ASTM D580-99

(Specification)Standard Specification for Greige Woven Glass Tapes and Webbings

Standard Specification for Greige Woven Glass Tapes and Webbings

SCOPE

1.1 This specification primarily covers greige tapes and webbings woven from "E" electrical classification glass fiber yarns. This specification can also be applied to tapes and webbings made of other glass fiber grades upon agreement between the purchaser and the supplier.

1.2 This specification is intended to assist ultimate users by designating the types of these products that are typical in the industry. This specification permits the application of organic materials to the glass fiber yarn during manufacture that helps facilitate weaving. When used as permitted in this specification, such materials will not interfere with the intended end use requirements.

1.3 This specification shows the values in both SI and inch-pound units. "SI" units is the technically correct name for the system of metric units known as the International System of Units. "Inch-pound" units is the technically correct name for the customary units used in the United States. The values stated in inch-pound units are to be regarded as the standard. The values in SI units are provided as information only. Note 1-This specification is one of a series to provide a substitute for the following Military Specifications: MIL-Y-1140H Yarn, Cord, Sleeving, Cloth, and Tape-Glass MIL-C-9084C Cloth, Glass Finished for Resin Laminates

1.4 The following precautionary caveat pertain only to the test methods portions, Sections 26 through 41, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 580 – 99

Standard Specification for

Greige Woven Glass Tapes and Webbings

This standard is issued under the fixed designation D580; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D3774 Test Methods for Width of Woven Fabric

D3775 Test Method for Fabric Count of Woven Fabric

1.1 This specification primarily covers greige tapes and

D3776 Test Methods for Mass per Unit Area (Weight) of

webbings woven from “E” electrical classification glass fiber

Woven Fabric

yarns. This specification can also be applied to tapes and

D4029 Specification for Finished Woven Glass Fabrics

webbings made of other glass fiber grades upon agreement

D4963 Test Method for Ignition Loss of Glass Strands and

between the purchaser and the supplier.

Fabrics

1.2 This specification is intended to assist ultimate users by

D5035 Test Method for Breaking Strength and Elongation

designating the types of these products that are typical in the

of Textile Fabrics (Strip Method)

industry. This specification permits the application of organic

2.2 ANSI Standard:

materials to the glass fiber yarn during manufacture that helps

ANSI/ASQC Z1.4 Sampling Procedures for Inspection by

facilitate weaving. When used as permitted in this specifica-

Attributes

tion,suchmaterialswillnotinterferewiththeintendedenduse

requirements.

3. Terminology

1.3 The values stated in either SI units or inch-pound units

3.1 Definitions:

are to be regarded separately as standard. The values stated in

3.1.1 continuous filament yarn, n—ayarnmadeoffilaments

each system may not be exact equivalents; therefore, each

that extend substantially throughout the length of the yarn.

system shall be used independently of the other. Combining

3.1.2 greige goods, n—textile fabrics that have received no

values from the two systems may result in nonconformance

bleaching, dyeing, or finishing treatment after being produced

with the standard.

by any textile process.

1.4 This standard does not purport to address all of the

3.1.3 tape, n—in textiles, a narrow fabric with a mass per

safety concerns, if any, associated with its use. It is the

2 2

unit area of less than 0.5 kg/m (0.1 lb/ft ) for each 25.4 mm

responsibility of the user of this standard to establish appro-

(1 in.) of width and which is used primarily for utilitarian

priate safety and health practices and determine the applica-

purposes.

bility of regulatory limitations prior to use.

3.1.4 webbing, n—in textiles, a stout narrow fabric with a

2 2

2. Referenced Documents mass per unit area of at least 0.5 kg/m (0.1 lb/ft ) for each

25.4 mm (1 in.) of width.

2.1 ASTM Standards:

2 3.1.5 For definitions of other textile terms used in this

D123 Terminology Relating to Textiles

specification, refer to Terminology D123.

D578 Specification for Glass Fiber Strands

D579 Specification for Greige Woven Glass Fabrics

CLASSIFICATION

D1059 Test Method for Yarn Number Based on Short-

Length Specimens

4. Classification

D1423 Test Method for Twist in Yarns by the Direct-

4.1 Greige glass fiber tapes and webbings are produced in

Counting Method

twotypesandareconstructedwithyarnsdesignatedasdirected

D1776 Practice for Conditioning Textiles for Testing

in Specification D578. The standard types are:

D1777 Test Method for Thickness of Textile Materials

4.1.1 Type A—Medium texture.

D3773 Test Methods for Length of Woven Fabric

4.1.2 Type B—Open texture.

4.2 The designation of a tape or webbing shall be by style

numbers that are standard throughout the industry.

This specification is under the jurisdiction of ASTM Committee D-13 on

4.3 Two segments of characters are used to describe tapes

TextilesandisthedirectresponsibilityofSubcommitteeD13.18onGlassFiberand

and webbings.

Its Products.

Current edition approved March 10, 1999. Published June 1999. Originally

published as D580–40T. Last previous edition D580–94.

2 4

Annual Book of ASTM Standards, Vol 07.01. Available from American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 07.02. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 580

4.3.1 Thefirstsegmentofthedescriptionoftapeorwebbing requirements of the individual elements of the designation are

describestheglassclassification,thetypefiberinthewarp,and specified in Sections 8-12.

the type fiber in the filling.

8. Yarn Number

4.3.1.1 The first letter in the first segment is one of the

following glass classification codes: “E” for electrical,“ C” for

8.1 For tapes and webbings, the nominal size-free yarn

chemical, “S” for high strength.

numbersoftheyarnsdesignatedshallconformtoSpecification

4.3.1.2 The second letter in the first segment specifies the

D578.

fiber type in the warp direction: “C” describes continuous

filament fiber using either SI units or inch-pound units, staple 9. Filament Diameter

(discontinuous) fiber is described by “D” in SI units or “S” in

9.1 The nominal values for the filament diameters when

inch-pound units.

agreeduponbetweenpurchaserandsupplierarelistedinTable

4.3.1.3 Thethirdletterinthefirstsegmentspecifiesthefiber

1ofSpecificationD578.Theaveragefilamentdiameterforthe

type in the filling direction: “C” describes continuous filament

yarns in the tape or webbing shall conform to Specification

fiber using either SI units or inch-pound units, staple (discon-

D578 for the specified filament diameter.

tinuous) fiber is described by “D” in SI units or “S” in

inch-pound units.

10. Strand Construction

4.3.2 The second segment of the description of tape or

10.1 The basis for specifying strand construction is given in

webbing describes the texture: “A” describes medium texture

Specification D 578. The construction of the component

and“ B” describes close texture.

strands shall be agreed upon between the purchaser and the

4.4 Examples of glass fiber tapes or webbings.

supplier.

4.4.1 Example 1a (SI units):

11. Direction of Twist

ECD 2 B (1)

11.1 Unless otherwise agreed upon between the purchaser

where:

and the supplier, the primary twist in the singles strands shall

E 5 electrical glass,

be “Z” twist and the final twist in the plied yarns shall be “S”

C 5 continuous filament yarn warp direction,

twist.

D 5 discontinuous (staple) yarn filling direction, and

B 5 close textured.

12. Twist Level

4.4.2 Example 1b (inch-pound units):

12.1 The nominal twist in the component strands and the

ECS 2 B (2)

finished yarns shall be agreed upon between the purchaser and

where: supplier.Thetolerancesfortheprimarytwistandthefinaltwist

E 5 electrical glass, shall conform to Table 4.

C 5 continuous filament yarn warp direction,

S 5 staple (discontinuous) filament yarn filling direction, 13. Tape Weave Type

and

13.1 For tapes listed in Tables 1 and 2 and webbings listed

B 5 close textured.

in Table 3, the weave type shall be plain weave. For tapes and

webbings not listed inTable 1,Table 2, andTable 3, the weave

REQUIREMENTS

type shall be agreed upon between the purchaser and the

supplier.

5. Material

5.1 The fiber shall be continuous filament or staple (discon-

14. Length per Unit Mass

tinuous) fiber, as agreed upon between the purchaser and

14.1 For tapes listed in Tables 1 and 2, and webbings listed

supplier, free of any free alkali metal salts, such as soda or

in Table 3, the nominal length per unit mass shall conform to

potash, and foreign particles, dirt, and other impurities.

the requirements ofTable 1,Table 2, andTable 3, respectively.

6. Fabric Count

FortapesandwebbingsnotlistedinTable1,Table2,andTable

3, the nominal length per unit mass shall be agreed upon

6.1 FortapeslistedinTables1and2,andwebbingslistedin

betweenthepurchaserandthesupplier.Theaveragelengthper

Table 3, the nominal fabric count shall conform to the

unit mass for the lot shall be within the interval: specified

requirementsofTable1,Table2,andTable3,respectively.For

length per unit mass 610% of the specified length per unit

tapes or webbings not listed in Table 1, Table 2, and Table 3,

mass.

the nominal fabric count shall be agreed upon between the

purchaser and the supplier. The average count of warp ends

15. Thickness

shall be within one end of the nominal count and the average

15.1 For tapes listed in Tables 1 and 2, and webbings listed

count of the filling picks shall be within two picks of the

in Table 3, the nominal thickness shall conform to the

nominal count.

requirementsofTable1,Table2,andTable3,respectively.For

7. Yarn Designations

tapes and webbings not listed in Table 1, Table 2, and Table 3,

7.1 For tapes and webbings, the yarn designations shall be the nominal thickness shall be agreed upon between the

as agreed upon between the purchaser and supplier. The purchaserandthesupplier.Theaveragethicknessofthetapeor

D 580

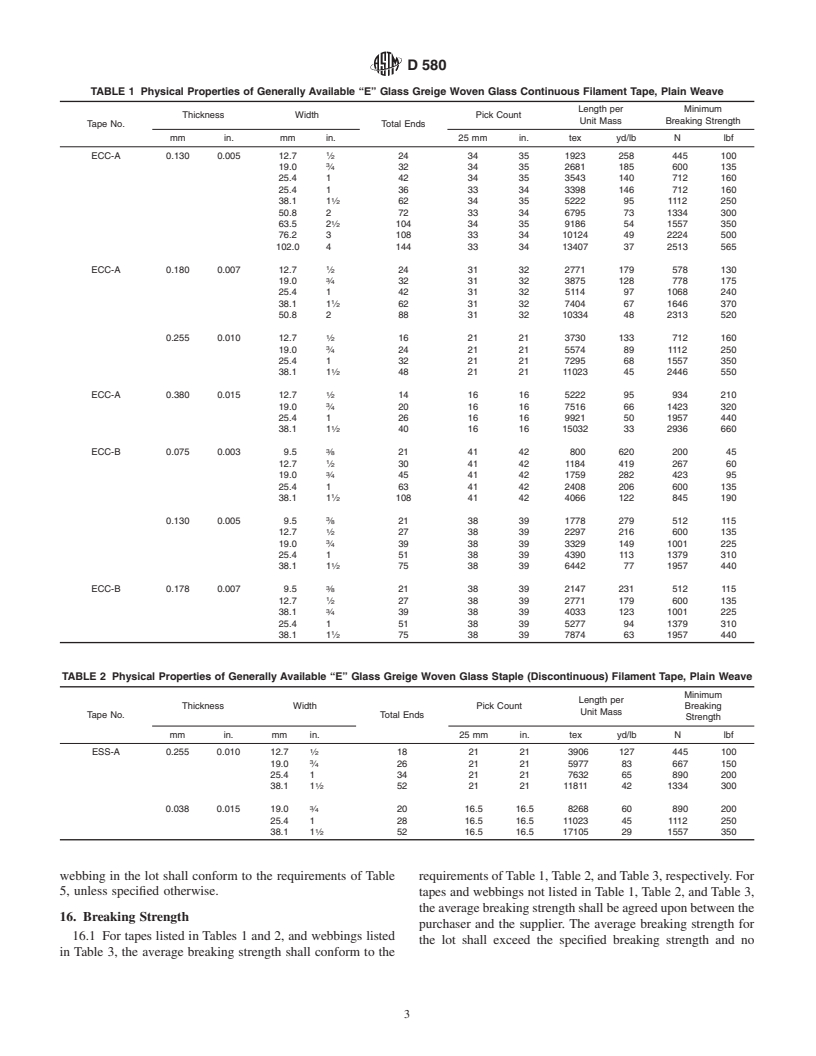

TABLE 1 Physical Properties of Generally Available “E” Glass Greige Woven Glass Continuous Filament Tape, Plain Weave

Length per Minimum

Thickness Width Pick Count

Unit Mass Breaking Strength

Tape No. Total Ends

mm in. mm in. 25 mm in. tex yd/lb N lbf

ECC-A 0.130 0.005 12.7 ⁄2 24 34 35 1923 258 445 100

19.0 ⁄4 32 34 35 2681 185 600 135

25.4 1 42 34 35 3543 140 712 160

25.4 1 36 33 34 3398 146 712 160

38.1 1 ⁄2 62 34 35 5222 95 1112 250

50.8 2 72 33 34 6795 73 1334 300

63.5 2 ⁄2 104 34 35 9186 54 1557 350

76.2 3 108 33 34 10124 49 2224 500

102.0 4 144 33 34 13407 37 2513 565

ECC-A 0.180 0.007 12.7 ⁄2 24 31 32 2771 179 578 130

19.0 ⁄4 32 31 32 3875 128 778 175

25.4 1 42 31 32 5114 97 1068 240

38.1 1 ⁄2 62 31 32 7404 67 1646 370

50.8 2 88 31 32 10334 48 2313 520

0.255 0.010 12.7 ⁄2 16 21 21 3730 133 712 160

19.0 ⁄4 24 21 21 5574 89 1112 250

25.4 1 32 21 21 7295 68 1557 350

38.1 1 ⁄2 48 21 21 11023 45 2446 550

ECC-A 0.380 0.015 12.7 ⁄2 14 16 16 5222 95 934 210

19.0 ⁄4 20 16 16 7516 66 1423 320

25.4 1 26 16 16 9921 50 1957 440

38.1 1 ⁄2 40 16 16 15032 33 2936 660

ECC-B 0.075 0.003 9.5 ⁄8 21 41 42 800 620 200 45

12.7 ⁄2 30 41 42 1184 419 267 60

19.0 ⁄4 45 41 42 1759 282 423 95

25.4 1 63 41 42 2408 206 600 135

38.1 1 ⁄2 108 41 42 4066 122 845 190

0.130 0.005 9.5 ⁄8 21 38 39 1778 279 512 115

12.7 ⁄2 27 38 39 2297 216 600 135

19.0 ⁄4 39 38 39 3329 149 1001 225

25.4 1 51 38 39 4390 113 1379 310

38.1 1 ⁄2 75 38 39 6442 77 1957 440

ECC-B 0.178 0.007 9.5 ⁄8 21 38 39 2147 231 512 115

12.7 ⁄2 27 38 39 2771 179 600 135

38.1 ⁄4 39 38 39 4033 123 1001 225

25.4 1 51 38 39 5277 94 1379 310

38.1 1 ⁄2 75 38 39 7874 63 1957 440

TABLE 2 Physical Properties of Generally Available “E” Glass Greige Woven Glass Staple (Discontinuous) Filament Tape, Plain Weave

Minimum

Length per

Thickness Width Pick Count Breaking

Unit Mass

Tape No. Total Ends

Strength

mm in. mm in. 25 mm in. tex yd/lb N lbf

ESS-A 0.255 0.010 12.7 ⁄2 18 21 21 3906 127 445 100

19.0 ⁄4 26 21 21 5977 83 667 150

25.4 1 34 21 21 7632 65 890 200

38.1 1 ⁄2 52 21 21 11811 42 1334 300

0.038 0.015 19.0 ⁄4 20 16.5 16.5 8268 60 890 200

25.4 1 28 16.5 16.5 11023 45 1112 250

38.1 1 ⁄2 52 16.5 16.5 17105 29 1557 350

webbing in the lot shall conform to the requirements of Table requirementsofTable1,Table2,andTable3,respectively.For

5, unless specified otherwise. tapes and webbings not listed in Table 1, Table 2, and Table 3,

theaveragebreakingstrengthshallbeagreeduponbetweenthe

16. Breaking Strength

purchaser and the supplier. The average breaking strength for

16.1 For tapes listed in Tables 1 and 2, and webbings listed

the lot shall exceed the specified breaking strength and no

in Table 3, the average breaking strength shall conform to the

D 580

TABLE 3 Physical Properties of Generally Available “E” Glass Greige Woven Glass Staple (Discontinuous) Filament Webbing, Plain

Weave

Minimum

Length per

Thickness Width Pick Count Breaking

Unit Mass

Tape No. Total Ends

Strength

mm in. mm in. 25 mm in. tex yd/lb N lbf

ESS-A 0.510 0.020 19.0 ⁄4 20 14 14 10124 49 1112 250

25.4 1 28 14 14 13779 36 1334 300

38.1 1 ⁄2 44 14 14 19842 25 2002 450

0.635 0.025 19.0 ⁄4 20 10 10 11274 44 934 210

25.4 1 28 10 10 15502 32 1334 300

38.1 1 ⁄2 44 10 10 27559 18 2446 550

TABLE 4 Twist Tolerances TABLE 5 Tolerances—Thickness

Tolerances Permissible Variations, Average

Nominal Thickness

Turns per Centimetre: Staple

Continuous

From zero to 0.4, incl 60.1 turn per centimetre (discontinuous)

Over 0.4 and up to and 60.2 turn per centimetre

millimetres

including 4.0

Over 4 65.0 % of the specified 0.125 and under 60.013 .

average twist

Over 0.125 to 0.250 60.025 60.050

Turns per Metre: Over 0.250 to 0.380 60.050 60.075

From zero to 40, incl 610 turns per metre Over 0.380 to 0.025 . 60.075

Over 40 and up to and 620 turns per metre

inches

including 400

Over 400 65.0 % of the specified

0.0050 and under 60.0005 .

average twist

Over 0.0050 to 0.0100 60.0010 60.0020

Turns per Inch:

Over 0.0100 to 0.0150 60.0020 60.0030

From zero to 1, incl 60.25 turn per inch

Over 0.0150 to 0.0250 . 60.0030

Over 1 and up to and 60.5 turn per inch

Permissible Variations, Individual

including 10

Over 10 65.0 % of the specified

Staple

Continuous

average twist

(discontinuous)

millimetres

0.125 and under 60.025 .

Over 0.125 to 0.250 60.040 60.075

individual break shall be less than 80% of the specified

Over 0.250 to 0.380 60.060 60.090

average breaking strength. Over 0.380 to 0.635 . 60.090

inches

17. Width

0.0050 and under 60.0010 .

Over 0.0050 to 0.0100 60.0015 60.0030

17.1 For tapes listed in Tables 1 and 2, and webbings listed

Over 0.0100 to 0.0150 60.0025 60.0035

inTable3,thenominalwidthshallconformtotherequirements

Over 0.0150 to 0.0250 . 60.0035

of Table 1, Table 2, and Table 3, respectively. For tapes and

webbings not listed in Table 1, Table 2, and Table 3, the

nominalwidthshallbeagreeduponbetweenthepurchaserand

TABLE 6 Tolerances—Tape Width

the supplier. The tolerances for width shall conform to Table 6

Nominal Tape Width, Permissible Variation,

mm (in.) mm (in.)

unless otherwise agreed upon between the purchaser and the

Less than 25.4 (1.0) 60.8 ( ⁄32)

supplier.

Over 25.4 (1.0) 61.6 ( ⁄16)

18. Length Per Package

18.1 The nominal length of tape or webbing on each

less than the combined length of those tubes or serving spools

package,suchasaspoolorservingtube,shallbenomorethan

on the identification labels.

36 m (40 yd) nor no less than 32 m (36 yd) except for 0.075

19. Ignition Loss

mm (0.003 in.) thick tape or webbing which shall be no more

than 68 m (76 yd) nor no less than 65 m (72 yd), unless

19.1 The organic conten

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.