ASTM D6021-06

(Test Method)Standard Test Method for Measurement of Total Hydrogen Sulfide in Residual Fuels by Multiple Headspace Extraction and Sulfur Specific Detection

Standard Test Method for Measurement of Total Hydrogen Sulfide in Residual Fuels by Multiple Headspace Extraction and Sulfur Specific Detection

SIGNIFICANCE AND USE

Excessive levels of hydrogen sulfide in the vapor phase above residual fuel oils in storage tanks may result in health hazard, OSHA limits violation, and public complaint. An additional concern is corrosion that can be caused by the presence of H2S during refining and other production activities. Control measures to maintain safe levels of H2S require a consistent method for the assessment of potentially hazardous levels of H2S in fuel oils. (Warning—H2S is a highly toxic substance. Extreme care must be used in the sampling and handling of samples that are suspected of containing high levels of H2S.)

A concentration of 0.1 μg/g (ppmw) of H2S in the liquid phase of a No. 4, 5, or 6 residual fuel oil can generate an actual gas concentration of 10 to 100 μL/L (ppmv) of H2S in the vapor phase; therefore an accurate analytical method is required to determine the total H2S concentration of these residual fuel oils. This test method was developed so refiners, fuel terminal operators, and independent testing laboratory personnel can analytically measure the amount of H2S in residual fuel oils.

Test Method D 5705 provides a simple and consistent field test method for the rapid determination of H2S in the residual fuel oils storage tank vapor phase. However, it does not necessarily simulate the vapor phase H2S concentration of a fuel storage tank nor does it provide any indication of the liquid phase H2S concentration. This test method provides a quantitative measure of a residual fuel oils liquid phase H2S concentration. It requires a laboratory and a skilled operator to perform the test but gives a more quantitative indication of potential H2S exposure than Test Method D 5705.

Note 1—Because of the reactivity, absorptivity, and volatility of H2S any measurement method only provides an H2S concentration at a given moment in time.

SCOPE

1.1 This test method covers a method suitable for measuring the total amount of hydrogen sulfide (H2S) in heavy distillates, heavy distillate/residual fuel blends, or residual fuels as defined in Specification D 396 Grade 4, 5 (Light), 5 (Heavy), and 6, when the H2S concentration in the fuel is in the 0.01 to 100 g/g (ppmw) range.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 5.1, 7.5, 8.2, 9.2, 10.1.4, and 11.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6021 – 06

Standard Test Method for

Measurement of Total Hydrogen Sulfide in Residual Fuels

by Multiple Headspace Extraction and Sulfur Specific

1

Detection

This standard is issued under the fixed designation D6021; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D4323 Test Method for Hydrogen Sulfide in the Atmo-

sphere by Rate of Change of Reflectance

1.1 Thistestmethodcoversamethodsuitableformeasuring

D5504 Test Method for Determination of Sulfur Com-

thetotalamountofhydrogensulfide(H S)inheavydistillates,

2

pounds in Natural Gas and Gaseous Fuels by Gas Chro-

heavydistillate/residualfuelblends,orresidualfuelsasdefined

matography and Chemiluminescence

in Specification D396 Grade 4, 5 (Light), 5 (Heavy), and 6,

D5705 Test Method for Measurement of Hydrogen Sulfide

when the H S concentration in the fuel is in the 0.01 to 100

2

in the Vapor Phase Above Residual Fuel Oils

µg/g (ppmw) range.

1.2 The values stated in SI units are to be regarded as

3. Terminology

standard. No other units of measurement are included in this

3.1 Definitions:

standard.

3.1.1 heavy distillate, n—a fuel produced from the distilla-

1.3 This standard does not purport to address all of the

tion of crude oil which has a kinematic viscosity at 40°C

safety concerns, if any, associated with its use. It is the

2

between 5.5 and 24.0 mm /s, inclusive.

responsibility of the user of this standard to establish appro-

3.1.2 heavy distillate/residual fuel blend, n—a blend of

priate safety and health practices and determine the applica-

heavydistillateandresidualfueloilhavingaviscosityat40°C

bility of regulatory limitations prior to use. For specific

2

between 5.5 and 24.0 mm /s, inclusive.

warning statements, see 5.1, 7.5, 8.2, 9.2, 10.1.4, and 11.1.

3.1.3 multiple headspace extraction, n—a technique to de-

2. Referenced Documents termine the total concentration of a gas trapped in a liquid by

2

analysis of successive gas extractions from the vapor space of

2.1 ASTM Standards:

a closed vessel containing a known amount of the sample.

D396 Specification for Fuel Oils

3.1.4 residual fuel oil, n—any liquid or liquefiable petro-

D1193 Specification for Reagent Water

leum product having a kinematic viscosity at 100°C between

D2420 Test Method for Hydrogen Sulfide in Liquefied

2

5.0 and 50.0 mm /s, inclusive, burned for the generation of

Petroleum (LP) Gases (Lead Acetate Method)

heatinafurnaceorfireboxorforthegenerationofpowerinan

D3609 Practice for Calibration Techniques Using Perme-

engine.

ation Tubes

D4057 Practice for Manual Sampling of Petroleum and

4. Summary of Test Method

Petroleum Products

4.1 A representative sample of residual fuel oil is obtained

D4084 Test Method for Analysis of Hydrogen Sulfide in

in sufficient quantity to completely fill the sample container.

Gaseous Fuels (Lead Acetate Reaction Rate Method)

The sample is taken to the laboratory preferably within one to

4h,within24hmaximumandplacedinarefrigeratoruntilthe

1

This test method is under the jurisdiction of ASTM Committee D02 on

hydrogen sulfide analysis can be run.At that time, the sample

PetroleumProductsandLubricantsandisthedirectresponsibilityofSubcommittee

is removed from the refrigerator and allowed to sit at ambient

D02.E0 on Burner, Diesel, Non-Aviation Gas Turbine, and Marine Fuels.

temperature until it flows freely.

Current edition approved Aug. 1, 2006. Published September 2006. Originally

´1

4.2 A 0.05 to 5.0 g test specimen (aliquot) is placed in a

approved in 1996. Last previous edition approved in 2001 as D6021–96(2001) .

DOI: 10.1520/D6021-06.

headspacevialandheatedinanovenat60°Cformorethanfive

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

but less than 15 min. The headspace gas is sampled and

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

injected into either of two types of apparatus capable of

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. measuring the hydrogen sulfide concentration in the gaseous

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6021 – 06

3

sample. The two types of apparatus are those using the 6. Apparatus

reaction of lead acetate with H S (see Test Method D4084 or

2

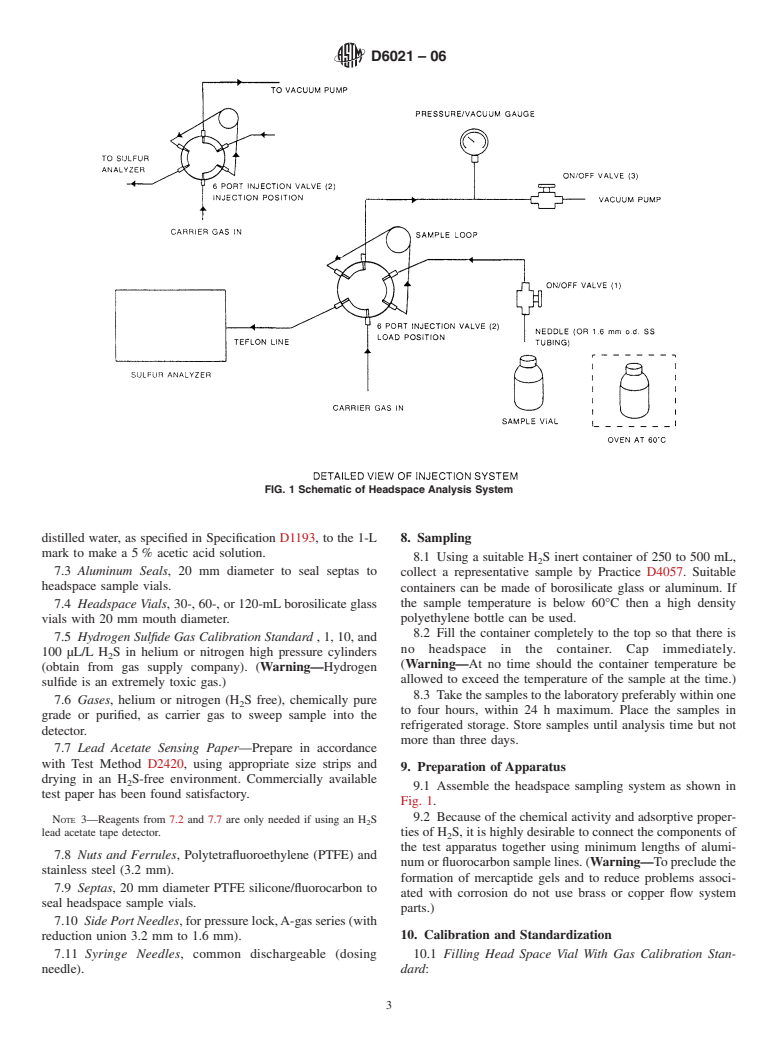

6.1 Aschematic of the headspace sampling system required

Test Method D4323) and those based on chemiluminescence

for this analysis is shown in Fig. 1. It consists of:

(see

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.