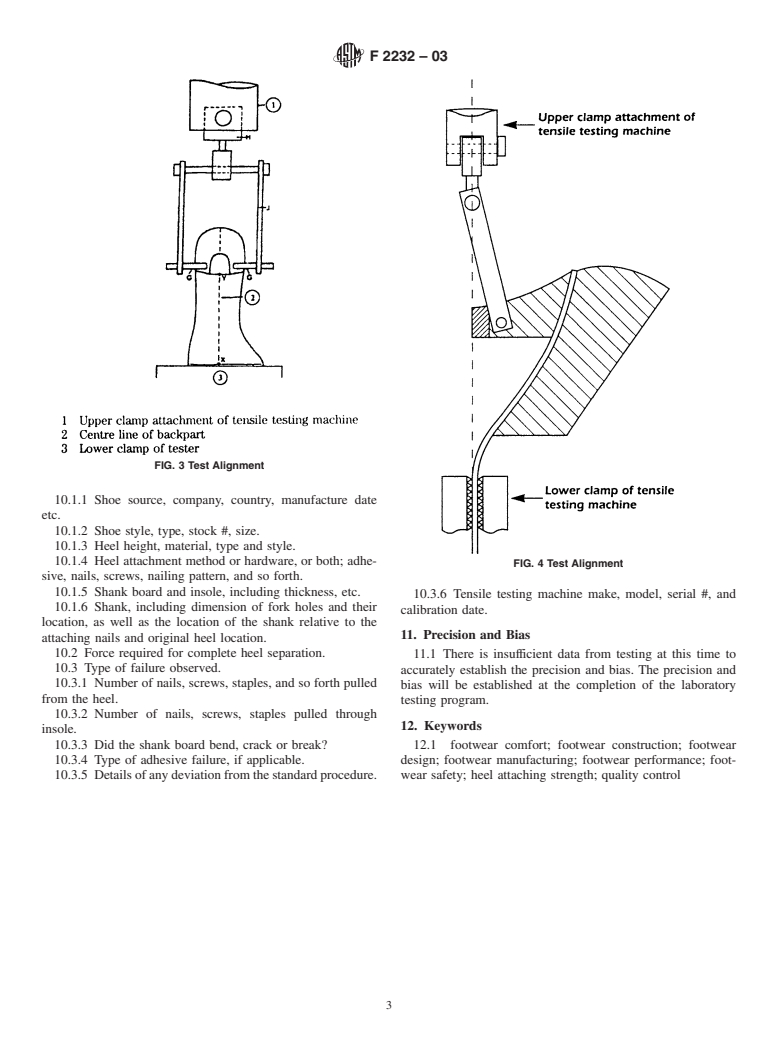

F2232–03

FIG. 1 Location of Pivot Axis on Heel

5. Apparatus

5.1 Tensile Testing Machine, with traverse rate of 100

mm/min (4 in./min) and autographic recorder.

5.1.1 Upper and Lower Attaching Mechanism, to clamp the

wire and toe and shank end of the shoe. See Fig. 2 and Fig. 4.

5.2 Drill Press.

5.3 Drill Bit,5mm( ⁄16 in.).

5.4 Vise, used to hold the shoe heel for drilling.

5.5 Wire, 2.5 mm ( ⁄32 in.) diameter piano or other high

strength wire.

5.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.