ASTM A1103/A1103M-16(2022)

(Specification)Standard Specification for Seamless Cold-Finished Carbon Steel Structural Frame Tubing for Automotive Racing Applications

Standard Specification for Seamless Cold-Finished Carbon Steel Structural Frame Tubing for Automotive Racing Applications

ABSTRACT

This specification covers seamless cold-finished carbon steel round structural frame tubing for automotive racing applications. Tubing may be used for other applications requiring similar tolerances and properties. The tubing is intended to be bent and joined by welding. The welding procedure shall be suitable for the grade, the condition of the components, and the intended service.

SCOPE

1.1 This specification is for seamless cold-finished carbon steel round structural frame tubing for automotive racing applications. The chemical requirements are listed in Table 1. Tubing may be used for other applications requiring similar tolerances and properties. The specification includes requirements for heat treatment and mechanical properties to meet the needs for the application. The tubing is intended to be bent and joined by welding. The welding procedure shall be suitable for the grade, the condition of the components, and the intended service.

1.2 The tubing outside diameter size range is from 0.625 to 2.0 in. [16 to 50 mm]. The wall thickness shall be specified as a minimum wall.

1.3 Optional supplementary requirements may be provided and, when one or more of these are desired, each shall be so stated in the order.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. The inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A1103/A1103M −16 (Reapproved 2022)

Standard Specification for

Seamless Cold-Finished Carbon Steel Structural Frame

Tubing for Automotive Racing Applications

This standard is issued under the fixed designation A1103/A1103M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This specification is for seamless cold-finished carbon

steel round structural frame tubing for automotive racing

2. Referenced Documents

applications. The chemical requirements are listed in Table 1.

2.1 ASTM Standards:

Tubing may be used for other applications requiring similar

A450/A450M Specification for General Requirements for

tolerances and properties. The specification includes require-

Carbon and Low Alloy Steel Tubes

ments for heat treatment and mechanical properties to meet the

A751 Test Methods and Practices for Chemical Analysis of

needs for the application.The tubing is intended to be bent and

Steel Products

joined by welding. The welding procedure shall be suitable for

the grade, the condition of the components, and the intended

3. Ordering Information

service.

3.1 Orders for material under this specification should

1.2 The tubing outside diameter size range is from 0.625 to

include the following, as required, to describe the desired

2.0 in. [16 to 50 mm]. The wall thickness shall be specified as

material adequately:

a minimum wall.

3.1.1 Specification designation,

1.3 Optional supplementary requirements may be provided 3.1.2 Name of material (seamless structural frame tubing),

and, when one or more of these are desired, each shall be so

3.1.3 Quantity (feet, weight, or number of pieces),

stated in the order. 3.1.4 Dimensions (outside diameters and wall thickness,

(Section 11),

1.4 The values stated in either inch-pound units or SI units

3.1.5 Length (specific or random, mill lengths, (Section

are to be regarded separately as standard. Within the text, the

11)),

SI units are shown in brackets. The values stated in each

3.1.6 Product analysis (Section 8, if required),

system may not be exact equivalents; therefore, each system

3.1.7 Special mechanical tests (flare or flatten, Section 10,if

shall be used independently of the other. Combining values

required),

from the two systems may result in non-conformance with the

3.1.8 Surface finish (as-cold finished stress relieved, or

standard. The inch-pound units shall apply unless the “M”

ground outside surface, if required),

designation of this specification is specified in the order.

3.1.9 Individual supplementary requirements, if required,

1.5 This standard does not purport to address all of the

3.1.10 Packaging,

safety concerns, if any, associated with its use. It is the

3.1.11 Special marking (Section 16), and

responsibility of the user of this standard to establish appro-

3.1.12 Special packing (Section 17).

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

4. General Requirements

1.6 This international standard was developed in accor-

4.1 Material furnished under this specification shall con-

dance with internationally recognized principles on standard-

form to the applicable requirements of the current edition of

ization established in the Decision on Principles for the

Specification A450/A450M, unless otherwise provided herein.

Development of International Standards, Guides and Recom-

5. Materials and Manufacture

5.1 The steel may be made by any process.

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.09 on Carbon Steel Tubular Products. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved March 1, 2022. Published April 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2016. Last previous edition approved in 2016 as A1103/A1103M – 16. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/A1103_A1103M-16R22. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

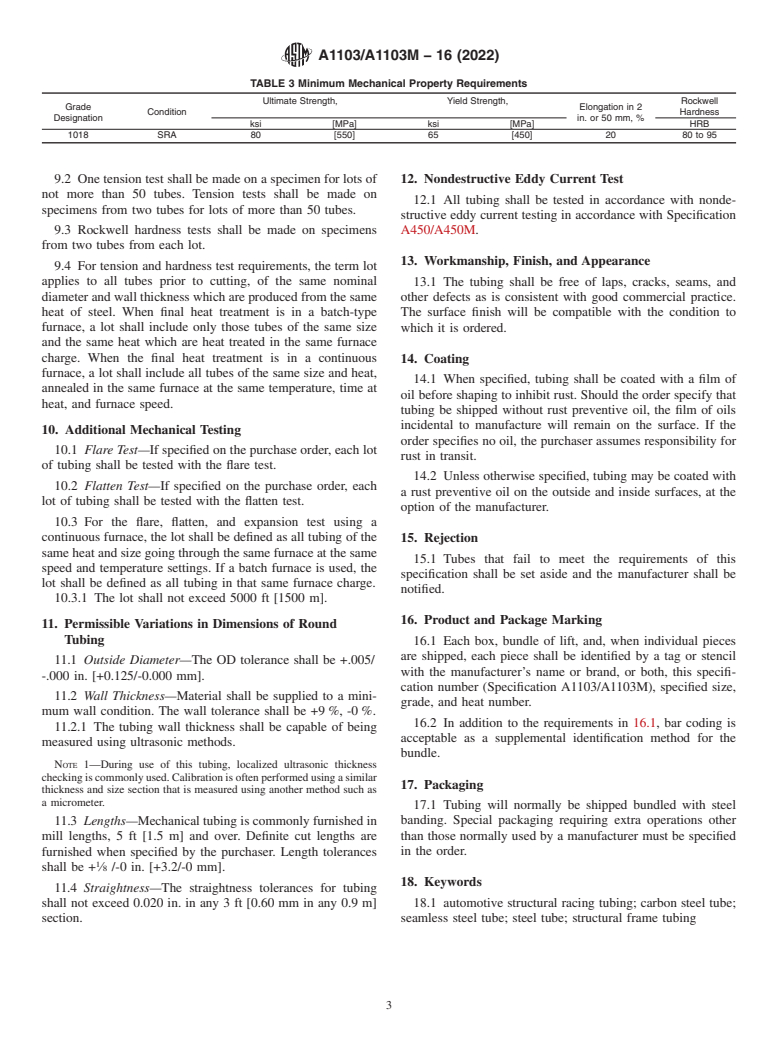

A1103/A1103M−16 (2022)

TABLE 1 Chemical Requirements of Carbon Steel

A

Grade Chemical Composition Limits, %

Designation

B

Carbon Manganese Phosphorous, Sulfur, max Nickel, max Chromium, Niobium, Vanadium, Titanium,

max

max max max max

1018 0.15–0.20 0.60–0.90 0.020 0.015 0.20 0.15 0.008 0.008 0.025

A

The ranges and limits given in this table apply to heat analysis; except as required by 6.1, product analyses are subject to the applicable additional tolerances given in

Table 2.

B

Columbium (Cb) and Niobium (Nb) are alternate names for element 41 in the Periodic Table of the Elements.

5.2 If a specific type of melting is required by the purchaser, product of one remelted ingot of each primary melt. The heat

it shall be as stated on the purchase order. analysis shall conform to the requirements specified, except

that where the heat identity has not been maintained or where

5.3 The primary melting may incorporate separate degas-

the analysis is not sufficiently complete to permit conformance

sing or refining, and may be followed by secondary melting,

to be determined, the chemical composition determined from a

such as electroslag or vacuum-arc remelting. If secondary

product analysis made by the tubular manufacturer shall

melting is employed, the heat shall be defined as all of the

conform to the requirements specified for heat analysis. When

ingots remelted from a single primary heat.

requested in the order or contract, a report of such analyses

5.4 Steel may be cast in ingots or may be strand cast. When

shall be furnished to the purchaser.

steel of different grades is sequentially strand cast, identifica-

tion of the resultant transition material is required. The

8. Product Analysis

producer shall remove the transition material by an established

procedure that positively separates the grades. 8.1 Except as required by 7.1, a product analysis by the

manufacturer shall be required when specified on the purchase

5.5 Tubes shall be made by a seamless process and shall be

order.

cold finished.

8.1.1 One product analysis per heat on either billet or tube

5.5.1 Seamless tubing is a tubular product made without a

is required.

welded seam. It is manufactured usually by hot working steel

and, if necessary, by subsequently cold finishing the hot-

8.2 Samples for chemical analysis shall be taken in accor-

worked tubular product to produce the desired shape,

dance with Practice A751. The composition thus determined

dimensions, and properties.

shall correspond to the requirements in the applicable section

5.6 The tubing shall be supplied in the cold finished of Tables 1 and 2 of this specification and shall be reported to

condition followed by a stress relief anneal (SRA).

the purchaser or the purchaser’s representative.

5.6.1 A light scale after the anneal is accep

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.