ASTM F1625-00(2018)

(Specification)Standard Specification and Test Method for Rear-Mounted Bicycle Child Carriers

Standard Specification and Test Method for Rear-Mounted Bicycle Child Carriers

ABSTRACT

This specification covers rear-mounted bicycle child carriers. It does not cover child carriers mounted in front of handlebars or to the top tube, head tube, or behind the handlebars in front of the rider. The carrier shall be manufactured free of burrs, sharp edges, and sharp points; when present, these shall be properly covered with protective coatings to prevent injuries. In addition, the carrier shall be equipped with a rear reflector, footrests, backrest, armrests, protective devices to prevent contact of hands and feet with moving or movable components of the bicycle, and belt or capturing devices to keep the child from standing in or leaving the carrier. The carrier shall be protected against corrosion, with any plastic or synthetic components stabilized against ultraviolet radiation and resistant to ozone. Tests for high and low temperature resistance, high and low temperature drop, and strength shall be performed and shall conform to the requirements specified. Additional tests for flammability, sharp points, sharp edges, ambient drop, retention system pull, and retention system security may be performed as well.

SCOPE

1.1 This specification covers child carriers that mount to the rear of bicycles in order to transport children or accessory loads with a maximum weight of 18 kg (40 lb). This specification does not apply to child carriers that mount in front of the handlebars, or to the top tube, head tube, or behind the handlebars in front of the rider.

Note 1: In the instructions, the manufacturer must warn the rider that a load added to the bicycle will lessen the stability and alter the riding characteristics of the bicycle. This complication is particularly important when riding with children who are near the high end of the weight range.

1.2 The following safety hazards caveat pertains only to the test method portions, Sections 5, 6, and 7, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1625 −00 (Reapproved 2018) An American National Standard

Standard Specification and Test Method for

Rear-Mounted Bicycle Child Carriers

This standard is issued under the fixed designation F1625; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.3 Government Standards:

Title 16,Code of Federal Regulations, Part 1500.44, Flam-

1.1 Thisspecificationcoverschildcarriersthatmounttothe

mability

rearofbicyclesinordertotransportchildrenoraccessoryloads

Title 16,Code of Federal Regulations, Part 1500.48, Sharp

with a maximum weight of 18 kg (40 lb). This specification

Points

does not apply to child carriers that mount in front of the

Title 16,Code of Federal Regulations, Part 1500.49, Sharp

handlebars, or to the top tube, head tube, or behind the

Edges

handlebars in front of the rider.

16CFR 1501, Small Parts

NOTE 1—In the instructions, the manufacturer must warn the rider that

16CFR 1303, Lead in Coatings

a load added to the bicycle will lessen the stability and alter the riding

characteristics of the bicycle. This complication is particularly important

3. Terminology

when riding with children who are near the high end of the weight range.

3.1 Definitions:

1.2 The following safety hazards caveat pertains only to the

3.1.1 bicycle child carrier—a seating device, the shape of

test method portions, Sections 5, 6, and 7, of this specification:

which is adapted to the seated position of a child and mounts

This standard does not purport to address all of the safety

to the rear of the bicycle, which keeps the child in a

concerns, if any, associated with its use. It is the responsibility

comfortable position during the ride.

of the user of this standard to establish appropriate safety,

health, and environmental practices and determine the appli-

4. Requirements

cability of regulatory limitations prior to use.

4.1 General—Childcarriersshallbedesignedandmanufac-

1.3 This international standard was developed in accor-

tured in such a way that components with which the child or

dance with internationally recognized principles on standard-

rider come into contact do not cause injuries during normal

ization established in the Decision on Principles for the

use, or when used in accordance with the manufacturer’s

Development of International Standards, Guides and Recom-

instructions.Surfacesmustbefreefromburrs,sharpedges,and

mendations issued by the World Trade Organization Technical

points; if such are present they must be covered by protective

Barriers to Trade (TBT) Committee.

coverings.Noopeningswithwhichthechild’shandscancome

in contact shall have dimensions larger than 6 mm (0.236 in.)

2. Referenced Documents

but also smaller than 13 mm (0.512 in.), that is, holes with

2.1 ASTM Standards:

dimensions between 0.236 and 0.512 in. (6 and 13 mm) are

B117Practice for Operating Salt Spray (Fog) Apparatus

forbidden.Childcarriersmustbeequippedwitharearreflector.

2.2 ISO Standards:

The manufacturer must warn the rider that a load added to the

ISO/TC149/SC1N368, Luggage Carriers for Bicycles

bicycle will lessen the stability and alter the riding character-

ISO/TC149/SC1 N369, Child Seats for Bicycles, Concepts,

istics of the bicycle.

Safety Requirements and Testing

4.2 Structure:

4.2.1 Assembly—When assembled in accordance with the

instructionsprovidedbythemanufacturer,theseatcomponents

This specification is under the jurisdiction ofASTM Committee F08 on Sports

must be firmly joined and fixed.

Equipment, Playing Surfaces, and Facilities and is the direct responsibility of

Subcommittee F08.10 on Bicycles.

4.2.2 Equipment—Child carriers shall be equipped with the

Current edition approved April 1, 2018. Published May 2018. Originally

following equipment:

approved in 1995. Last previous edition approved in 2012 as F1625–00 (2012).

4.2.2.1 Footrests,

DOI: 10.1520/F1625-00R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 4.2.2.2 Backrest,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St., 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

4th Floor, New York, NY 10036, http://www.ansi.org. www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1625 − 00 (2018)

4.2.2.3 Armrests (that may be extensions of the sides of the 5. Environmental Temperature Tests

seat surface),

5.1 General—Performthetestsinthissectiononallcarriers

4.2.2.4 Protective devices that prevent contact of hands and

to determine whether there are any adverse affects on the

feet with moving or movable components of the bicycle which strength and function of the carrier under conditioned environ-

ments.

could cause injury, and

5.1.1 Conduct these environmental temperature tests prior

4.2.2.5 Belt or other capturing devices designed to restrain

to the dynamic load tests that follow.

the child from standing in or leaving the carrier. Buckles, if

used, must be difficult for the child passenger to open. 5.2 Resistance to High Temperatures:

5.2.1 Store the carrier for at least 4 h, but not more than 24

4.2.3 Attachment—The attachment process for connecting

h at a temperature of 50 6 3°C (122 6 5°F).

the seat portion of the carrier either to dedicated mounting

5.2.2 Examine the carrier for damage or distortion that

hardware or to a luggage carrier, and attachment of the

could affect the safety or function of the carrier.

mounting hardware or the luggage carrier to the bicycle frame,

5.2.3 Damage or distortion that could affect the safety or

shall be of a simple and secure procedure. If tools are required

function of the carrier constitutes failure of the test.

for mounting, mounting must be accomplished with common

5.3 High-Temperature Drop Test:

household tools, and must offer no reasonable opportunity of

5.3.1 Store the carrier for at least 4 h, but not more than 24

incorrect mounting.

h, at a temperature of 50 6 3°C (122 6 5°F).

4.2.4 Test Criteria—After testing in accordance with Sec-

5.3.2 Remove the carrier from the hot environment and

tions 5 and 6 of this specification the child carrier shall show

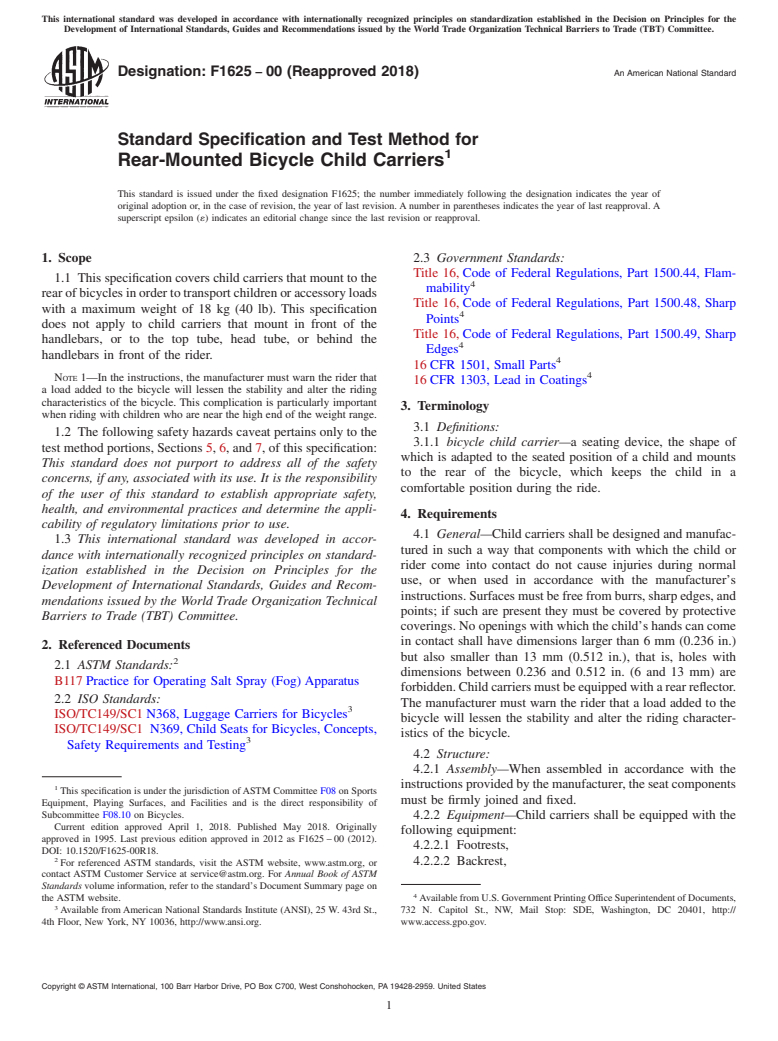

mount it on the test fixture depicted in Fig. 1 that holds the

no visible signs of fracture, nor any deformation or displace-

lowest point of the underside of the seating area of the carrier

ment that would impair the function of the child carrier or the

shell at a height of 1.00 6 0.01 m (39.37 6 0.39 in.) above a

bicycle, as defined by the allowable amounts set forth in

concrete floor. The bottom of the fixture has a pivoting device

Sections 5 and 6.

that allows the fixture to rotate until it contacts the floor. The

mass of the drop arm of the fixture is 11+0.5−0 kg

4.3 Security of Seat Assembled to Bicycle:

4.3.1 Ifthemeansofattachmentofthecarriertothebicycle

is within easy reach of the child, and also is of a type that the

child may be able to loosen, then there shall be a secondary

device to restrict movement of the carrier, either by providing

an additional and independent attachment or by ensuring that

loosening the primary attachment will not fully release the

connection.

4.3.2 Child carriers that do not attach directly to the bicycle

seat tube, such as rack-mounting models, shall have an

additional attachment device connecting the seat portion either

to a frame tube or to the saddle pillar, with sufficient strength

to limit rearward movement of the seat.

4.4 Dimensions:

4.4.1 Dimensions of the interior of the carrier seating area

shall be adequate for the seated child at the upper range of the

weight limitation.

4.4.2 Thebackrestmusthaveaminimumheightof350mm

(13.8 in.).

4.4.3 The armrests must be high enough to keep the child

stable in lateral directions.

4.5 Materials:

4.5.1 Plastics or other synthetic materials, if used, shall be

stabilized against ultraviolet radiation and resistant to ozone.

4.5.2 The carrier shall be protected against corrosion and

tested in accordance with salt spray test defined in Practice

B117, for a period of 96 h. Tested components shall show no

visible evidence of corrosion or deterioration which could

jeopardizestructuralintegrityoftheentireassembly.Thetested

NOTE 1—Figures are intended only to indicate one possible configura-

unit shall continue to operate in accordance with the manufac-

tion for test fixtures and are not intended to be adequate for fabrication.

turer’s written instructions. FIG. 1 Child Carrier Drop Test Fixture

F1625 − 00 (2018)

(24+1.0−0 lb). Within 1 min after removal from the condi-

tioned environment, release the carrier under gravity from rest

to one side or the other onto a flat concrete surface, as if the

bicycle to which it was mounted fell over.

5.3.3 Examine the carrier for damage or distortion that

could affect the safety or function of the carrier.

5.3.4 Damage or distortion that could affect the safety or

function of the carrier constitutes failure of the test.

5.4 Low-Temperature Resistance:

5.4.1 Store the carrier for at least 4 h, but not more than 24

h, at a temperature of−7 6 3°C (20 6 5°F).

5.4.2 Examine the carrier for damage or distortion that

could affect the safety or function of the carrier.

5.4.3 Damage or distortion that could affect the safety or

function of the carrier constitutes failure of the test.

5.5 Low-Temperature Drop Test:

5.5.1 Store the carrier for at least 4 h, but not more than 24

h, at a temperature of−7 6 3°C (20 6 5°F).

5.5.2 Remove the carrier from the cold environment and

mount it on the test fixture depicted in Fig. 1 that holds the

lowest point of the underside of the seating area of the carrier

shell at a height of 1.00 6 0.01 m (39.37 6 0.39 in.) above a

concrete floor. The bottom of the fixture has a pivoting device

that allows the fixture to rotate until it contacts the floor. The

mass of the drop arm is 11+0.5−0 kg (24+1.0−0 lb).

Within 1 min after removal from the conditioned environment,

release the carrier under gravity from rest to one side or the

other onto a flat concrete surface, as if the bicycle to which it

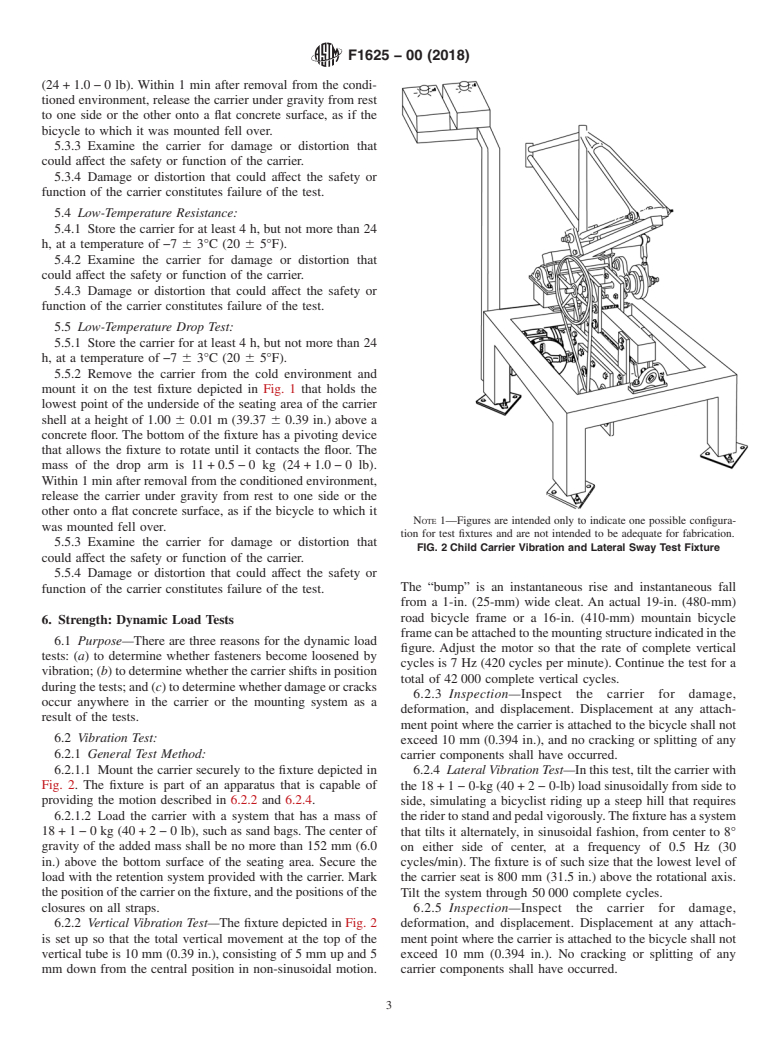

NOTE 1—Figures are intended only to indicate one possible configura-

was mounted fell over.

tion for test fixtures and are not intended to be adequate for fabrication.

5.5.3 Examine the carrier for damage or distortion that

FIG. 2 Child Carrier Vibration and Lateral Sway Test Fixture

could affect the safety or function of the carrier.

5.5.4 Damage or distortion that could affect the safety or

The “bump” is an instantaneous rise and instantaneous fall

function of the carrier constitutes failure of the test.

from a 1-in. (25-mm) wide cleat. An actual 19-in. (480-mm)

road bicycle frame or a 16-in. (410-mm) mountain bicycle

6. Strength: Dynamic Load Tests

framecanbeattachedtothemountingstructureindicatedinthe

6.1 Purpose—There are three reasons for the dynamic load

figure. Adjust the motor so that the rate of complete vertical

tests: (a) to determine whether fasteners become loosened by

cycles is 7 Hz (420 cycles per minute). Continue the test for a

vibration;(b)todeterminewhetherthecarriershiftsinposition

total of 42000 complete vertical cycles.

duringthetests;and(c)todeterminewhetherdamageorcracks

6.2.3 Inspection—Inspect the carrier for damage,

occur anywhere in the carrier or the mounting system as a

deformation, and displacement. Displacement at any attach-

result of the tests.

mentpointwherethecarrierisattachedtothebicycleshallnot

6.2 Vibration Test:

exceed 10 mm (0.394 in.), and no cracking or splitting of any

6.2.1 General Test Method: carrier components shall have occurred.

6.2.1.1 Mount the carrier securely to the fixture depicted in

6.2.4 Lateral Vibration Test—Inthistest,tiltthecarrierwith

Fig. 2. The fixture is part of an apparatus that is capable of the18+1−0-kg(40+2−0-lb)loadsinusoidallyfromsideto

providing the motion described in 6.2.2 and 6.2.4.

side, simulating a bicyclist riding up a steep hill that requires

6.2.1.2 Load the carrier with a system that has a mass of theridertostandandpedalvigorously.Thefixturehasasystem

18+1−0kg(40+2−0 lb), such as sand bags. The center of that tilts it alternately, in sinusoidal fashion, from center to 8°

gravity of the added mass shall be no more than 152 mm (6.0 on either side of center, at a frequency of 0.5 Hz (30

in.) above the bottom surface of the seating area. Secure the cycles/min). The fixture is of such size that the lowest level of

load with the retention system provided with the carrier. Mark the carrier seat is 800 mm (31.5 in.) above the rotational axis.

thepositionofthecarrieronthefixture,andthepositionsofthe

Tilt the system through 50000 complete cycles.

closures on all straps. 6.2.5 Inspection—Inspect the carrier for damage,

6.2.2 Vertical Vibration Test—The fixture depicted in Fig. 2 deformation, and displacement. Displacement at any attach-

is set up so that the total vertical movement at the top of the mentpointwherethecarrierisattachedtothebicycleshallnot

vertical tube is 10 mm (0.39 in.), consisting of 5 mm up and 5 exceed 10 mm (0.394 in.). No cracking or splitting of any

mm down from the central position in non-sinusoidal motion. carrier components shall have occurred.

F1625 − 00 (2018)

7. Additional Test Criteria information. Position the information in a location that is

obvious and readily seen on a completely assembled carrier.

7.1 Flammability—All components of the carrier shall meet

Stickers, if used, must not peel, degrade or fade to the point of

the flammability requirements defined in Title 16, Code of

being difficult to read upon completion of the above tests:

Federal Regulations, Part 1500.44.

8.1.1.1 The 40-lb (18-kg) maximum weight of child that

7.2 Sharp Points—All components of the carrier shall meet

may be transported in the carrier,

therequirementsofTitle16,CodeofFederalRegulations,Part

8.1.1.2 The name or symbol of the manufacturer,

1500.48, regarding sharp points that could cause puncture or

8.1.1.3 The uncoded date of manufacture,

laceration injuries.

8.1.1.4 Warning that a load added to the bicycle will lessen

the stability and alter the ri

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.