ASTM F476-14

(Test Method)Standard Test Methods for Security of Swinging Door Assemblies

Standard Test Methods for Security of Swinging Door Assemblies

SCOPE

1.1 These test methods cover door assemblies of various materials and types of construction for use in wall openings to deter unwanted intruders.

1.2 Door assemblies, covered by these test methods, also include individual components such as the hinge, lock, door, strike, and jamb.

1.3 These test methods are designed to measure the capability of a swinging door assembly to restrain or delay and frustrate the commission of “break-in” crimes.

1.4 These test methods apply primarily to typical entry door assemblies.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F476 − 14

Standard Test Methods for

1

Security of Swinging Door Assemblies

This standard is issued under the fixed designation F476; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.3 component, n—as distinguished from a part, a subas-

sembly that combines with other components to make up a

1.1 These test methods cover door assemblies of various

total door assembly.

materials and types of construction for use in wall openings to

3.1.3.1 Discussion—The prime components of a door as-

deter unwanted intruders.

sembly include: door, lock, hinges, jamb, strike, and wall.

1.2 Door assemblies, covered by these test methods, also

3.1.4 cylinder, n—complete operating unit that usually con-

include individual components such as the hinge, lock, door,

sists of the plug shell, tumblers, springs, plug retainer, a

strike, and jamb.

cam/tailpiece or other actuating device, and all other necessary

1.3 These test methods are designed to measure the capa-

operating parts.

bility of a swinging door assembly to restrain or delay and

3.1.5 cylinder core (or cylinder plug), n—central part of a

frustrate the commission of “break-in” crimes.

cylinder, containing the keyway, that is rotated by the key to

1.4 These test methods apply primarily to typical entry door

operate the lock mechanism.

assemblies.

3.1.6 deadbolt, n—bolt, which requires a deliberate action

1.5 This standard does not purport to address all of the

to extend, and resists end pressure in the unlocking direction

safety concerns, if any, associated with its use. It is the

when fully extended.

responsibility of the user of this standard to establish appro-

3.1.7 dead latch (or dead locking latch bolt), n—latchbolt

priate safety and health practices and determine the applica-

with a deadlocking mechanism.

bility of regulatory limitations prior to use.

3.1.8 door assembly, n—any combination of a door, frame,

2. Referenced Documents

hardware, and other accessories that is placed in an opening in

2

2.1 ASTM Standards:

a wall that is intended primarily for access or for human

F471 Terminology Relating to Combination Locks (With-

entrance or exit.

3

drawn 2011)

3.1.9 jamb, n—vertical members of a door frame (such as,

3. Terminology those fixed members to which the door is secured).

3.1.10 key-in-knob lockset, n—any lockset with a key oper-

3.1 Definitions:

3.1.1 bolt, n—any movable projection that blocks the move- ated cylinder in one or more knobs.

ment of one object relative to another.

3.1.11 key-in-lever lockset, n—any lockset with a key oper-

3.1.2 bolt projection (or bolt throw), n—distance from the

ated cylinder in one or more level handles.

edge of the door, at the bolt center line, to the farthest point on

3.1.12 latch:

the bolt in the projected position, when subjected to end

3.1.12.1 n—mechanical or magnetic door fastener that can

pressure.

automatically keep a door, gate, and so forth, closed.

3.1.12.2 v—engagement of a latch when a door, gate, and so

1

These test methods are under the jurisdiction of ASTM Committee F12 on

forth, is pushed or pulled closed.

Security Systems and Equipment and are the direct responsibility of Subcommittee

F12.50 on Locking Devices.

3.1.13 latch bolt, n—spring-actuated bolt, normally with

Current edition approved Feb. 1, 2014. Published March 2014. Originally

one or more beveled surfaces, that, when aligned with the

approved in 1976 as F476 – 76 . Last previous edition approved in 2002 as

strike, engages it automatically.

F476 – 84 (2002) which was withdrawn July 2011 and reinstated February 2014.

DOI: 10.1520/F0476-14.

3.1.14 lock, n—any device that prevents access or use by

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

requiring special knowledge or equipment.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

3.1.15 lock front, n—outer plate through which the locking

the ASTM website.

3 bolt projects and which is usually flush with the edge of the

The last approved version of this historical standard is referenced on www.ast-

m.org. door.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F476 − 14

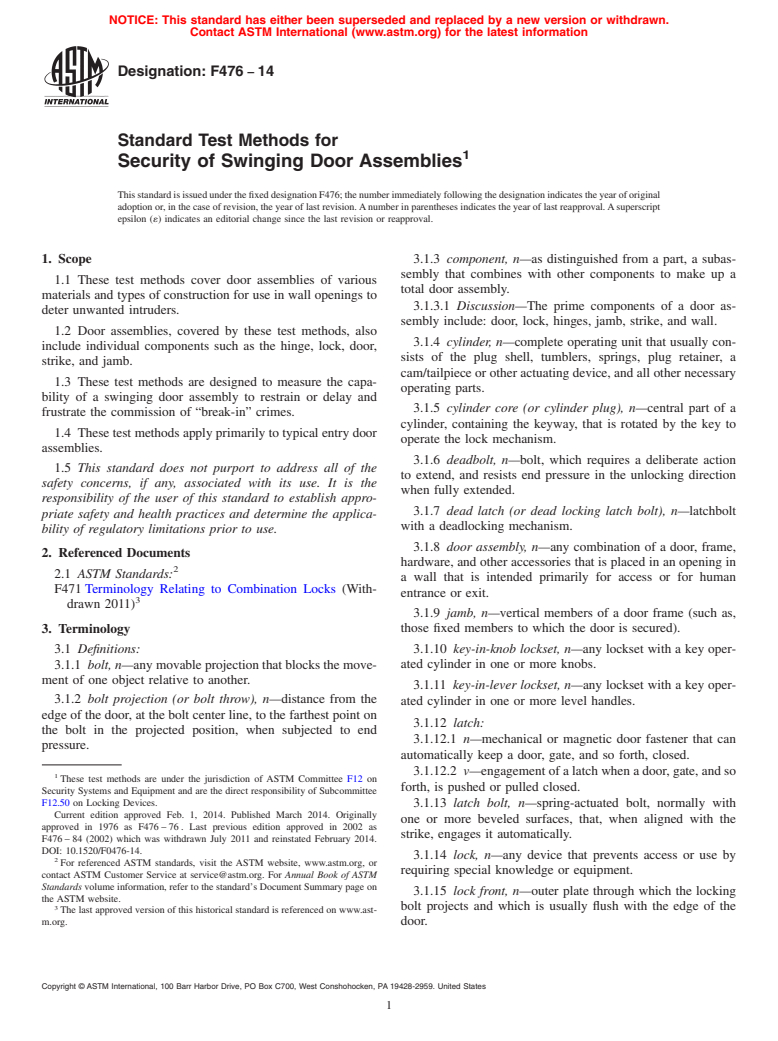

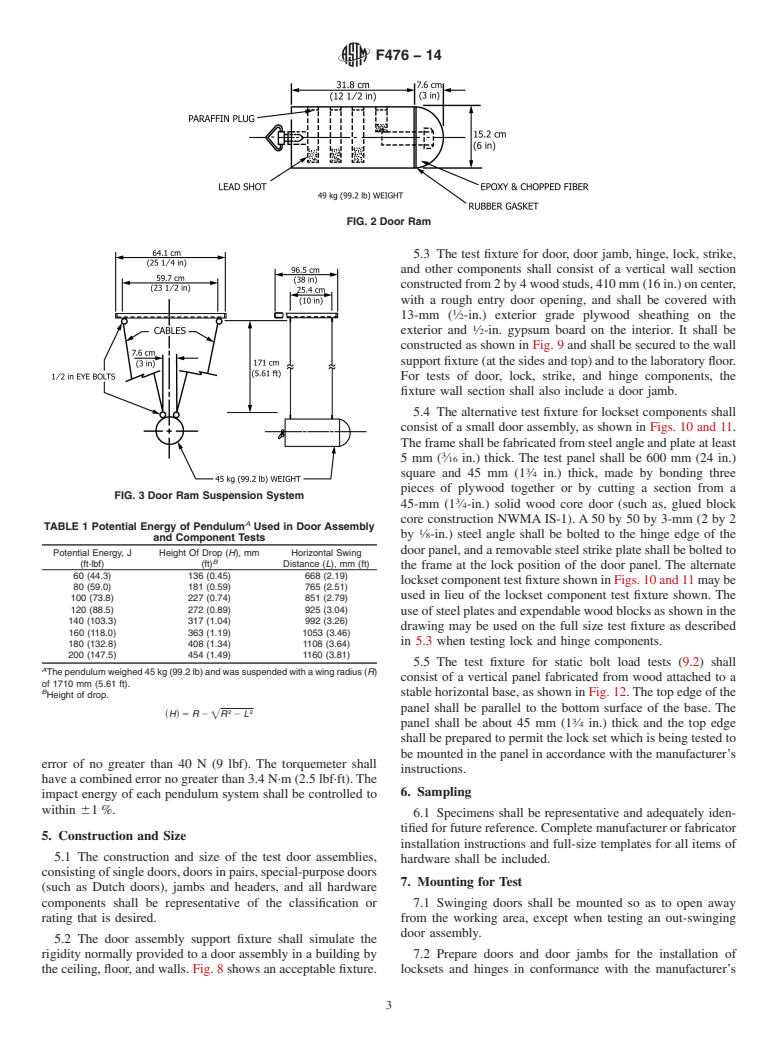

3.1.16 part, n—as distinguished from component, a unit (or consists of four flexible steel cables providing a swing radius of

subassembly) that combines with other units to make up a 1.71 m (5.61 ft), as shown in Fig. 3. These cables are adjusted

c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.