ASTM A799/A799M-92(2002)

(Practice)Standard Practice for Steel Castings, Stainless, Instrument Calibration, for Estimating Ferrite Content

Standard Practice for Steel Castings, Stainless, Instrument Calibration, for Estimating Ferrite Content

SCOPE

1.1 This practice covers the procedure for calibration of instruments to be used for estimating the ferrite content of the microstructure of cast stainless steels by magnetic response or measurement of permeability. This procedure covers both primary and secondary instruments.

1.1.1 A primary instrument is one that has been calibrated using National Institute of Standards and Technology-Standard Reference Material (NIST-SRM) thickness coating standards. It is a laboratory tool to be used with test specimens. Some primary instruments may be used to directly measure the ferrite content of castings.

1.1.2 A secondary instrument is one that has been calibrated by the use of secondary standards that have been measured by a calibrated primary instrument. Secondary instruments are to be used to directly measure the ferrite content of castings.

1.2 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 799/A799M – 92 (Reapproved 2002)

Standard Practice for

Steel Castings, Stainless, Instrument Calibration, for

Estimating Ferrite Content

This standard is issued under the fixed designation A 799/A799M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 NIST Standard:

NIST-SRM Coating Thickness Standards, No. 1321 through

1.1 This practice covers the procedure for calibration of

1323, 1357 through 1360, and 1361a through 1364a, (All

instruments to be used for estimating the ferrite content of the

are in sets of three or four standards.)

microstructure of cast stainless steels by magnetic response or

measurement of permeability. This procedure covers both

3. Terminology

primary and secondary instruments.

3.1 Definitions:

1.1.1 A primary instrument is one that has been calibrated

3.1.1 ferrite—the body-centered cubic microconstituent in

using National Institute of Standards and Technology-Standard

stainless steel castings.

Reference Material (NIST-SRM) thickness coating standards.

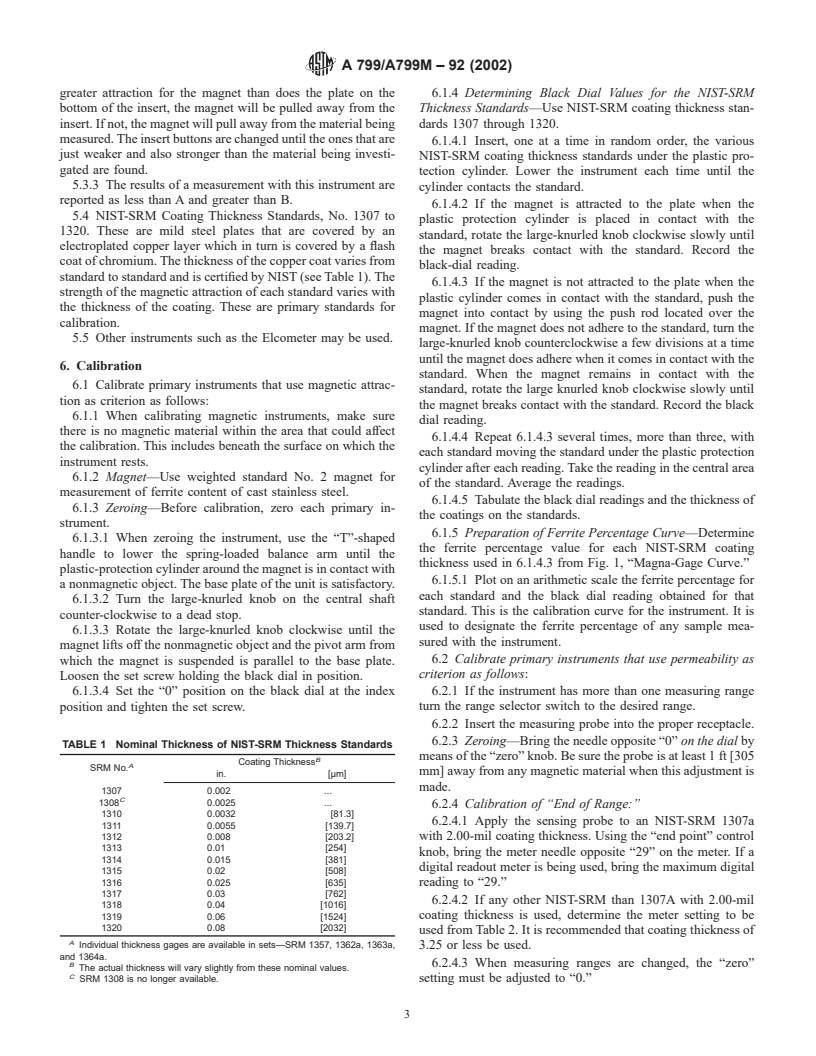

3.1.2 ferrite percentage—a value designating the ferrite

It is a laboratory tool to be used with test specimens. Some

content of cast stainless steels. The Steel Founders’ Society of

primary instruments may be used to directly measure the ferrite

America (SFSA) has assigned ferrite percentages to the series

content of castings.

of NIST coating thickness standards. This assignment was

1.1.2 A secondary instrument is one that has been calibrated

based on the magnetic attraction for a weighted No. 2 magnet

by the use of secondary standards that have been measured by

by the coating standards when compared with the magnetic

a calibrated primary instrument. Secondary instruments are to

attraction of the same magnet by a series of cast stainless steels

be used to directly measure the ferrite content of castings.

whose ferrite content had been determined by an accurate

1.2 The values stated in either inch-pound units or SI units

metallographic point count. Fig. 1 is a plot of the thickness of

are to be regarded separately as standard. Within the text, the

these standards and the assigned ferrite percentages. By the use

SI units are shown in brackets. The values stated in each

of Fig. 1, any primary instrument will have its calibration

system are not exact equivalents; therefore, each system must

traceable to the SFSA’s instruments or any other calibrated

be used independently of the other. Combining values from the

instrument and thus afford comparable reproducible ferrite

two systems may result in nonconformance with the specifi-

percentages. It also allows traceability to NIST.

cation.

3.1.3 secondary standards—pieces of cast stainless steel

1.3 This standard does not purport to address all of the

whose ferrite percentage has been determined “in house” by a

safety problems, if any, associated with its use. It is the

calibrated primary instrument. These are used to calibrate

responsibility of the user of this standard to establish appro-

secondary instruments (see Section 8).

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Significance and Use

2. Referenced Documents 4.1 The amount of ferrite present in an austenitic stainless

steel has been shown to influence the strength, toughness and

2.1 ASTM Standards:

corrosion resistance of this type of cast alloy. The amount of

B 499 Test Method for Measurement of Coating Thick-

ferrite present tends to correlate well with the magnetic

nesses by the Magnetic Method: Nonmagnetic Coatings on

permeability of the steel. The methods described in this

Magnetic Basis Metals

standard cover calibration practice for estimating ferrite by the

E 562 Practice for Determining Volume Fraction by Sys-

magnetic permeability of the steel. The practice is inexpensive

tematic Manual Point Count

to use over large areas of the cast part and is non-destructive.

4.2 This practice has been used for research, alloy develop-

This practice is under the jurisdiction of ASTM Committee A01 on Steel, ment, quality control, and manufacturing control.

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

A01.18 on Castings.

Current edition approved Dec. 15, 1992. Published June 1993. Originally

published as A 799 – 82. Last previous edition A 799/A 799M – 90. Available from Office of Standard Reference Materials, Chemistry Building,

Annual Book of ASTM Standards, Vol 02.05. Room B 311, National Institute of Standards and Technology, 100 Bureau Dr., Stop

Annual Book of ASTM Standards, Vol 03.01. 3460, Gaithersburg, MD 20899–3460.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 799/A799M – 92 (2002)

FIG. 1 Assigned Ferrite Percentages to NIST Coating Thickness Standards

4.2.1 Many instruments are available having two-point 5.1.3 The amount of force that the coiled spring has

probes, single-point probes, and differing excitation current developed is determined from a marked dial securely attached

levels. When the probe is placed on the material being to the shaft that is used to coil or uncoil the spring.

investigated, a closed magnetic circuit is formed and energized 5.1.3.1 A weighted number 2 is used with this instrument,

by a low-frequency magnetic field. The voltage induced in the U5-0664W.

probe coil by this field is a measure of the permeability. When 5.2 When using a Feritscope, follow the manufacturer’s

calibrated with standards having known ferrite content, this instructions for calibration. When traceability is required,

permeability indicates the ferrite content of the material being confirm the calibration using the appropriate NIST standards

analyzed. The estimated ferrite content is read from a cali- listed in 2.2.

brated dial or from a digital-readout dial. Follow the manufac- 5.2.1 This instrument has a two-point probe as the sensing

turer’s instructions for proper calibration of the instrument. device. When this probe is placed on the material being

4.3 Since this practice measures magnetic attraction and not investigated, a closed magnetic circuit is formed and energized

ferrite directly, it is subject to all of the variables that affect by a low-frequency magnetic field. The voltage induced in the

magnetic permeability, such as thermal history. probe coil by this field is a measure of the permeability. When

4.4 Magnetic methods should not be used for arbitration of calibrated with standards having known ferrite content, this

conflicts on ferrite content except when agreed upon between permeability indicates the ferrite content of the material being

manufacturer and purchaser. analyzed. The estimated ferrite content is read from a cali-

brated dial or from a digital-readout dial.

5. Apparatus

5.3 One secondary instrument consists of a balance arm that

has a rod-shaped magnet attached to one end. The opposite

5.1 One primary instrument that uses magnetic attraction

end is counterweighted to balance the magnet.

consists of a spring-loaded balance arm from which a rod-

5.3.1 This arm with its magnet and counterweight is en-

shaped magnet is suspended. The opposite end of the balance

closed in a transparent box. The top face of this container has

arm from the magnet has counterweights that balance most but

a threaded hole directly over the magnet. Into this hole are

not all of the weight of the magnet.

screwed-marked inserts that have metal plates on their bottom

5.1.1 When this instrument is used, the spring load is

face. These plates have different strengths of attraction for the

relaxed sufficiently to allow the magnet to make contact with

magnet.

the material being tested.

5.3.2 In use, the bottom end of the magnet is touched to the

5.1.2 The spring is then wound until the force of the coiled

material being investigated. The other end of the magnet is in

spring overcomes the magnetic attraction of the magnet for the

contact with the metal plate on the bottom of the insert. The

material being tested, causing the magnet to break contact and

container is then raised. If the material being measured has a

the lever arm to rise.

5 6

Magna Gage, produced by Magna Gage Sales and Service, 6417 Chell Rd., Feritscope, produced by Fisher Technology, Inc., Windsor, CT 06708.

Columbia, MD 21044. Severn Gage, Severn Instrument Co., Annapolis, MD.

A 799/A799M – 92 (2002)

greater attraction for the magnet than does the plate on the 6.1.4 Determining Black Dial Values for the NIST-SRM

bottom of the insert, the magnet will be pulled away from the Thickness Standards—Use NIST-SRM coating thickness stan-

insert. If not, the magnet will pull away from the material being dards 1307 through 1320.

measured. The insert buttons are changed until the ones that are

6.1.4.1 Insert, one at a time in random order, the various

just weaker and also stronger than the material being investi-

N

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.