ASTM F2953-12

(Specification)Standard Specification for Phenolic Raw Materials for the Use in Bearing Cages

Standard Specification for Phenolic Raw Materials for the Use in Bearing Cages

SCOPE

1.1 This specification covers basic characteristics required for porous laminated phenolic materials intended for use as instrument and thin-section ball-bearing retainers (cages) and the methods of determining these characteristics.

1.2 Forms—Sheets, rolled tubes, molded tubes, and rods are recommended forms of laminated material covered by this specification.

1.3 Intended Use—Materials produced to this specification are intended for use as ball-bearing retainers (cages). Temperature range is limited to 250°F (117°C) and below.

1.4 Units—The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2953 −12

Standard Specification for

1

Phenolic Raw Materials for the Use in Bearing Cages

This standard is issued under the fixed designation F2953; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

4

1. Scope 2.3 Federal Standard:

MIL-STD-129 Military Making for Shipment and Storage

1.1 This specification covers basic characteristics required

for porous laminated phenolic materials intended for use as

3. Classification

instrument and thin-section ball-bearing retainers (cages) and

3.1 The material shall be furnished in the following types

the methods of determining these characteristics.

and forms as specified:

1.2 Forms—Sheets, rolled tubes, molded tubes, and rods are

Type Description

recommended forms of laminated material covered by this

2 2

FB Rolled tube made from cotton fabric weighing 4 oz/yd (0.14 kg/m )

specification.

or less, with a nominal thread count of 80 by 80 threads per inch

(31.5 by 31.5 cm).

1.3 Intended Use—Materials produced to this specification 2 2

FBFW Rolled tube made from cotton fabric weighing 4 oz/yd (0.14 kg/m )

are intended for use as ball-bearing retainers (cages).Tempera- or less, with a nominal thread count of 100 by 100 threads per inch

(39.4 by 39.4 cm).

ture range is limited to 250°F (117°C) and below.

2 2

FBEFW Rolled tube made from cotton fabric weighing 3 oz/yd (0.1 kg/m)or

less, with a nominal thread count of 130 by 130 threads per inch

1.4 Units—The values stated in inch-pound units are to be

(51.2 by 51.2 cm).

regarded as the standard. The values given in parentheses are

mathematical conversions to SI units that are provided for

4. Ordering Information

information only and are not considered standard.

4.1 Procurement documents should specify the following:

1.5 This standard does not purport to address all of the

4.1.1 Title, designation, and date of this specification;

safety concerns, if any, associated with its use. It is the

4.1.2 Type required (see Section 3); Property values for

responsibility of the user of this standard to establish appro-

tubes (see Table 1);

priate safety and health practices and determine the applica-

4.1.3 Dimensions required; and

bility of regulatory limitations prior to use.

4.1.4 Special marking required (see 9.2).

2. Referenced Documents

4.2 Required test data shall be requested at the time the

2

purchase order is submitted and listed on the purchase order.

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

5. Order of Precedence

D695 Test Method for Compressive Properties of Rigid

Plastics

5.1 In the event of a conflict between the text of this

D792 Test Methods for Density and Specific Gravity (Rela- specification and references cited herein, the text of this

tive Density) of Plastics by Displacement specification takes precedence. Nothing in this specification,

E11 Specification for Woven Wire Test Sieve Cloth and Test however, supersedes applicable laws and regulations unless a

Sieves specific exemption has been obtained.

3

2.2 ANSI/ASQC Standard:

6. Performance Requirements

ANSI/ASQC Z1.4 Sampling Procedures and Tables for In-

spection by Attributes

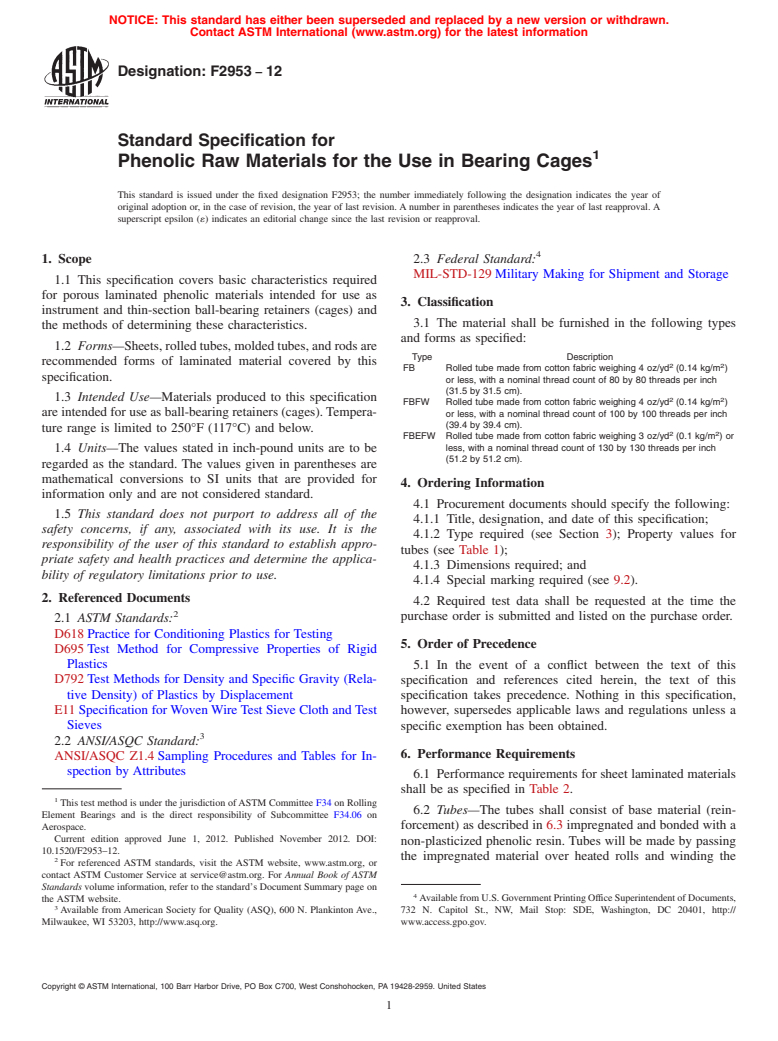

6.1 Performance requirements for sheet laminated materials

shall be as specified in Table 2.

1

This test method is under the jurisdiction ofASTM Committee F34 on Rolling

6.2 Tubes—The tubes shall consist of base material (rein-

Element Bearings and is the direct responsibility of Subcommittee F34.06 on

Aerospace. forcement) as described in 6.3 impregnated and bonded with a

Current edition approved June 1, 2012. Published November 2012. DOI:

non-plasticized phenolic resin. Tubes will be made by passing

10.1520/F2953–12.

the impregnated material over heated rolls and winding the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

4

the ASTM website. AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

3

Available from American Society for Quality (ASQ), 600 N. Plankinton Ave., 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

Milwaukee, WI 53203, http://www.asq.org. www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2953−12

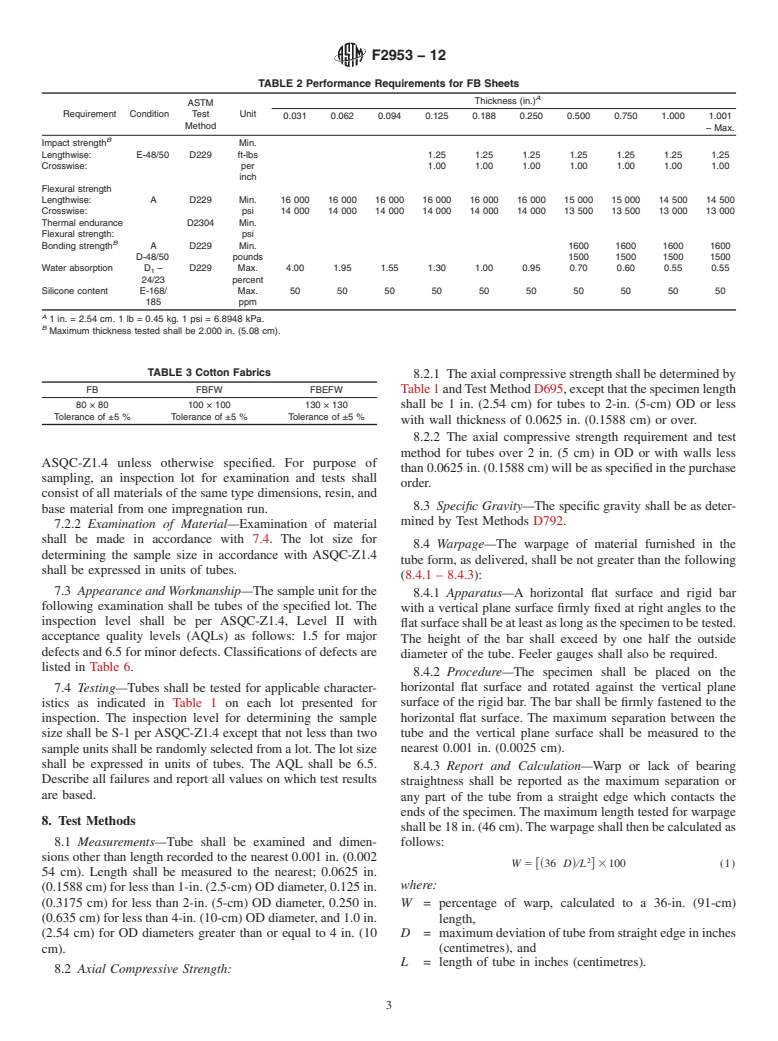

TABLE 1 Performance Requirements for Tubes

6.7 Surface Defects—Finished OD diameters shall be free

ASTM Test from blisters, loose layers, resin pockets, voids and wrinkles.

PB FB FBFW FBEFW

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.