ASTM D6973-03

(Test Method)Standard Test Method for Indicating Wear Characteristics of Petroleum Hydraulic Fluids in a High Pressure Constant Volume Vane Pump

Standard Test Method for Indicating Wear Characteristics of Petroleum Hydraulic Fluids in a High Pressure Constant Volume Vane Pump

SCOPE

1.1 This test method covers a constant volume high-pressure vane pump test procedure for indicating the wear characteristics of petroleum hydraulic fluids. See for recommended testing conditions for water-based synthetic fluids.

1.2 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 6973 – 03

Standard Test Method for

Indicating Wear Characteristics of Petroleum Hydraulic

Fluids in a High Pressure Constant Volume Vane Pump

This standard is issued under the fixed designation D 6973; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 flushing, v—the process of cleaning the test system

before testing to prevent cross-contamination.

1.1 This test method covers a constant volume high-

pressure vane pump test procedure for indicating the wear

4. Summary of Test Method

characteristics of petroleum hydraulic fluids. See Annex A1 for

4.1 Hydraulic fluid in the amount of 190 6 4 L (50 6 1 gal)

recommended testing conditions for water-based synthetic

is circulated through a rotary vane pump system for 50 h at a

fluids.

pump speed of 2400 6 20 r/min and a pump outlet pressure of

1.2 The values stated in SI units are to be regarded as

20.7 6 0.2 MPa (3000 6 20 psig). Fluid temperature at the

standard. The values in parentheses are for information only.

pump inlet is 95 6 3°C (203 6 5°F). An ISO Grade 32 or 10W

1.3 This standard does not purport to address all of the

viscosity is required.

safety concerns, if any, associated with its use. It is the

4.2 The cam ring and all ten vanes should be individually

responsibility of the user of this standard to establish appro-

weighed before and after the test. The weight loss of the cam

priate safety and health practices and determine the applica-

ring should be reported with the combined weight loss of all

bility of regulatory limitations prior to use.

ten vanes. The intra-vanes are not part of the required weight

2. Referenced Documents loss measurements and should be separately measured if

desired. Other reported values are fluid cleanliness before and

2.1 ISO Standards:

after the test, initial flow rate, and final flow rate.

ISO 4021 Hydraulic Fluid Power—Particulate Contamina-

4.3 Prior to installing the hydraulic test fluid into the rig, a

tion Analysis—Extraction of Fluid Samples from Lines of

stand flush is required to remove any contaminants. A mini-

an Operating System

mum quantity of 190 6 4 L (50 6 1 gal) of fluid (see Note 1)

ISO 4406 Hydraulic Fluid Power—Fluids—Method for

made of the same chemical formulation as the test fluid, is

Coding the Level of Contamination by Solids Particles

required for the stand flush. Therefore the total quantity of oil

ISO 11171 Hydraulic Fluid Power—Calibration of Auto-

required for the test is 380 L (100 gal).

matic Particle Counters for Liquids

ISO 11500 Hydraulic Fluid Power—Determination of Par-

5. Significance and Use

ticulate Contamination by Automatic Counting Using the

5.1 This test method is an indicator of the wear character-

Light Extinction Principle

3 istics of petroleum hydraulic fluids operating in a constant

2.2 SAE Standard:

volume vane pump. Excessive wear in vane pumps could lead

SAE 100R13–20 Hydraulic Hose Specification

to malfunction of hydraulic systems in critical industrial or

3. Terminology mobile hydraulic applications.

3.1 Definitions of Terms Specific to This Standard:

6. Apparatus

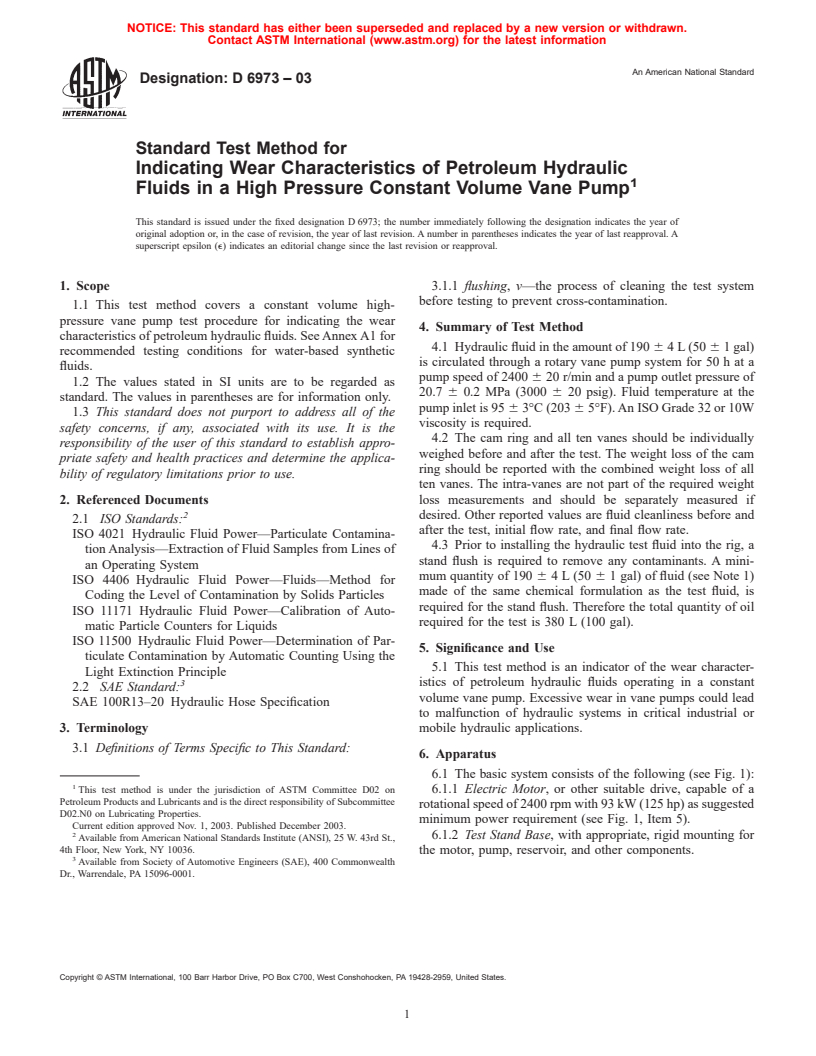

6.1 The basic system consists of the following (see Fig. 1):

This test method is under the jurisdiction of ASTM Committee D02 on 6.1.1 Electric Motor, or other suitable drive, capable of a

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

rotational speed of 2400 rpm with 93 kW (125 hp) as suggested

D02.N0 on Lubricating Properties.

minimum power requirement (see Fig. 1, Item 5).

Current edition approved Nov. 1, 2003. Published December 2003.

6.1.2 Test Stand Base, with appropriate, rigid mounting for

Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036.

the motor, pump, reservoir, and other components.

Available from Society of Automotive Engineers (SAE), 400 Commonwealth

Dr., Warrendale, PA 15096-0001.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6973–03

NOTE—See Eaton Overhaul Manual I-3144–S (Appendix B)

FIG. 1 System Schematic

,

4 5

6.1.3 Rotary Intra-Vane Pump, replaceable cartridge type, 6.1.4 Reservoir, equipped with a baffle and lid, all of

Vickers 35VQ25A-11*20 (Cartridge Kit P/N 413421) rated at stainless steel construction.

3 3

81 cm /rev (4.98 in. /rev) flow at 1200 rev/min. A protective 6.1.4.1 Additional fluid ports may be added to the reservoir

shield around the pump is recommended.

as required by the user to assist in measuring fluid level,

6.1.3.1 There are to be no modifications to the pump reservoir temperature, and so forth.

housing.

6.1.4.2 If the reservoir is positioned so that the contents

cannot be visually checked for air entrainment by removing the

lid, a fluid-sight glass viewing port may be located in the side

The replaceable cartridge consists of the inlet support plate, outlet support

of the reservoir.

plate, flex side plates, seal pack, rotor, cam ring, intra-vane, and vanes.

6.1.5 Pump Outlet Pressure Control Valve, with either

The individual cartridge parts can be purchased separately, if desired. The

Eaton part numbers for these items are cartridge screws: P/N 410609, alignment

manual or remote control (see Fig. 1, Item 7).

pins: P/N 418108, inlet support plate: P/N 430806, outlet support plate: P/N 412003,

6.1.6 Temperature-control Device, suitable for controlling

flex side plate kit: P/N 923953, seal pack: P/N 433766, rotor: P/N 262154, cam ring:

coolant flow to the heat exchanger to maintain test fluid at the

P/N 319396, vane kit (includes ten intra-vanes and ten vanes): 922700.

Available from any Eaton distributor. specified temperature (see Fig. 1, Item 9).

D6973–03

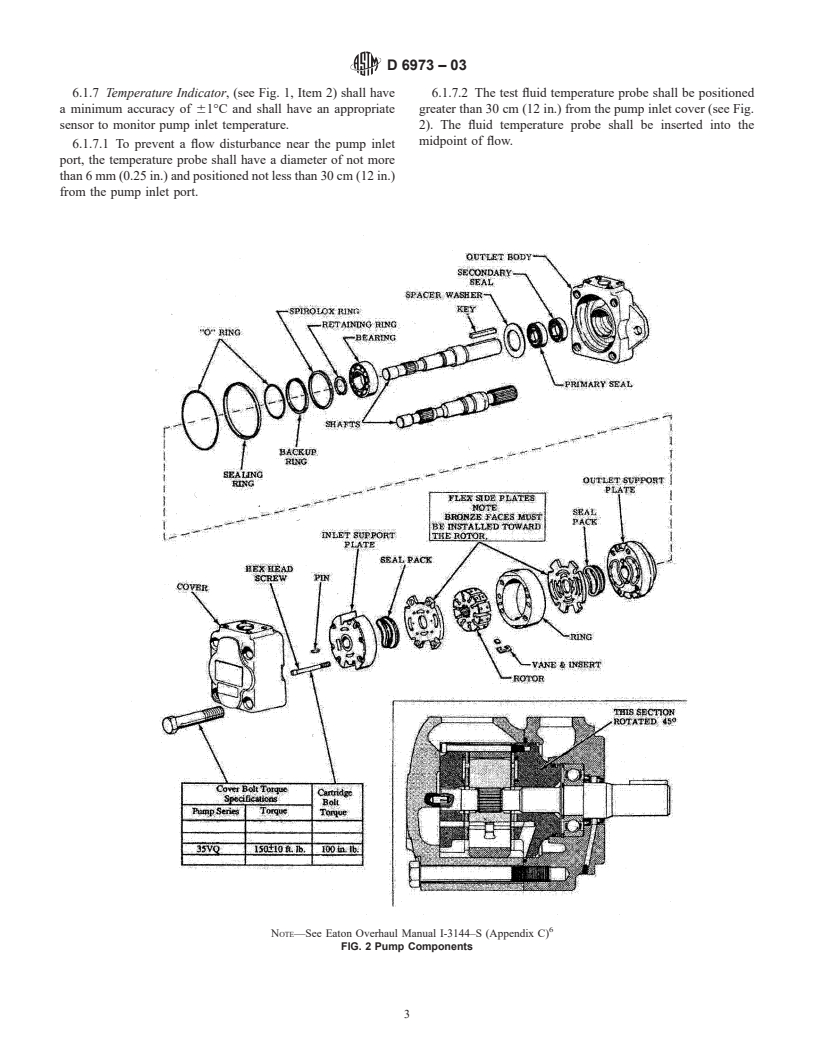

6.1.7 Temperature Indicator, (see Fig. 1, Item 2) shall have 6.1.7.2 The test fluid temperature probe shall be positioned

a minimum accuracy of 61°C and shall have an appropriate greater than 30 cm (12 in.) from the pump inlet cover (see Fig.

sensor to monitor pump inlet temperature. 2). The fluid temperature probe shall be inserted into the

midpoint of flow.

6.1.7.1 To prevent a flow disturbance near the pump inlet

port, the temperature probe shall have a diameter of not more

than 6 mm (0.25 in.) and positioned not less than 30 cm (12 in.)

from the pump inlet port.

NOTE—See Eaton Overhaul Manual I-3144–S (Appendix C)

FIG. 2 Pump Components

D6973–03

6.1.8 Heat-Exchanger, (see Fig. 1, Item 9). The heat ex- 6.2.7 The inlet line (from the reservoir to the pump intake)

changer should be of adequate size and design to remove the shall have an internal diameter of at least 5.08 cm (2 in.) and

excess heat from the test system when utilizing the available shall have a straight run of at least 61 cm (24 in.) to the pump

coolant supply. inlet port.

6.1.9 Outlet Pressure Indicator, (see Fig. 1, Item 6), to

NOTE 2—Some users prefer to use a radius bend at the reservoir outlet

measure pump discharge pressure, and shall have an accuracy

instead of an elbow. If used, the straight run described in 6.2.7, shall still

of at least 61 bar (615 psi). be measured between the end of the bend and the pump inlet port.

6.1.10 Inlet Pressure Indicator, (see Fig. 1, Item 3), to

6.2.8 The high pressure discharge line (from the pump to the

measure pump inlet pressure, and shall have an accuracy of at

pressure control valve) shall have a minimum inside diameter

least 67 kPa (61 psi). 1

of 1 ⁄4 in. with a maximum allowable working pressure rating

6.1.11 Filter Unit, (see Fig. 1, Item 8), to limit system debris

greater than 207 Bar (3000 psi). A seamless steel pipe size and

from causing wear to the test pump. The filter performance

schedule (2 in. double extra strong pipe–XXS) or equivalent

should be b $ 100.

3 high-pressure hose (SAE 100R13–20) are recommended for

6.1.11.1 The filter housing shall be installed with dual the discharge line.

6.2.9 The fluid return line and fittings (from the pressure

pressure gages (see Fig. 1, Item 13) or a differential pressure

transducer to monitor pressure across the filter to warn of control valve to the filter, flow meter, heat exchanger, and

impending collapse of the element. reservoir) should have a minimum inside diameter of 2.54 cm

(1 in.). A seamless steel pipe size of (1 in. Schedule 40) is

6.1.11.2 If dual pressure gages are used to monitor filter

recommended.

pressure, the rated collapse pressure of the filter element should

be known.

NOTE 3—Some users find the addition of a shut-off valve on the return

6.1.12 Flow-Measuring Device, (see Fig. 1, Item 12), with

line to be a useful addition to the piping since it allows filter changes and

other system maintenance to be performed without draining the reservoir.

an accuracy of at least 61 L/min (60.25 gpm).

(Warning—If a shut-off valve is installed in the fluid return line, the user

6.1.12.1 It is suggested that the test circuit be equipped with

shall take procedural steps to ensure that this valve has been opened before

some automated shutdown capabilities for safety reasons.

the pump is started. If the valve is not opened, low pressure system

Safety relays could be any of the following: low-level, high

components may rupture.)

pressure, high temperature, and low flow safety switches

6.2.10 A shut-off valve may be located in the plumbing

incorporated into the system.

between the reservoir and the inlet to the pump. The full flow

6.1.12.2 A check should be made to ensure that the flush and

valve shall have a minimum orifice diameter of 5.08 cm (2 in.)

test fluid are compatible with seals or any other materials in the

and shall be positioned no closer than 30 cm (12 in.) from the

system.

pump inlet port.

6.1.13 Flexible Motor Coupling, to connect the motor drive

and the pump.

7. Reagents and Materials

6.1.14 Fluid Sampling Port, in accordance with ISO 4021.

7.1 Warning—Use adequate safety provisions with all

6.2 The various components of the test system shall be

solvents.

placed in the system as indicated in Fig. 1.

7.2 Aliphatic Naphtha, Stoddard solvent or equivalent is

6.2.1 The test system shall be arranged and provided with

satisfactory. (Warning—Combustible. Vapor harmful.)

necessary drain valves so that complete draining is possible

7.3 Precipitation Naphtha.(Warning—Extremely flam-

with no fluid trap areas.

mable. Harmful if inhaled. Vapors can cause flash fire.)

6.2.2 Good hydraulics piping practices should be used when

7.4 Isopropanol.(Warning—Flammable.) (Warning—In

constructing the test system to avoid air entrainment points and

instances when the solvents listed in Section 7 are not effective,

flow restrictions.

alternative solvents may be used. It is the responsibility of the

6.2.3 The pump should be mounted so that its internal user to determine the suitability of alternative solvents and any

hazards associated with their use.)

surfaces can easily be inspected and cleaned, alignment can be

checked, and the operator has comfortable access when torqu-

8. Test Stand Maintenance

ing the head.

6.2.4 A pressure transducer, to measure inlet pressure, shall 8.1 Sensors and shut-off switches shall be checked periodi-

be placed within 30.5 cm (12 in.) of the opening of the pump cally for proper calibration and operation in accordance with

cover.

good engineering practice, as determined by the user.

8.2 It is recommended that the pump shaft (P\N 242287),

6.2.5 The inlet pressure of the pump shall be 13.8 6 7 kPa

shaft seal (P\N 394973), and shaft bearings (P\N 38441 or

(2 6 1 psig) once the break-in procedure is complete and test

equivalent) (see Fig. 2) be replaced after every ten test runs (or

conditions have been met (see 12.2).

sooner if high weight loss, vibration, cavitation, or visual

NOTE 1—See Annex A1 for recommended testing conditions for

deterioration is encountered).

water-based synthetic fluids.

8.3 Inspect the pump cover and body for evidence of galling

6.2.6 The reservoir should be mounted so that it can be marks or excessive wear and replace if distress is observed.

cleaned and filled with ease and the contents may be readily Visually examine the interior of the pump cover and outlet

inspected by removal of the reservoir lid or inspection cover. body. Replace if evidence of deterioration is observed.

D6973–03

8.4 Check the surface inside the pump outlet body, where 11. Preparation and Installation of Test Cartridge

the shaft seal is positioned, for conditions that may cause the

11.1 Disassemble the 35VQ25A-11*20, Fig. 1, and identify

seal to leak.

the vanes, cam ring, and side plates, Fig. 2, for reassembly into

8.5 Check alignment of the pump and motor shafts. Maxi-

the same location.

mum values of 0.08 mm (0.003 in.) parallel misalignment and

11.2 Using a solvent, thoroughly clean the cam ring and set

0.3° angular misalignment are suggested limits.

of ten vanes. Allow the cam ring and vanes to dry. Weigh

8.6 Alignment checks shall be made with a torqued car-

(separately) the cam ring and the complete set of ten vanes

tridge in place.

(without intra-vanes). Determine these weights to the nearest

8.7 Using a dial indicator to check run out, inspect the shaft

milligram and record the values. The vanes shall be demagne-

for a bent condition by rotating it by hand with the motor

tized before being weighed. Demagnetize with a degausser as

coupling removed.

needed.

8.8 Periodically clean the four tapped holes, which receive

11.3 Assemble the test cartridge according to Eaton Over-

the pump head bolts and the threads of the head bolts

haul Manual I-3144-S. Make certain of proper vane insertion

themselves. The threads may be coated with a light oil to

into the rotor and correct rotor and inner and outer bushing

prevent corrosion. To ensure even torquing of the cartridge,

direction and alignment. The vanes shall be checked for free

housings, or head bolts with damaged threads shall be dis-

movement in rotor slots when assembling.

carded.

8.9 Periodic disassembly of the relief valve for cleaning and

12. Procedure

inspection is recommended.

12.1 Break-in:

9. Sampling

12.1.1 Install the 35VQ25A-11*20 pump.

12.1.2 Jog the pump to release any entrained air that is in the

9.1 The sample of fluid shall be thoroughly representative of

system.

the material in question, and the portion used for the test shall

12.1.3 Set the pump speed to 2400 6 20 rpm, pump outlet

be thoroughly representative of the sample itself.

pressure

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.