ASTM F2946-12

(Specification)Standard Specification for PVC Hub and Elastomeric Seal (Gasket) Tee Connection for Joining Plastic Pipe to Insitu Pipelines and Manholes

Standard Specification for PVC Hub and Elastomeric Seal (Gasket) Tee Connection for Joining Plastic Pipe to Insitu Pipelines and Manholes

ABSTRACT

This specification covers the minimum performance and material requirements for a three piece tee connector for connection between plastic pipe and insitu pipes, manholes and wastewater structures in sanitary and storm sewer applications. The three piece seal system consists of a 4 through 30-in. PVC (polyvinyl chloride) hub pipe, an elastomeric seal (gasket) and a mechanical band. The system is installed in either a bored or cast hole opening in the host pipe or structure to a specific dimension that corresponds to the combined diameter of the PVC pipe outside diameter/tolerance and the elastomeric seal thickness. These tee connectors are designed to provide a non-pressure (gravity flow) watertight connection between the incoming pipe and an insitu pipe or manhole/structure to the limits defined in this standard. This specification deals with materials and manufacture, principles of design, basis of acceptance, test methods and requirements, rejection and rehearing, certification, markings, quality assurance, and packaging and package marking.

SCOPE

1.1 This specification covers the minimum performance and material requirements for a three piece tee connector for connection between plastic pipe and insitu pipes, manholes and wastewater structures in sanitary and storm sewer applications.

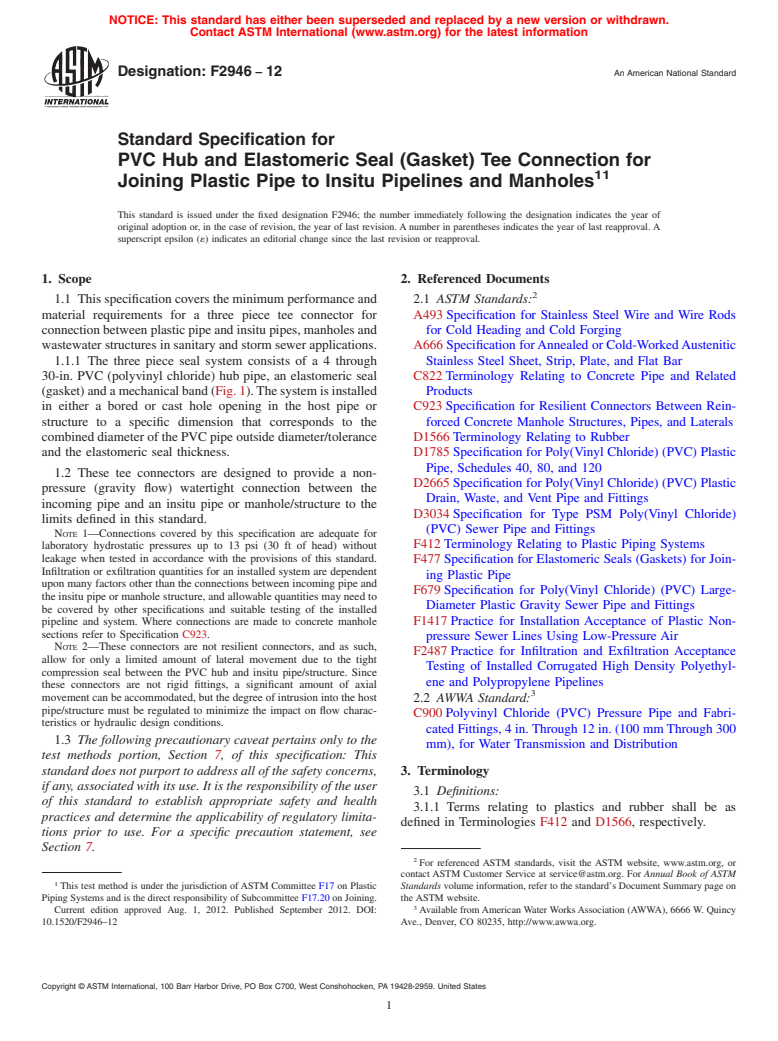

1.1.1 The three piece seal system consists of a 4 through 30-in. PVC (polyvinyl chloride) hub pipe, an elastomeric seal (gasket) and a mechanical band (Fig. 1). The system is installed in either a bored or cast hole opening in the host pipe or structure to a specific dimension that corresponds to the combined diameter of the PVC pipe outside diameter/tolerance and the elastomeric seal thickness.

FIG. 1 Three-Piece Sealing System (Connector)

1.2 These tee connectors are designed to provide a non-pressure (gravity flow) watertight connection between the incoming pipe and an insitu pipe or manhole/structure to the limits defined in this standard.Note 1—Connections covered by this specification are adequate for laboratory hydrostatic pressures up to 13 psi (30 ft of head) without leakage when tested in accordance with the provisions of this standard. Infiltration or exfiltration quantities for an installed system are dependent upon many factors other than the connections between incoming pipe and the insitu pipe or manhole structure, and allowable quantities may need to be covered by other specifications and suitable testing of the installed pipeline and system. Where connections are made to concrete manhole sections refer to Specification C923.Note 2—These connectors are not resilient connectors, and as such, allow for only a limited amount of lateral movement due to the tight compression seal between the PVC hub and insitu pipe/structure. Since these connectors are not rigid fittings, a significant amount of axial movement can be accommodated, but the degree of intrusion into the host pipe/structure must be regulated to minimize the impact on flow characteristics or hydraulic design conditions.

1.3 The following precautionary caveat pertains only to the test methods portion, Section 7, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific precaution statement, see Section 7.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2946 −12 An American National Standard

Standard Specification for

PVC Hub and Elastomeric Seal (Gasket) Tee Connection for

Joining Plastic Pipe to Insitu Pipelines and Manholes

This standard is issued under the fixed designation F2946; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This specification covers the minimum performance and 2.1 ASTM Standards:

material requirements for a three piece tee connector for A493 Specification for Stainless Steel Wire and Wire Rods

connectionbetweenplasticpipeandinsitupipes,manholesand for Cold Heading and Cold Forging

wastewater structures in sanitary and storm sewer applications. A666 Specification forAnnealed or Cold-WorkedAustenitic

1.1.1 The three piece seal system consists of a 4 through Stainless Steel Sheet, Strip, Plate, and Flat Bar

30-in. PVC (polyvinyl chloride) hub pipe, an elastomeric seal C822 Terminology Relating to Concrete Pipe and Related

(gasket)andamechanicalband(Fig.1).Thesystemisinstalled Products

in either a bored or cast hole opening in the host pipe or C923 Specification for Resilient Connectors Between Rein-

structure to a specific dimension that corresponds to the forced Concrete Manhole Structures, Pipes, and Laterals

combined diameter of the PVC pipe outside diameter/tolerance D1566 Terminology Relating to Rubber

and the elastomeric seal thickness. D1785 Specification for Poly(Vinyl Chloride) (PVC) Plastic

Pipe, Schedules 40, 80, and 120

1.2 These tee connectors are designed to provide a non-

D2665 Specification for Poly(Vinyl Chloride) (PVC) Plastic

pressure (gravity flow) watertight connection between the

Drain, Waste, and Vent Pipe and Fittings

incoming pipe and an insitu pipe or manhole/structure to the

D3034 Specification for Type PSM Poly(Vinyl Chloride)

limits defined in this standard.

(PVC) Sewer Pipe and Fittings

NOTE 1—Connections covered by this specification are adequate for

F412 Terminology Relating to Plastic Piping Systems

laboratory hydrostatic pressures up to 13 psi (30 ft of head) without

leakage when tested in accordance with the provisions of this standard.

F477 Specification for Elastomeric Seals (Gaskets) for Join-

Infiltration or exfiltration quantities for an installed system are dependent

ing Plastic Pipe

upon many factors other than the connections between incoming pipe and

F679 Specification for Poly(Vinyl Chloride) (PVC) Large-

the insitu pipe or manhole structure, and allowable quantities may need to

Diameter Plastic Gravity Sewer Pipe and Fittings

be covered by other specifications and suitable testing of the installed

F1417 Practice for Installation Acceptance of Plastic Non-

pipeline and system. Where connections are made to concrete manhole

sections refer to Specification C923.

pressure Sewer Lines Using Low-Pressure Air

NOTE 2—These connectors are not resilient connectors, and as such,

F2487 Practice for Infiltration and Exfiltration Acceptance

allow for only a limited amount of lateral movement due to the tight

Testing of Installed Corrugated High Density Polyethyl-

compression seal between the PVC hub and insitu pipe/structure. Since

ene and Polypropylene Pipelines

these connectors are not rigid fittings, a significant amount of axial

movement can be accommodated, but the degree of intrusion into the host

2.2 AWWA Standard:

pipe/structure must be regulated to minimize the impact on flow charac-

C900 Polyvinyl Chloride (PVC) Pressure Pipe and Fabri-

teristics or hydraulic design conditions.

cated Fittings, 4 in. Through 12 in. (100 mm Through 300

1.3 The following precautionary caveat pertains only to the

mm), for Water Transmission and Distribution

test methods portion, Section 7, of this specification: This

standard does not purport to address all of the safety concerns, 3. Terminology

if any, associated with its use. It is the responsibility of the user

3.1 Definitions:

of this standard to establish appropriate safety and health

3.1.1 Terms relating to plastics and rubber shall be as

practices and determine the applicability of regulatory limita-

defined in Terminologies F412 and D1566, respectively.

tions prior to use. For a specific precaution statement, see

Section 7.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This test method is under the jurisdiction of ASTM Committee F17 on Plastic Standards volume information, refer to the standard’s Document Summary page on

Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining. the ASTM website.

Current edition approved Aug. 1, 2012. Published September 2012. DOI: Available fromAmerican Water WorksAssociation (AWWA), 6666 W. Quincy

10.1520/F2946–12 Ave., Denver, CO 80235, http://www.awwa.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2946−12

FIG. 1Three-Piece Sealing System (Connector)

3.1.2 Terms relating to precast concrete pipe, manholes, and The minimum torque requirement for securing the band around

related products shall be as defined in Terminology C822. the PVC hub shall be 60 in-lbs.

3.2 Definitions of Terms Specific to This Standard:

4.3 PVC Hubs—PVC pipe and joint sections that constitute

3.2.1 connector, n—the entire assembly including pipe hub, the hub component of this system shall be fabricated from pipe

elastomeric seal and mechanical band.

and joint that meet the requirements of either Specification

D1785, D2665, D3034, F679 or AWWA C900.

3.2.2 insitu, adj—reflects the condition of the pipe, manhole

NOTE 3—Experience has shown that successful performance of this

orwastewaterstructurethatservesasthehosttotheconnector.

product depends on the type of bedding and backfill and the care in the

These facilities are existing structures that has been excavated

field installation of the manhole or wastewater structure and connecting

for the purposes of tapping or connecting into the line.

pipes. The owner is cautioned that field inspection at the construction site

may be necessary.

3.2.3 mechanical band, n—metallic or nonmetallic me-

chanical device used for compressing an elastomeric seal

5. Principles of Design

againstapipe’soutsidediameterwall,typicallyastainlesssteel

worm screw clamp.

5.1 The design of the connector shall be such that positive

3.2.4 pipe hub, n—a short section of pipe used to made a seal is accomplished at two locations: (1) between the elasto-

meric seal and the wall of the insitu pipe, manhole or

watertight connection to the incoming pipeline. This pipe hub

is typically made from the same pipe material and meeting the wastewater structure and (2) between the elastomeric seal and

the pipe hub. The watertight seal between the insitu pipe,

same ASTM standard as the incoming pipeline.

manhole or waste water structure is made by the compression

4. Materials and Manufacture

of the gasket between the insitu structure and the pipe hub.

5.1.1 The seal between the connector and the wall of the

4.1 All materials shall conform to the following require-

insitu pipe, manhole or wastewater structure shall be made by

ments:

mechanical means, compression of the elastomeric seal be-

4.1.1 Elastomeric Seals—Gasket materials for connectors

tweentheoutsidesurfaceofthepipehubandtheopeninginthe

shall meet the requirements of F477.

wall of the insitu pipe, manhole or wastewater structure.

4.2 Mechanical Device or Band—Take-up devices used for

5.1.2 The seal between the connector and the pipe hub shall

mechanically compressing the resilient portion of the connec-

be made by mechanical means by compression of the elasto-

tor against the pipe, manhole or wastewater structure shall be

meric material against the outside of the pipe hub with a

made from a material or materials in combination that will

mechanical devise or band. Devices used to effect mechanical

ensure durability, strength, resistance to corrosion, and have

seals shall conform to the requirements specified in Section 4.

properties that will ensure continued resistance to leakage. All

metallic mechanical devices, including castings and bolt as- 5.2 All pipe stubs installed shall allow for future connection

semblies used to mechanically deform elastomeric seals shall to the insitu pipe, manhole or wastewater structure, and be

be constructed of corrosion resistant mater

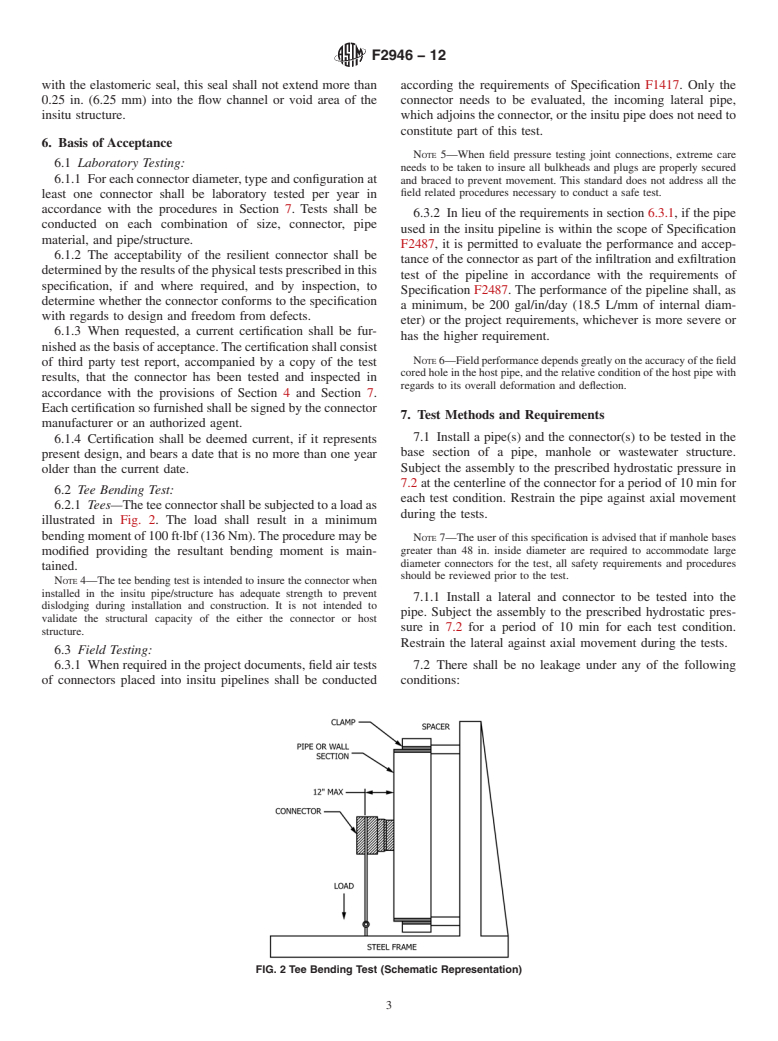

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.