ASTM B917/B917M-01

(Practice)Standard Practice for Heat Treatment of Aluminum-Alloy Castings from All Processes

Standard Practice for Heat Treatment of Aluminum-Alloy Castings from All Processes

SCOPE

1.1 This practice is intended, when specified by material specification or purchase order, for the use in the heat treatment of aluminum alloy castings from all casting processes.

1.1.1 The heat treatment of aluminum alloy castings used in specific aerospace applications is covered in AMS 2771 and specific AMS material specifications.

1.1.2 The heat treatment of wrought aluminum alloys is covered in Practice B 918.

1.2 The values stated in either inch-pound units or SI units are to be regarded separately as standards. The SI units are shown in brackets or in separate tables. The values stated in each system are not exact equivalents, therefore each system must be used independent of the other. Combining values from the two systems may result in non-conformance with the practice.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the usre of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B917/B917M–01

Standard Practice for

Heat Treatment of Aluminum-Alloy Castings from All

Processes

This standard is issued under the fixed designation B 917/B 917M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* B 557M TestMethodsofTensionTestingWroughtandCast

Aluminum and Magnesium- Alloy Products [Metric]

1.1 This practice is intended, when specified by material

B 618 Specification for Aluminum-Alloy Investment Cast-

specificationorpurchaseorder,fortheuseintheheattreatment

ings

of aluminum alloy castings from all casting processes.

B 686 Specification for Aluminum-Alloy Castings, High

1.1.1 The heat treatment of aluminum alloy castings used in

2 Strength

specific aerospace applications is covered in AMS 2771 and

B 881 Terminology Relating to Aluminum- and

specific AMS material specifications.

Magnesium-Alloy Products

1.1.2 The heat treatment of wrought aluminum alloys is

B 918 Practice for Heat Treatment of Wrought Aluminum

covered in Practice B 918.

Aloys

1.2 The values stated in either inch-pound units or SI units

G110 Practice for Evaluating Intergranular Corrosion Re-

are to be regarded separately as standards. The SI units are

sistance of Heat Treatable Aluminium Alloys by Immer-

shown in brackets or in separate tables. The values stated in

sion in Sodium Chloride + Hydrogen Peroxide Solution

each system are not exact equivalents, therefore each system

2.3 ANSI Standard:

must be used independent of the other. Combining values from

H35.1 Alloy and Temper Designation Systems for Alumi-

the two systems may result in non-conformance with the

num

practice.

1.3 This standard does not purport to address all of the

3. Terminology

safety concerns, if any, associated with its use. It is the

3.1 Definitions:

responsibility of the usre of this standard to establish appro-

3.1.1 Refer to Terminology B 881 for terminology relating

priate safety and health practices and determine the applica-

to the heat treatment of castings.

bility of regulatory limitations prior to use.

4. Equipment

2. Referenced Documents

4.1 Heating Media—Aluminum castings are typically heat

2.1 The following documents of the issue in effect on the

treated in air chamber furnaces; however lead baths, oil baths,

dateofmaterialpurchaseformapartofthisspecificationtothe

fluidized beds, or even superheated steam may be used in

extent referenced herein:

specific applications. However the use of uncontrolled heating

2.2 ASTM Standards:

is not permitted. Whichever heating means are employed,

B 26/B 26M Specification for Aluminum-Alloy Sand Cast-

3 careful evaluation is required to ensure that the casting

ings

responds properly to heat treatment and is not overheated or

B 108 Specification for Aluminum-Alloy Permanent Mold

3 damaged by the heat treatment environment. Salt baths are not

Castings

recommended for the commercial heat treatment of aluminum

B 275 Practice for Codification of Certain Nonferrous Met-

3 castings in volume. (Warning: Nitrate baths must not be used

als and Alloys, Cast and Wrought

in the heat treatment of 5xx.0 series castings because of the

B 557 Test Methods of Tension Testing Wrought and Cast

3 inherent explosion hazard.

Aluminum and Magnesium-Alloy Products

4.2 Air Chamber Furnaces may be oil or gas-fired or may

be electrically heated. The atmosphere in air chamber furnaces

must be controlled to prevent porosity resulting from solution

This practice is under the jurisdiction of ASTM Committee B07 on Light heat treatment. Furnace components that are significantly

Metals and Alloys and is the direct responsibility of Subcommittee B07.01 on

Aluminum Alloy Ingots and Castings.

Current edition approved June 10, 2001. Published September 2001.

2 4

Available from SAE-AEROSPACE, 400 Commonwealth Drive, Warrendale, Annual Book of ASTM Standards, Vol 03.02.

PA 15096-0001, USA. Available fromAmerican National Standards Institute, 25West 43rd Street, 4th

Annual Book of ASTM Standards, Vol 02.02. Floor, New York, NY 10036.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B917/B917M–01

hotter than the metal should be suitably shielded for section 5.2.2 A new temperature survey shall be made after any

thicknesses of less than 0.250 in. [6 mm] to prevent adverse modification, repair, adjustment (for example, to power con-

radiation effects. The atmosphere in air chamber furnaces must trols, or baffles), or rebuild which may have altered the

be controlled to prevent porosity resulting from solution heat temperature uniformity characteristics of the furnace and

treatment (see Note 1). The suitability of the atmosphere in an

reduced the effectiveness of the heat treatment.

air-chamber furnace can be demonstrated by testing, in accor-

5.3 Batch Furnace Surveys:

dance with 8.4.3.1, that products processed in that furnace are

5.3.1 The initial temperature survey shall be made at the

substantially free of heat treat induced porosity.

maximum and minimum temperature of solution heat treat-

ments and precipitation heat treatments for which each furnace

NOTE 1—Heat treat induced porosity may lower mechanical properties

and commonly causes blistering of the surface of the material. The is to be used. There shall be at least one test location for each

3 3

condition is most likely to occur in furnaces in which the products of

25 ft [0.70 m ] of air furnace volume up to a maximum of 40

combustion contact the work, particularly if the gases are high in water

test locations, with a minimum of nine test locations, one in

vapor or contain compounds of sulfur. Surface discoloration is a normal

each corner and one in the center.

result of solution heat treatment of aluminum alloys and should not be

5.3.2 After the initial survey, each furnace shall be surveyed

interpreted as evidence of damage from overheating or as heat treat

induced porosity. monthly, except as provided in 5.3.7.The monthly survey shall

be at one operating temperature for solution heat treatment and

4.3 Automatic Recording and Control Equipment to control

one for precipitation heat treatment.

temperature of air furnaces shall be capable of maintaining

5.3.3 There shall be at least one test location for each 40 ft

temperature in the working zone to within 6 10°F [6 5°C] of

[1 m ] of load volume, with a minimum of nine test locations,

the specified temperature.

one in each corner and one in the center.

4.4 Quench Baths—Quenching is normally performed by

5.3.4 The surveys shall reflect the normal operating charac-

immersion of castings in a hot-water bath as described in

teristics of the furnace. If the furnace is normally charged after

Tables 1-4. The water baths must be located close enough to

being stabilized at the correct operating temperature, the

solutionheat-treatingfacilitiestominimizedelayinquenching.

temperature-sensing elements shall be similarly charged. If the

Tanks must be of adequate size for the expected work load and

furnace is normally charged cold, the temperature-sensing

must have the means of providing adequate circulation of the

quenching media about the work load. Means for heating or elements shall be charged cold. After insertion of the

temperature-sensing elements, readings should be taken fre-

cooling the quench water should be available when needed.

quently enough to determine when the temperature of the

NOTE 2—Quenching may be performed by alternative means such as

hottest region of the furnace approaches the bottom of the

total immersion in a glycol and water solution, a liquefied gas, cold water,

temperaturerangebeingsurveyed.Fromthattimeuntilthermal

hot water, or boiling water, or by air blast or fog to minimize distortion

equilibrium is reached, the temperature of all test locations

provided samples from the material, so quenched, will conform to the (a)

mechanical properties, (b) other requirements of the applicable casting should be determined at 2-min intervals in order to detect any

specification and (c) not exhibit more intergranular corrosion susceptibil-

over-shooting. After thermal equilibrium is reached, readings

ity than if the metal was immersion quenched in cold water. The use of

should be taken at 5-min intervals for sufficient time to

water sprays or high-velocity high-volume jets of water in which the

determine the recurrent temperature pattern, but for not less

material is thoroughly and effectively flushed is satisfactory for quench-

than30min.Beforethermalequilibriumisreached,noneofthe

ing. Alternative quench media are frequently contingent on the particular

temperature readings should exceed the maximum temperature

alloy and the end use of the casting.

of the range being surveyed. After thermal equilibrium is

5. Furnace Temperature Uniformity and Calibration reached, the maximum temperature variation of all elements

Requirements

(both load and furnace thermocouples) shall not exceed 20°F

[10°C] and shall not vary outside the range being surveyed.

5.1 Calibration of Equipment:

3 3

5.3.5 Forfurnacesof10ft [0.25m ]orlessthetemperature

5.1.1 Thermocouple wire and sensors shall be calibrated

survey may be made with a minimum of three thermocouples

against wire or sensors whose calibration is traceable to the

located at front, center, and rear or at top, center, and bottom of

National Institute of Standards and Technology (NIST). Ther-

the furnace.

mocouples made from calibrated wire rolls may be used in lieu

of individually calibrated thermocouples in which case, the roll 5.3.6 For furnaces used only for precipitation treatment,

calibration shall be that of the average of samples taken from after the initial temperature-uniformity survey, as outlined in

both ends of the roll.The roll shall not be used if the difference 5.3.7, surveys need not be made more often than at each

in the highest and lowest reading exceeds 2°F [1°C]. 6-month interval provided that (a) test specimens from each lot

are tested and meet applicable material specifications require-

5.1.2 Working instruments shall be calibrated at least once

every three months against a test instrument that is traceable to ments, (b) the furnace is equipped with a multipoint recorder,

or (c) one or more separate load thermocouples are employed

the National Institute of Standards and Technology (NIST).

Accuracy shall be 6 0.3 % of range. to measure and record actual metal temperatures.

5.2 Furnace Temperature Survey:

5.3.7 Monthly surveys for batch furnaces are not necessary

5.2.1 A temperature survey, to ensure compliance with the when the furnace or bath is equipped with a permanent

applicable recommendations presented herein, shall be per- multipoint recording system with at least two sensing thermo-

formed for each furnace. couples in each zone or when one or more separate load

B917/B917M–01

thermocouples are employed to measure actual metal tempera- 5.5 Monitoring of Quench—A monitoring plan shall be

ture, providing that uniformity surveys show a history of developed and utilized for all modes of quenching for all

products covered by this practice. The plan should incorporate

satisfactory performance for a period of at least 6 months. The

sensing thermocouples shall be installed so as to record the conductivity or hardness checking, or both, to determine the

uniformity of the quench. Areas having substantially higher

temperature of the heated media (air, lead, etc.) or actual metal

conductivity or lower hardness than other areas of similar

temperatures. However, periodic surveys shall also be made at

thickness in the lot shall be investigated to ensure that the

6-month intervals in accordance with the procedures outlined

requirements of the material specification are met.

for the monthly survey.

5.6 Temperature-Measuring System Check—The accuracy

5.4 Continuous Furnace Surveys:

of the temperature-measuring system shall be checked under

5.4.1 For continuous heat-treating furnaces, the type of

operating conditions weekly. Check should be made by insert-

survey and the procedures for performing the survey should be

ing a calibrated test temperature-sensing element adjacent to

established for each particular furnace involved. The types of

the furnace temperature-sensing element and reading the test

continuous heat-treating furnaces may vary considerably, de-

temperature-sensing element with a calibrated test potentiom-

pending upon the product and sizes involved. For some types

eter. When the furnace is equipped with dual potentiometer

and sizes of furnaces, the only practical way to survey the

measuring systems which are checked daily against each other,

furnace is to perform an extensive mechanical property survey

the above checks may be conducted every 3 months rather than

of the limiting product sizes to verify conformance with the

every week. The test temperature-sensing element, potentiom-

specified mechanical properties for such items. When the type

eter, and cold junction compensation combination shall have

and size of the furnace makes this practical, monthly surveys

been calibrated against National Institute of Standards and

should be made, using a minimum of two load thermocouples

Technology primary or secondary certified temperature-

attached to the material. The surveys should reflect the normal

sensing elements, within the previous 3 months, to an accuracy

operating characteristics of the furnace. The results of these

of 6 2°F [6 1°C].

surveys shall indicate that the metal temperature never exceeds

5.6.1 If the difference between the two readings in 5.6

the allowable maximum metal temperature specified for solu-

exceeds 6 10°F [6 6°C], the cause of the difference shall be

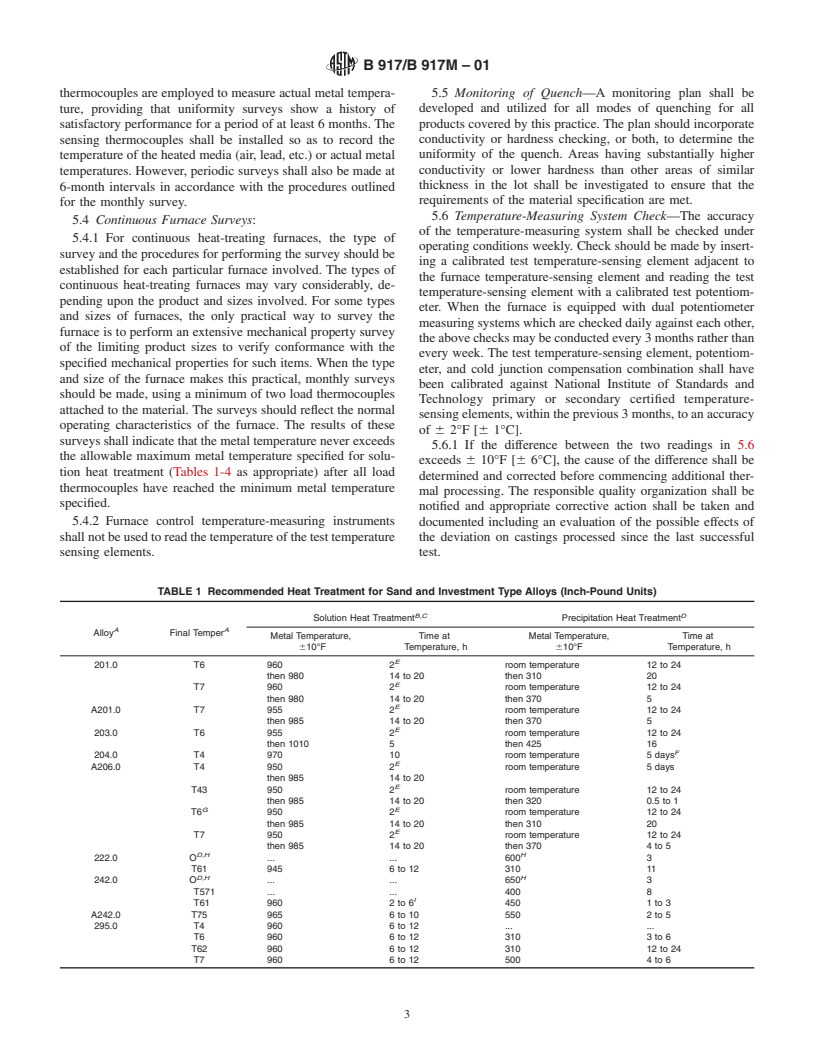

tion heat treatment (Tables 1-4 as appropriate) after all load

determined and corrected before commencing additional ther-

thermocouples have reached the minimum metal temperature

mal processing. The responsible quality organization shall be

specified.

notified and appropriate corrective action shall be taken and

5.4.2 Furnace control temperature-measuring instruments

documented including an evaluation of the possible effects of

shallnotbeusedtoreadthetemperatureofthetesttemperature the deviation on castings processed since the last successful

sensing elements. test.

TABLE 1 Recommended Heat Treatment for Sand and Investment Type Alloys (Inch-Pound Units)

B,C D

Solution Heat Treatment Precipitation Heat Treatment

A A

Alloy Final Temper

Metal

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.