ASTM F1574-95

(Test Method)Standard Test Method for Compressive Strength of Gaskets at Elevated Temperatures

Standard Test Method for Compressive Strength of Gaskets at Elevated Temperatures

SCOPE

1.1 This test method covers the determination of compressive strength characteristics (crush-extrusion resistance) of gasket materials at elevated temperature.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1574 – 95

Standard Test Method for

Compressive Strength of Gaskets at Elevated

Temperatures

This standard is issued under the fixed designation F 1574; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope part, on the assumption that a material, once it has been

crushed or extruded, will no longer function as effectively as a

1.1 This test method covers the determination of compres-

seal. This assumption can only be used as a guide, however,

sive strength characteristics (crush-extrusion resistance) of

since exact yield or failure points are difficult to define for

gasket materials at elevated temperature.

gasket materials (which are usually viscoelastic in nature). Two

1.2 This standard does not purport to address all of the

or more materials can be compared to determine differences in

safety concerns, if any, associated with its use. It is the

their resistance to compressive stress. A sample of material can

responsibility of the user of this standard to establish appro-

be compared to an established standard or previously deter-

priate safety and health practices and determine the applica-

mined characteristics on original lots of the same material, for

bility of regulatory limitations prior to use.

quality assurance purposes. See 6.2 for discussion of specimen

2. Referenced Documents area and geometry effects.

2.1 ASTM Standards:

5. Apparatus

F 104 Classification System for Nonmetallic Gasket Mate-

2 5.1 Testing Machine , for applying a known value of com-

rials

pressive stresses to specimens. The machine should be capable

3. Summary of the Test Method of applying a stress of up to 517 MPa (75 000 psi) (tolerance

of 6 5 %), depending on the indent resistance of the steel

3.1 Specimens cut from gasket material are subjected to

platens and the means of reading the applied load.

various stresses perpendicular to the flat surface of the speci-

5.2 Hardened Steel Platens, Two (Rockwell of C35 to 40 or

mens for a specified time at 149°C (300°F). Dimensional

equivalent), circular shape, larger than the specimen diameter.

changes to the thickness and in the plane of the specimen while

A suitable size is a diameter of approximately 101 mm (4 in.).

under stress and after the stress has been removed are deter-

The surface finish shall be RMS 0.25 to 0.50 μm (10 to 20 μm).

mined. A graphical display of percent deformation plotted

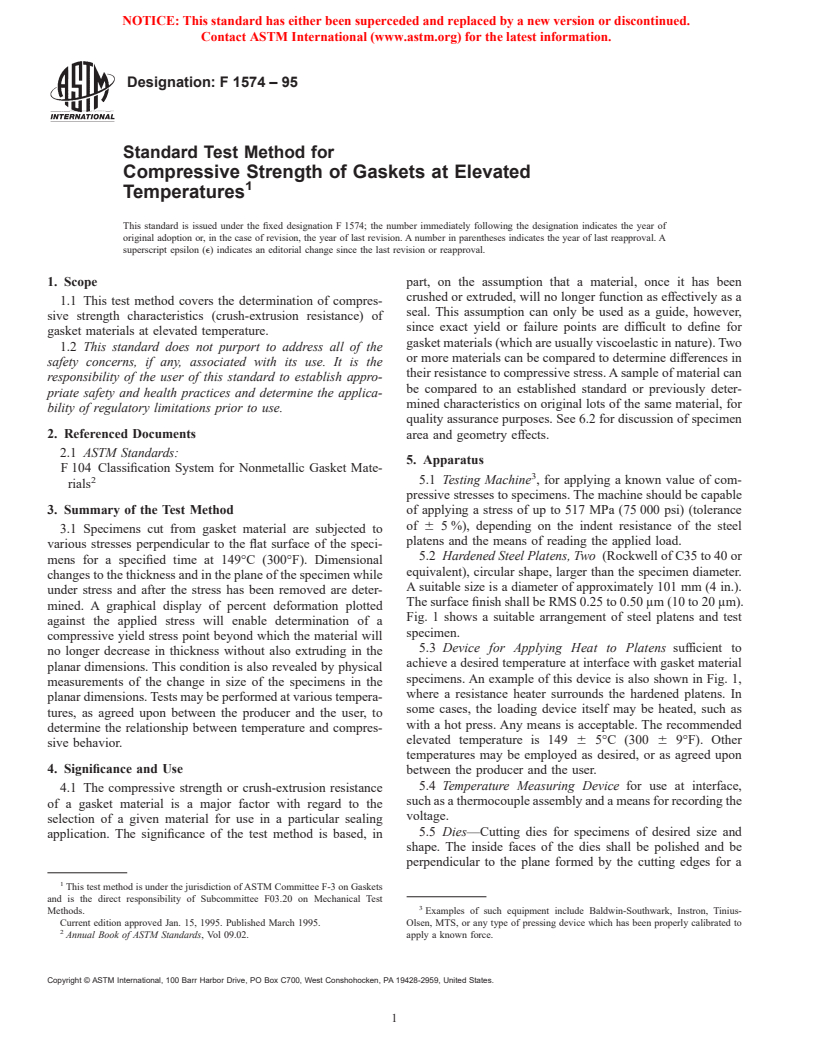

Fig. 1 shows a suitable arrangement of steel platens and test

against the applied stress will enable determination of a

specimen.

compressive yield stress point beyond which the material will

5.3 Device for Applying Heat to Platens sufficient to

no longer decrease in thickness without also extruding in the

achieve a desired temperature at interface with gasket material

planar dimensions. This condition is also revealed by physical

specimens. An example of this device is also shown in Fig. 1,

measurements of the change in size of the specimens in the

where a resistance heater surrounds the hardened platens. In

planar dimensions. Tests may be performed at various tempera-

some cases, the loading device itself may be heated, such as

tures, as agreed upon between the producer and the user, to

with a hot press. Any means is acceptable. The recommended

determine the relationship between temperature and compres-

elevated temperature is 149 6 5°C (300 6 9°F). Other

sive behavior.

temperatures may be employed as desired, or as agreed upon

4. Significance and Use

between the producer and the user.

5.4 Temperature Measuring Device for use at interface,

4.1 The compressive strength or crush-extrusion resistance

such as a thermocouple assembly and a means for recording the

of a gasket material is a major factor with regard to the

voltage.

selection of a given material for use in a particular sealing

5.5 Dies—Cutting dies for specimens of desired size and

application. The significance of the test method is based, in

shape. The inside faces of the dies shall be polished and be

perpendicular to the plane formed by the cutting edges for a

This test method is under the jurisdiction of ASTM Committee F-3 on Gaskets

and is the direct responsibility of Subcommittee F03.20 on Mechanical Test

Methods. Examples of such equipment include Baldwin-Southwark, Instron, Tinius-

Current edition approved Jan. 15, 1995. Published March 1995. Olsen, MTS, or any type of pressing device which has been properly calibrated to

Annual Book of ASTM Standards, Vol 09.02. apply a known force.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F1574–95

FIG. 1 Device for Testing Gasket for Compressive Strength at Elevated Temperature

depth sufficient to prevent any bevel on the edge. The die shall other than to acknowledge it will most likely influence the

be sharp and free of nicks in order to prevent ragged edges on results and should therefore be a part of the report in accor-

the specimen. The bore and outside diameter shall be concen- dance with Section 10. See Table 3 in Classification F 104 for

tric. recommended thicknesses for different types of materials.

5.6 Lead Pellets, Solder Plugs, or Similar Soft Metallic

7. Conditioning

Particles, approximately 1.6 mm [0.063 in.] in diameter.

5.7 Micrometer, for specimen thickness measurements in

7.1 Condition the cut specimens in accordance with the

accordance with Classification F 104.

appropriate procedure in Classification F 104 with respect to

5.8 Micrometer, for measuring metallic particle thickness.

the type of gasket material for which the specimens are cut.

5.9 Vernier Calipers or other suitable device for linear

8. Procedure

dimensional measurements in the plane of the specimens,

capable of reading to the nearest 0.025 mm (0.001 in.) or less.

8.1 Prepare the testing machine by arranging the steel

platens to accommodate the test specimens. Verify that the

6. Test Specimens

temperature at the platen interface equals 149 6 5°C (300 6

6.1 The gasket shall be die cut in the shape of an annulus, 9°F), required for the test.

which may be considered indicative of an area of a gasket. The 8.2 Determine applied stresses at which the gasket material

area shall be sufficiently small as to allow an applied stress of will be evaluated. It should be representative of typical

up to 517 MPa (75 000 psi) (65 %). Three specimens should operating conditions for gaskets made of the material, and

be prepared for each applied stress at which the material is to additional higher and lower stress conditions when a full range

be evaluated. evaluation of the material is desired. Several different stresses

6.2 The recommended annular specimen size is 23.8 6 should be selected to cover the entire range.

0.5-mm (0.937 6 0.02-in.) outside diameter by 12.7 6 0.5- 8.3 Measure and record the original thicknesses of each

mm (0.500 6 0.02-in.) inside diameter. This size will therefore specimen, in accordance with the method described in Classi-

have an annular width of approximately 5.5 mm (0.219 in.), fication F 104 for the particular type of material. Each sample

where the annular width is the difference between the outer and should also be weighed to the nearest 0.001 g. The density

inner radius. The a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.