ASTM D7751-14e1

(Test Method)Standard Test Method for Determination of Additive Elements in Lubricating Oils by EDXRF Analysis

Standard Test Method for Determination of Additive Elements in Lubricating Oils by EDXRF Analysis

SIGNIFICANCE AND USE

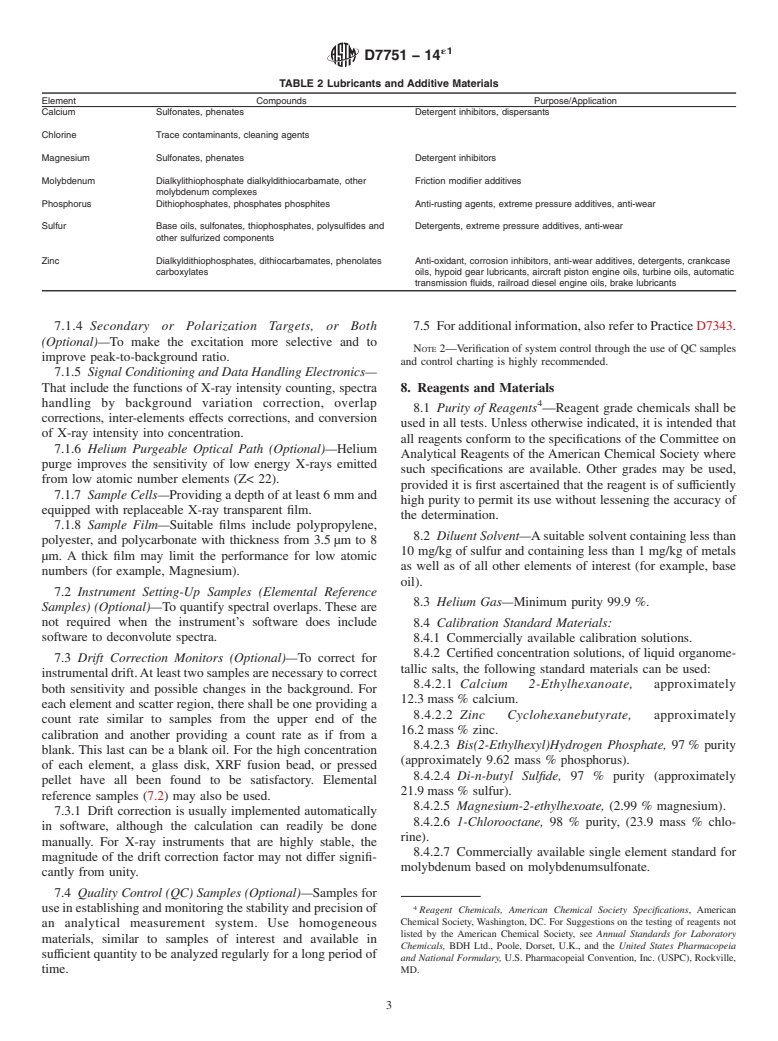

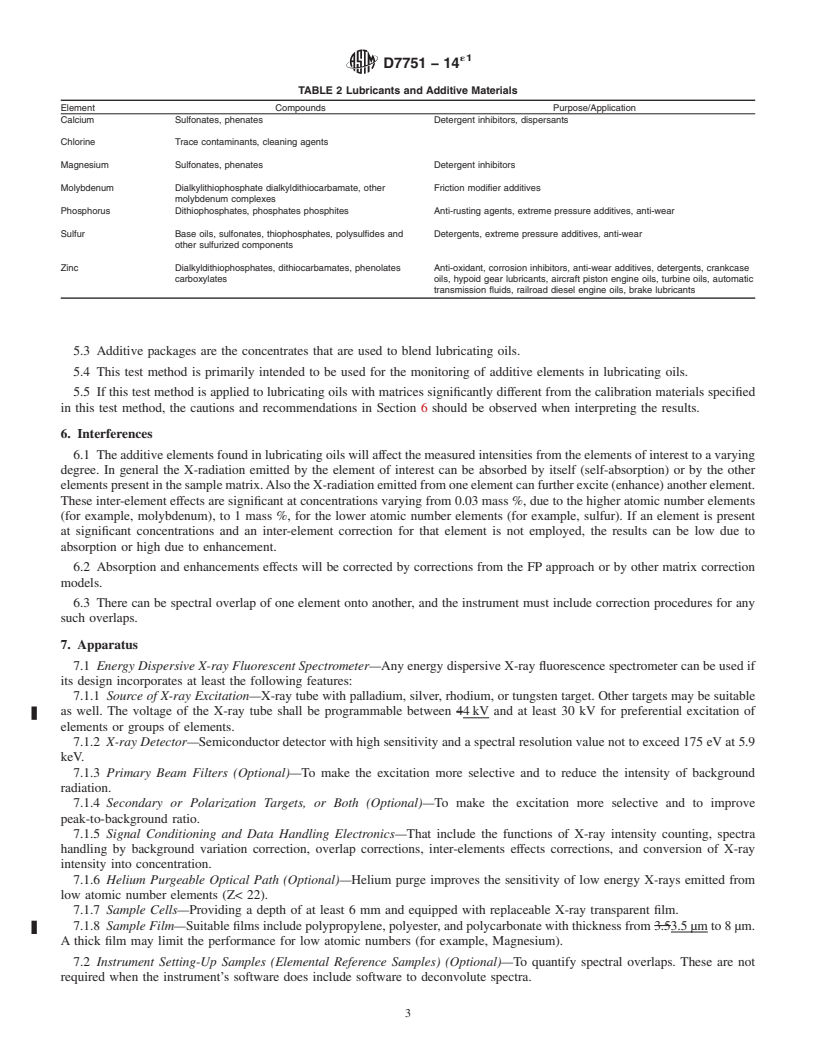

5.1 Lubricating oils are formulated with organo-metallic additives, which act, for example, as detergents, antioxidants, antifoaming, or antiwear agents, or a combination thereof. Some of these additives contain one or more of the following elements: magnesium, phosphorus, sulfur, chlorine, calcium, zinc, and molybdenum. This test method provides a means of determining the concentrations of these elements, which in turn provides an indication of the additive content of these oils.

5.2 Several additive elements and their compounds are added to the lubricating oils to give beneficial performance (Table 2).

5.3 Additive packages are the concentrates that are used to blend lubricating oils.

5.4 This test method is primarily intended to be used for the monitoring of additive elements in lubricating oils.

5.5 If this test method is applied to lubricating oils with matrices significantly different from the calibration materials specified in this test method, the cautions and recommendations in Section 6 should be observed when interpreting the results.

SCOPE

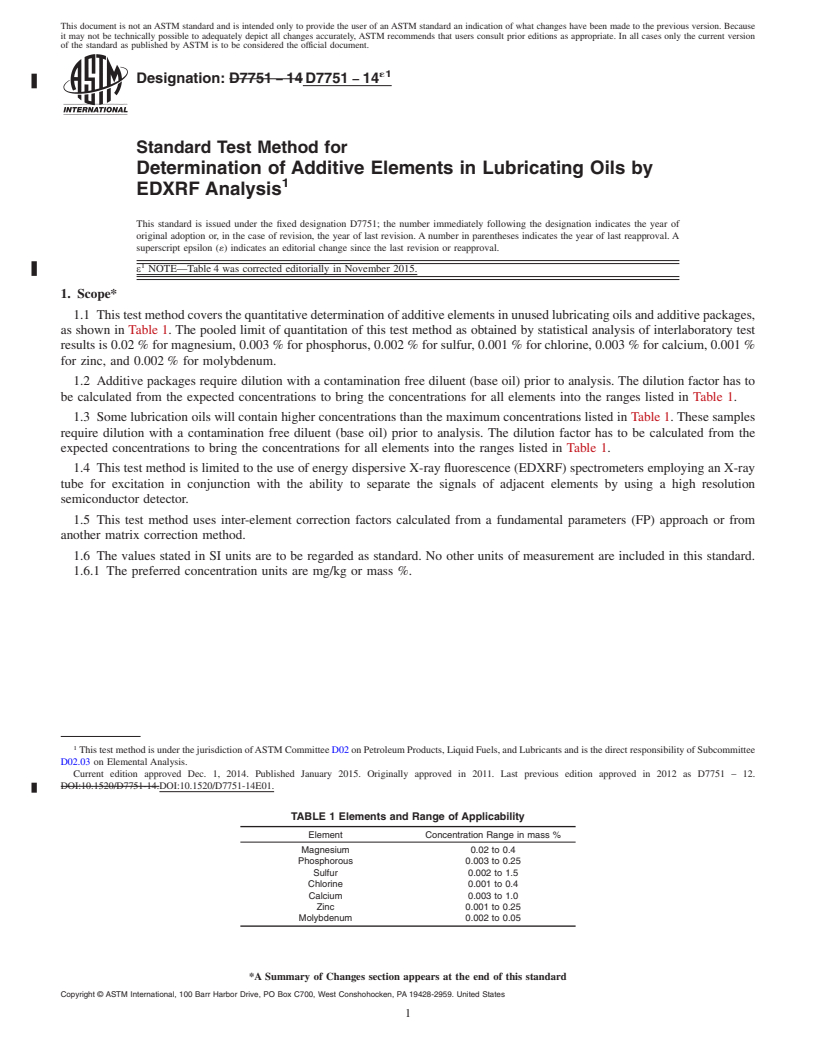

1.1 This test method covers the quantitative determination of additive elements in unused lubricating oils and additive packages, as shown in Table 1. The pooled limit of quantitation of this test method as obtained by statistical analysis of interlaboratory test results is 0.02 % for magnesium, 0.003 % for phosphorus, 0.002 % for sulfur, 0.001 % for chlorine, 0.003 % for calcium, 0.001 % for zinc, and 0.002 % for molybdenum.

1.2 Additive packages require dilution with a contamination free diluent (base oil) prior to analysis. The dilution factor has to be calculated from the expected concentrations to bring the concentrations for all elements into the ranges listed in Table 1.

1.3 Some lubrication oils will contain higher concentrations than the maximum concentrations listed in Table 1. These samples require dilution with a contamination free diluent (base oil) prior to analysis. The dilution factor has to be calculated from the expected concentrations to bring the concentrations for all elements into the ranges listed in Table 1.

1.4 This test method is limited to the use of energy dispersive X-ray fluorescence (EDXRF) spectrometers employing an X-ray tube for excitation in conjunction with the ability to separate the signals of adjacent elements by using a high resolution semiconductor detector.

1.5 This test method uses inter-element correction factors calculated from a fundamental parameters (FP) approach or from another matrix correction method.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6.1 The preferred concentration units are mg/kg or mass %.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D7751 − 14

Standard Test Method for

Determination of Additive Elements in Lubricating Oils by

1

EDXRF Analysis

This standard is issued under the fixed designation D7751; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Table 4 was corrected editorially in November 2015.

1. Scope* 1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the quantitative determination

responsibility of the user of this standard to establish appro-

of additive elements in unused lubricating oils and additive

priate safety and health practices and determine the applica-

packages,asshowninTable1.Thepooledlimitofquantitation

bility of regulatory limitations prior to use.

of this test method as obtained by statistical analysis of

interlaboratory test results is 0.02 % for magnesium, 0.003 %

2. Referenced Documents

for phosphorus, 0.002 % for sulfur, 0.001 % for chlorine,

2

2.1 ASTM Standards:

0.003 % for calcium, 0.001 % for zinc, and 0.002 % for

D4057 Practice for Manual Sampling of Petroleum and

molybdenum.

Petroleum Products

1.2 Additivepackagesrequiredilutionwithacontamination

D4177 Practice for Automatic Sampling of Petroleum and

free diluent (base oil) prior to analysis. The dilution factor has

Petroleum Products

to be calculated from the expected concentrations to bring the

D6299 Practice for Applying Statistical Quality Assurance

concentrationsforallelementsintotherangeslistedinTable1.

and Control Charting Techniques to Evaluate Analytical

1.3 Some lubrication oils will contain higher concentrations

Measurement System Performance

than the maximum concentrations listed in Table 1. These

D6300 Practice for Determination of Precision and Bias

samples require dilution with a contamination free diluent

Data for Use in Test Methods for Petroleum Products and

(base oil) prior to analysis. The dilution factor has to be

Lubricants

calculated from the expected concentrations to bring the

D6792 Practice for Quality System in Petroleum Products

concentrationsforallelementsintotherangeslistedinTable1.

and Lubricants Testing Laboratories

D7343 Practice for Optimization, Sample Handling,

1.4 This test method is limited to the use of energy

Calibration, and Validation of X-ray Fluorescence Spec-

dispersive X-ray fluorescence (EDXRF) spectrometers em-

trometry Methods for Elemental Analysis of Petroleum

ploying an X-ray tube for excitation in conjunction with the

Products and Lubricants

ability to separate the signals of adjacent elements by using a

E1621 Guide for ElementalAnalysis by Wavelength Disper-

high resolution semiconductor detector.

sive X-Ray Fluorescence Spectrometry

1.5 This test method uses inter-element correction factors

3

2.2 ISO Standards:

calculated from a fundamental parameters (FP) approach or

ISO 4259 Determination and application of precision data in

from another matrix correction method.

relation to methods of test

1.6 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

3. Terminology

standard.

3.1 Definitions:

1.6.1 The preferred concentration units are mg/kg or mass

3.1.1 energy dispersive X-ray spectrometry, n—XRF spec-

%.

trometry applying energy dispersive selection of radiation.

1 2

This test method is under the jurisdiction of ASTM Committee D02 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee D02.03 on Elemental Analysis. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Dec. 1, 2014. Published January 2015. Originally the ASTM website.

3

approved in 2011. Last previous edition approved in 2012 as D7751 – 12. Available from International Organization for Standardization (ISO), 1, ch. de

DOI:10.1520/D7751-14E01. la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

D7751 − 14

TABLE 1 Elements and Range of Applicability

Some of these additives contain one or more of the following

Element Concentration Range in mass % elements: magnesium, phosphorus, sulfur, chlorine, calcium,

Magnesium 0.02 to 0.4 zinc, and molybdenum. This

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D7751 − 14 D7751 − 14

Standard Test Method for

Determination of Additive Elements in Lubricating Oils by

1

EDXRF Analysis

This standard is issued under the fixed designation D7751; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Table 4 was corrected editorially in November 2015.

1. Scope*

1.1 This test method covers the quantitative determination of additive elements in unused lubricating oils and additive packages,

as shown in Table 1. The pooled limit of quantitation of this test method as obtained by statistical analysis of interlaboratory test

results is 0.02 % for magnesium, 0.003 % for phosphorus, 0.002 % for sulfur, 0.001 % for chlorine, 0.003 % for calcium, 0.001 %

for zinc, and 0.002 % for molybdenum.

1.2 Additive packages require dilution with a contamination free diluent (base oil) prior to analysis. The dilution factor has to

be calculated from the expected concentrations to bring the concentrations for all elements into the ranges listed in Table 1.

1.3 Some lubrication oils will contain higher concentrations than the maximum concentrations listed in Table 1. These samples

require dilution with a contamination free diluent (base oil) prior to analysis. The dilution factor has to be calculated from the

expected concentrations to bring the concentrations for all elements into the ranges listed in Table 1.

1.4 This test method is limited to the use of energy dispersive X-ray fluorescence (EDXRF) spectrometers employing an X-ray

tube for excitation in conjunction with the ability to separate the signals of adjacent elements by using a high resolution

semiconductor detector.

1.5 This test method uses inter-element correction factors calculated from a fundamental parameters (FP) approach or from

another matrix correction method.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6.1 The preferred concentration units are mg/kg or mass %.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.03 on Elemental Analysis.

Current edition approved Dec. 1, 2014. Published January 2015. Originally approved in 2011. Last previous edition approved in 2012 as D7751 – 12.

DOI:10.1520/D7751-14.DOI:10.1520/D7751-14E01.

TABLE 1 Elements and Range of Applicability

Element Concentration Range in mass %

Magnesium 0.02 to 0.4

Phosphorous 0.003 to 0.25

Sulfur 0.002 to 1.5

Chlorine 0.001 to 0.4

Calcium 0.003 to 1.0

Zinc 0.001 to 0.25

Molybdenum 0.002 to 0.05

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

D7751 − 14

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measure-

ment System Performance

D6300 Practice for Determination of Precision and Bias Data for Use in Test Methods for Petroleum Products and Lubricants

D6792 Practice for Quality System in Petroleum Products and Lubricants Testing Laboratories

D7343 Practice for Optimization, Sample Handling, Calibration, and Validation of X-ray Fluorescence Spectrometry Methods

for Elemental Analysis of Petroleum Products and Lubricants

E1621 Guide for Elemental Analysis by Wavelength Dispersive X-Ray Fluorescence Spectrometry

3

2.2 ISO Standards:

ISO 4259 Determination and application of precision data in relation to methods of test

3. Terminology

3.1 Definitions:

3.1.1 energy dispersive X-ray spectrometry, n—XRF spectrometry applying energy dispersive selection of radiation.

3.2 Abbreviations:

3.2.1 EDXRF—Energy Dispersive X-ray Fluorescence Spectromet

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.