ASTM A497-99

(Specification)Standard Specification for Steel Welded Wire Reinforcement, Deformed, for Concrete

Standard Specification for Steel Welded Wire Reinforcement, Deformed, for Concrete

SCOPE

1.1 This specification covers welded wire reinforcement made from cold-worked drawn or rolled deformed wire, or a combination of deformed and non-deformed wires, to be used for the reinforcement of concrete.

Note 1—Welded wire for concrete reinforcement has been described by various terms: welded wire fabric, WWF, fabric, and mesh. The wire reinforcement industry prefers the term "welded wire reinforcement" (WWF) as being more representative of the range of products being manufactured. Therefore, the term "welded wire fabric" has been replaced with the term "welded wire reinforcement" in this specifcation and in other related specifications.

1.2 The values stated in either inch-pound or SI units are to be regarded as the standard. Within the text the inch-pound units are shown in parenthesis. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 497 – 99

Standard Specification for

Steel Welded Wire Fabric, Deformed, for Concrete

1

Reinforcement

This standard is issued under the fixed designation A 497; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.2 welded wire fabric, n—as used within the scope and

intent of this specification, welded wire fabric designates a

1.1 This specification covers welded wire fabric made from

material composed of cold-worked steel wire, fabricated into

cold-worked drawn or rolled deformed wire, or a combination

sheets or rolls by the process of electric resistance welding. The

of deformed and non-deformed wires, to be used for the

finished material shall consist essentially of a series of longi-

reinforcement of concrete.

tudinal and transverse wires arranged substantially at right

1.2 The values stated in either inch-pound or SI units are to

angles to each other, and welded together at points of intersec-

be regarded as the standard. Within the text the inch-pound

tion.

units are shown in parenthesis. The values stated in each

system are not exact equivalents; therefore, each system must

4. Ordering Information

be used independently of the other. Combining values may

4.1 Orders for material to this specification should include

result in nonconformance with the specification.

the following information:

2. Referenced Documents 4.1.1 Quantity (weight or square area),

4.1.2 Name of material (deformed welded wire fabric for

2.1 ASTM Standards:

concrete reinforcement),

A 82 Specification for Steel Wire, Plain, for Concrete Re-

2 4.1.3 Wire spacings and sizes,

inforcement

4.1.4 Minimum yield strength if Supplement S1 of Specifi-

A 496 Specification for Steel Wire, Deformed, for Concrete

2

cation A 496 applies; and minimum yield strength if wire

Reinforcement

conforming to Specification A 82 is to be used and Supplement

A 700 Practices for Packaging, Marking, and Loading

3

S1 of Specification A 82 applies.

Methods for Steel Products for Domestic Shipment

4.1.5 Exclusion of over-steeling, if required (see 9.4.1),

2.2 Military Standards:

4

4.1.6 Length and width of sheets or rolls,

MIL-STD-129 Marking for Shipment and Storage

4.1.7 Packaging (see Section 16), and

MIL-STD-163 Steel Mill Products Preparation for Ship-

4

4.1.8 ASTM designation and year of issue.

ment and Storage

2

2.3 Federal Standard:

NOTE 1—A typical ordering description is as follows: 10 000 ft welded

4

Fed. Std. No. 123 Marking for Shipments (Civil Agencies) deformed wire fabric for concrete reinforcement, 6 3 12–D63 D2, in flat

sheets 96 in. wide by 240 in. long, in secured lifts, to ASTM A 497 – ____.

3. Terminology

5. Materials

3.1 Definitions of Terms Specific to This Standard:

5.1 The wire used in the manufacture of welded wire fabrics

3.1.1 convoluted wire, n—when wire for welded fabric is

shall conform to Specification A 496 and its Supplement S1 if

shaped into a sinusoidal wave shape, it is commonly referred to

so ordered, either solely or in combination with wire conform-

as convoluted wire. The wire is used in the manufacture of

ing to Specification A 82 and its Supplement S1 if so ordered.

cages for certain applications of concrete pipe reinforcing.

5.2 Welded wire fabric shall be furnished either in flat

Only non-deformed wire is normally subject to convolution.

sheets, or in rolls, as specified by the purchaser.

1

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

6. Manufacture

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

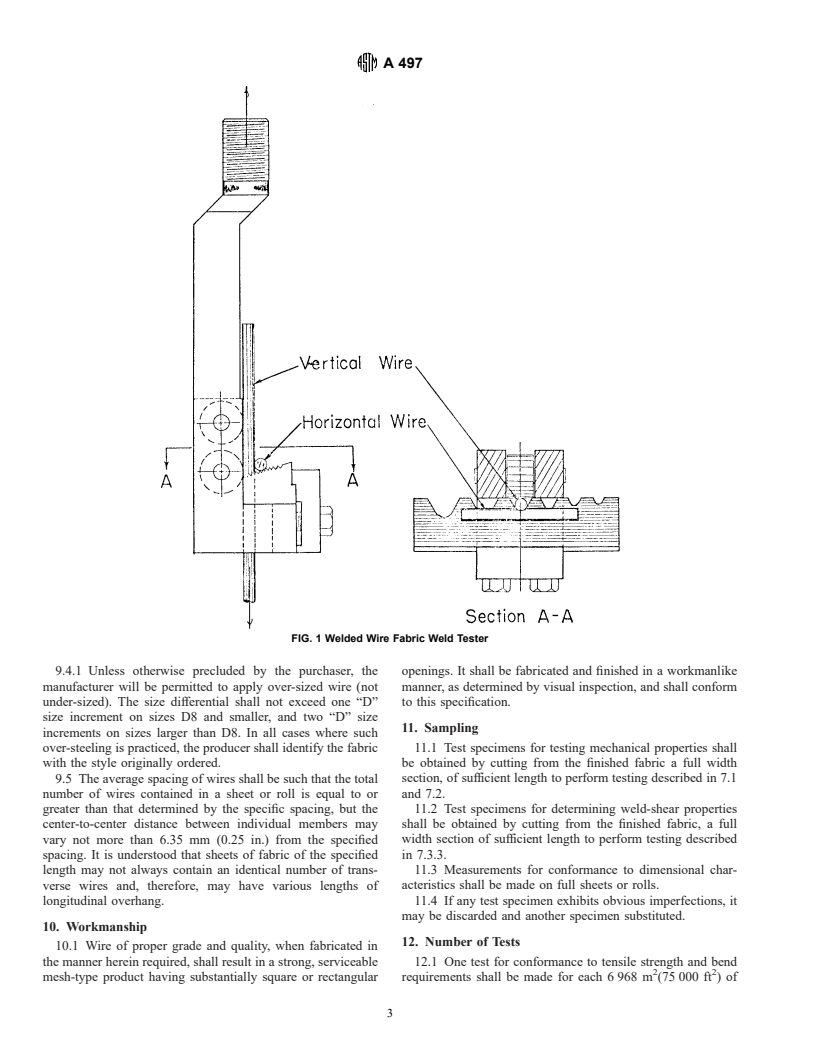

6.1 The wires shall be assembled by automatic machines or

A01.05 on Steel Reinforcement.

Current edition approved Oct. 10, 1999. Published December 1999. Originally by other suitable mechanical means which will assure accurate

published as A 497 – 64. Last previous edition A 497 – 97.

spacing and alignment of all members of the finished fabric.

2

Annual Book of ASTM Standards, Vol 01.04.

6.2 Longitudinal and transverse members shall be securely

3

Annual Book of ASTM Standards, Vol 01.05.

4

Available from Standardization Documents Order Desk, Building 4, Section D,

700 Robbins Ave., Philadelphia, PA 19111-5094.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 497

connected at every intersection by a process of electrical- the specimen shall then be tested. The fabric will be acceptable

resistance welding which employs the principle of fusion if the average of all w

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.