ASTM D7421-08

(Test Method)Standard Test Method for Determining Extreme Pressure Properties of Lubricating Oils Using High-Frequency, Linear-Oscillation (SRV) Test Machine

Standard Test Method for Determining Extreme Pressure Properties of Lubricating Oils Using High-Frequency, Linear-Oscillation (SRV) Test Machine

SIGNIFICANCE AND USE

This laboratory test method can be used to quickly determine extreme pressure properties of lubricating oils at selected temperatures specified for use in applications where not only high-speed vibrational or start-stop motions are present with high Hertzian point contact. This test method has found wide application in qualifying lubricating oils used in constant velocity joints of front-wheel-drive automobiles, gear-hydraulic circuit, rear axles, gears and engine components. Users of this test method should determine whether results correlate with field performance or other applications.

SCOPE

1.1 This test method covers a procedure for determining extreme pressure properties of lubricating oils for hydraulics, gears and engines under high-frequency linear-oscillation motion using the SRV test machine.

Note 1—This test method was developed and the international round robin tests were jointly performed with the DIN 51834 working group. This procedure is based on the 2005 revision of Test Method D 5706 for greases and differs regarding the stroke length and the cleaning solvent.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7421–08

Standard Test Method for

Determining Extreme Pressure Properties of Lubricating

Oils Using High-Frequency, Linear-Oscillation (SRV) Test

Machine

This standard is issued under the fixed designation D7421; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E45 Test Methods for Determining the Inclusion Content of

Steel

1.1 This test method covers a procedure for determining

G40 Terminology Relating to Wear and Erosion

extreme pressure properties of lubricating oils for hydraulics,

2.2 DIN Standards:

gears and engines under high-frequency linear-oscillation mo-

DIN 51631:1999 Mineral spirits; special boiling point spir-

tion using the SRV test machine.

its; requirements

NOTE 1—This test method was developed and the international round

DIN EN ISO 683-17 Heat-treated Steels, alloy steels and

robin tests were jointly performed with the DIN 51834 working group.

free-cutting steels – Part 17 : Ball and roller bearing steels

This procedure is based on the 2005 revision of Test Method D5706 for

(Replaces DIN 17230-1980)

greases and differs regarding the stroke length and the cleaning solvent.

DIN EN ISO 13565-2:1998 Geometrical Product Specifica-

1.2 The values stated in SI units are to be regarded as

tions (GPS) – Surface texture: Profile method; Surfaces

standard. No other units of measurement are included in this

having stratified functional properties – Part 2: Height

standard.

characterization using linear material ratio curve [Re-

1.3 This standard does not purport to address all of the

placement of DIN 4776:1990: Measurement of surface

safety concerns, if any, associated with its use. It is the

roughness; parameters R ,R ,R ,M ,M for the

K PK VK r1 r2

responsibility of the user of this standard to establish appro-

description of the material portion]

priate safety and health practices and determine the applica-

2.3 ISO Standards:

bility of regulatory limitations prior to use.

ISO 1250:1972 Mineral solvents for paints, white spirits

and related hydrocarbon solvents

2. Referenced Documents

2.1 ASTM Standards:

3. Terminology

A295/A295M Specification for High-Carbon Anti-Friction

3.1 Definitions:

Bearing Steel

3.1.1 break-in, n—in tribology, an initial transition process

D235 Specification for Mineral Spirits (Petroleum Spirits)

occurring in newly established wearing contacts, often accom-

(Hydrocarbon Dry Cleaning Solvent)

panied by transients in coefficient of friction or wear rate, or

D4175 Terminology Relating to Petroleum, Petroleum

both, which are uncharacteristic of the given tribological

Products, and Lubricants

system’s long-term behavior. G40

D5706 Test Method for Determining Extreme Pressure

3.1.2 coeffıcient of friction, µorf, n—in tribology, the

Properties of Lubricating Greases Using a High-

dimensionless ratio of the friction force (F) between two

Frequency, Linear-Oscillation (SRV) Test Machine

bodies to the normal force (N) pressing these bodies together.

D6425 Test Method for Measuring Friction and Wear Prop-

G40

erties of Extreme Pressure (EP) Lubricating Oils Using

3.1.3 Hertzian contact area, n—apparent area of contact

SRV Test Machine

between two nonconforming solid bodies pressed against each

other, as calculated from Hertz’s equations of elastic deforma-

tion published in 1881. G40

3.1.4 Hertzian contact pressure, n—magnitude of the pres-

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

sure at any specified location in a Hertzian contact area, as

D02.L0 on Industrial Lubricants.

Current edition approved Feb. 1, 2008. Published March 2008. DOI: 10.1520/

D7421-08.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Beuth Verlag GmbH (DIN, Deutsches Institut fur Normung

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM e.V.), Burggrafenstrasse 6, 10787, Berlin, Germany, http://www.en.din.de.

Standards volume information, refer to the standard’s Document Summary page on Available from International Organization for Standardization (ISO), 1 rue de

the ASTM website. Varembé, Case postale 56, CH-1211, Geneva 20, Switzerland, http://www.iso.ch.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7421–08

calculated from Hertz’s equations of elastic deformation. The

Hertzian contact pressure can also be calculated and reported

as maximum value P in the centre of the contact or as

max

P as average over the total contact area. G40

average

3.1.5 lubricant, n—any material interposed between two

surfaces that reduces the friction or wear, or both between

them. D4175

3.1.6 Ra (C.L.A.), n—in measuring surface finish, the arith-

metic average of the absolute distances of all profile points

from the mean line for a given distance. Amstutz

3.1.6.1 Discussion—C.L.A. means center line average, and

it is the synonym to Ra.

3.1.7 Rpk, n—Reduced peak height according to DIN EN

ISO13565-2:1998.Rpkisthemeanheightofthepeaksticking

out above the core profile section.

3.1.8 Rvk,, n—Reduced valley height according to DIN EN

ISO 13565-2:1998. Rvk is the mean depth of the valley

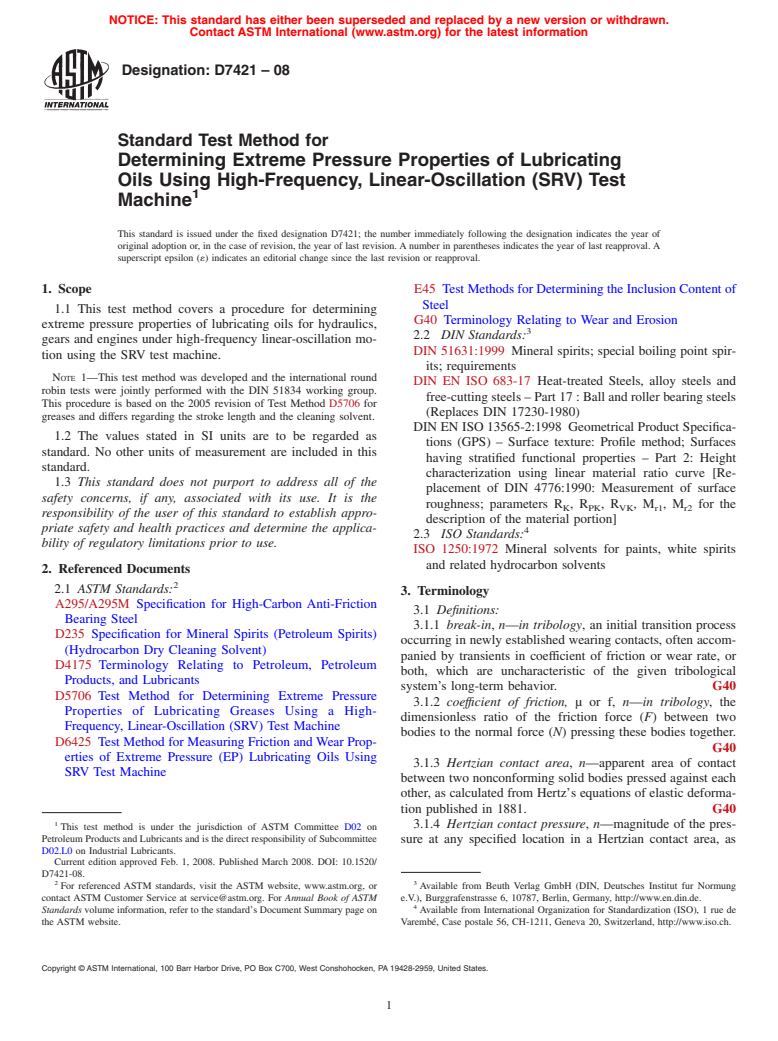

FIG. 1 SRV Test Machine (Model III)

reaching into the material below the core profile section.

3.1.9 Ry, n—in measuring surface finish, the vertical dis-

In SRV IV models, the test described here is run horizontally and without

tancebetweenthetopofthehighestpeakandthebottomofthe

inclination. SRV I and II models can also perform this test, but they are

deepest valley in one sampling length. Amstutz

limited with regard to maximum load and stroke. As modern and high

3.1.10 Rz (DIN), n—in measuring surface finish, the aver-

performance oils may exceed an O.K.-load of 1200 N, seizure may not be

age of all Ry values (peak to valley heights) in the assessment

reached. Optimol Instruments supplies an upgrade kit to allow for SRV I

5 6

length. Amstutz and SRV II models to be operated at 1600 N, if needed.

3.2 Definitions of Terms Specific to This Standard:

5. Significance and Use

3.2.1 extreme pressure, adj—in lubrication, characterized

5.1 This laboratory test method can be used to quickly

by metal surfaces in contact under high-stress rubbing condi-

determine extreme pressure properties of lubricating oils at

tions. It is not limited to metallic materials.

selected temperatures specified for use in applications where

3.2.2 seizure, n—localized fusion of metal or other materi-

not only high-speed vibrational or start-stop motions are

als between the rubbing surfaces of the test pieces.

present with high Hertzian point contact. This test method has

3.2.2.1 Discussion—In this test method, seizure is indicated

found wide application in qualifying lubricating oils used in

by a sharp rise in the coefficient of friction, over steady state,

constantvelocityjointsoffront-wheel-driveautomobiles,gear-

of >0.2 for over 20 s. In severe cases, a stoppage in the motor

hydraulic circuit, rear axles, gears and engine components.

will occur. (These criteria were believed to be right, because

Users of this test method should determine whether results

this test method is related to liquid lubricants.)

correlate with field performance or other applications.

3.2.3 SRV, n—Schwingung, Reibung, Verschleiß (Ger-

man); oscillating, friction, wear (English translation).

6. Apparatus

4. Summary of Test Method

illustrated in Figs. 1-3.

6.1 SRV Test Machine,

4.1 This test method is performed on an SRV test machine 6.2 Test Balls, 52100 steel, 60 6 2 Rc hardness, 0.025 6

0.005-µm Ra surface finish, 10-mm diameter.

using a steel test ball oscillating against a stationary steel test

disk with lubricant between them. Test load is increased in 6.3 Lower Test Disk, vacuum arc remelted (VAR) AISI

52100 steel with a inclusion rating using Method D, Type A,

100-N increments until seizure occurs. The load, immediately

prior to the load at which seizure occurs, is measured and and a severity level number of 0.5 according to Specification

A295/A295M or Test Methods E45 or an inclusion sum value

reported as O.K.-load, which can be converted in Hertzian

contact pressures. K1 # 10 in accordance with DIN EN ISO 683-17 and

spherodized annealed to obtain globular carbide, 60 62Rc

NOTE 2—Test frequency, stroke length, temperature, and ball and disk

hardness, with the surfaces of the disk being lapped and free of

material can be varied to simulate field conditions. The test ball yields

lapping raw materials. The topography of the disk will be

point-contact geometry. To obtain line or area contact, test pieces of

determined by four values, 24-mm diameter by 7.85 mm thick:

differing configurations can be substituted for the test balls.

NOTE 3—With regard to the test chamber and the operating conditions,

SRV models III and IV are identical. However, the SRV IV allows to

incline the axis of movement. Both models are fully computer controlled.

The sole source of supply of the apparatus known to the committee at this time

is Optimol Instruments GmbH,Westendstr. 125, D-80339 Munich, Germany. If you

are aware of alternative suppliers, please provide this information to ASTM

Amstutz, Hu, “Surface Texture: The Parameters,” Bulletin MI-TP-003-0785, International Headquarters. Your comments will receive careful consideration at a

Sheffield Measurement Division, Warner and Swasey, 1985. meeting of the responsible technical committee, which you may attend.

D7421–08

8.3 Turn the amplitude knob to ZERO.

8.4 Switch the stroke adjustment to AUTO position.

8.5 Set the frequency to 50 Hz.

8.6 Set the desired span and calibrate the chart recorder in

accordance with the manufacturer’s instructions. Select the

desired chart speed.

8.7 Turnontheheatercontrol,andpreheatthediskholderto

the desired temperature. 50°C, 80°C, and 120°C are recom-

mended (see Table 1). When the temperature has stabilized,

turn on the chart recorder and depress the drive start toggle

switchuntilthetimerbeginstocountandthenadjustthestroke

amplitude knob to 2.00 mm.

8.8 Set the load charge amplifier to setting that corresponds

to the 400-N load.

8.9 Change the load charge amplifier at each load in

accordance with the manufacturer’s instructions whe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.