ASTM D2434-68(2006)

(Test Method)Standard Test Method for Permeability of Granular Soils (Constant Head) (Withdrawn 2015)

Standard Test Method for Permeability of Granular Soils (Constant Head) (Withdrawn 2015)

ABSTRACT

This test method covers the determination of the coefficient of permeability by a constant-head method for the laminar flow of water through granular soils. The procedure is to establish representative values of the coefficient of permeability of granular soils that may occur in natural deposits as placed in embankments, or when used as base courses under pavements. The different apparatus used in determining the granular soil permeability are presented. The methods in preparing the test specimen are presented in details. The testing and calculation procedure for granular soil permeability determination are presented.

SCOPE

1.1 This test method covers the determination of the coefficient of permeability by a constant-head method for the laminar flow of water through granular soils. The procedure is to establish representative values of the coefficient of permeability of granular soils that may occur in natural deposits as placed in embankments, or when used as base courses under pavements. In order to limit consolidation influences during testing, this procedure is limited to disturbed granular soils containing not more than 10 % soil passing the 75-m (No. 200) sieve.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers the determination of the coefficient of permeability by a constant-head method for the laminar flow of water through granular soils. The procedure is to establish representative values of the coefficient of permeability of granular soils that may occur in natural deposits as placed in embankments, or when used as base courses under pavements. In order to limit consolidation influences during testing, this procedure is limited to disturbed granular soils containing not more than 10 % soil passing the 75-μm (No. 200) sieve.

Formerly under the jurisdiction of Committee D18 on Soil and Rock, this test method was withdrawn in January 2015 in accordance with section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2434 − 68(Reapproved 2006)

Standard Test Method for

Permeability of Granular Soils (Constant Head)

This standard is issued under the fixed designation D2434; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 3.1.3 Flow in the steady state with no changes in hydraulic

gradient, and

1.1 This test method covers the determination of the coef-

3.1.4 Direct proportionality of velocity of flow with hydrau-

ficient of permeability by a constant-head method for the

lic gradients below certain values, at which turbulent flow

laminar flow of water through granular soils. The procedure is

starts.

to establish representative values of the coefficient of perme-

ability of granular soils that may occur in natural deposits as

3.2 All other types of flow involving partial saturation of

placed in embankments, or when used as base courses under

soil voids, turbulent flow, and unsteady state of flow are

pavements. In order to limit consolidation influences during

transient in character and yield variable and time-dependent

testing, this procedure is limited to disturbed granular soils

coefficients of permeability; therefore, they require special test

containing not more than 10 % soil passing the 75-µm (No.

conditions and procedures.

200) sieve.

1.2 This standard does not purport to address all of the

4. Apparatus

safety problems, if any, associated with its use. It is the

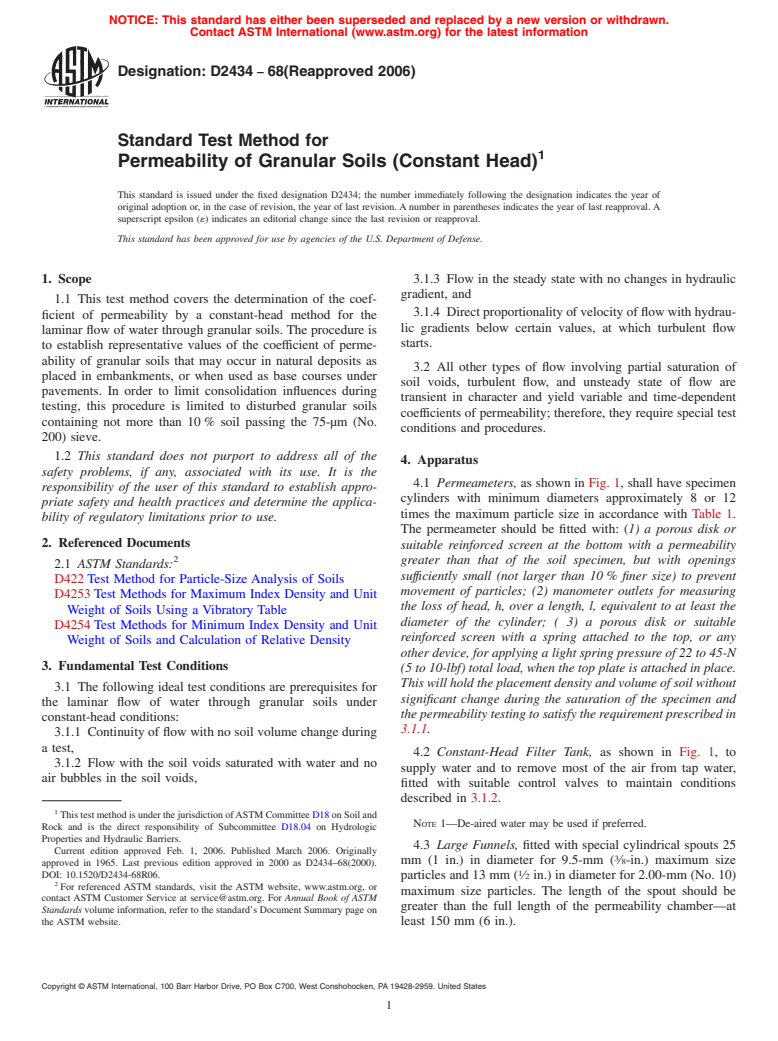

4.1 Permeameters, as shown in Fig. 1, shall have specimen

responsibility of the user of this standard to establish appro-

cylinders with minimum diameters approximately 8 or 12

priate safety and health practices and determine the applica-

times the maximum particle size in accordance with Table 1.

bility of regulatory limitations prior to use.

The permeameter should be fitted with: (1) a porous disk or

2. Referenced Documents

suitable reinforced screen at the bottom with a permeability

greater than that of the soil specimen, but with openings

2.1 ASTM Standards:

suffıciently small (not larger than 10% finer size) to prevent

D422 Test Method for Particle-Size Analysis of Soils

movement of particles; (2) manometer outlets for measuring

D4253 Test Methods for Maximum Index Density and Unit

the loss of head, h, over a length, l, equivalent to at least the

Weight of Soils Using a Vibratory Table

diameter of the cylinder; ( 3) a porous disk or suitable

D4254 Test Methods for Minimum Index Density and Unit

reinforced screen with a spring attached to the top, or any

Weight of Soils and Calculation of Relative Density

other device, for applying a light spring pressure of 22 to 45-N

3. Fundamental Test Conditions

(5 to 10-lbf) total load, when the top plate is attached in place.

Thiswillholdtheplacementdensityandvolumeofsoilwithout

3.1 The following ideal test conditions are prerequisites for

significant change during the saturation of the specimen and

the laminar flow of water through granular soils under

thepermeabilitytestingtosatisfytherequirementprescribedin

constant-head conditions:

3.1.1.

3.1.1 Continuity of flow with no soil volume change during

a test,

4.2 Constant-Head Filter Tank, as shown in Fig. 1,to

3.1.2 Flow with the soil voids saturated with water and no

supply water and to remove most of the air from tap water,

air bubbles in the soil voids,

fitted with suitable control valves to maintain conditions

described in 3.1.2.

ThistestmethodisunderthejurisdictionofASTMCommitteeD18onSoiland

NOTE 1—De-aired water may be used if preferred.

Rock and is the direct responsibility of Subcommittee D18.04 on Hydrologic

Properties and Hydraulic Barriers.

4.3 Large Funnels, fitted with special cylindrical spouts 25

Current edition approved Feb. 1, 2006. Published March 2006. Originally

mm (1 in.) in diameter for 9.5-mm ( ⁄8-in.) maximum size

approved in 1965. Last previous edition approved in 2000 as D2434–68(2000).

DOI: 10.1520/D2434-68R06.

particles and 13 mm ( ⁄2 in.) in diameter for 2.00-mm (No. 10)

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

maximum size particles. The length of the spout should be

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

greater than the full length of the permeability chamber—at

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. least 150 mm (6 in.).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2434 − 68 (2006)

FIG. 1 Constant-Head Permeameter

TABLE 1 Cylinder Diameter

Minimum Cylinder Diameter

Maximum Particle Size

Less than 35 % of Total Soil Retained on Sieve Opening More than 35 % of Total Soil Retained on Sieve Opening

Lies Between Sieve Openings

3 3

2.00-mm (No. 10) 9.5-mm ( ⁄8-in.) 2.00-mm (No. 10) 9.5-mm ( ⁄8-in.)

2.00-mm (No. 10) and 9.5-mm 76 mm (3 in.) . 114 mm (4.5 in.) .

( ⁄8 in.)

9.5-mm ( ⁄8-in.) and 19.0-mm . 152 mm (6 in.) . 229 mm (9 in.)

( ⁄4 in.)

4.4 Specimen Compaction Equipment —Compaction 5. Sample

equipmentasdeemeddesirablemaybeused.Thefollowingare

5.1 A representative sample of air-dried granular soil, con-

suggested: a vibrating tamper fitted with a tamping foot 51 mm

taining less than 10 % of the material passing the 75-µm (No.

(2 in.) in diameter; a sliding tamper with a tamping foot 51 mm

200) sieve and equal to an amount sufficient to satisfy the

(2 in.) in diameter, and a rod for sliding weights of 100 g (0.25

requirements prescribed in 5.2 and 5.3, shall be selected by the

lb) (for sands) to 1 kg (2.25 lb) (for soils with a large gravel

method of quartering.

content), having an adjustable height of drop to 102 mm (4 in.)

for sands and 203 mm (8 in.) for soils with large gravel

5.2 Asieve analysis (see Method D422) shall be made on a

contents.

representative sample of the complete soil prior to the perme-

ability test. Any particles larger than 19 mm ( ⁄4 in.) shall be

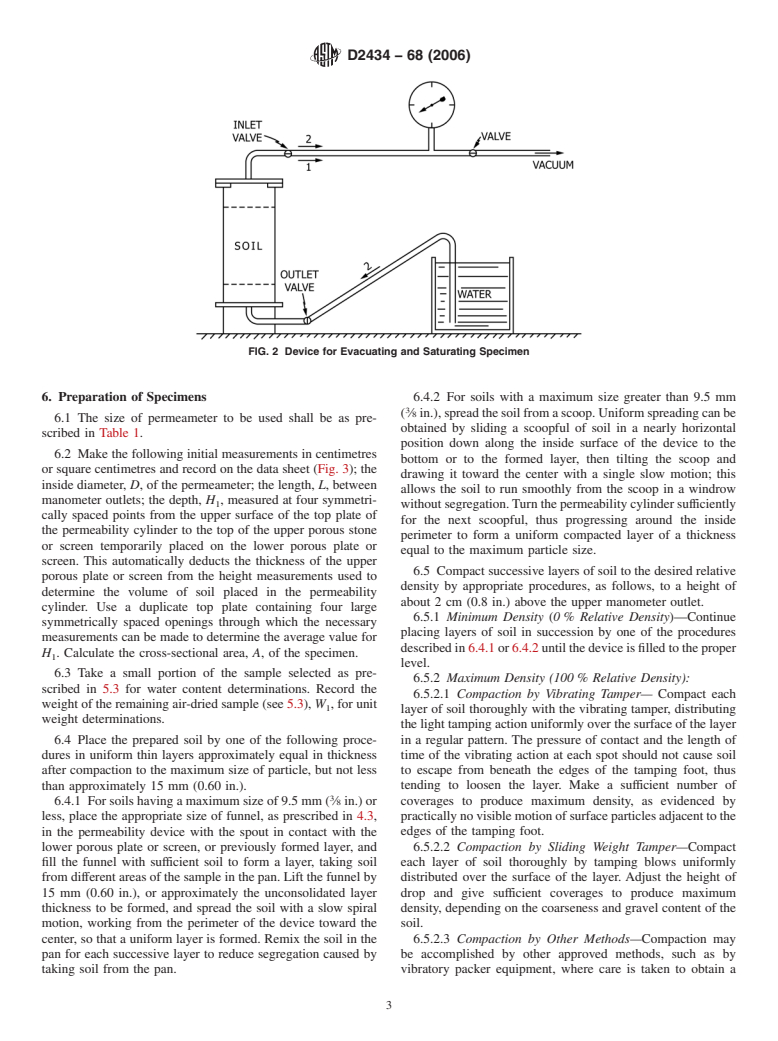

4.5 Vacuum Pump or Water-Faucet Aspirator, for evacuat-

separated out by sieving (Method D422). This oversize mate-

ing and for saturating soil specimens under full vacuum (see

rial shall not be used for the permeability test, but the

Fig. 2).

percentage of the oversize material shall be recorded.

4.6 Manometer Tubes, with metric scales for measuring

head of water.

NOTE 2—In order to establish representative values of coefficients of

permeabilities for the range that may exist in the situation being

4.7 Balance, of 2-kg (4.4-lb) capacity, sensitive to 1 g

investigated, samples of the finer, average, and coarser soils should be

(0.002 lb).

obtained for testing.

4.8 Scoop, with a capacity of about 100 g (0.25 lb) of soil.

5.3 From the material from which the oversize has been

4.9 Miscellaneous Apparatus—Thermometers, clock with removed(see5.2),selectbythemethodofquartering,asample

sweep second hand, 250-mL graduate, quart jar, mixing pan, for testing equal to an amount approximately twice that

etc. required for filling the permeameter chamber.

D2434 − 68 (2006)

FIG. 2 Device for Evacuating and Saturating Specimen

6. Preparation of Specimens 6.4.2 For soils with a maximum size greater than 9.5 mm

( ⁄8in.),spreadthesoilfromascoop.Uniformspreadingcanbe

6.1 The size of permeameter to be used shall be as pre-

obtained by sliding a scoopful of soil in a nearly horizontal

scribed in Table 1.

position down along the inside surface of the device to the

6.2 Make the following initial measurements in centimetres

bottom or to the formed layer, then tilting the scoop and

or square centimetres and record on the data sheet (Fig. 3); the

drawing it toward the center with a single slow motion; this

inside diameter, D, of the permeameter; the length, L, between

allows the soil to run smoothly from the scoop in a windrow

manometer outlets; the depth, H , measured at four symmetri-

withoutsegregation.Turnthepermeabilitycylindersufficiently

cally spaced points from the upper surface of the top plate of

for the next scoopful, thus progressing around the inside

the permeability cylinder to the top of the upper porous stone

perimeter to form a uniform compacted layer of a thickness

or screen temporarily placed on the lower porous plate or

equal to the maximum particle size.

screen. This automatically deducts the thickness of the upper

6.5 Compact successive layers of soil to the desired relative

porous plate or screen from the height measurements used to

density by appropriate procedures, as follows, to a height of

determine the volume of soil placed in the permeability

about 2 cm (0.8 in.) above the upper manometer outlet.

cylinder. Use a duplicate top plate containing four large

6.5.1 Minimum Density (0% Relative Density)—Continue

symmetrically spaced openings through which the necessary

placing layers of soil in succession by one of the procedures

measurements can be made to determine the average value for

describedin6.4.1or6.4.2untilthedeviceisfilledtotheproper

H . Calculate the cross-sectional area, A, of the specimen.

level.

6.3 Take a small portion of the sample selected as pre-

6.5.2 Maximum Density (100% Relative Density):

scribed in 5.3 for water content determinations. Record the

6.5.2.1 Compaction by Vibrating Tamper— Compact each

weight of the remaining air-dried sample (see 5.3),W , for unit

layer of soil thoroughly with the vibrating tamper, distributing

weight determinations.

the light tamping action uniformly over th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.