ASTM D1230-94

(Test Method)Standard Test Method for Flammability of Apparel Textiles

Standard Test Method for Flammability of Apparel Textiles

SCOPE

1.1 This test method covers the evaluation of the flammability of textile fabrics as they reach the consumer for or from apparel other than children's sleepwear or protective clothing.

1.2 This standard should be used to measure and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire-risk assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard of a particular end use. Note 1—This test method is not identical to 16 CFR Part 1610, Flammability of Clothing Textiles. Consumer Product Safety Commission regulations require that fabrics introduced into commerce meet the requirements of 16 CFR Part 1610.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary information is found in 9.2.1.3.

1.4 The values stated in SI units are to be regarded as the standard; inch-pound units are provided for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 1230 – 94

Standard Test Method for

Flammability of Apparel Textiles

This standard is issued under the fixed designation D 1230; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope of Durable Press Woven or Knit Fabrics

1.1 This test method covers the evaluation of the flamma-

3. Terminology

bility of textile fabrics as they reach the consumer for or from

3.1 Definitions:

apparel other than children’s sleepwear or protective clothing.

3.1.1 combustible textile, n—a textile that will ignite and

1.2 This standard should be used to measure and describe

burn or that will give off vapors that ignite and burn when

the properties of materials, products, or assemblies in response

subjected to external sources of ignition.

to heat and flame under controlled laboratory conditions and

3.1.2 flame spread, n—the propagation of a flame away

should not be used to describe or appraise the fire hazard or

from the source of ignition.

fire risk of materials, products, or assemblies under actual fire

3.1.3 flame-spread time, n—the time taken by a flame on a

conditions. However, results of this test may be used as

burning material to travel a specified distance under specified

elements of a fire-risk assessment which takes into account all

conditions.

of the factors which are pertinent to an assessment of the fire

3.1.4 flammability, n—those characteristics of a material

hazard of a particular end use.

that pertain to its relative ease of ignition and relative ability to

NOTE 1—This test method is not identical to 16 CFR Part 1610,

sustain combustion.

Flammability of Clothing Textiles. Consumer Product Safety Commission

3.1.5 flame retardant, n—a chemical used to impart flame

regulations require that fabrics introduced into commerce meet the

resistance.

requirements of 16 CFR Part 1610.

3.1.6 flame-retardant-treated, adj—having received a

1.3 This standard does not purport to address all of the

flame-retardant treatment.

safety problems, if any, associated with its use. It is the

3.1.6.1 The term “flame-retardant-treated” does not apply to

responsibility of the user of this standard to establish appro-

textiles that are inherently flame resistant due to the intrinsic

priate safety and health practices and determine the applica-

properties of the material or the fiber-forming polymer.

bility of regulatory limitations prior to use. Specific precau-

3.1.7 interlining, n—any textile which is intended for incor-

tionary information is found in 9.2.1.3.

poration into an article of wearing apparel as a layer between

1.4 The values stated in SI units are to be regarded as the

an outer shell and an inner lining.

standard; inch-pound units are provided for information only.

3.1.8 raised fiber surface, n—in textile fabrics, intentionally

lifted fibers or yarns such as pile, napped, tufted, flocked, or

2. Referenced Documents

similar surfaces.

2.1 ASTM Standards:

3.2 For definitions of other terms used in this test method,

D 123 Terminology Relating to Textiles

refer to Terminology D 123 and to the Technical Manual of the

D 484 Specification of Hydrocarbon Drycleaning Solvents

American Association of Textile Chemists and Colorists.

D 2724 Test Methods for Bonded, Fused, and Laminated

Apparel Fabrics

4. Summary of Test Method

E 122 Practice for Choice of Sample Size to Estimate a

4.1 The standard provides methods of testing the flamma-

Measure of Quality for Lot or Process

bility of textiles from or intended to be used for apparel,

2.2 AATCC Test Method:

explains three classes of flammability, sets forth the require-

135 Dimensional Changes in Automatic Home Laundering

ments for classifying textiles, and warns against the use of

single or multilayer textile fabrics that have burning character-

istics considered by the trade to make them unsuitable for

apparel.

This test method is under the jurisdiction of ASTM Committee D-13 on Textiles

4.2 Specimens cut from the textile are prepared by brushing

and is the direct responsibility of Subcommittee D13.52 on Flammability.

Current edition approved June 15, 1994. Published August 1994. Originally

if they have a raised fiber surface, by drycleaning and laun-

published as D 1230 – 52 T. Last previous edition D 1230 – 92.

dering if they have been flame-retardant-treated. A dried

Annual Book of ASTM Standards, Vol 07.01.

Discontinued—See 1983 Annual Book of ASTM Standards, Vol 06.03.

Annual Book of ASTM Standards, Vol 14.02.

Available from the American Association of Textile Chemists and Colorists,

P.O. Box 12215, Research Triangle Park, NC 27709.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 1230

specimen is inserted in a frame and held in a special apparatus closely reproducible either in the same laboratory or among

at an angle of 45°, a standardized flame is applied to the surface several laboratories.

near the lower end for 1 s, and the timerequired for the flame 5.4 Finishes and fabric surface changes can exert a large

to proceed up the fabric a distance of 127 mm (5 in.) is effect on flammability. Therefore, some fabrics are tested

recorded. Notation is made as to whether the base of a before as well as after laundering or drycleaning or both (see

raised-surface fabric ignites, chars, or melts. Section 9).

5.5 This standard is not applicable to hats, gloves, footwear,

5. Uses and Significance

or interlining fabrics.

5.1 Test Method D 1230 for the determination of the flam-

6. Apparatus and Materials

mability of apparel textiles cannot be recommended for the

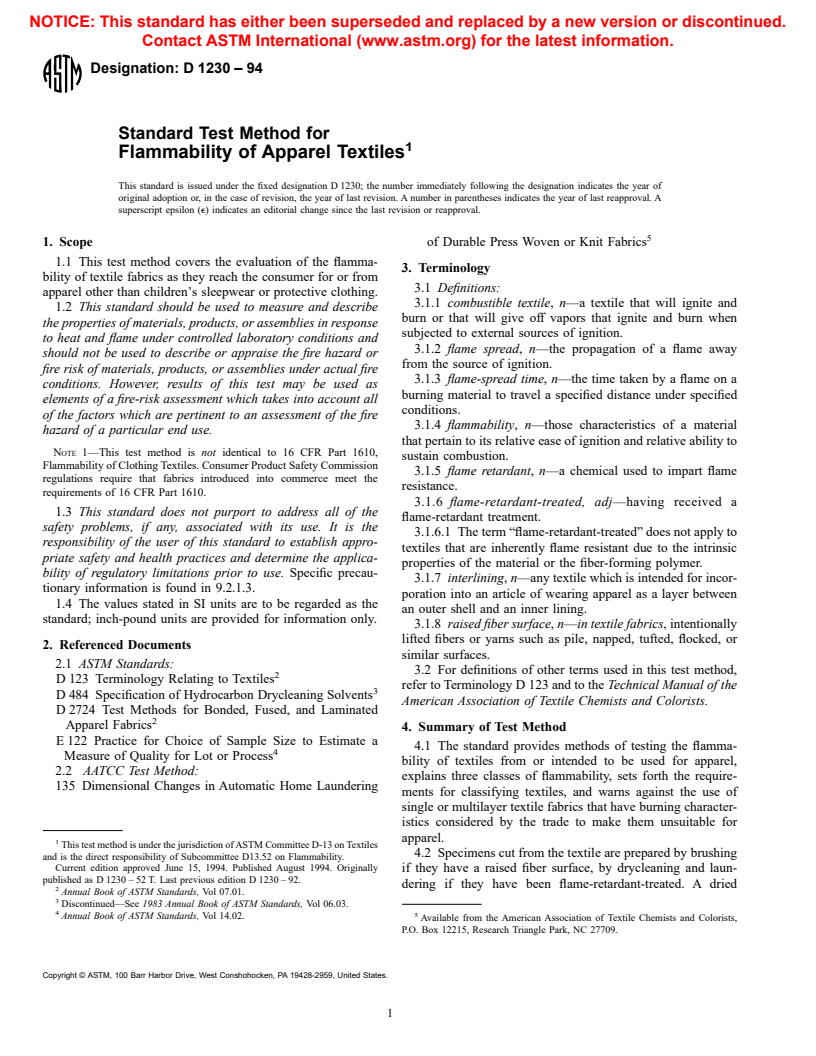

6.1 Flammability Tester , with a separate timer capable of

acceptance testing of commercial shipments since Federal

providing flame impingement on the specimen for 1 + 0.05 s as

regulations require apparel fabrics to meet the criteria of 16

shown in Fig. 1 or an equivalent electrically operated tester

CFR 1610 and correlation of test results with actual perfor-

equipped with an automatic electric timer, as described in

mance has not been established. Although Test Method D 1230

Annex A1. Testers are normally supplied with specimen

is not recommended for acceptance testing, it is useful because

holders.

it provides a less expensive and time consuming research tool

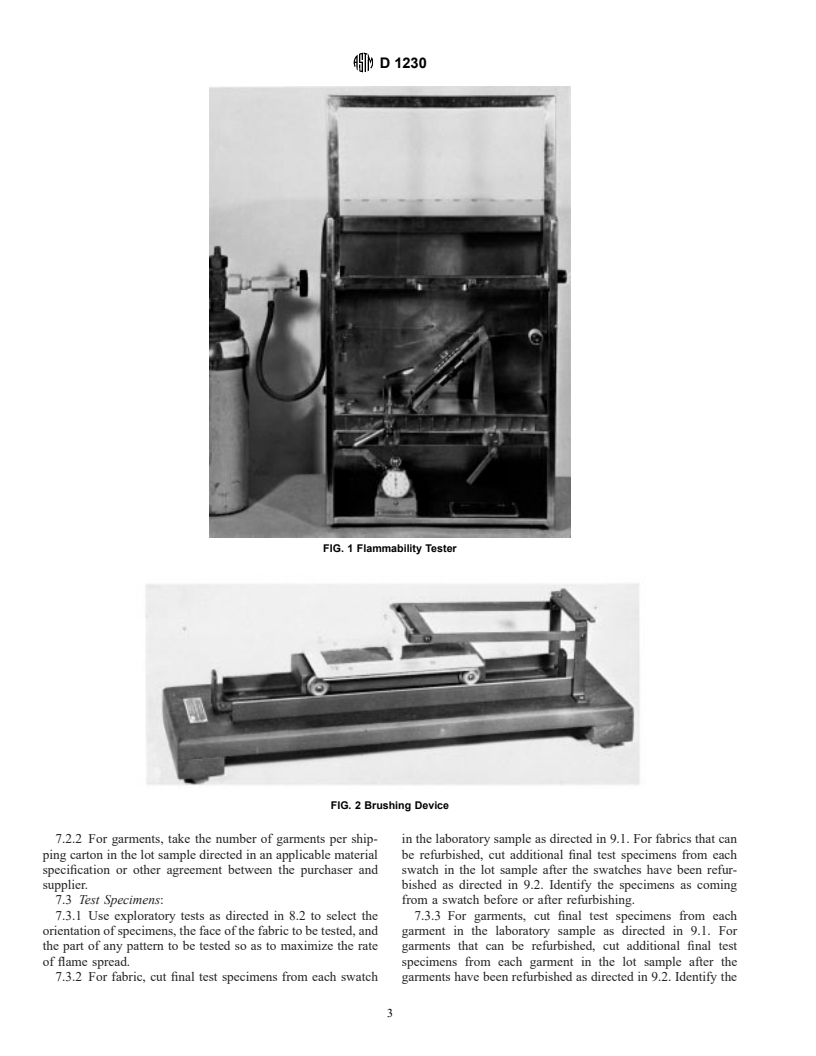

6.2 Brushing Device , as shown in Fig. 2, and described in

than 16 CFR 1610. Also, since the Consumer Product Safety

Annex A1.

Commission is presently considering action to allow alternate

6.3 Drycleaning Machine—Single unit, coin-operated type

test methods to 16 CFR 1610, and has shown a willingness to

capable of providing a complete automatic dry-to-dry cycle

consider changes to it, Test Method D 1230 should serve as the

using perchlorethylene (see 6.1 of Test Methods D 2724).

industry standard and as a guide for needed changes to federal

6.4 Laboratory Drying Oven.

regulations. See 1.2 and Note 1.

6.5 Desiccator, 250 mm (10 in.) diameter.

5.1.1 In case of a dispute arising from differences in

6.6 Calcium Chloride, anhydrous.

reported test results when using Test Method D 1230 for

6.7 Butane,CP.

acceptance testing of commercial shipments, the purchaser and

6.8 AATCC Standard Detergent 124.

the supplier should conduct comparative tests to determine if

6.9 Perchlorethylene, commercial grade.

there is a statistical bias between their laboratories. Competent

6.10 Drycleaning Detergent , amine sulfonate type.

statistical assistance is recommended for the investigation of

6.11 Cotton Sewing Thread, No. 50, mercerized.

bias. As a minimum, the two parties should take a group of test

specimens which are as homogeneous as possible and which

7. Sampling

are from a lot of material of the type in question. The test

7.1 Lot Sample—As a lot sample for testing, take at random

specimens should then be randomly assigned in equal numbers

the number of primary sampling units directed in an applicable

to each laboratory for testing. The average results from the two

material specification or other agreement between the pur-

laboratories should be compared using a nonparametric test for

chaser and the supplier. For fabric, consider rolls of fabric to be

unpaired data and an acceptable probability level chosen by the

the primary sampling units. For garments, consider shipping

two parties before testing is begun. If a bias is found, either its

cartons to be the primary sampling units.

cause must be found and corrected or the purchaser and the

NOTE 2—A realistic specification or other agreement between the

supplier must agree to interpret future test results in light of the

purchaser and the supplier requires taking into account the variability

known bias.

between primary sampling units and within primary sampling units so as

5.2 All fabrics made of natural or regenerated cellulose, as

to provide a sampling plan which has a meaningful producer’s risk,

well as many made from other natural or man-made fibers, are

consumer’s risk, acceptable quality level, and limiting quality level. A lot

combustible. Some combustible fabrics when used for clothing

sample normally consists of a very small fraction of the total primary

are potentially dangerous to the wearer because of such factors sampling units.

as ease of ignition, flame spread time, amount of heat released,

7.2 Laboratory Sample—As a laboratory sample for testing,

and design of the garment. This test measures two such factors:

proceed as follows:

ease of ignition and flame spread time. 1 1

7.2.1 For fabric take a full-width swatch ⁄2 m( ⁄2 yd) long

5.3 In order to place fabrics in one of the three flammability

from the end of each roll of fabric in the lot sample, after first

classes, arbitrary limits have been selected for time of appli-

discarding any fabric from the very outside of the roll that

cation of the flame and for time of flame spread. These limits

contains folds, creases, or any evidence of displaced weave.

are based on extensive testing experience and are believed to

be a useful guide in judging the relative flammability of apparel

The Flammability Tester and Brushing Device can be obtained from U.S.

textiles. It must be understood, however, that no guarantee can

Testing Co., Inc., 1415 Park Ave., Hoboken, NJ 07030; Custom Scientific Instru-

be given and none is implied that garments made from a fabric

ments, Inc., 13 Wing Drive, Whippany, NJ 07981; and The Govmark Organization,

or product falling into any one of the flammability classes will

Inc., P.O. Box 807, Bellmore, NY 11710.

not be hazardous under some conditions. Butane, cp. No. 4 cylinders, containing 2 lb may be obtained from Matheson

Co., Inc., East Rutherford, NJ.

5.3.1 Because of the sensitivity of fabrics to ambient atmo-

Staticol, amine sulfonate type, available from R. R. Street, Inc., 561 W. Monroe

spheric conditions, technique of specimen preparation, and

St., Chicago, IL; or Perksheen 324, amine sulfonate type, available from Adco, Inc.,

inherent variability in the cloth itself, test results are not always 900 W. Main St., Sedalia MO, have been found suitable for this purpose.

D 1230

FIG. 1 Flammability Tester

FIG. 2 Brushing Device

7.2.2 For garments, take the number of garments per ship- in the laboratory sample as directed in 9.1. For fabrics that can

ping carton in the lot sample directed in an applicable material be refurbished, cut additional final test specimens from each

specification or other agreement between the purchaser and swatch in the lot sample after the swatches have been refur-

supplier. bished as directed in 9.2. Identify the specimens as coming

7.3 Test Specimens: from a swatch before or after refurbishing.

7.3.1 Use exploratory tests as directed in 8.2 to select the 7.3.3 For garments, cut final test specimens from each

orientation of specimens, the face of the fabric to be tested, and garment in the laboratory sample as directed in 9.1. For

the part of any pattern to be tested so as to maximize the rate garments that can be refurbished, cut additional final test

of flame spread. specimens from each garment in the lot sample after the

7.3.2 For fabric, cut final test specimens from each swatch garments have been refurbished as directed in 9.2. Identify the

D 1230

specimens as coming from a garment before or after refurbish- mL of water for each gallon of perchlorethylene solvent

ing. Specimens from multi-layered garments should include all required for the drycleaning machine. Put this solvent in the

of the layers held in the same relative position they occupy in machine storage tank. The same solution may be used for

the garment. Test the outer surface of the garment unless the repeated cleanings until it becomes dirty. The solution then

inner surface of the lining yields a faster flame spread in should be replaced.

exploratory tests. See 7.3.1. 9.2.1.3 Perchlorethylene is toxic and a suspected carcino-

gen, and the usual precautions for handling chlorinated sol-

8. Preparation of Specimens

vents should be taken. It should be used only under well-

8.1 Perform tests on the fabric as it will reach the consumer.

ventilated conditions. The solvent is nonflammable.

Process any partially finished fabrics first in accordance with a

9.2.1.4 Sample and Dummy Load Preparation—Prepare a

manufacturer’s instructions.

load consisting of all specimens to be tested and made up to 8

8.2 Accomplish exploratory testing to determine the proper

lb (3.6 kg) total with dummy load of approximately 380 by 380

orientation of specimens, face of fabric and part of pattern to be

mm (15 by 15 in.) fabric pieces of similar material.

tested by marking and cutting (see 8.3) a single 50 by 150 mm

9.2.1.5 Drycleaning Procedure—Run through the complete

(2 by 6 in.) specimen for each fabric surface, direction, and

dry-to-dry cycle in the single unit coin-operated type dryclean-

pattern and testing according to Section 10.

ing machine. Run the solvent phase of the drycleaning cycle

with the solvent temperature no higher than 32°C (90°F).

NOTE 3—For fabric with a raised-fiber surface, it is usually found that

During the drying phase of the drycleaning cycle, either the air

the long dimension of the specimen should be parallel with the lay of the

outlet temperature should not exceed 60°C (140°F) or the inlet

pile, and that flame spread is most rapid when progressing against the lay

of the pile. air temperature should not exceed 80°C (175°F). If heat-

sensitive fibers (for example, modacrylic fibers) are involved,

8.3 Marking and Cutting, General Directions—Mark out

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.