ASTM D7751-14

(Test Method)Standard Test Method for Determination of Additive Elements in Lubricating Oils by EDXRF Analysis

Standard Test Method for Determination of Additive Elements in Lubricating Oils by EDXRF Analysis

SIGNIFICANCE AND USE

5.1 Lubricating oils are formulated with organo-metallic additives, which act, for example, as detergents, antioxidants, antifoaming, or antiwear agents, or a combination thereof. Some of these additives contain one or more of the following elements: magnesium, phosphorus, sulfur, chlorine, calcium, zinc, and molybdenum. This test method provides a means of determining the concentrations of these elements, which in turn provides an indication of the additive content of these oils.

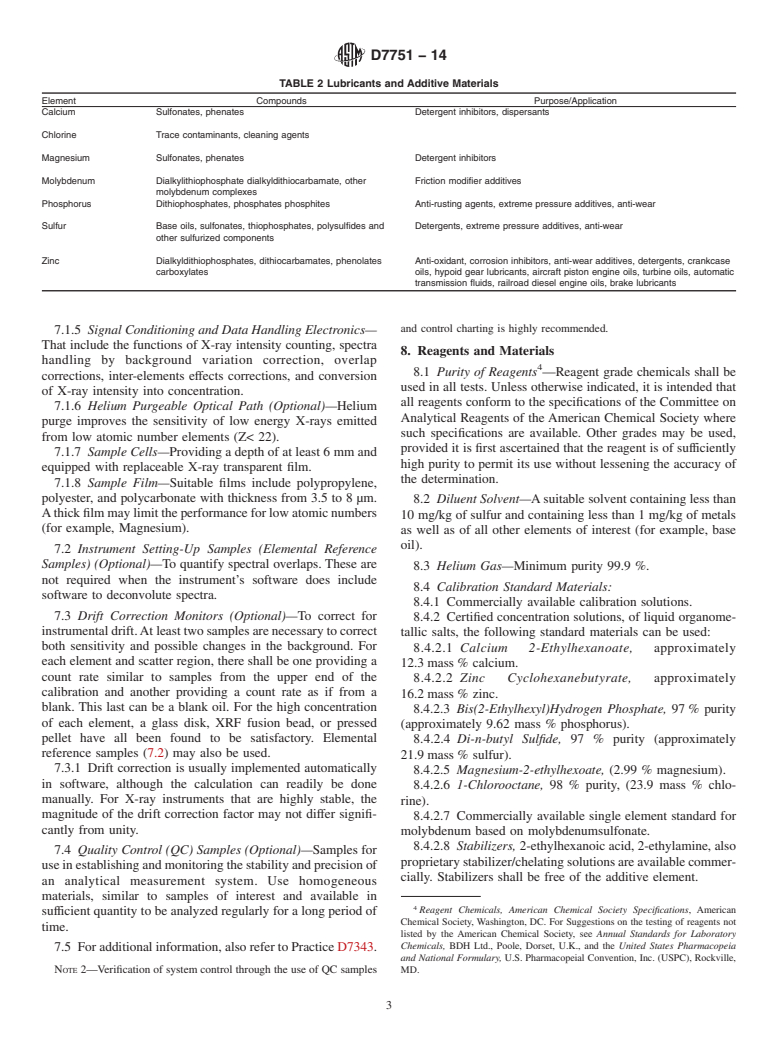

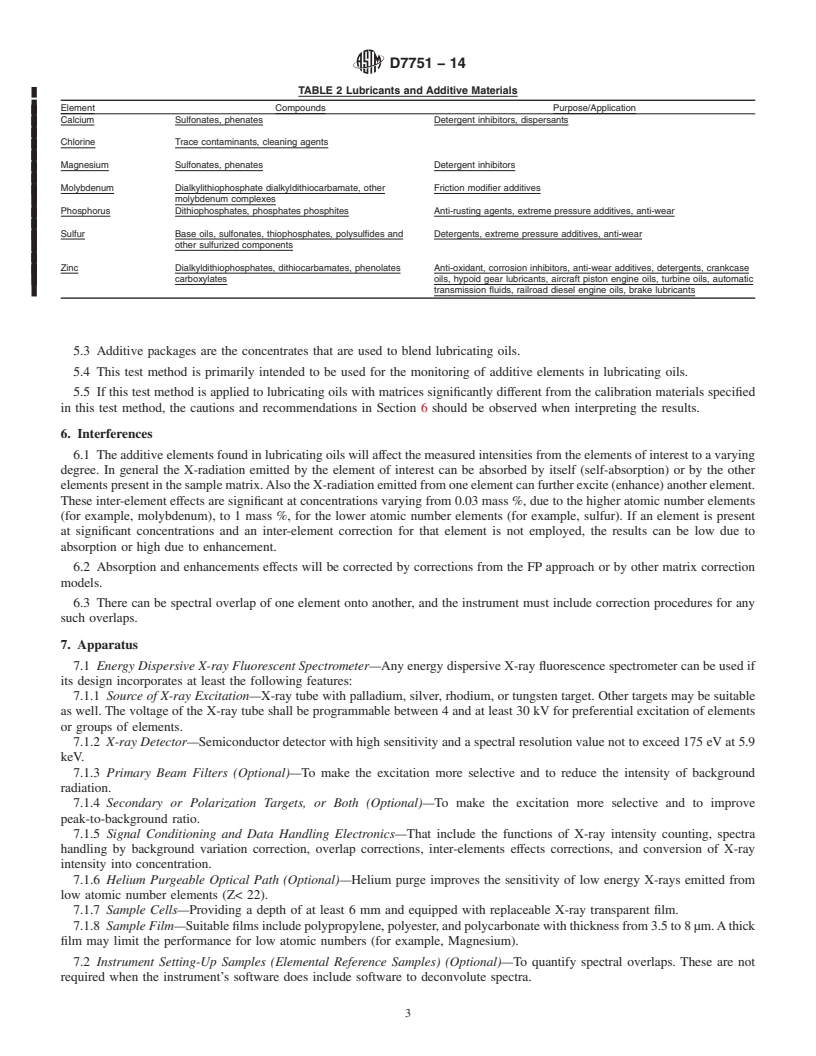

5.2 Several additive elements and their compounds are added to the lubricating oils to give beneficial performance (Table 2).

5.3 Additive packages are the concentrates that are used to blend lubricating oils.

5.4 This test method is primarily intended to be used for the monitoring of additive elements in lubricating oils.

5.5 If this test method is applied to lubricating oils with matrices significantly different from the calibration materials specified in this test method, the cautions and recommendations in Section 6 should be observed when interpreting the results.

SCOPE

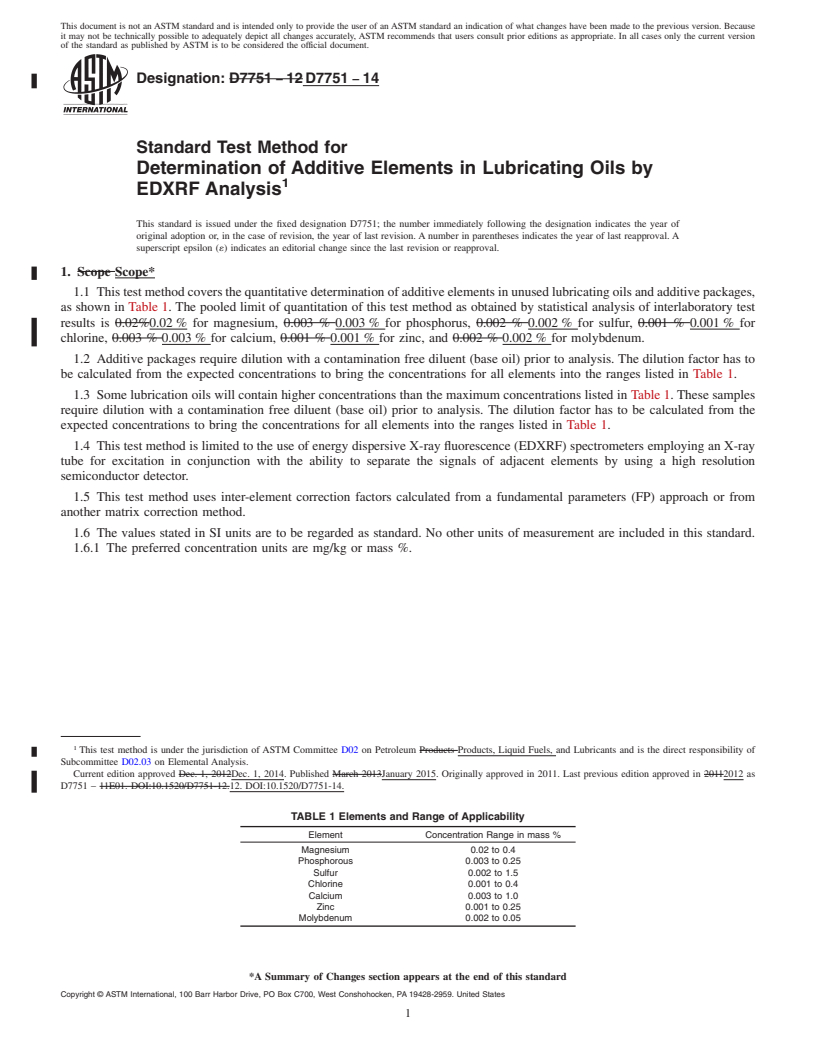

1.1 This test method covers the quantitative determination of additive elements in unused lubricating oils and additive packages, as shown in Table 1. The pooled limit of quantitation of this test method as obtained by statistical analysis of interlaboratory test results is 0.02 % for magnesium, 0.003 % for phosphorus, 0.002 % for sulfur, 0.001 % for chlorine, 0.003 % for calcium, 0.001 % for zinc, and 0.002 % for molybdenum.

1.2 Additive packages require dilution with a contamination free diluent (base oil) prior to analysis. The dilution factor has to be calculated from the expected concentrations to bring the concentrations for all elements into the ranges listed in Table 1.

1.3 Some lubrication oils will contain higher concentrations than the maximum concentrations listed in Table 1. These samples require dilution with a contamination free diluent (base oil) prior to analysis. The dilution factor has to be calculated from the expected concentrations to bring the concentrations for all elements into the ranges listed in Table 1.

1.4 This test method is limited to the use of energy dispersive X-ray fluorescence (EDXRF) spectrometers employing an X-ray tube for excitation in conjunction with the ability to separate the signals of adjacent elements by using a high resolution semiconductor detector.

1.5 This test method uses inter-element correction factors calculated from a fundamental parameters (FP) approach or from another matrix correction method.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6.1 The preferred concentration units are mg/kg or mass %.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7751 − 14

StandardTest Method for

Determination of Additive Elements in Lubricating Oils by

EDXRF Analysis

This standard is issued under the fixed designation D7751; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the quantitative determination

responsibility of the user of this standard to establish appro-

of additive elements in unused lubricating oils and additive

priate safety and health practices and determine the applica-

packages,asshowninTable1.Thepooledlimitofquantitation

bility of regulatory limitations prior to use.

of this test method as obtained by statistical analysis of

interlaboratory test results is 0.02 % for magnesium, 0.003 %

2. Referenced Documents

for phosphorus, 0.002 % for sulfur, 0.001 % for chlorine,

2.1 ASTM Standards:

0.003 % for calcium, 0.001 % for zinc, and 0.002 % for

D4057 Practice for Manual Sampling of Petroleum and

molybdenum.

Petroleum Products

1.2 Additivepackagesrequiredilutionwithacontamination

D4177 Practice for Automatic Sampling of Petroleum and

free diluent (base oil) prior to analysis. The dilution factor has

Petroleum Products

to be calculated from the expected concentrations to bring the

D6299 Practice for Applying Statistical Quality Assurance

concentrationsforallelementsintotherangeslistedinTable1.

and Control Charting Techniques to Evaluate Analytical

1.3 Some lubrication oils will contain higher concentrations

Measurement System Performance

than the maximum concentrations listed in Table 1. These

D6300 Practice for Determination of Precision and Bias

samples require dilution with a contamination free diluent

Data for Use in Test Methods for Petroleum Products and

(base oil) prior to analysis. The dilution factor has to be

Lubricants

calculated from the expected concentrations to bring the

D6792 Practice for Quality System in Petroleum Products

concentrationsforallelementsintotherangeslistedinTable1.

and Lubricants Testing Laboratories

D7343 Practice for Optimization, Sample Handling,

1.4 This test method is limited to the use of energy

Calibration, and Validation of X-ray Fluorescence Spec-

dispersive X-ray fluorescence (EDXRF) spectrometers em-

trometry Methods for Elemental Analysis of Petroleum

ploying an X-ray tube for excitation in conjunction with the

Products and Lubricants

ability to separate the signals of adjacent elements by using a

E1621 Guide for ElementalAnalysis by Wavelength Disper-

high resolution semiconductor detector.

sive X-Ray Fluorescence Spectrometry

1.5 This test method uses inter-element correction factors

2.2 ISO Standards:

calculated from a fundamental parameters (FP) approach or

ISO 4259 Determination and application of precision data in

from another matrix correction method.

relation to methods of test

1.6 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

3. Terminology

standard.

3.1 Definitions:

1.6.1 The preferred concentration units are mg/kg or mass

3.1.1 energy dispersive X-ray spectrometry, n—XRF spec-

%.

trometry applying energy dispersive selection of radiation.

3.2 Abbreviations:

1 2

This test method is under the jurisdiction of ASTM Committee D02 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee D02.03 on Elemental Analysis. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Dec. 1, 2014. Published January 2015. Originally the ASTM website.

approved in 2011. Last previous edition approved in 2012 as D7751 – 12. Available from International Organization for Standardization (ISO), 1, ch. de

DOI:10.1520/D7751-14. la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7751 − 14

TABLE 1 Elements and Range of Applicability

elements: magnesium, phosphorus, sulfur, chlorine, calcium,

Element Concentration Range in mass % zinc, and molybdenum. This test method provides a means of

Magnesium 0.02 to 0.4 determiningtheconcentrationsoftheseelements,whichinturn

Phosphorous 0.003 to 0.25

provides an indication of the additive content of these oils.

Sulfur 0.002 to 1.5

Chlorine 0.001 to 0.4

5.2 Several additive elements and their compounds are

Calcium 0.003 to 1.0

added to the lubricating oils to give beneficial performance

Zinc 0.001 to 0.25

(Table 2).

Molybdenum 0.002 to 0.05

5.3 Additive packages are the concentrates that are used to

blend lubricating oils.

3.2.1 EDXRF—Energy Dispersive X-ray Fluorescence

5.4 This test method is primarily intended to be used for the

Spectrometry.

monitoring of additive elements in lubricating oils.

3.2.2 FP—Fundamental Parameters.

5.5 If this test method is applied to lubricating oils with

matrices significantly different from the calibration materials

4. Summary of Test Method

specified in this test method, the cautions and recommenda-

4.1 A specimen is placed in the X-ray beam, and the

tions in Section 6 should be observed when interpreting the

appropriate regions of its spectrum are measured to give the

results.

fluorescent intensities of magnesium, phosphorus, sulfur,

chlorine, calcium, zinc, and molybdenum. Other regions of the

6. Interferences

spectrum are measured to compensate for matrix variation. To

6.1 The additive elements found in lubricating oils will

optimize the sensitivity for each element or group of elements,

affect the measured intensities from the elements of interest to

a combination of optimized excitation and detection conditions

a varying degree. In general the X-radiation emitted by the

may be used (no more than two conditions should be used in

element of interest can be absorbed by itself (self-absorption)

order to keep the analysis time as short as possible, typically

or by the other elements present in the sample matrix.Also the

under ten minutes). There may be a correction of measured

X-radiation emitted from one element can further excite

intensities for spectral overlap.

(enhance) another element. These inter-element effects are

4.1.1 Concentrations of the elements of interest are deter-

significant at concentrations varying from 0.03 mass %, due to

mined by comparison of these intensities against a calibration

the higher atomic number elements (for example,

curve using a fundamental parameters (FP) approach, possibly

molybdenum), to 1 mass %, for the lower atomic number

combined with corrections from backscatter. The FP approach

elements (for example, sulfur). If an element is present at

uses the physical processes forming the basis of X-ray fluo-

significant concentrations and an inter-element correction for

rescence emission in order to provide a theoretical model for

that element is not employed, the results can be low due to

the correction of matrix effects. The correction term is calcu-

absorption or high due to enhancement.

lated from first principle expressions derived from basic

6.2 Absorption and enhancements effects will be corrected

physical principles and contain physical constants and param-

by corrections from the FP approach or by other matrix

eters that include absorption coefficients, fluorescence yield,

correction models.

primary spectral distribution and spectrometry geometry. The

calculation of concentrations in samples is based on making

6.3 There can be spectral overlap of one element onto

successively better estimates of composition by an iteration

another, and the instrument must include correction procedures

procedure.

for any such overlaps.

NOTE 1—The algorithm used for the procedure is usually implemented

in the instrument manufacturer’s software. 7. Apparatus

4.2 The EDXRF spectrometer is initially calibrated using a

7.1 Energy Dispersive X-ray Fluorescent Spectrometer—

set of standards to collect the necessary intensity data. Each

Any energy dispersive X-ray fluorescence spectrometer can be

calibration line and any correction coefficient are obtained by a

used if its design incorporates at least the following features:

regression of this data, using the program supplied with the

7.1.1 Source of X-ray Excitation—X-ray tube with

spectrometer. (Warning—Exposure to excessive quantities of palladium, silver, rhodium, or tungsten target. Other targets

X-radiation is injurious to health. The operator needs to take

may be suitable as well. The voltage of the X-ray tube shall be

appropriate actions to avoid exposing any part of their body, programmable between 4 and at least 30 kV for preferential

not only to primary X-rays, but also to secondary or scattered

excitation of elements or groups of elements.

radiation that might be present.The X-ray spectrometer should 7.1.2 X-ray Detector—Semiconductor detector with high

be operated in accordance with the regulations governing the

sensitivity and a spectral resolution value not to exceed 175 eV

use of ionizing radiation.) at 5.9 keV.

7.1.3 Primary Beam Filters (Optional)—To make the exci-

5. Significance and Use

tation more selective and to reduce the intensity of background

5.1 Lubricating oils are formulated with organo-metallic radiation.

additives, which act, for example, as detergents, antioxidants, 7.1.4 Secondary or Polarization Targets, or Both

antifoaming, or antiwear agents, or a combination thereof. (Optional)—To make the excitation more selective and to

Some of these additives contain one or more of the following improve peak-to-background ratio.

D7751 − 14

TABLE 2 Lubricants and Additive Materials

Element Compounds Purpose/Application

Calcium Sulfonates, phenates Detergent inhibitors, dispersants

Chlorine Trace contaminants, cleaning agents

Magnesium Sulfonates, phenates Detergent inhibitors

Molybdenum Dialkylithiophosphate dialkyldithiocarbamate, other Friction modifier additives

molybdenum complexes

Phosphorus Dithiophosphates, phosphates phosphites Anti-rusting agents, extreme pressure additives, anti-wear

Sulfur Base oils, sulfonates, thiophosphates, polysulfides and Detergents, extreme pressure additives, anti-wear

other sulfurized components

Zinc Dialkyldithiophosphates, dithiocarbamates, phenolates Anti-oxidant, corrosion inhibitors, anti-wear additives, detergents, crankcase

carboxylates oils, hypoid gear lubricants, aircraft piston engine oils, turbine oils, automatic

transmission fluids, railroad diesel engine oils, brake lubricants

and control charting is highly recommended.

7.1.5 Signal Conditioning and Data Handling Electronics—

That include the functions of X-ray intensity counting, spectra

8. Reagents and Materials

handling by background variation correction, overlap

8.1 Purity of Reagents —Reagent grade chemicals shall be

corrections, inter-elements effects corrections, and conversion

used in all tests. Unless otherwise indicated, it is intended that

of X-ray intensity into concentration.

all reagents conform to the specifications of the Committee on

7.1.6 Helium Purgeable Optical Path (Optional)—Helium

Analytical Reagents of the American Chemical Society where

purge improves the sensitivity of low energy X-rays emitted

such specifications are available. Other grades may be used,

from low atomic number elements (Z< 22).

provided it is first ascertained that the reagent is of sufficiently

7.1.7 Sample Cells—Providing a depth of at least 6 mm and

high purity to permit its use without lessening the accuracy of

equipped with replaceable X-ray transparent film.

the determination.

7.1.8 Sample Film—Suitable films include polypropylene,

polyester, and polycarbonate with thickness from 3.5 to 8 µm.

8.2 Diluent Solvent—Asuitable solvent containing less than

Athickfilmmaylimittheperformanceforlowatomicnumbers

10 mg/kg of sulfur and containing less than 1 mg/kg of metals

(for example, Magnesium).

as well as of all other elements of interest (for example, base

oil).

7.2 Instrument Setting-Up Samples (Elemental Reference

Samples) (Optional)—To quantify spectral overlaps. These are

8.3 Helium Gas—Minimum purity 99.9 %.

not required when the instrument’s software does include

8.4 Calibration Standard Materials:

software to deconvolute spectra.

8.4.1 Commercially available calibration solutions.

7.3 Drift Correction Monitors (Optional)—To correct for

8.4.2 Certified concentration solutions, of liquid organome-

instrumentaldrift.Atleasttwosamplesarenecessarytocorrect

tallic salts, the following standard materials can be used:

both sensitivity and possible changes in the background. For

8.4.2.1 Calcium 2-Ethylhexanoate, approximately

each element and scatter region, there shall be one providing a

12.3 mass % calcium.

count rate similar to samples from the upper end of the

8.4.2.2 Zinc Cyclohexanebutyrate, approximately

calibration and another providing a count rate as if from a

16.2 mass % zinc.

blank. This last can be a blank oil. For the high concentration

8.4.2.3 Bis(2-Ethylhexyl)Hydrogen Phosphate, 97 % purity

of each element, a glass disk, XRF fusion bead, or pressed

(approximately 9.62 mass % phosphorus).

pellet have all been found to be satisfactory. Elemental

8.4.2.4 Di-n-butyl Sulfide, 97 % purity (approximately

reference samples (7.2) may also be used.

21.9 mass % sulfur).

7.3.1 Drift correction is usually implemented automatically

8.4.2.5 Magnesium-2-ethylhexoate, (2.99 % magnesium).

in software, although the calculation can readily be done

8.4.2.6 1-Chlorooctane, 98 % purity, (23.9 mass % chlo-

manually. For X-ray instruments that are highly stable, the

rine).

magnitude of the drift correction factor may not differ signifi-

8.4.2.7 Commercially available single element standard for

cantly from unity.

molybdenum based on molybdenumsulfonate.

8.4.2.8 Stabilizers, 2-ethylhexanoic acid, 2-ethylamine, also

7.4 Quality Control (QC) Samples (Optional)—Samples for

proprietarystabilizer/chelatingsolutionsareavailablecommer-

useinestablishingandmonitoringthestabilityandprecisionof

cially. Stabilizers shall be free of the additive element.

an analytical measurement system. Use homogeneous

materials, similar to samples of interest and available in

Reagent Chemicals, American Chemical Society Specifications

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7751 − 12 D7751 − 14

Standard Test Method for

Determination of Additive Elements in Lubricating Oils by

EDXRF Analysis

This standard is issued under the fixed designation D7751; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method covers the quantitative determination of additive elements in unused lubricating oils and additive packages,

as shown in Table 1. The pooled limit of quantitation of this test method as obtained by statistical analysis of interlaboratory test

results is 0.02%0.02 % for magnesium, 0.003 % 0.003 % for phosphorus, 0.002 % 0.002 % for sulfur, 0.001 % 0.001 % for

chlorine, 0.003 % 0.003 % for calcium, 0.001 % 0.001 % for zinc, and 0.002 % 0.002 % for molybdenum.

1.2 Additive packages require dilution with a contamination free diluent (base oil) prior to analysis. The dilution factor has to

be calculated from the expected concentrations to bring the concentrations for all elements into the ranges listed in Table 1.

1.3 Some lubrication oils will contain higher concentrations than the maximum concentrations listed in Table 1. These samples

require dilution with a contamination free diluent (base oil) prior to analysis. The dilution factor has to be calculated from the

expected concentrations to bring the concentrations for all elements into the ranges listed in Table 1.

1.4 This test method is limited to the use of energy dispersive X-ray fluorescence (EDXRF) spectrometers employing an X-ray

tube for excitation in conjunction with the ability to separate the signals of adjacent elements by using a high resolution

semiconductor detector.

1.5 This test method uses inter-element correction factors calculated from a fundamental parameters (FP) approach or from

another matrix correction method.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6.1 The preferred concentration units are mg/kg or mass %.

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.03 on Elemental Analysis.

Current edition approved Dec. 1, 2012Dec. 1, 2014. Published March 2013January 2015. Originally approved in 2011. Last previous edition approved in 20112012 as

D7751 – 11E01. DOI:10.1520/D7751-12.12. DOI:10.1520/D7751-14.

TABLE 1 Elements and Range of Applicability

Element Concentration Range in mass %

Magnesium 0.02 to 0.4

Phosphorous 0.003 to 0.25

Sulfur 0.002 to 1.5

Chlorine 0.001 to 0.4

Calcium 0.003 to 1.0

Zinc 0.001 to 0.25

Molybdenum 0.002 to 0.05

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7751 − 14

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measure-

ment System Performance

D6300 Practice for Determination of Precision and Bias Data for Use in Test Methods for Petroleum Products and Lubricants

D6792 Practice for Quality System in Petroleum Products and Lubricants Testing Laboratories

D7343 Practice for Optimization, Sample Handling, Calibration, and Validation of X-ray Fluorescence Spectrometry Methods

for Elemental Analysis of Petroleum Products and Lubricants

E1621 Guide for Elemental Analysis by Wavelength Dispersive X-Ray Fluorescence Spectrometry

2.2 ISO Standards:

ISO 4259 Determination and application of precision data in relation to methods of test

3. Terminology

3.1 Definitions:

3.1.1 energy dispersive X-ray spectrometry, n—XRF spectrometry applying energy dispersive selection of radiation.

3.2 Abbreviations:

3.2.1 EDXRF—Energy Dispersive X-ray Fluorescence Spectrometry.

3.2.2 FP—Fundamental Parameters.

4. Summary of Test Method

4.1 A specimen is placed in the X-ray beam, and the appropriate regions of its spectrum are measured to give the fluorescent

intensities of magnesium, phosphorus, sulfur, chlorine, calcium, zinc, and molybdenum. Other regions of the spectrum are

measured to compensate for matrix variation. To optimize the sensitivity for each element or group of elements, a combination of

optimized excitation and detection conditions may be used (no more than two conditions should be used in order to keep the

analysis time as short as possible, typically under ten minutes). There may be a correction of measured intensities for spectral

overlap.

4.1.1 Concentrations of the elements of interest are determined by comparison of these intensities against a calibration curve

using a fundamental parameters (FP) approach, possibly combined with corrections from backscatter. The FP approach uses the

physical processes forming the basis of X-ray fluorescence emission in order to provide a theoretical model for the correction of

matrix effects. The correction term is calculated from first principle expressions derived from basic physical principles and contain

physical constants and parameters that include absorption coefficients, fluorescence yield, primary spectral distribution and

spectrometry geometry. The calculation of concentrations in samples is based on making successively better estimates of

composition by an iteration procedure.

NOTE 1—The algorithm used for the procedure is usually implemented in the instrument manufacturer’s software.

4.2 The EDXRF spectrometer is initially calibrated using a set of standards to collect the necessary intensity data. Each

calibration line and any correction coefficient are obtained by a regression of this data, using the program supplied with the

spectrometer. (Warning—Exposure to excessive quantities of X-radiation is injurious to health. The operator needs to take

appropriate actions to avoid exposing any part of their body, not only to primary X-rays, but also to secondary or scattered radiation

that might be present. The X-ray spectrometer should be operated in accordance with the regulations governing the use of ionizing

radiation.)

5. Significance and Use

5.1 Lubricating oils are formulated with organo-metallic additives, which act, for example, as detergents, antioxidants,

antifoaming, or antiwear agents, or a combination thereof. Some of these additives contain one or more of the following elements:

magnesium, phosphorus, sulfur, chlorine, calcium, zinc, and molybdenum. This test method provides a means of determining the

concentrations of these elements, which in turn provides an indication of the additive content of these oils.

5.2 Several additive elements and their compounds are added to the lubricating oils to give beneficial performance (Table 2).

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from International Organization for Standardization (ISO), 1, ch. de la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org.

D7751 − 14

TABLE 2 Lubricants and Additive Materials

Element Compounds Purpose/Application

Calcium Sulfonates, phenates Detergent inhibitors, dispersants

Chlorine Trace contaminants, cleaning agents

Magnesium Sulfonates, phenates Detergent inhibitors

Molybdenum Dialkylithiophosphate dialkyldithiocarbamate, other Friction modifier additives

molybdenum complexes

Phosphorus Dithiophosphates, phosphates phosphites Anti-rusting agents, extreme pressure additives, anti-wear

Sulfur Base oils, sulfonates, thiophosphates, polysulfides and Detergents, extreme pressure additives, anti-wear

other sulfurized components

Zinc Dialkyldithiophosphates, dithiocarbamates, phenolates Anti-oxidant, corrosion inhibitors, anti-wear additives, detergents, crankcase

carboxylates oils, hypoid gear lubricants, aircraft piston engine oils, turbine oils, automatic

transmission fluids, railroad diesel engine oils, brake lubricants

5.3 Additive packages are the concentrates that are used to blend lubricating oils.

5.4 This test method is primarily intended to be used for the monitoring of additive elements in lubricating oils.

5.5 If this test method is applied to lubricating oils with matrices significantly different from the calibration materials specified

in this test method, the cautions and recommendations in Section 6 should be observed when interpreting the results.

6. Interferences

6.1 The additive elements found in lubricating oils will affect the measured intensities from the elements of interest to a varying

degree. In general the X-radiation emitted by the element of interest can be absorbed by itself (self-absorption) or by the other

elements present in the sample matrix. Also the X-radiation emitted from one element can further excite (enhance) another element.

These inter-element effects are significant at concentrations varying from 0.03 mass %, due to the higher atomic number elements

(for example, molybdenum), to 1 mass %, for the lower atomic number elements (for example, sulfur). If an element is present

at significant concentrations and an inter-element correction for that element is not employed, the results can be low due to

absorption or high due to enhancement.

6.2 Absorption and enhancements effects will be corrected by corrections from the FP approach or by other matrix correction

models.

6.3 There can be spectral overlap of one element onto another, and the instrument must include correction procedures for any

such overlaps.

7. Apparatus

7.1 Energy Dispersive X-ray Fluorescent Spectrometer—Any energy dispersive X-ray fluorescence spectrometer can be used if

its design incorporates at least the following features:

7.1.1 Source of X-ray Excitation—X-ray tube with palladium, silver, rhodium, or tungsten target. Other targets may be suitable

as well. The voltage of the X-ray tube shall be programmable between 4 and at least 30 kV for preferential excitation of elements

or groups of elements.

7.1.2 X-ray Detector—Semiconductor detector with high sensitivity and a spectral resolution value not to exceed 175 eV at 5.9

keV.

7.1.3 Primary Beam Filters (Optional)—To make the excitation more selective and to reduce the intensity of background

radiation.

7.1.4 Secondary or Polarization Targets, or Both (Optional)—To make the excitation more selective and to improve

peak-to-background ratio.

7.1.5 Signal Conditioning and Data Handling Electronics—That include the functions of X-ray intensity counting, spectra

handling by background variation correction, overlap corrections, inter-elements effects corrections, and conversion of X-ray

intensity into concentration.

7.1.6 Helium Purgeable Optical Path (Optional)—Helium purge improves the sensitivity of low energy X-rays emitted from

low atomic number elements (Z< 22).

7.1.7 Sample Cells—Providing a depth of at least 6 mm and equipped with replaceable X-ray transparent film.

7.1.8 Sample Film—Suitable films include polypropylene, polyester, and polycarbonate with thickness from 3.5 to 8 μm. A thick

film may limit the performance for low atomic numbers (for example, Magnesium).

7.2 Instrument Setting-Up Samples (Elemental Reference Samples) (Optional)—To quantify spectral overlaps. These are not

required when the instrument’s software does include software to deconvolute spectra.

D7751 − 14

7.3 Drift Correction Monitors (Optional)—To correct for instrumental drift. At least two samples are necessary to correct both

sensitivity and possible changes in the background. For each element and scatter region, there shall be one providing a count rate

similar to samples from the upper end of the calibration and another providing a count rate as if from a blank. This last can be

a blank oil. For the high concentration of each element, a glass disk, XRF fusion bead, or pressed pellet have all been found to

be satisfactory. Elemental reference samples (7.2) may also be used.

7.3.1 Drift correction is usually implemented automatically in software, although the calculation can readily be done manually.

For X-ray instruments that are highly stable, the magnitude of the drift correction factor may not differ significantly from unity.

7.4 Quality Control (QC) Samples (Optional)—Samples for use in establishing and monitoring the stability and precision of an

analytical measurement system. Use homogeneous materials, similar to samples of interest and available in sufficient quantity to

be analyzed regularly for a long period of time.

7.5 For additional information, also refer to Practice D7343.

NOTE 2—Verification of system control through the use of QC samples and control charting is highly recommended.

8. Reagents and Materials

8.1 Purity of Reagents —Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society where such

specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high purity

to permit its use without lessening the accuracy of the determination.

8.2 Diluent Solvent—A suitable solvent containing less than 10 mg/kg of sulfur and containing less than 1 mg/kg of metals as

well as of all other elements of interest (for example, base oil).

8.3 Helium Gas—Minimum purity 99.9 %.

8.4 Calibration Standard Materials:

8.4.1 Commercially available calibration solutions.

8.4.2 Certified concentration solutions, of liquid organometallic salts, the following standard materials can be used:

8.4.2.1 Calcium 2-Ethylhexanoate

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.