ASTM D1348-94(1998)

(Test Method)Standard Test Methods for Moisture in Cellulose

Standard Test Methods for Moisture in Cellulose

SCOPE

1.1 These test methods cover the determination of moisture in cellulose using two oven-drying procedures and one Karl Fischer procedure.

1.2 The test procedures appear in the following order: Sections Test Method A-Specimen Weighed in Oven 4 to 10 Test Method B-Specimen Weighed Outside of Oven 11 to 17 Test Method C-Karl Fischer Method 18 to 25

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

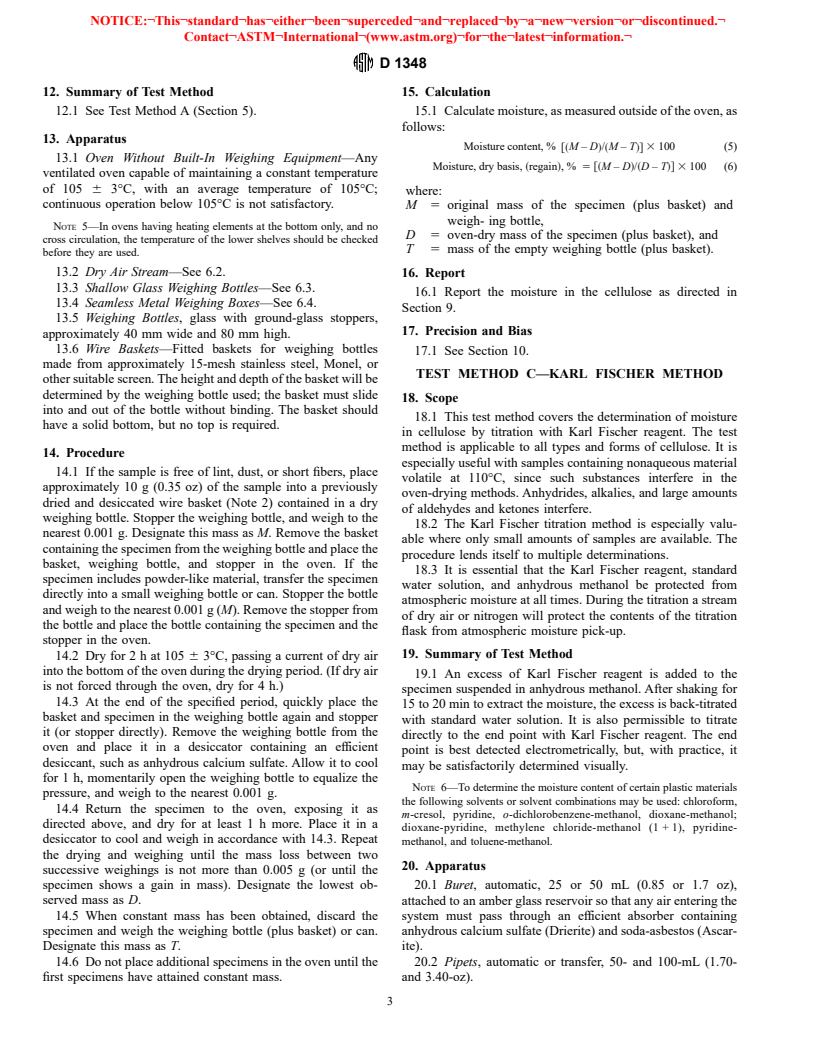

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact

ASTM International (www.astm.org) for the latest information.

Designation: D 1348 – 94 (Reapproved l998)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Methods for

1

Moisture in Cellulose

This standard is issued under the fixed designation D 1348; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 Except for those samples taken in an atmosphere with

which the sample is in equilibrium, the moisture content of the

1.1 These test methods cover the determination of moisture

sample will begin to change immediately after it is removed

in cellulose using two oven-drying procedures and one Karl

from its original surroundings. This change can be reduced by

Fischer procedure.

taking extra layers of sheeted material and discarding a few

1.2 The test procedures appear in the following order:

layers from the top and bottom before weighing, folding, or

Sections

rolling the sample to reduce the exposed area, and by placing

Test Method A—Specimen Weighed in Oven 4-10

Test Method B—Specimen Weighed Outside of Oven 11-17

small samples in cans or bottles and protecting larger samples

Test Method C—Karl Fischer Method 18-25

by wrapping in rubber sheets, moistureproof cellophane, or

1.3 The values stated in SI units are to be regarded as the other protective wrappings. These means do not provide

standard. The values given in parentheses are for information

continuous protection, and the test samples should be weighed

only. as soon as possible.

1.4 This standard does not purport to address all of the

3.1.3 When possible, bulk samples should be taken. These

safety concerns, if any, associated with its use. It is the samples should weigh from 100 to 300 g (3.5 to 10.5 oz), the

responsibility of the user of this standard to establish appro-

larger samples being taken when the moisture content is low or

priate safety and health practices and determine the applica- variable. Following the initial weighing, the bulk samples

bility of regulatory limitations prior to use.

should be cut up or torn into small pieces and then mixed and

allowed to stand overnight or longer in a sealed container to

2. Significance and Use

obtain moisture equilibrium before weighing out test speci-

2.1 These test methods determine the amount of moisture

mens; or the sample may be allowed to come to approximate

contained in a cellulose sample which determines the amount

equilibrium with the laboratory air and reweighed to determine

of bone dry cellulose present in a sample. The actual amount of

moisture change before weighing test specimens. The latter

cellulose in a sample is an essential entity when using cellulose

procedure is recommended since it permits routine weighing of

as a starting material for the production of cellulose deriva-

samples without the use of special weighing bottles or boxes,

tives.

and a series of accumulated samples can be weighed simulta-

neously. Predrying is very desirable on samples with a high

3. Sampling

moisture content (more than 5 % above equilibrium value).

3.1 Cellulose in a variety of forms is sampled for moisture,

When samples have been predried, calculate the moisture lost,

and no single set of directions can be given that is applicable

as follows:

to all types of cellulose material. The following general

R 5 M – A/A 3 100 (1)

@ #

considerations should be borne in mind.

3.1.1 Cellulose, either in compact form, such as wood,

where:

sheeted pulp or paper, baled cotton or baled staple rayon, or in R 5 moisture, air-dry sample basis, %,

loose form such as sawdust or chips, may have an appreciably M 5 original mass of the sample, g, and

A 5 air-dry mass of sample, g.

different moisture content in sections lying relatively close

3.1.4 The apparent moisture subsequently observed when

together. In order to secure representative samples, therefore, a

testing a predried sample must be calculated on the basis of the

bulk sample should be made up of small portions taken from

original sample mass in order to get the original moisture

various parts of the lot and having the proper proportion of

content. Calculate the original mass of the air-dried sample as

edge and center material.

follows:

Original sample mass, g 5 @A 3 ~100 1 R!#/100 (2)

1

These test methods are under the jurisdiction of ASTM Committee D-1 on Paint

NOTE 1—Example—If 1000 g (35 oz) of bulk (wet) sample on exposure

and Related Coatings, Materials, and Applications, and are the direct responsibility

to air lose 200 g (7 oz) of water, the apparent moisture content is 20 % and

of Subcom

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.