ASTM C1621/C1621M-17

(Test Method)Standard Test Method for Passing Ability of Self-Consolidating Concrete by J-Ring

Standard Test Method for Passing Ability of Self-Consolidating Concrete by J-Ring

SIGNIFICANCE AND USE

5.1 This test method provides a procedure to determine the passing ability of self-consolidating concrete. This test method is applicable for laboratory use in comparing the passing ability of different concrete mixtures. It is also applicable in the field as a quality control test.

5.2 The difference between the slump flow and J-Ring flow is an indication of the passing ability of the concrete. A difference less than 25 mm [1 in.] indicates good passing ability and a difference greater than 50 mm [2 in.] indicates poor passing ability. The orientation of the mold for the J-Ring test and for the slump flow test without the J-Ring shall be the same.

5.3 This test method is limited to self-consolidating concrete with nominal maximum size of aggregate of up to 25 mm [1 in.].

SCOPE

1.1 This test method covers determination of the passing ability of self-consolidating concrete (SCC) by using the J-Ring in combination with a mold.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 The text of this standard references notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (Warning—Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and tissue upon prolonged exposure.2)

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1621/C1621M − 17

Standard Test Method for

1

Passing Ability of Self-Consolidating Concrete by J-Ring

This standard is issued under the fixed designation C1621/C1621M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* C143/C143M Test Method for Slump of Hydraulic-Cement

Concrete

1.1 This test method covers determination of the passing

C172 Practice for Sampling Freshly Mixed Concrete

ability of self-consolidating concrete (SCC) by using the

C173/C173M Test Method forAir Content of Freshly Mixed

J-Ring in combination with a mold.

Concrete by the Volumetric Method

1.2 The values stated in either SI units or inch-pound units

C1611/C1611M Test Method for Slump Flow of Self-

are to be regarded separately as standard. The values stated in

Consolidating Concrete

each system may not be exact equivalents; therefore, each

C1758/C1758M Practice for Fabricating Test Specimens

system shall be used independently of the other. Combining

with Self-Consolidating Concrete

values from the two systems may result in non-conformance

with the standard.

3. Terminology

1.3 The text of this standard references notes and footnotes

3.1 Definitions:

that provide explanatory material. These notes and footnotes

3.1.1 For definitions of terms used in this test method, refer

(excluding those in tables and figures) shall not be considered

to Terminology C125.

as requirements of the standard.

3.2 Definitions of Terms Specific to This Standard:

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.2.1 halo, n—an observed cement paste or mortar ring that

responsibility of the user of this standard to establish appro-

has clearly separated from the coarse aggregate, around the

priate safety and health practices and determine the applica-

outside circumference of concrete after flowing from the mold.

bility of regulatory limitations prior to use. (Warning—Fresh

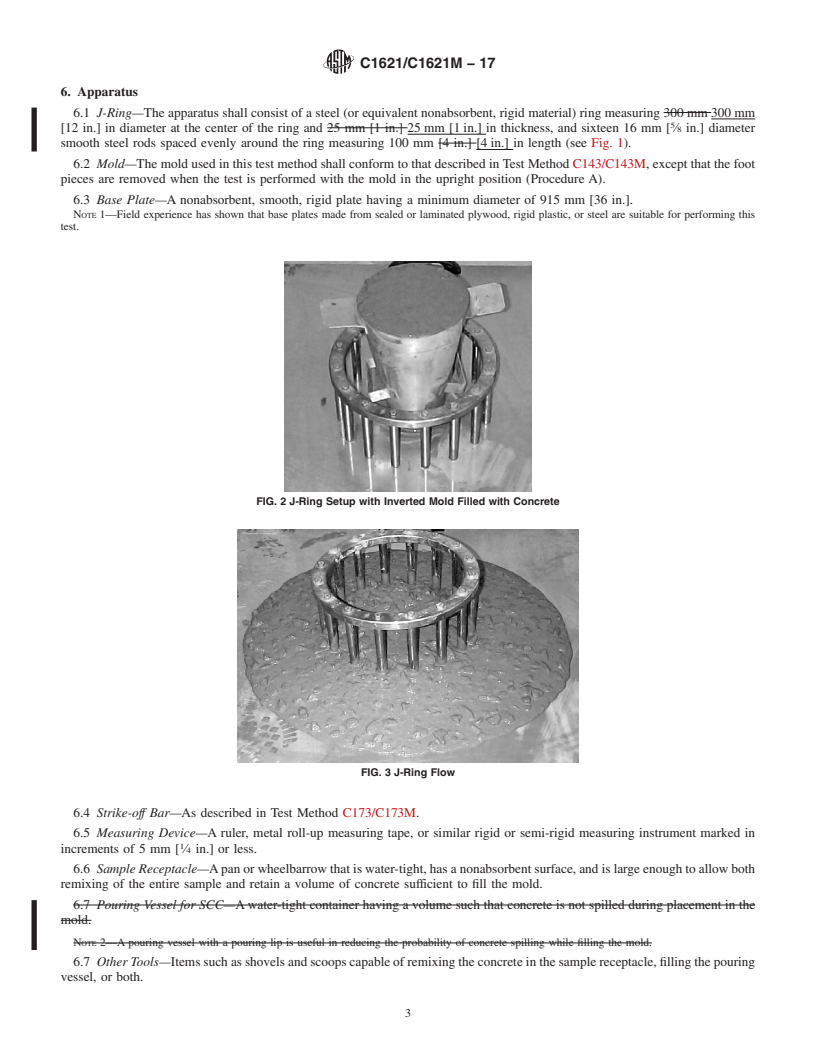

3.2.2 J-ring, n—an apparatus consisting of a rigid ring

hydraulic cementitious mixtures are caustic and may cause

5

supported on sixteen 16 mm [ ⁄8 in.] diameter rods equally

2

chemical burns to skin and tissue upon prolonged exposure. )

spaced on a 300 mm [12 in.] diameter circle 100 mm [4 in.]

1.5 This international standard was developed in accor-

above a flat surface as shown in Fig. 1.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 3.2.3 J-ring flow, n—the distance of lateral flow of concrete

Development of International Standards, Guides and Recom-

using the J-Ring in combination with a mold.

mendations issued by the World Trade Organization Technical

3.2.4 passing ability, n—the ability of self-consolidating

Barriers to Trade (TBT) Committee.

concrete to flow under its own weight (without vibration) and

fill completely all spaces within intricate formwork, containing

2. Referenced Documents

obstacles, such as reinforcement.

3

2.1 ASTM Standards:

C125 Terminology Relating to Concrete and Concrete Ag-

4. Summary of Test Method

gregates

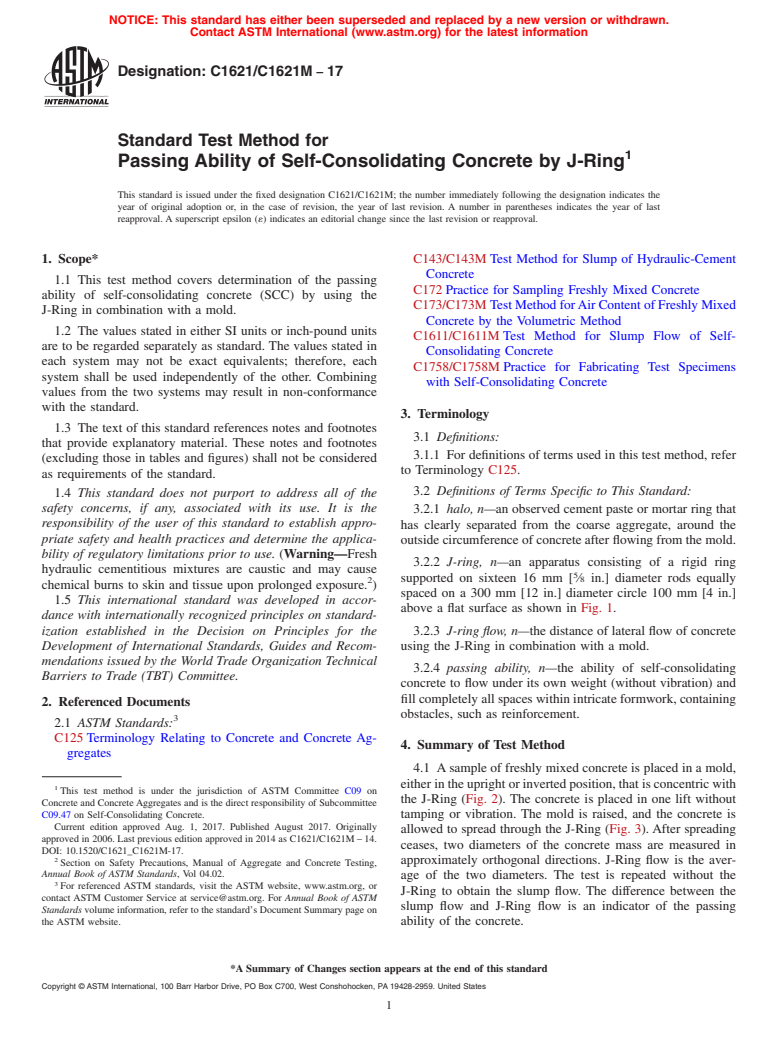

4.1 Asample of freshly mixed concrete is placed in a mold,

either in the upright or inverted position, that is concentric with

1

This test method is under the jurisdiction of ASTM Committee C09 on

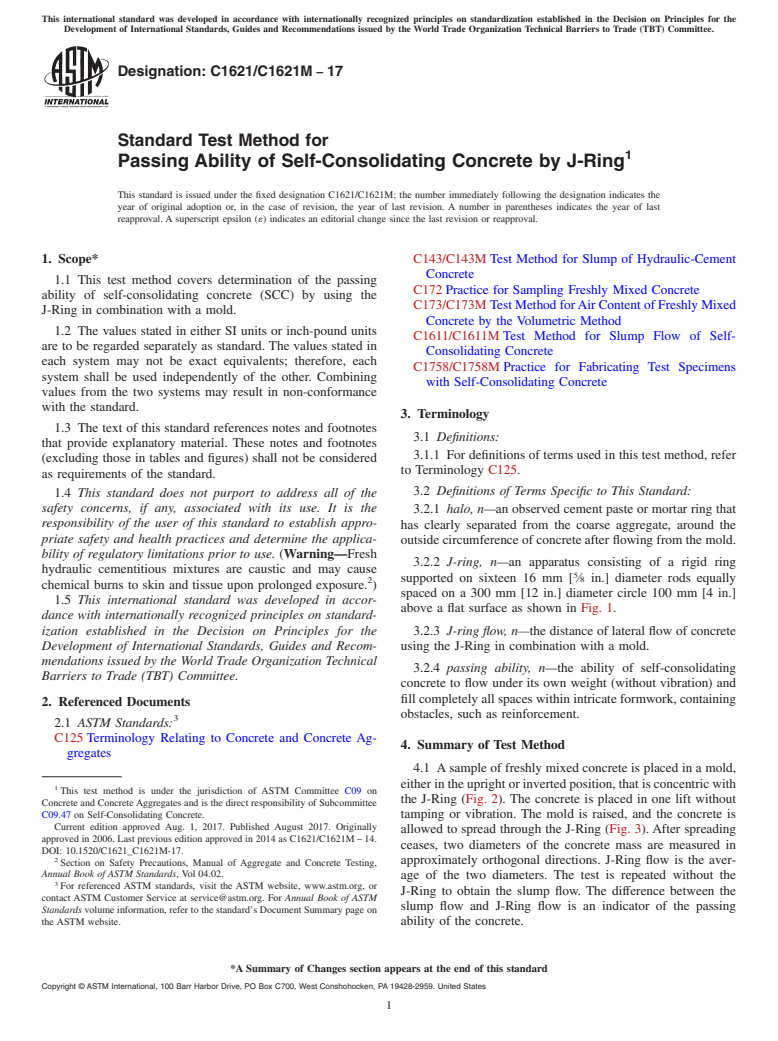

the J-Ring (Fig. 2). The concrete is placed in one lift without

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

C09.47 on Self-Consolidating Concrete.

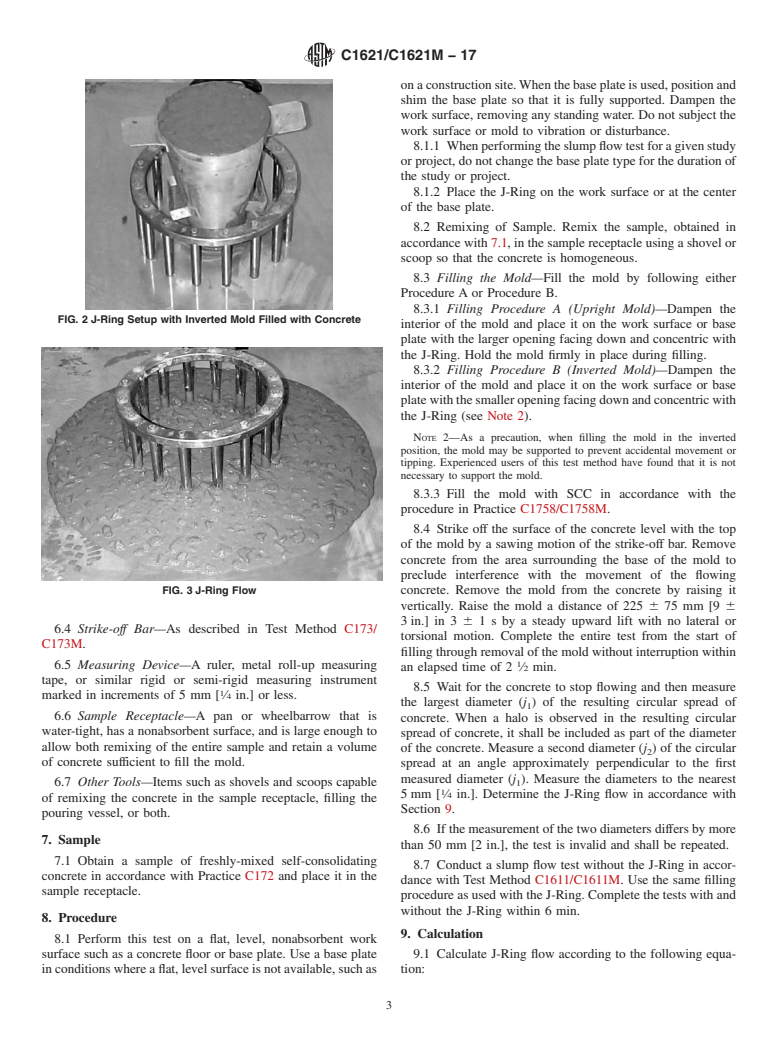

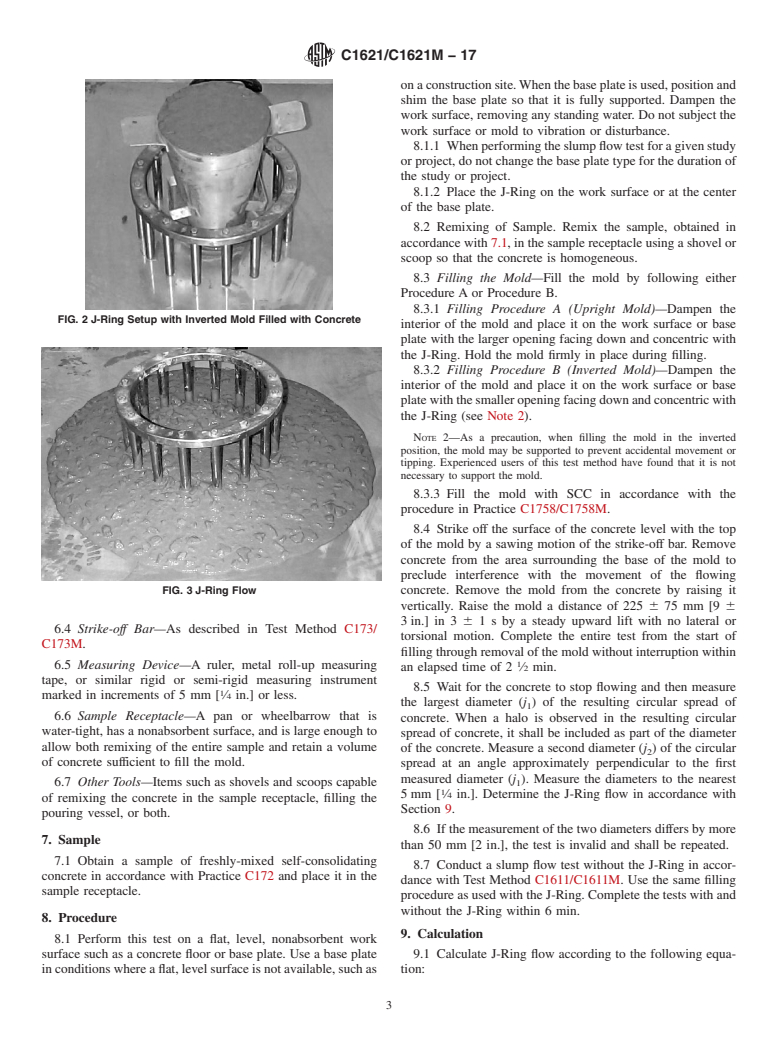

tamping or vibration. The mold is raised, and the concrete is

Current edition approved Aug. 1, 2017. Published August 2017. Originally

allowed to spread through the J-Ring (Fig. 3). After spreading

approved in 2006. Last previous edition approved in 2014 as C1621/C1621M – 14.

ceases, two diameters of the concrete mass are measured in

DOI: 10.1520/C1621_C1621M-17.

2

approximately orthogonal directions. J-Ring flow is the aver-

Section on Safety Precautions, Manual of Aggregate and Concrete Testing,

Annual Book of ASTM Standards, Vol 04.02.

age of the two diameters. The test is repeated without the

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

J-Ring to obtain the slump flow. The difference between the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

slump flow and J-Ring flow is an indicator of the passing

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. ability of the concre

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1621/C1621M − 14 C1621/C1621M − 17

Standard Test Method for

1

Passing Ability of Self-Consolidating Concrete by J-Ring

This standard is issued under the fixed designation C1621/C1621M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers determination of the passing ability of self-consolidating concrete (SCC) by using the J-Ring in

combination with a mold.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 The text of this standard references notes and footnotes that provide explanatory material. These notes and footnotes

(excluding those in tables and figures) shall not be considered as requirements of the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. (Warning—Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and

2

tissue upon prolonged exposure. )

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

C125 Terminology Relating to Concrete and Concrete Aggregates

C143/C143M Test Method for Slump of Hydraulic-Cement Concrete

C172 Practice for Sampling Freshly Mixed Concrete

C173/C173M Test Method for Air Content of Freshly Mixed Concrete by the Volumetric Method

C1611/C1611M Test Method for Slump Flow of Self-Consolidating Concrete

C1758/C1758M Practice for Fabricating Test Specimens with Self-Consolidating Concrete

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in this test method, refer to Terminology C125.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 halo, n—an observed cement paste or mortar ring that has clearly separated from the coarse aggregate, around the outside

circumference of concrete after flowing from the mold.

5

3.2.2 J-ring, n—an apparatus consisting of a rigid ring supported on sixteen 16 mm [ ⁄8 in.] diameter rods equally spaced on

a 300 mm [12 in.] diameter circle 100 mm [4 in.] above a flat surface as shown in Fig. 1.

3.2.3 J-ring flow, n—the distance of lateral flow of concrete using the J-Ring in combination with a mold.

1

This test method is under the jurisdiction of ASTM Committee C09 on Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee C09.47 on

Self-Consolidating Concrete.

Current edition approved April 1, 2014Aug. 1, 2017. Published May 2014August 2017. Originally approved in 2006. Last previous edition approved in 20092014 as

C1621/C1621M – 09b.C1621/C1621M – 14. DOI: 10.1520/C1621_C1621M-14.10.1520/C1621_C1621M-17.

2

Section on Safety Precautions, Manual of Aggregate and Concrete Testing, Annual Book of ASTM Standards, Vol 04.02.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1621/C1621M − 17

FIG. 1 J-Ring Apparatus

3.2.4 passing ability, n—the ability of self-consolidating concrete to flow under its own weight (without vibration) and fill

completely all spaces within intricate formwork, containing obstacles, such as reinforcement.

4. Summary of Test Method

4.1 A sample of freshly mixed concrete is placed in a mold, either in the upright or inverted position, that is concentric with

the J-Ring (Fig. 2). T

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1621/C1621M − 17

Standard Test Method for

1

Passing Ability of Self-Consolidating Concrete by J-Ring

This standard is issued under the fixed designation C1621/C1621M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* C143/C143M Test Method for Slump of Hydraulic-Cement

Concrete

1.1 This test method covers determination of the passing

C172 Practice for Sampling Freshly Mixed Concrete

ability of self-consolidating concrete (SCC) by using the

C173/C173M Test Method for Air Content of Freshly Mixed

J-Ring in combination with a mold.

Concrete by the Volumetric Method

1.2 The values stated in either SI units or inch-pound units

C1611/C1611M Test Method for Slump Flow of Self-

are to be regarded separately as standard. The values stated in

Consolidating Concrete

each system may not be exact equivalents; therefore, each

C1758/C1758M Practice for Fabricating Test Specimens

system shall be used independently of the other. Combining

with Self-Consolidating Concrete

values from the two systems may result in non-conformance

with the standard.

3. Terminology

1.3 The text of this standard references notes and footnotes

3.1 Definitions:

that provide explanatory material. These notes and footnotes

3.1.1 For definitions of terms used in this test method, refer

(excluding those in tables and figures) shall not be considered

to Terminology C125.

as requirements of the standard.

3.2 Definitions of Terms Specific to This Standard:

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3.2.1 halo, n—an observed cement paste or mortar ring that

responsibility of the user of this standard to establish appro-

has clearly separated from the coarse aggregate, around the

priate safety and health practices and determine the applica-

outside circumference of concrete after flowing from the mold.

bility of regulatory limitations prior to use. (Warning—Fresh

3.2.2 J-ring, n—an apparatus consisting of a rigid ring

hydraulic cementitious mixtures are caustic and may cause

5

supported on sixteen 16 mm [ ⁄8 in.] diameter rods equally

2

chemical burns to skin and tissue upon prolonged exposure. )

spaced on a 300 mm [12 in.] diameter circle 100 mm [4 in.]

1.5 This international standard was developed in accor-

above a flat surface as shown in Fig. 1.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 3.2.3 J-ring flow, n—the distance of lateral flow of concrete

Development of International Standards, Guides and Recom- using the J-Ring in combination with a mold.

mendations issued by the World Trade Organization Technical

3.2.4 passing ability, n—the ability of self-consolidating

Barriers to Trade (TBT) Committee.

concrete to flow under its own weight (without vibration) and

fill completely all spaces within intricate formwork, containing

2. Referenced Documents

obstacles, such as reinforcement.

3

2.1 ASTM Standards:

C125 Terminology Relating to Concrete and Concrete Ag-

4. Summary of Test Method

gregates

4.1 A sample of freshly mixed concrete is placed in a mold,

either in the upright or inverted position, that is concentric with

1

This test method is under the jurisdiction of ASTM Committee C09 on

the J-Ring (Fig. 2). The concrete is placed in one lift without

Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee

C09.47 on Self-Consolidating Concrete. tamping or vibration. The mold is raised, and the concrete is

Current edition approved Aug. 1, 2017. Published August 2017. Originally

allowed to spread through the J-Ring (Fig. 3). After spreading

approved in 2006. Last previous edition approved in 2014 as C1621/C1621M – 14.

ceases, two diameters of the concrete mass are measured in

DOI: 10.1520/C1621_C1621M-17.

2

approximately orthogonal directions. J-Ring flow is the aver-

Section on Safety Precautions, Manual of Aggregate and Concrete Testing,

Annual Book of ASTM Standards, Vol 04.02.

age of the two diameters. The test is repeated without the

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

J-Ring to obtain the slump flow. The difference between the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

slump flow and J-Ring flow is an indicator of the passing

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. ability of the concrete.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.