ASTM D7305-08a(2020)

(Test Method)Standard Test Method for Reflection Density of Printed Matter

Standard Test Method for Reflection Density of Printed Matter

SIGNIFICANCE AND USE

6.1 One of the key properties for printing in the lab or on production equipment is the intensity of the color, color balance and uniformity. This test can be used to ensure that the proper amount of ink is transferred to the substrate by obtaining a target density value, in addition to determining whether the print is uniform by measuring the reflection density over a wide print area. This then allows the use of the print for controlled testing of other appearance properties, such as gloss and color, and performance properties, such as resistance to abrasion and chemicals.

6.2 This test can be used to help achieve consistent color reproduction of printed color on flat surfaces.

6.3 Transfer of density readings from one set of inks to another, or from one substrate to another, carries a high risk of producing a color or tone shift. It is not in the scope of this test method to use density readings as digital proof of target points for printing process control.

SCOPE

1.1 This test method describes a procedure for measuring reflection density of printed matter using a reflection densitometer or spectrodensitometer.

1.2 This test method is intended primarily for process colors (yellow, magenta and cyan) and black. With appropriate instrumentation, it may also be used for other colors.

1.3 This test method applies to prints made by any printing process on a flat surface, with reflection density values ranging from just above zero, on the unprinted substrate, through to around 2.5 for very dense prints.

1.4 This test method can be used for prints on paper, film or board but not for those on metal or foil. It can be conducted in the pressroom or laboratory.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7305 −08a (Reapproved 2020)

Standard Test Method for

Reflection Density of Printed Matter

This standard is issued under the fixed designation D7305; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E691Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method describes a procedure for measuring

2.2 ANSI Standards:

reflectiondensityofprintedmatterusingareflectiondensitom-

CGATS.4-1993Graphic Technology – GraphicArts Reflec-

eter or spectrodensitometer.

tion Densitometry Measurements — Terminology,

1.2 Thistestmethodisintendedprimarilyforprocesscolors

Equations, Image Elements and Procedures

(yellow, magenta and cyan) and black. With appropriate

CGATS.6GraphicTechnology—SpecificationsforGraphic

instrumentation, it may also be used for other colors.

Arts Printing

1.3 This test method applies to prints made by any printing

CGATS.11-1999Graphic Technology — Certified Refer-

processonaflatsurface,withreflectiondensityvaluesranging

enceMaterialsforReflectionandTransmissionMetrology

from just above zero, on the unprinted substrate, through to

– Documentation Requirements and Recommended Pro-

around 2.5 for very dense prints.

cedures

PH 2.17Geometric Conditions for Reflection Density

1.4 Thistestmethodcanbeusedforprintsonpaper,filmor

PH2.18SpectralConditionsfortheMeasurementofOptical

board but not for those on metal or foil. It can be conducted in

Density

the pressroom or laboratory.

2.3 ISO Standard:

1.5 The values stated in SI units are to be regarded as

ISO 15790Graphic technology and photography — Certi-

standard. No other units of measurement are included in this

fied reference materials for reflection and transmission

standard.

metrology — Documentation and procedures for use,

1.6 This standard does not purport to address all of the

including determination of combined standard uncertainty

safety concerns, if any, associated with its use. It is the

2.4 Other Standard:

responsibility of the user of this standard to establish appro-

DIN 16536-2:1986Testing of prints and printing inks in

priate safety, health, and environmental practices and deter-

graphic technology — Colour density measurements on

mine the applicability of regulatory limitations prior to use.

on-press or off-press prints

1.7 This international standard was developed in accor-

dance with internationally recognized principles on standard-

3. Terminology

ization established in the Decision on Principles for the

3.1 Definitions related to appearance are in Terminology

Development of International Standards, Guides and Recom-

E284.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 reflection density, n—the light-absorbing property of a

2. Referenced Documents

material, expressed as the logarithm of the reciprocal of the

reflectance factor (i.e. higher density indicates more light is

2.1 ASTM Standards:

absorbed). [D = log (1/R) = -log (R)]

E284Terminology of Appearance 10 10

3.2.2 reflection densitometry, n—the practice of characteriz-

ing the amount of light absorption of materials by measuring

This test method is under the jurisdiction of ASTM Committee D01 on Paint

reflectance and calculating and reporting reflection density.

and Related Coatings, Materials, andApplications and is the direct responsibility of

3.2.3 spectrodensitometer, n—a spectrophotometer with ap-

Subcommittee D01.56 on Printing Inks.

CurrenteditionapprovedJune1,2020.PublishedJuly2020.Originallyapproved propriate software to convert the measured reflectance values

in 2008. Last previous edition approved in 2013 as D7305–08a (2013). DOI:

to reflection density.

10.1520/D7305-08AR20.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7305 − 08a (2020)

chromatic inks at typical printing densities.

3.2.4 process color, n—a color having the main attribute of

absorbing approximately one-third (1/3) the visible spectrum

4. Symbols

and transmitting the other two-thirds (2/3).

4.1 Symbols—The following symbols are defined or re-

3.2.5 dry back, n—the reduction in density that occurs over

ferred to in this standard.

time after printing on paper and other absorbent substrates due

D reflection density

to ink penetration into the substrate.

R reflectance factor

3.2.6 status T, n—an ISO Reflection Status Density.

5. Summary of Test Method

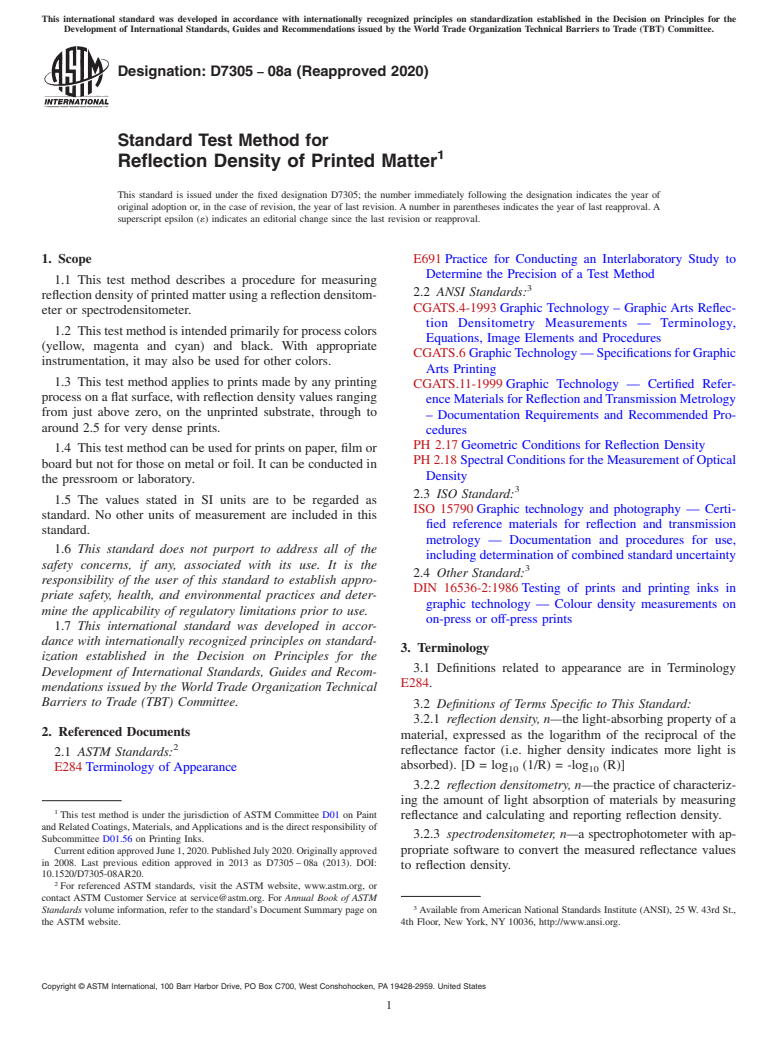

NOTE 1—ISO Reflection Status Density is defined by its Spectral

Products (Fig. 1), that is, the wavelength by wavelength combination of a

5.1 The densitometer or spectrodensitometer is calibrated

standard influx spectrum (CIE illuminantA) and the filter-modifed efflux

and set for the desired spectral response and color.

spectrum. Originally, these modifiers were defined by combinations of

Wratten filters but today, either more durable materials, such as glass are 5.2 Multiple reflection density measurements are taken in

used or the Spectral Products are computed numerically from tables of

specifiedpositionsontheprintinordertodetermineanaverage

weights and the spectral reflectance factors measured with a spectroden-

result.

sitometer.

The status T spectral products are applicable to the measurement of

6. Significance and Use

artwork for color separation and graphics arts materials such as ink-on-

paper printed sheets, and off-press proofs. StatusTwas originally defined

6.1 One of the key properties for printing in the lab or on

to closely match the spectral products historically used in evaluating

production equipment is the intensity of the color, color

originalartworktobecolorseparatedbutwerelaterapplied,notablyinthe

balanceanduniformity.Thistestcanbeusedtoensurethatthe

USA, to the measurement of most other printed graphic arts materials.

proper amount of ink is transferred to the substrate by

The status E spectral products are also applicable to the measurement

obtaining a target density value, in addition to determining

of graphics arts materials such as ink-on-paper printed sheets, and

off-press proofs. They evolved from the wider of the two passband filter

whether the print is uniform by measuring the reflection

specifications of DIN 16536-2:1986 for the Yellow and the Magenta and

density over a wide print area. This then allows the use of the

Cyan spectral products were chosen to match those of Status T. Status E

printforcontrolledtestingofotherappearanceproperties,such

spectral products have been applied, primarily in Europe, to the measure-

as gloss and color, and performance properties, such as

ment of graphic arts materials.The narrower passband of theYellow filter

(compared to Status T) produces values that are more similar for all three resistance to abrasion and chemicals.

FIG. 1 ISO Status Density Spectral Products

D7305 − 08a (2020)

6.2 This test can be used to help achieve consistent color T-Ref standard. Readings that differ from the labelled value on

reproduction of printed color on flat surfaces. thecertifiedreferencematerialbymorethanthegreaterof0.02

density units or 2% should be discussed with the densitometer

6.3 Transfer of density readings from one set of inks to

manufacturer in order to determine whether the particul

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.