ASTM E1136-17

(Specification)Standard Specification for P195/75R14 Radial Standard Reference Test Tire

Standard Specification for P195/75R14 Radial Standard Reference Test Tire

ABSTRACT

This specification covers the general requirements for a radial-ply standard reference test tire for use as a reference for tire traction performance evaluations and for other evaluations, such as pavement roughness, noise, or other tests that require a reference tire. The test tire shall be of the specified size, current technology All Season tread design steel-belted radial. Tread compounding, fabric processing, and all the manufacturing steps shall be controlled for minimum variability between tires. The tire shall be as originally molded without any tread grinding or repairs. The oil-extended styrene-butadiene blend rubber tread shall conform to the prescribed composition for: SBR 1778, SBR 1502, CIS 1 polybutadiene, N351 black, naphthenic oil, zinc oxide, stearic acid, 6 PPD, TMQ, antidegradant wax, tackifying hydrocarbon resin, TBBS, DPG, and sulfur. The tire shall be constructed as one-ply sidewall and a three-ply thread. The tread compound shall conform to the physical property requirements for: tensile sheet cure, stress at elongation, tensile strength, elongation, Durometer hardness, and restored energy (rebound or resilience). The dimensional requirements for (1) inflated dimensions and cured cord angles, (2) ribs, (3) grooves, and (4) wear indicators are specified. The prescribed physical property test methods including tire tread hardness test shall be used. Tire storage requirements and recommendations for tire use and operational requirements are detailed. The front and side views of a radial reference tire, the cross section including inflated tire dimensions, and the tread radius measurement using three point drop method are illustrated.

SCOPE

1.1 This specification covers the general requirements for the P195/75R14 radial standard reference test tire. The tire covered by this specification is primarily for use as a reference tire for braking traction, snow traction, and wear performance evaluations, but may also be used for other evaluations, such as pavement roughness, noise, or other tests that require a reference tire.

1.1.1 Other standard reference test tires are also used for these purposes and are referenced in Section 2.

1.2 This specification provides a rim code diameter of 14, standard tire design and construction, standard dimensions, and specifies the conditions of storage.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1136 −17

Standard Specification for

1

P195/75R14 Radial Standard Reference Test Tire

This standard is issued under the fixed designation E1136; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1765Classification System for Carbon Blacks Used in

Rubber Products

1.1 This specification covers the general requirements for

D2240TestMethodforRubberProperty—DurometerHard-

the P195/75R14 radial standard reference test tire. The tire

ness

covered by this specification is primarily for use as a reference

D3182PracticeforRubber—Materials,Equipment,andPro-

tire for braking traction, snow traction, and wear performance

cedures for Mixing Standard Compounds and Preparing

evaluations,butmayalsobeusedforotherevaluations,suchas

Standard Vulcanized Sheets

pavement roughness, noise, or other tests that require a

D7121Test Method for Rubber Property—Resilience Using

reference tire.

Schob Type Rebound Pendulum

1.1.1 Other standard reference test tires are also used for

E867Terminology Relating to Vehicle-Pavement Systems

these purposes and are referenced in Section 2.

F538Terminology Relating to the Characteristics and Per-

1.2 This specification provides a rim code diameter of 14,

formance of Tires

standardtiredesignandconstruction,standarddimensions,and

F2493Specification for P225/60R16 97S Radial Standard

specifies the conditions of storage.

Reference Test Tire

1.3 The values stated in SI units are to be regarded as the F2870 Specification for 315/70R22.5 154/150L Radial

Truck Standard Reference Test Tire

standard. The values given in parentheses are mathematical

conversions to inch-pound units that are provided for informa- F2871 Specification for 245/70R19.5 136/134M Radial

Truck Standard Reference Test Tire

tion only and are not considered standard.

F2872Specification for 225/75R16C 116/114S M+S Radial

1.4 This standard does not purport to address all of the

Light Truck Standard Reference Test Tire

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

3.1 Definitions:

1.5 This international standard was developed in accor-

3.1.1 Fordefinitionsoftermsusedinthisspecification,refer

dance with internationally recognized principles on standard-

to Terminology F538.

ization established in the Decision on Principles for the

3.1.2 all-season tread, n—tread design providing dry, wet,

Development of International Standards, Guides and Recom-

and snow traction performance for an optimized balance for

mendations issued by the World Trade Organization Technical

year-round performance and which may meet the U.S. Tire

Barriers to Trade (TBT) Committee.

Manufacturers Association (USTMA) definition for an M&S,

M+S, M/S, MS, etc. marked tire (see USTMA “Snow Tire

3

2. Referenced Documents

Definitions for Passenger and Light Truck (LT) Tires” ). F538

2

3.1.3 pavement characteristic, n—physical feature or prop-

2.1 ASTM Standards:

D412TestMethodsforVulcanizedRubberandThermoplas- erty of a pavement surface such as type, roughness, texture,

and skid resistance. E867

tic Elastomers—Tension

3.1.4 pitch, n—unitoftreadpatternelementsusedinvarious

combinations to obtain optimum noise levels. F538

1

This specification is under the jurisdiction of ASTM Committee F09 on Tires

3.1.5 standard reference test tire, SRTT, n—tire that is used

and is the direct responsibility of Subcommittee F09.20 on Vehicular Testing.

as a control tire or surface monitoring tire (for example,

Current edition approved Oct. 1, 2017. Published November 2017. Originally

Specification F2493, F2870, F2871, and F2872 tires). F538

approved in 1986. Last previous edition approved in 2014 as E1136–14. DOI:

10.1520/E1136-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from the U.S. Tire Manufacturers Association, 1400 K Street, N.W.

the ASTM website. Washington, D.C. 20005.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

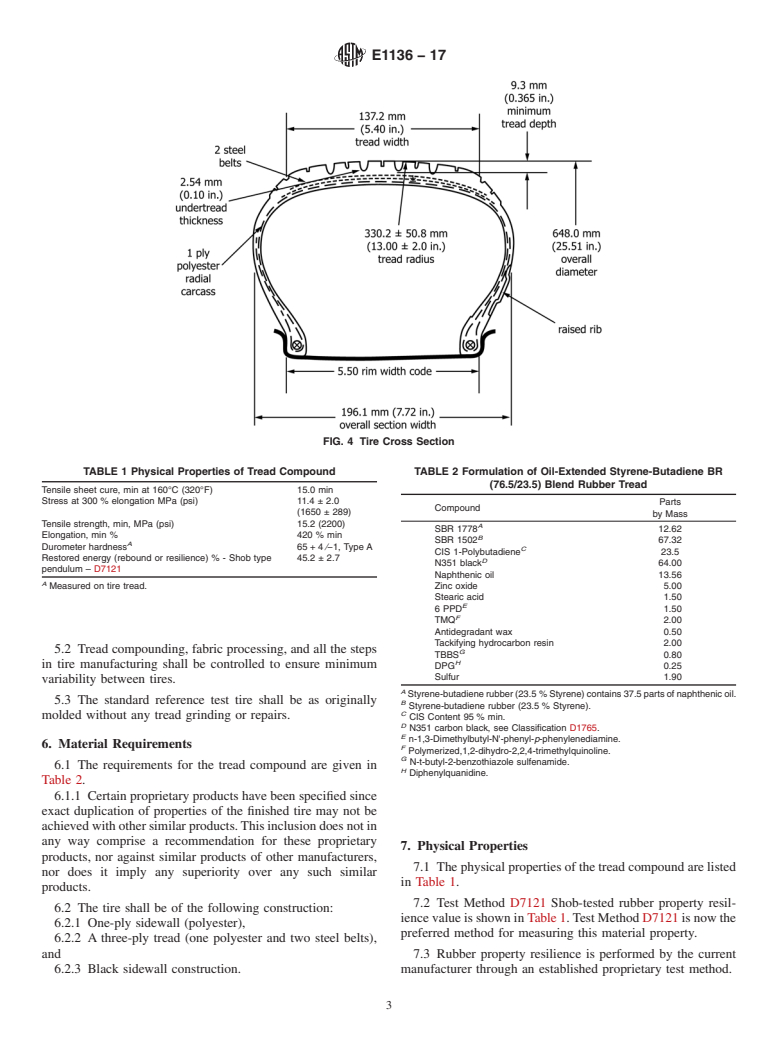

E1136−17

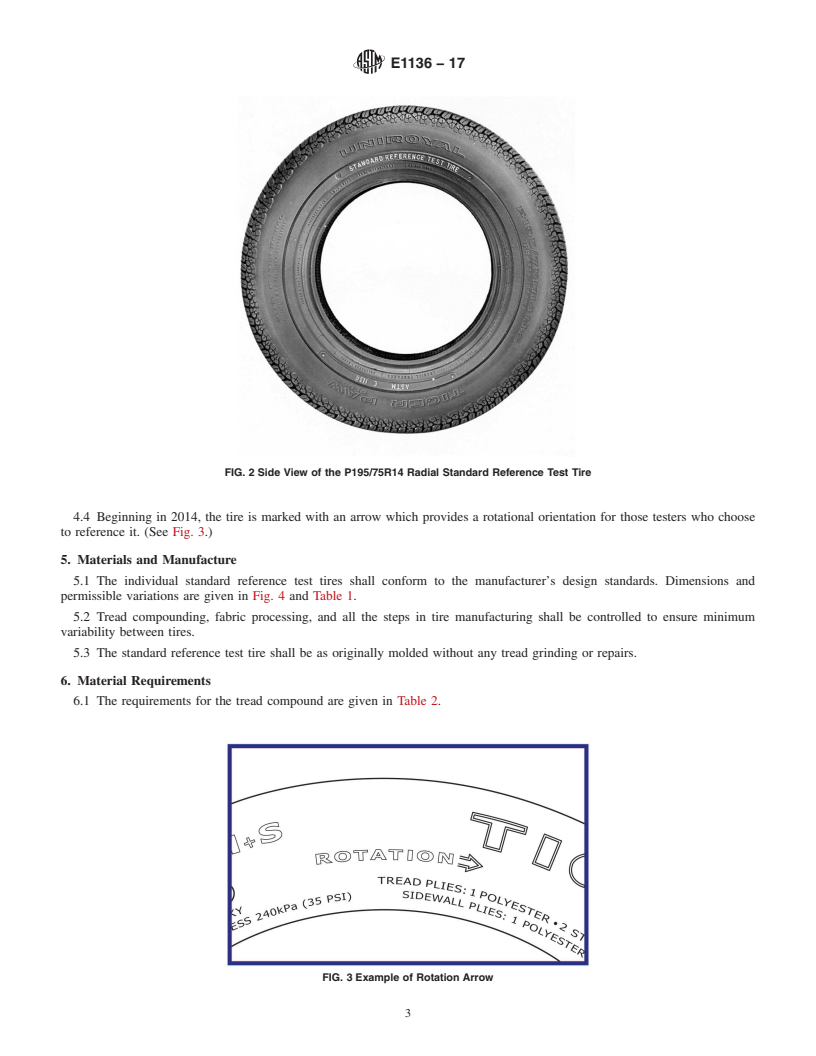

FIG. 2Side View of the P195/75R14 Radial Standard Reference

Test Tire

“StandardReferenceTestTire,”andECE(EconomicCommis-

sion for Europe) and DOT (Department of Transportation)

certification marks.

FIG. 1Front View of the P1

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1136 − 14 E1136 − 17

Standard Specification for

1

P195/75R14 Radial Standard Reference Test Tire

This standard is issued under the fixed designation E1136; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the general requirements for the P195/75R14 radial standard reference test tire. The tire covered

by this specification is primarily for use as a reference tire for braking traction, snow traction, and wear performance evaluations,

but may also be used for other evaluations, such as pavement roughness, noise, or other tests that require a reference tire.

1.1.1 Other standard reference test tires are also used for these purposes and are referenced in Section 2.

1.2 This specification provides a rim code diameter of 14, standard tire design and construction, standard dimensions, and

specifies the conditions of storage.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are mathematical

conversions to inch-pound units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D412 Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension

3

D1054 Test Method for Rubber Property—Resilience Using a Goodyear-Healey Rebound Pendulum (Withdrawn 2010)

D1765 Classification System for Carbon Blacks Used in Rubber Products

D2240 Test Method for Rubber Property—Durometer Hardness

D3182 Practice for Rubber—Materials, Equipment, and Procedures for Mixing Standard Compounds and Preparing Standard

Vulcanized Sheets

D7121 Test Method for Rubber Property—Resilience Using Schob Type Rebound Pendulum

E867 Terminology Relating to Vehicle-Pavement Systems

F538 Terminology Relating to the Characteristics and Performance of Tires

F2493 Specification for P225/60R16 97S Radial Standard Reference Test Tire

F2870 Specification for 315/70R22.5 154/150L Radial Truck Standard Reference Test Tire

F2871 Specification for 245/70R19.5 136/134M Radial Truck Standard Reference Test Tire

F2872 Specification for 225/75R16C 116/114S M+S Radial Light Truck Standard Reference Test Tire

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in this specification, refer to Terminology F538.

3.1.2 all-season tread, n—tread design providing dry, wet, and snow traction performance for an optimized balance for

year-round performance and which may meet the Rubber U.S. Tire Manufacturers Association (RMA)(USTMA) definition for an

1

This specification is under the jurisdiction of ASTM Committee F09 on Tires and is the direct responsibility of Subcommittee F09.20 on Vehicular Testing.

Current edition approved Aug. 15, 2014Oct. 1, 2017. Published September 2014November 2017. Originally approved in 1986. Last previous edition approved in 20102014

as E1136 – 10.E1136 – 14. DOI: 10.1520/E1136-14.10.1520/E1136-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1136 − 17

3

M&S, M+S, M/S, MS, etc. marked tire (see RMAUSTMA “Snow Tire Definitions for Passenger and Light Truck (LT) Tires” ).

F538

3.1.3 pavement characteristic, n—physical feature or property of a pavement surface such as type, roughness, texture, and skid

resistance. E867

3.1.4 pitch, n—unit of tread pattern elements used in various combinations to obtain

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.