ASTM D955-08(2014)

(Test Method)Standard Test Method of Measuring Shrinkage from Mold Dimensions of Thermoplastics

Standard Test Method of Measuring Shrinkage from Mold Dimensions of Thermoplastics

SIGNIFICANCE AND USE

5.1 Injection Molding—In injection molding, the difference between the dimensions of a mold cavity and of the molded specimen may vary according to the design of the mold and operation of the molding process. Factors such as mold and melt temperature, fill times, and packing conditions are known to affect shrinkage significantly. Adherence to the specified mold design (see 7.1) and specifications outlined in Practice D3641 or ISO 294-4 or the appropriate material specification will improve the reproducibility of the test.

5.2 Compression Molding—In compression molding, the difference between the dimensions of a mold cavity and of the molded specimen may vary according to the design of the mold and operation of the molding process. Factors, such as the amount of material in charge, cooling time, and pressure application are known to affect shrinkage significantly. Adherence to the specified mold design (see 7.2) and specifications outlined in Practice D4703 or ISO 293 or the appropriate material specifications will improve the reproducibility of the test.

SCOPE

1.1 This test method is intended to measure shrinkage from mold cavity to molded dimensions of thermoplastics when molded by compression or injection processes with specified process conditions.

1.2 This test method covers shrinkage measurements at 24 and 48 hours.

1.3 This method will give comparable data based on standard specimens and can not predict absolute values in actual molded parts with varying flow paths, wall thicknesses, pressure and temperature gradients and process conditions. Differences in mold shrinkage may also be observed among the three specimen geometries described in this test method.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are given for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

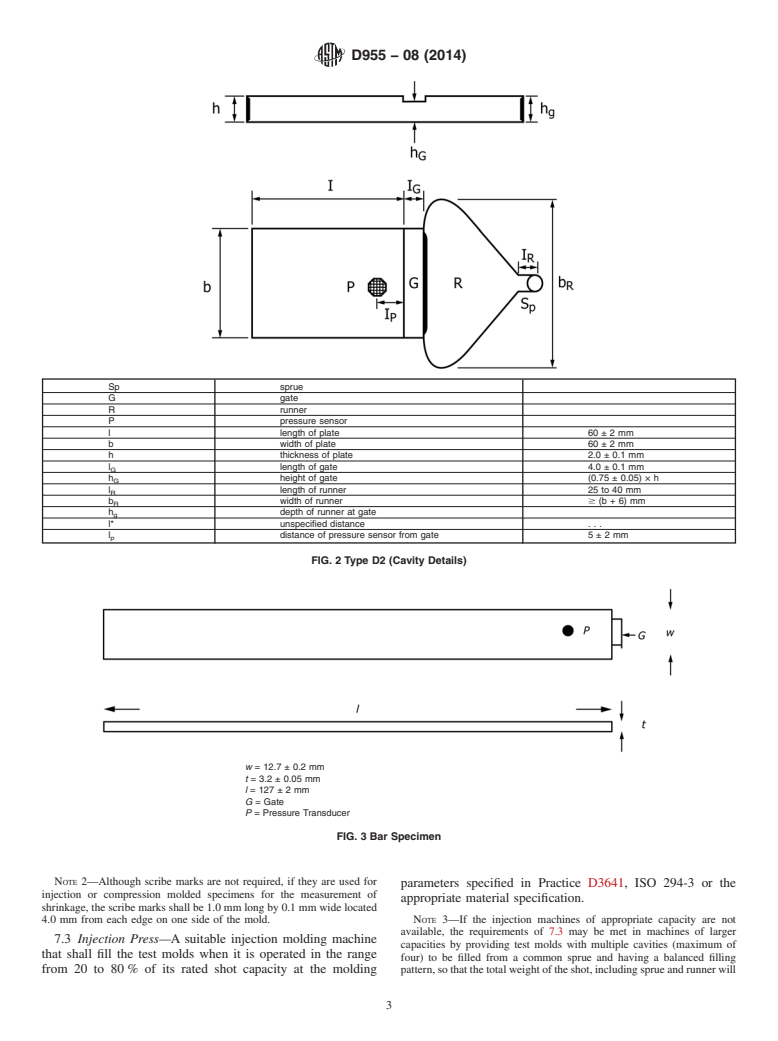

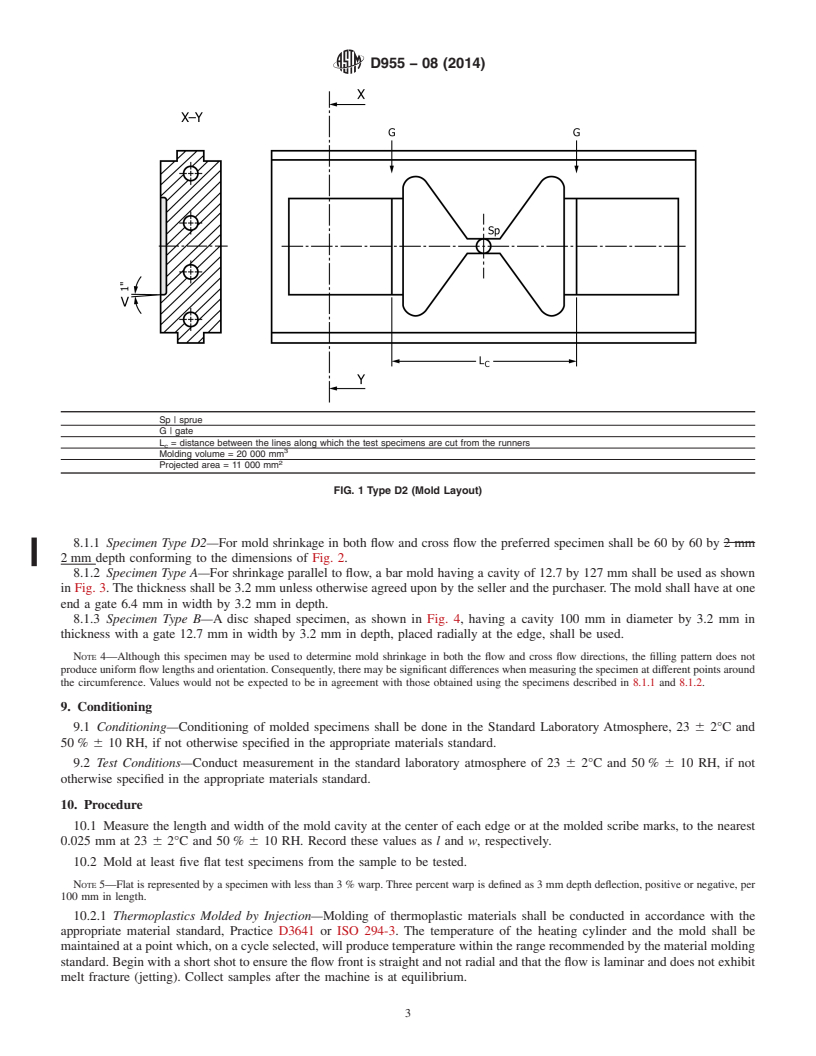

Note 1: This standard and ISO 294-3 are equivalent in the design of specimen D2. This test method is equivalent to ISO 294-4 where Type D2 specimens and the procedure in Appendix X2 are used.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D955 − 08 (Reapproved 2014)

Standard Test Method of

Measuring Shrinkage from Mold Dimensions of

1

Thermoplastics

This standard is issued under the fixed designation D955; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope D3641Practice for Injection Molding Test Specimens of

Thermoplastic Molding and Extrusion Materials

1.1 This test method is intended to measure shrinkage from

D4066Classification System for Nylon Injection and Extru-

mold cavity to molded dimensions of thermoplastics when

sion Materials (PA)

molded by compression or injection processes with specified

D4549Classification System and Basis for Specification for

process conditions.

Polystyrene and Rubber-Modified Polystyrene Molding

1.2 This test method covers shrinkage measurements at 24

and Extrusion Materials (PS)

and 48 hours.

D4703Practice for Compression Molding Thermoplastic

1.3 This method will give comparable data based on stan-

Materials into Test Specimens, Plaques, or Sheets

dard specimens and can not predict absolute values in actual D4976Specification for Polyethylene Plastics Molding and

molded parts with varying flow paths, wall thicknesses, pres-

Extrusion Materials

sure and temperature gradients and process conditions. Differ- D5947Test Methods for Physical Dimensions of Solid

encesinmoldshrinkagemayalsobeobservedamongthethree

Plastics Specimens

specimen geometries described in this test method. D6778Classification System and Basis for Specification for

Polyoxymethylene Molding and Extrusion Materials

1.4 The values stated in SI units are to be regarded as the

(POM)

standard. The values given in parentheses are given for

D6779Classification System for and Basis of Specification

information only.

for Polyamide Molding and Extrusion Materials (PA)

1.5 This standard does not purport to address all of the

E691Practice for Conducting an Interlaboratory Study to

safety concerns, if any, associated with its use. It is the

Determine the Precision of a Test Method

responsibility of the user of this standard to establish appro-

3

2.2 ISO Standards:

priate safety and health practices and determine the applica-

ISO 293Plastics—Compression Moulding Test Specimens

bility of regulatory limitations prior to use.

of Thermoplastic Materials

NOTE 1—This standard and ISO 294-3 are equivalent in the design of

ISO 294-1Plastics—Injection Moulding of Test Specimens

specimenD2.ThistestmethodisequivalenttoISO294-4whereTypeD2

of Thermoplastic Materials—Part 1: General Principles,

specimens and the procedure in Appendix X2 are used.

and Moulding of Multipurpose and Bar Test specimens

2. Referenced Documents

ISO 294-3Plastics—Injection Moulding of Test Specimens

2

of Thermoplastic Materials—Part 3: Small Plates

2.1 ASTM Standards:

ISO 294-4 Plastics—Injection Moulding of Test

D618Practice for Conditioning Plastics for Testing

Specimens—Part 4: Determination of Moulding Shrink-

D788Classification System for Poly(Methyl Methacrylate)

age

(PMMA) Molding and Extrusion Compounds

D883Terminology Relating to Plastics

3. Terminology

3.1 Definitions—General definitions of terms applying to

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics

and is the direct responsibility of Subcommittee D20.09 on Specimen Preparation. this test method appear in Terminology D883.

Current edition approved Aug. 1, 2014. Published August 2014. Originally

3.2 Definitions of Terms Specific to This Standard:

approved in 1948. Last previous edition approved in 2008 as D955-08. DOI:

10.1520/D0955-08R14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D955 − 08 (2014)

3.2.1 jetting, n—non-uniform multi-directional flow front 6. Sample Preparation

apparent on the surface of the mold due to rapid filling of the

6.1 Somematerialsrequirespecialtreatmentbeforetheyare

mold cavity.

molded. For example, thermoplastics, which absorb moisture

must be dried before molding. For required conditions for

4. Summary of Test Method

sample preparation, refer to the appropriate material specifica-

4.1 The

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D955 − 08 D955 − 08 (Reapproved 2014)

Standard Test Method of

Measuring Shrinkage from Mold Dimensions of

1

Thermoplastics

This standard is issued under the fixed designation D955; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*Scope

1.1 This test method is intended to measure shrinkage from mold cavity to molded dimensions of thermoplastics when molded

by compression or injection processes with specified process conditions.

1.2 This test method covers shrinkage measurements at 24 and 48 h.hours.

1.3 This method will give comparable data based on standard specimens and can not predict absolute values in actual molded

parts with varying flow paths, wall thicknesses, pressure and temperature gradients and process conditions. Differences in mold

shrinkage may also be observed among the three specimen geometries described in this test method.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are given for information

only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE 1—This standard and ISO 294-3 are equivalent in the design of specimen D2. This test method is equivalent to ISO 294-4 where Type D2

specimens and the procedure in Appendix X2 are used.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D788 Classification System for Poly(Methyl Methacrylate) (PMMA) Molding and Extrusion Compounds

D883 Terminology Relating to Plastics

D3641 Practice for Injection Molding Test Specimens of Thermoplastic Molding and Extrusion Materials

D4066 Classification System for Nylon Injection and Extrusion Materials (PA)

D4549 Classification System and Basis for Specification for Polystyrene and Rubber-Modified Polystyrene Molding and

Extrusion Materials (PS)

D4703 Practice for Compression Molding Thermoplastic Materials into Test Specimens, Plaques, or Sheets

D4976 Specification for Polyethylene Plastics Molding and Extrusion Materials

D5947 Test Methods for Physical Dimensions of Solid Plastics Specimens

D6778 Classification System and Basis for Specification for Polyoxymethylene Molding and Extrusion Materials (POM)

D6779 Classification System for and Basis of Specification for Polyamide Molding and Extrusion Materials (PA)

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3

2.2 ISO Standards:

ISO 293 Plastics—Compression Moulding Test Specimens of Thermoplastic Materials

ISO 294-1 Plastics—Injection Moulding of Test Specimens of Thermoplastic Materials—Part 1: General Principles, and

Moulding of Multipurpose and Bar Test specimens

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.09 on Specimen Preparation.

Current edition approved Nov. 1, 2008Aug. 1, 2014. Published December 2008August 2014. Originally approved in 1948. Last previous edition approved in 20002008

as D955 - 00.D955 - 08. DOI: 10.1520/D0955-08.10.1520/D0955-08R14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D955 − 08 (2014)

ISO 294-3 Plastics—Injection Moulding of Test Specimens of Thermoplastic Materials—Part 3: Small Plates

ISO 294-4 Plastics—Injection Moulding of Test Specimens—Part 4: Determination of Moulding Shrinkage

3. Terminology

3.1 Definitions—General definitions of terms applying to this test method appear in Terminology D883.

3.2 Definition

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.