ASTM D1921-12

(Test Method)Standard Test Methods for Particle Size (Sieve Analysis) of Plastic Materials

Standard Test Methods for Particle Size (Sieve Analysis) of Plastic Materials

SIGNIFICANCE AND USE

4.1 These test methods are used to determine particle size distribution and therefore are useful for determining lot-to-lot uniformity.

4.2 The particle sizes of plastic materials affect the handling characteristics and sometimes will affect the processing characteristics of some polymers.

SCOPE

1.1 These test methods cover the measurement of the particle size of plastic materials in the powdered, granular, or pelleted forms in which they are commonly supplied. As these test methods utilize dry sieving, the lower limit of measurement is considered to be about 38 μm (No. 400 sieve). For smaller particle sizes, sedimentation test methods are recommended.

1.2 Two test methods are described:

1.2.1 Test Method A—This test method uses multiple sieves selected to span the particle size of the material. This method is used to determine the mean particle diameter and particle size distribution.

1.2.2 Test Method B—This test method is an abbreviated version of Test Method A conducted with a few specific sieves. This test method determines “percent passing” or “percent retained” on a given sieve. Test Method B is applicable to materials which do not have a normal particle size distribution such as pellets and cubes.

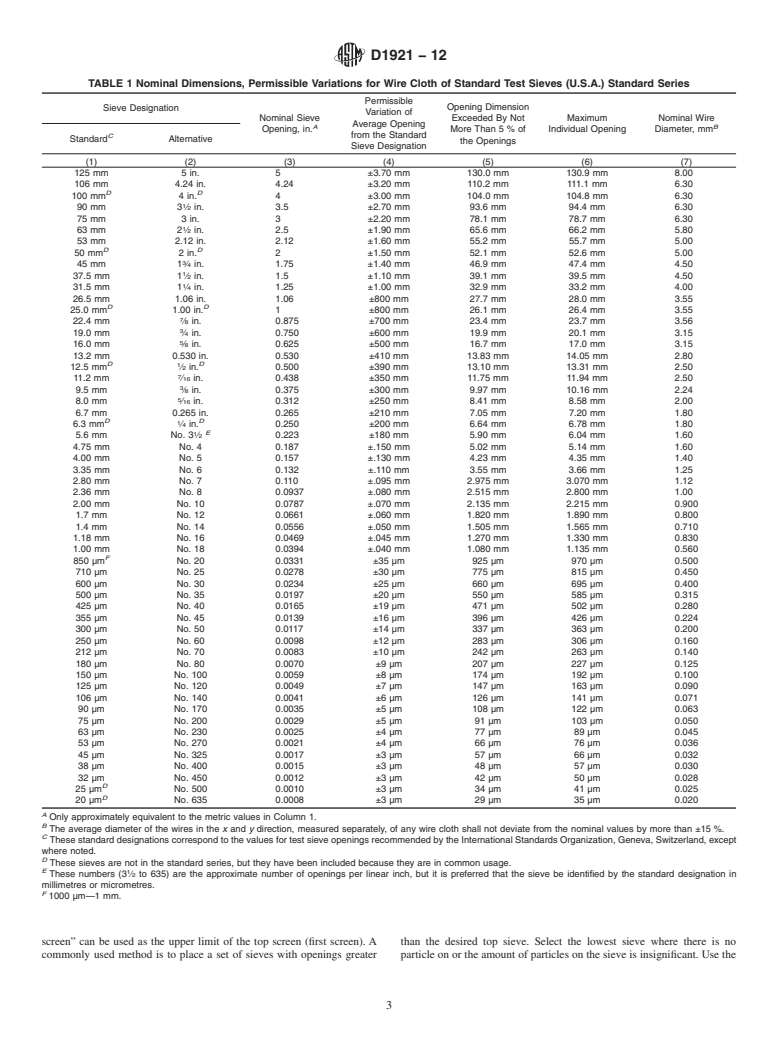

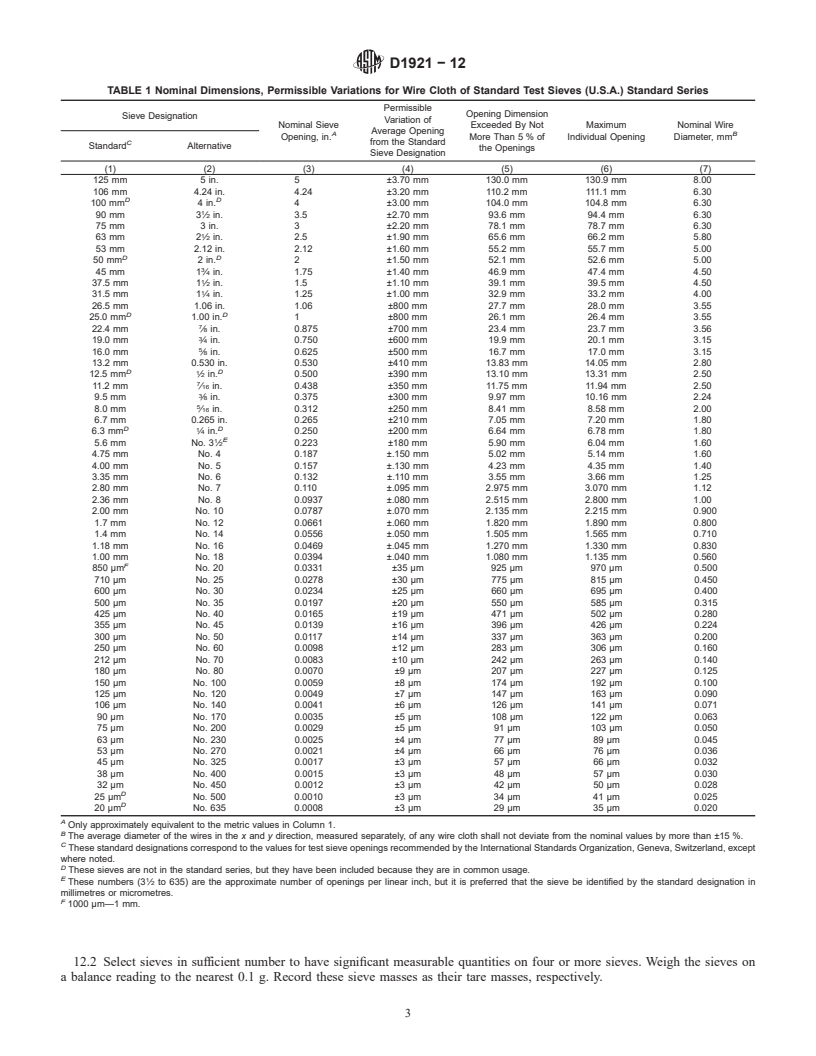

1.3 The values stated in SI units shall be considered standard for dimensions of the wire cloth openings and the diameter of the wires used in the wire cloth. The values stated in inch-pound units shall be considered standard with regard to the sieve frames.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 1—There is no known ISO equivalent for this test method.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1921 − 12

Standard Test Methods for

1

Particle Size (Sieve Analysis) of Plastic Materials

This standard is issued under the fixed designation D1921; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 2. Referenced Documents

2

1.1 These test methods cover the measurement of the 2.1 ASTM Standards:

particle size of plastic materials in the powdered, granular, or E11Specification forWovenWireTest Sieve Cloth andTest

pelleted forms in which they are commonly supplied.As these Sieves

test methods utilize dry sieving, the lower limit of measure- E691Practice for Conducting an Interlaboratory Study to

ment is considered to be about 38 µm (No. 400 sieve). For Determine the Precision of a Test Method

smaller particle sizes, sedimentation test methods are recom-

3. Summary of Test Methods

mended.

3.1 A dry mass of plastic material is placed on a series of

1.2 Two test methods are described:

sieves arranged in order of increasing fineness and the mass is

1.2.1 Test Method A—This test method uses multiple sieves

divided into fractions corresponding to the sieve opening.

selected to span the particle size of the material. This method

is used to determine the mean particle diameter and particle

4. Significance and Use

size distribution.

1.2.2 Test Method B—This test method is an abbreviated 4.1 These test methods are used to determine particle size

versionofTestMethodAconductedwithafewspecificsieves. distribution and therefore are useful for determining lot-to-lot

This test method determines “percent passing” or “percent uniformity.

retained” on a given sieve. Test Method B is applicable to

4.2 Theparticlesizesofplasticmaterialsaffectthehandling

materials which do not have a normal particle size distribution

characteristics and sometimes will affect the processing char-

such as pellets and cubes.

acteristics of some polymers.

1.3 The values stated in SI units shall be considered

5. Interferences

standard for dimensions of the wire cloth openings and the

diameter of the wires used in the wire cloth. The values stated

5.1 Some materials develop a static charge during sieving.

ininch-poundunitsshallbeconsideredstandardwithregardto

This charge interferes with the sieving process and results in a

the sieve frames.

coarse bias. Use of an antistat is necessary to obtain meaning-

ful results.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5.2 The choice of antistat (or slip agent) has been known to

responsibility of the user of this standard to establish appro-

affect the coarse bias. Some materials are more effective in

priate safety and health practices and determine the applica-

aiding the fines to separate from the mass.

bility of regulatory limitations prior to use.

5.3 Too much material on a sieve causes mass blinding and

NOTE 1—There is no known ISO equivalent for this test method.

results in a coarse bias. The sieve selection and charge weight

must be chosen to avoid overloading any sieve.

1

These test methods are under the jurisdiction of ASTM Committee D20 on

Plastics and are the direct responsibility of Subcommittee D20.70 on Analytical

2

Methods (Section D20.70.01). For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Aug. 1, 2012. Published September 2012. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

´1

approved in 1961. Last previous edition approved in 2006 as D1921-06 . DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D1921-12. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1921 − 12

5.4 Wavy, improperly stretched wire-cloth potentially al- 11. Conditioning

lows wires to separate without being visually damaged. Sieves

11.1 The plastic material must be in a free-flowing condi-

with wavy or torn wires shall not be used, as they no longer

tion.

conform to Specification E11.

11.2 If possible, condition the material to the laboratory

temperature and humidity.

6. Apparatus

6.1 Balance,500-gminimumcapacitywiththecapabilityof

TEST METHOD A

reading to the nearest 0.1 g.

12. Procedure

6.2 Mechanical Sieving Device and Time Switch—A me-

chanicalsieve-shakingdeviceequippedwithanautomatictime

12.1 Selectsievesinsufficient

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D1921 − 06 D1921 − 12

Standard Test Methods for

1

Particle Size (Sieve Analysis) of Plastic Materials

This standard is issued under the fixed designation D1921; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

´ NOTE—Added research report information to Section 17 editorially in September 2010.

1. Scope*

1.1 These test methods cover the measurement of the particle size of plastic materials in the powdered, granular, or pelleted

forms in which they are commonly supplied. As these test methods utilize dry sieving, the lower limit of measurement is

considered to be about 38 μm (No. 400 sieve). For smaller particle sizes, sedimentation test methods are recommended.

1.2 Two test methods are described:

1.2.1 Test Method A—This test method uses multiple sieves selected to span the particle size of the material. This method is used

to determine the mean particle diameter and particle size distribution.

1.2.2 Test Method B—This test method is an abbreviated version of Test Method A conducted with a few specific sieves. This

test method determines “percent passing” or “percent retained” on a given sieve. Test Method B is applicable to materials which

do not have a normal particle size distribution such as pellets and cubes.

1.3 The values stated in SI units shall be considered standard for dimensions of the wire cloth openings and the diameter of the

wires used in the wire cloth. The values stated in inch-pound units shall be considered standard with regard to the sieve frames.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE 1—There is no technically equivalent ISO standard.known ISO equivalent for this test method.

2. Referenced Documents

2

2.1 ASTM Standards:

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Summary of Test Methods

3.1 A dry mass of plastic material is placed on a series of sieves arranged in order of increasing fineness and the mass is divided

into fractions corresponding to the sieve opening.

4. Significance and Use

4.1 These test methods can be are used to determine particle size distribution and therefore are useful for determining lot-to-lot

uniformity.

4.2 The particle sizes of plastic materials affect the handling characteristics and sometimes will affect the processing

characteristics of some polymers.

1

These test methods are under the jurisdiction of ASTM Committee D20 on Plastics and are the direct responsibility of Subcommittee D20.70 on Analytical Methods

(Section D20.70.01).

Current edition approved April 1, 2006Aug. 1, 2012. Published June 2006September 2012. Originally approved in 1961. Last previous edition approved in 20012006 as

´1

D1921 - 01.D1921 - 06 . DOI: 10.1520/D1921-06E01.10.1520/D1921-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1921 − 12

5. Interferences

5.1 Some materials develop a static charge during sieving. This charge interferes with the sieving process and results in a coarse

bias. Use of an antistat is necessary to obtain meaningful results.

5.2 The choice of antistat (or slip agent) has been known to affect the coarse bias. Some materials are more effective in aiding

the fines to separate from the mass.

5.3 Too much material on a sieve causes mass blinding and results in a coarse bias. The sieve selection and charge weight must

be chosen to avoid overloading any sieve.

5.4 Wavy, improperly stretched wire-cloth may allowpotentially allows wires to separate without being visually damaged.

Sieves

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.