ASTM B807-02

(Practice)Standard Practice for Extrusion Press Solution Heat Treatment for Aluminum Alloys

Standard Practice for Extrusion Press Solution Heat Treatment for Aluminum Alloys

SCOPE

1.1 This practice is intended to cover the controls necessary to press solution heat treat some 6xxx and 7xxx series aluminum alloys at extrusion facilities when the alloy design permits them to be so treated; specific alloys are shown in Table 1. For the alloys listed in , this practice is an alternate process to solution heat treatment in a furnace, such as specified in Practice B 918 for the attainment of T3, T4, T6, T7, T8 and T9-type tempers (See ANSI H35.1).

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B807–02

Standard Practice for

Extrusion Press Solution Heat Treatment for Aluminum

1

Alloys

This standard is issued under the fixed designation B 807; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

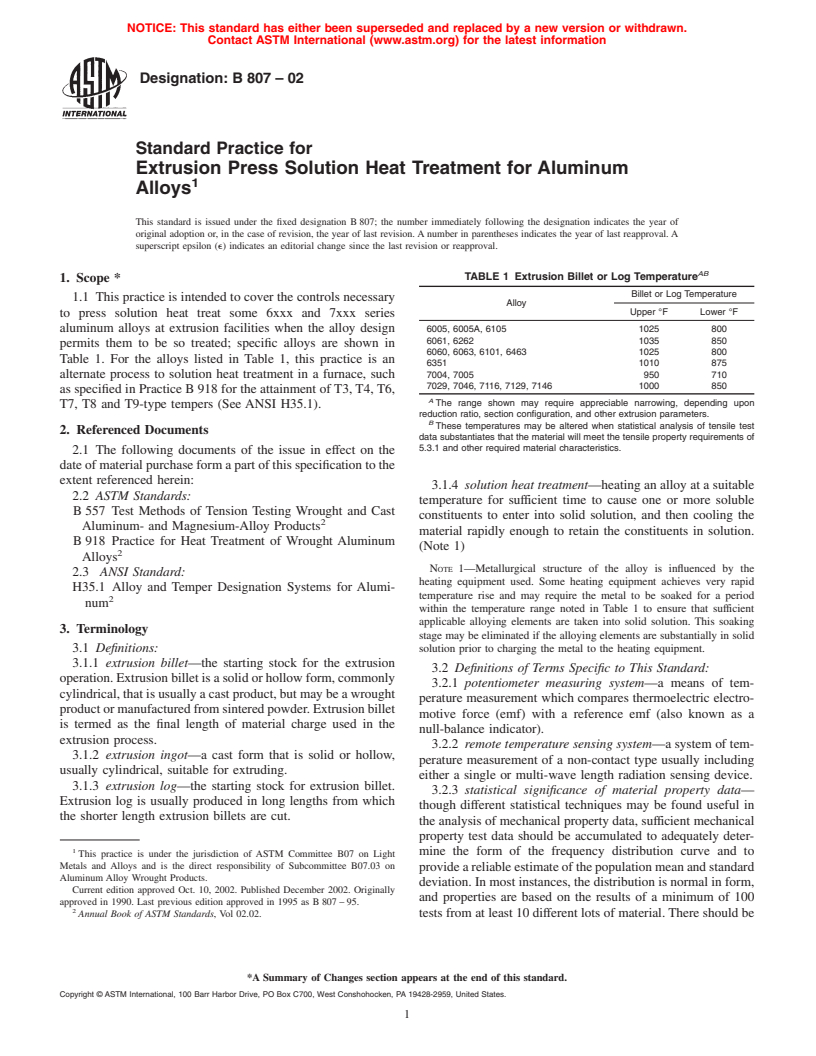

AB

TABLE 1 Extrusion Billet or Log Temperature

1. Scope *

Billet or Log Temperature

1.1 This practice is intended to cover the controls necessary

Alloy

Upper °F Lower °F

to press solution heat treat some 6xxx and 7xxx series

aluminum alloys at extrusion facilities when the alloy design

6005, 6005A, 6105 1025 800

6061, 6262 1035 850

permits them to be so treated; specific alloys are shown in

6060, 6063, 6101, 6463 1025 800

Table 1. For the alloys listed in Table 1, this practice is an

6351 1010 875

alternate process to solution heat treatment in a furnace, such 7004, 7005 950 710

7029, 7046, 7116, 7129, 7146 1000 850

as specified in Practice B 918 for the attainment of T3, T4, T6,

A

The range shown may require appreciable narrowing, depending upon

T7, T8 and T9-type tempers (See ANSI H35.1).

reduction ratio, section configuration, and other extrusion parameters.

B

These temperatures may be altered when statistical analysis of tensile test

2. Referenced Documents

data substantiates that the material will meet the tensile property requirements of

5.3.1 and other required material characteristics.

2.1 The following documents of the issue in effect on the

date of material purchase form a part of this specification to the

extent referenced herein:

3.1.4 solution heat treatment—heating an alloy at a suitable

2.2 ASTM Standards:

temperature for sufficient time to cause one or more soluble

B 557 Test Methods of Tension Testing Wrought and Cast

constituents to enter into solid solution, and then cooling the

2

Aluminum- and Magnesium-Alloy Products

material rapidly enough to retain the constituents in solution.

B 918 Practice for Heat Treatment of Wrought Aluminum

(Note 1)

2

Alloys

NOTE 1—Metallurgical structure of the alloy is influenced by the

2.3 ANSI Standard:

heating equipment used. Some heating equipment achieves very rapid

H35.1 Alloy and Temper Designation Systems for Alumi-

temperature rise and may require the metal to be soaked for a period

2

num

within the temperature range noted in Table 1 to ensure that sufficient

applicable alloying elements are taken into solid solution. This soaking

3. Terminology

stage may be eliminated if the alloying elements are substantially in solid

3.1 Definitions: solution prior to charging the metal to the heating equipment.

3.1.1 extrusion billet—the starting stock for the extrusion

3.2 Definitions of Terms Specific to This Standard:

operation.Extrusionbilletisasolidorhollowform,commonly

3.2.1 potentiometer measuring system—a means of tem-

cylindrical,thatisusuallyacastproduct,butmaybeawrought

perature measurement which compares thermoelectric electro-

productormanufacturedfromsinteredpowder.Extrusionbillet

motive force (emf) with a reference emf (also known as a

is termed as the final length of material charge used in the

null-balance indicator).

extrusion process.

3.2.2 remote temperature sensing system—a system of tem-

3.1.2 extrusion ingot—a cast form that is solid or hollow,

perature measurement of a non-contact type usually including

usually cylindrical, suitable for extruding.

either a single or multi-wave length radiation sensing device.

3.1.3 extrusion log—the starting stock for extrusion billet.

3.2.3 statistical significance of material property data—

Extrusion log is usually produced in long lengths from which

though different statistical techniques may be found useful in

the shorter length extrusion billets are cut.

the analysis of mechanical property data, sufficient mechanical

property test data should be accumulated to adequately deter-

1

mine the form of the frequency distribution curve and to

This practice is under the jurisdiction of ASTM Committee B07 on Light

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on

provideareliableestimateofthepopulationmeanandstandard

Aluminum Alloy Wrought Products.

deviation. In most instances, the distribution is normal in form,

Current edition approved Oct. 10, 2002. Published December 2002. Originally

and properties are based on the results of a minimum of 100

approved in 1990. Last previous edition approved in 1995 as B 807 – 95.

2

Annual Book of ASTM Standards, Vol 02.02. tests from at least 10 different lots of material. There should be

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.