ASTM D3929-03(2015)

(Test Method)Standard Test Method for Evaluating Stress Cracking of Plastics by Adhesives Using the Bent-Beam Method

Standard Test Method for Evaluating Stress Cracking of Plastics by Adhesives Using the Bent-Beam Method

SIGNIFICANCE AND USE

5.1 This test method is designed for obtaining a qualitative estimate of the compatibility of plastics and adhesives. Due to the many process variables associated with the fabrication of plastic parts, it is not possible to use this test as a substitute for compatibility tests on actual parts.

5.2 The detection of cracks or crazes may be determined with or without optical aid. Make comparisons only among tests employing crack detection methods of equivalent sensitivity.

SCOPE

1.1 This test method describes a procedure for determining the compatibility of adhesives with plastics based on whether the adhesive causes cracking of stressed samples.

1.2 Specimen configurations and test fixture designs are given.

1.3 This test method is suitable for products in the form of sheet or strip. It can also be used on injection molded tensile specimens or flexural bars.

1.4 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3929 − 03 (Reapproved 2015)

Standard Test Method for

Evaluating Stress Cracking of Plastics by Adhesives Using

the Bent-Beam Method

This standard is issued under the fixed designation D3929; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.1 cracking, n—a continuous localized failure of the

plastic, leading to loss of structural integrity.

1.1 This test method describes a procedure for determining

3.2.2 crazing, n—apparent fine cracks at or under the

the compatibility of adhesives with plastics based on whether

surface of a plastic.

the adhesive causes cracking of stressed samples.

3.2.2.1 Discussion—This is a form of localized yielding of

1.2 Specimen configurations and test fixture designs are

the plastic due to the combined action of stress and an attacking

given.

medium. Initial crazing may be detectable only by inspection

1.3 This test method is suitable for products in the form of

under magnification.

sheet or strip. It can also be used on injection molded tensile

3.2.3 failure, n—an arbitrary point defined by the initial

specimens or flexural bars.

detection of cracks or crazes.

1.4 The values stated in SI units are to be regarded as the

4. Summary of Test Method

standard. The inch-pound units given in parentheses are for

information only.

4.1 This test method involves the qualitative determination

of the compatibility of adhesives with plastics by observing the

1.5 This standard does not purport to address all of the

effect of adhesives applied in the liquid state on stressed plastic

safety concerns, if any, associated with its use. It is the

specimens. Bars of plastic are bent in a three-point loading

responsibility of the user of this standard to establish appro-

fixture to cause a predetermined initial tensile stress on the

priate safety and health practices and determine the applica-

surface of the bar. The liquid adhesive is then applied to the

bility of regulatory limitations prior to use.

area of maximum stress which is checked periodically for

crazing or cracking.

2. Referenced Documents

4.1.1 Due to the stress relaxation behavior of certain

2.1 ASTM Standards:

plastics, initial stress only can be determined and the stress

D638 Test Method for Tensile Properties of Plastics

level may decrease significantly during the course of the test.

D790 Test Methods for Flexural Properties of Unreinforced

and Reinforced Plastics and Electrical Insulating Materi-

5. Significance and Use

als

5.1 This test method is designed for obtaining a qualitative

D907 Terminology of Adhesives

estimate of the compatibility of plastics and adhesives. Due to

the many process variables associated with the fabrication of

3. Terminology

plastic parts, it is not possible to use this test as a substitute for

3.1 Definitions—Many of the terms in this test method are

compatibility tests on actual parts.

defined in Terminology D907.

5.2 The detection of cracks or crazes may be determined

3.2 Definitions of Terms Specific to This Standard:

with or without optical aid. Make comparisons only among

tests employing crack detection methods of equivalent sensi-

tivity.

This test method is under the jurisdiction of ASTM Committee D14 on

Adhesives and is the direct responsibility of Subcommittee D14.40 on Adhesives for 6. Apparatus

Plastics.

6.1 Test Fixtures—Bent beam test fixtures (see Fig. 1) are

Current edition approved Sept. 1, 2015. Published September 2015. Originally

ɛ1

approved in 1980. Last previous edition approved in 2010 as D3929 – 03 (2010) . designed to place the specimen in three-point bending. The

DOI: 10.1520/D3929-03R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Detailed drawings are shown in Figs. 3–5. Also necessary to complete the test

1 1

Standards volume information, refer to the standard’s Document Summary page on fixture are the following parts: 2 pieces at 6 by 38 mm ( ⁄4 by 1 ⁄2-in.) dowel pins

the ASTM website. and 2 pieces of M4–0.7 (8–32 unc) by 32 mm (1 ⁄4-in.) socket head cap screws.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3929 − 03 (2015)

8.2.1 If the adhesive contains a solvent, allow it to evaporate

at a normal rate.

8.2.2 If the adhesive is a curing type, cure in a normal

fashion.

8.2.3 If the adhesive is a hot melt, apply at the normal

application temperature and then allow to cool. This is a less

severe condition than would occur if the adhesive were

continually applied, but is more consistent with situations that

occur in actual adhesive use.

8.3 Control Specimens—Concurrently run one control

specimen with the test specimens in the same location. Exces-

sive molded-in stresses or airborne solvent vapors may cause

stress cracking even without application of adhesive.

9. Stress Calculations

9.1 The equation given below is valid only for specimens of

rectangular cross section at stresses below the elastic limit of

the material. The deflection is based on initial stress only. The

level of stress will normally decrease with time as the plastic

undergoes relaxation. Deflection is calculated based on the

desired stress level as follows:

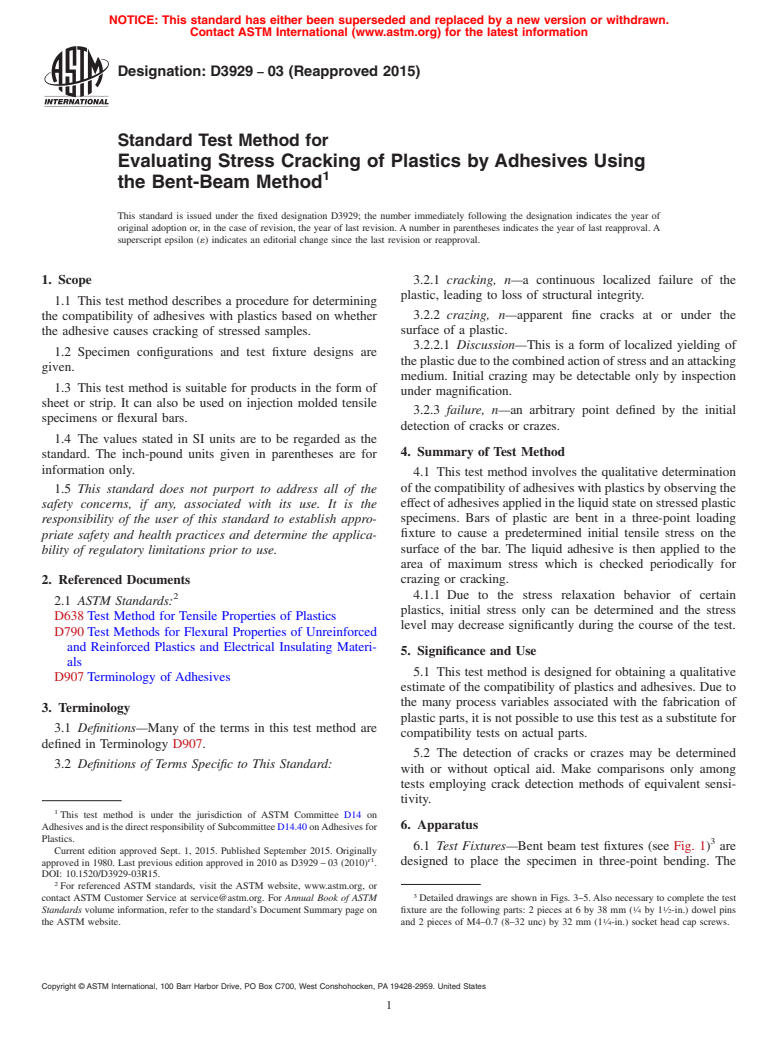

FIG. 1 Test Fixture with Plastic Bar in Place

D 5 SL /6 d E (1)

where:

amount of deflection is adjustable as well as the loading span.

D = deflection, m (in.),

Other fixtures may be used as long as specimen deflection is S = stress, Pa (psi),

known. L = loading span, m (in.),

d = specimen depth, m (in.), and

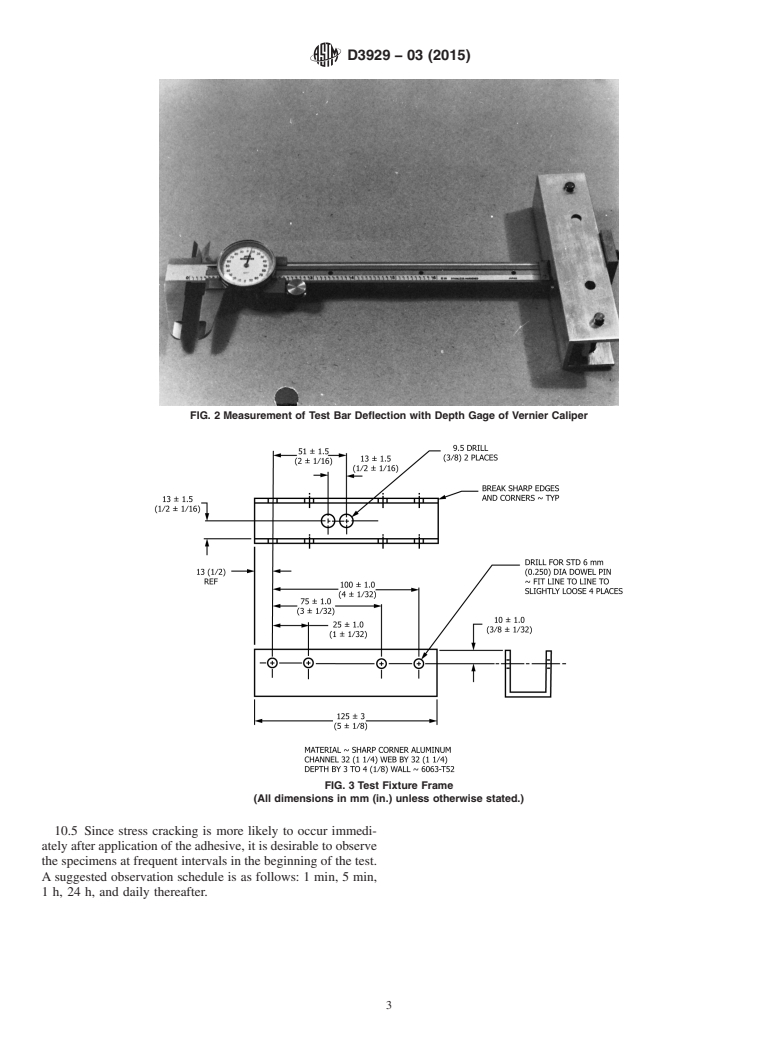

6.2 The amount of deflection on the specimen is measured

E = modulus of the plastic, Pa (psi).

by use of a dial gage indicator or a vernier caliper having a

NOTE 1—T

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D3929 − 03 (Reapproved 2010) D3929 − 03 (Reapproved 2015)

Standard Test Method for

Evaluating Stress Cracking of Plastics by Adhesives Using

the Bent-Beam Method

This standard is issued under the fixed designation D3929; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Captions of Figures 3, 4, 5, and 6 were corrected editorially in April 2010.

1. Scope

1.1 This test method describes a procedure for determining the compatibility of adhesives with plastics based on whether the

adhesive causes cracking of stressed samples.

1.2 Specimen configurations and test fixture designs are given.

1.3 This test method is suitable for products in the form of sheet or strip. It can also be used on injection molded tensile

specimens or flexural bars.

1.4 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for

information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D638 Test Method for Tensile Properties of Plastics

D790 Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

D907 Terminology of Adhesives

3. Terminology

3.1 Definitions—Many of the terms in this test method are defined in Terminology D907.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 cracking, n—a continuous localized failure of the plastic, leading to loss of structural integrity.

3.2.2 crazing, n—apparent fine cracks at or under the surface of a plastic.

This test method is under the jurisdiction of ASTM Committee D14 on Adhesives and is the direct responsibility of Subcommittee D14.40 on Adhesives for Plastics.

Current edition approved April 1, 2010Sept. 1, 2015. Published April 2010September 2015. Originally approved in 1980. Last previous edition approved in 20032010 as

ɛ1

D3929 – 03.D3929 – 03 (2010) . DOI: 10.1520/D3929-03R10E01.10.1520/D3929-03R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

3.2.2.1 Discussion—

This is a form of localized yielding of the plastic due to the combined action of stress and an attacking medium. Initial crazing

may be detectable only by inspection under magnification.

3.2.3 failure, n—an arbitrary point defined by the initial detection of cracks or crazes.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3929 − 03 (2015)

4. Summary of Test Method

4.1 This test method involves the qualitative determination of the compatibility of adhesives with plastics by observing the

effect of adhesives applied in the liquid state on stressed plastic specimens. Bars of plastic are bent in a three-point loading fixture

to cause a predetermined initial tensile stress on the surface of the bar. The liquid adhesive is then applied to the area of maximum

stress which is checked periodically for crazing or cracking.

4.1.1 Due to the stress relaxation behavior of certain plastics, initial stress only can be determined and the stress level may

decrease significantly during the course of the test.

5. Significance and Use

5.1 This test method is designed for obtaining a qualitative estimate of the compatibility of plastics and adhesives. Due to the

many process variables associated with the fabrication of plastic parts, it is not possible to use this test as a substitute for

compatibility tests on actual parts.

5.2 The detection of cracks or crazes may be determined with or without optical aid. Make comparisons only among tests

employing crack detection methods of equivalent sensitivity.

6. Apparatus

6.1 Test Fixtures—Bent beam test fixtures (see Fig. 1) are designed to place the specimen in three-point bending. The amount

of deflection is adjustable as well as the loading span. Other fixtures may be used as long as specimen deflection is known.

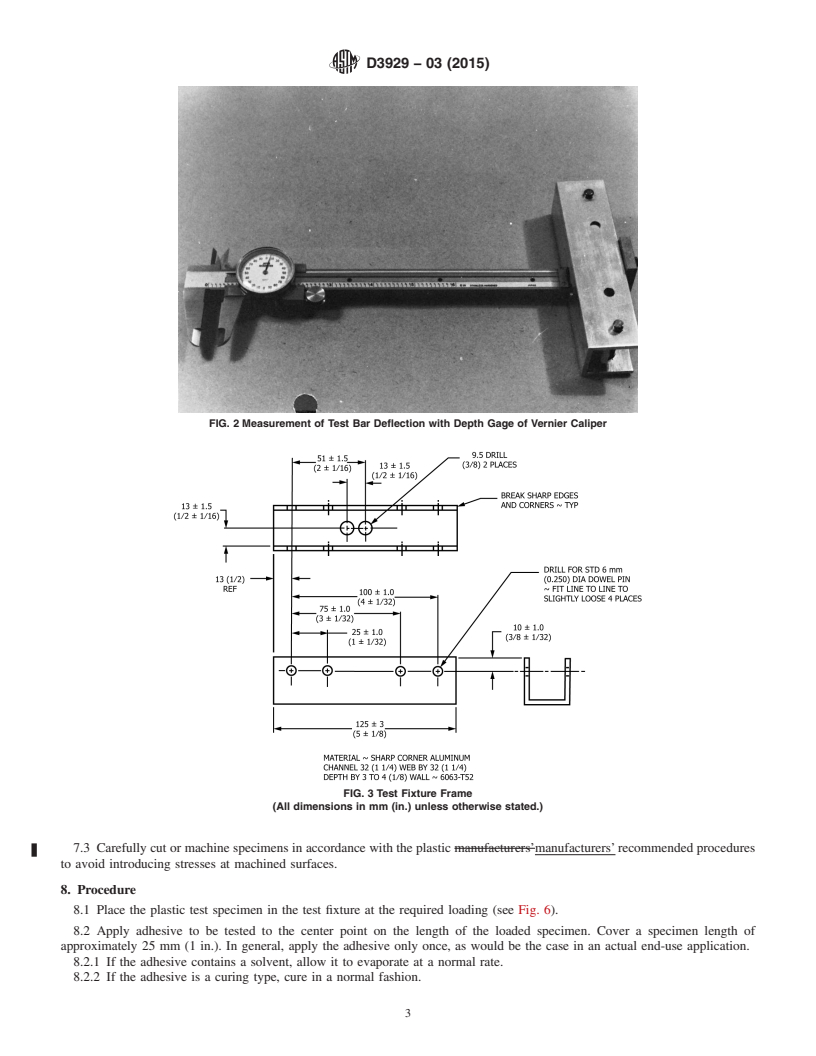

6.2 The amount of deflection on the specimen is measured by use of a dial gage indicator or a vernier caliper having a depth

indicator (see Fig. 2). Use a measuring device capable of reading to 0.025 mm (0.001 in.).

7. Test Specimen

7.1 The preferred specimen is a flexural bar designed in accordance with Test Methods D790.

Depth 6.4 mm ( ⁄4 in.)

Width 13 mm ( ⁄2 in.)

Length 130 mm (5 in.)

Loading Span 100 mm (4 in.)

L/d 16/1

Tensile bars, such as Type I in Test Method D638, can also be used. Specimens of rectangular section may also be cut from sheets

or molded plastic articles.

7.2 Mold specimens in a low-stress condition or anneal so that molded-in stresses will not have a significant effect.

1 1

Detailed drawings are shown in Figs. 3–5. Also necessary to complete the test fixture are the following parts: 2 pieces at 6 by 38 mm ( ⁄4 by 1 ⁄2-in.) dowel pins and

2 pieces of M4–0.7 (8–32 unc) by 32 mm (1 ⁄4-in.) socket head cap screws.

FIG. 1 Test Fixture with Plastic Bar in Place

D3929 − 03 (2015)

FIG. 2 Measurement of Test Bar Deflection with Depth Gage of Vernier Caliper

FIG. 3 Test Fixture Frame

(All dimensions in mm (in.) unless otherwise stated.)

7.3 Carefully cut or machine specimens in accordance with the plastic manufacturers’manufacturers’ recommended procedures

to avoid introducing stresses at machined surfaces.

8. Procedure

8.1 Place the plastic test specimen in the test fixture at the required loading (

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.