ASTM D6375-09(2019)

(Test Method)Standard Test Method for Evaporation Loss of Lubricating Oils by Thermogravimetric Analyzer (TGA) Noack Method

Standard Test Method for Evaporation Loss of Lubricating Oils by Thermogravimetric Analyzer (TGA) Noack Method

SIGNIFICANCE AND USE

5.1 This test method is a safe and fast alternative for determination of the Noack evaporation loss of a lubricant.

5.2 The evaporation loss of a lubricant is important in the hot zones of equipment where evaporation of part of the lubricant may increase lubricant consumption.

5.3 Some lubricant specifications cite a maximum allowable evaporative loss.

SCOPE

1.1 This test method covers the procedure for determining the Noack evaporation loss of lubricating oils using a thermogravimetric analyzer test (TGA). The test method is applicable to base stocks and fully formulated lubricant oils having a Noack evaporative loss ranging from 0 % to 30 % by mass. This procedure requires much smaller specimens, and is faster when multiple samples are sequentially analyzed, and safer than the standard Noack method using Wood's metal.

1.2 The evaporative loss determined by this test method is the same as that determined using the standard Noack test methods.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6375 − 09 (Reapproved 2019)

Standard Test Method for

Evaporation Loss of Lubricating Oils by Thermogravimetric

Analyzer (TGA) Noack Method

This standard is issued under the fixed designation D6375; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D6299 Practice for Applying Statistical Quality Assurance

and Control Charting Techniques to Evaluate Analytical

1.1 This test method covers the procedure for determining

Measurement System Performance

the Noack evaporation loss of lubricating oils using a thermo-

D6792 Practice for Quality Management Systems in Petro-

gravimetric analyzer test (TGA). The test method is applicable

leum Products, Liquid Fuels, and Lubricants Testing

to base stocks and fully formulated lubricant oils having a

Laboratories

Noack evaporative loss ranging from 0 % to 30 % by mass.

E1582 Test Method for Temperature Calibration of Thermo-

This procedure requires much smaller specimens, and is faster

gravimetric Analyzers

when multiple samples are sequentially analyzed, and safer

than the standard Noack method using Wood’s metal.

3. Terminology

1.2 The evaporative loss determined by this test method is

3.1 Definitions of Terms Specific to This Standard:

the same as that determined using the standard Noack test

3.1.1 Noackreferenceoil—theoilprovidedbyNoackequip-

methods.

ment manufacturers to check proper operation of the Noack

1.3 The values stated in SI units are to be regarded as

evaporation tester.

standard. No other units of measurement are included in this

3.1.2 Noack reference time—the time (in minutes) required

standard.

for the Noack reference oil to reach its known Noack evapo-

1.4 This standard does not purport to address all of the

rative loss under the conditions used in this test method.

safety concerns, if any, associated with its use. It is the

3.1.3 TGA Noack volatility—the evaporative loss (in mass

responsibility of the user of this standard to establish appro-

percent) of a lubricant as determined in this test method.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

4. Summary of Test Method

1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

4.1 A lubricant specimen is placed in an appropriate TGA

ization established in the Decision on Principles for the

specimen pan. The pan is placed on the TGA pan holder and

Development of International Standards, Guides and Recom-

quickly heated to between 247 °C and 249 °C under a stream

mendations issued by the World Trade Organization Technical

of air, and then held isothermal for an appropriate time.

Barriers to Trade (TBT) Committee.

Throughout this process, the TGA monitors and records the

masslossexperiencedbythespecimenduetoevaporation.The

2. Referenced Documents

Noack evaporation loss is subsequently determined from the

2.1 ASTM Standards: specimen weight percent loss versus time curve (TG curve) as

the mass percent lost by the specimen at the Noack reference

D5800 Test Method for Evaporation Loss of Lubricating

Oils by the Noack Method time determined under the same TGA conditions.

5. Significance and Use

This test method is under the jurisdiction of ASTM Committee D02 on

5.1 This test method is a safe and fast alternative for

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

determination of the Noack evaporation loss of a lubricant.

Subcommittee D02.06 on Analysis of Liquid Fuels and Lubricants.

Current edition approved Dec. 1, 2019. Published December 2019. Originally

5.2 The evaporation loss of a lubricant is important in the

approved in 1999. Last previous edition approved in 2014 as D6375 – 09 (2014).

hot zones of equipment where evaporation of part of the

DOI: 10.1520/D6375-09R19.

lubricant may increase lubricant consumption.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.3 Somelubricantspecificationsciteamaximumallowable

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. evaporative loss.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6375 − 09 (2019)

FIG. 1 Examples Showing Adaptation of Alternative Sample Pans

6. Apparatus air purge from 200 mL⁄min to 500 mL⁄min, and by maintain-

ing it at this high temperature until no smoke is detected from

6.1 ThermogravimetricAnalyzer,withthecapabilitytomeet

the TGAgas exhaust tube. Normally 15 min to 20 min at these

all the conditions required for this test method, along with the

conditions are enough to remove most deposits.

software necessary to complete the required analyses.

(Warning—Do not place a specimen pan in the TGA during

6.2 Aluminum Specimen Pan—This shall be cylindrical, and

this operation. It will melt and may damage the balance or

have a minimum inside diameter/height ratio of 0.45 and a

furnace mechanisms.)

volume of 50 µL 6 3 µL. If the pans provided by the particular

8.3 Check operation of TGA balance and adjust when

TGA manufacturer do not meet these criteria, alternative pans

necessary. Follow manufacturer’s procedure and recommenda-

may be used and adapted to fit the pan holder of the TGA.

tions.

Examples of some of the adaptations used during the evalua-

tion of this test method are shown in Fig. 1.

9. Procedure

6.3 Pressure Regulator, capable of maintaining air delivery

9.1 Determination of Specimen Mass:

pressure at the level required by the TGA instrument.

9.1.1 Determine the nominal internal diameter (in centime-

6.4 Flowmeter, with a flow control valve capable of setting

tres) of the specimen pans by measuring the internal diameter

and measuring the air throughput required by the TGA instru-

of10differentpansandaveragingtheresults.Acalipershallbe

ment.

used to make this measurement.

9.1.2 Calculate the specimen mass using following equa-

7. Reagents and Materials

tion:

7.1 TGA Temperature Calibration Standards—These mate- 3

M 5 350 ID (1)

~ !

s

rials will depend on the particular TGA apparatus and its

M = Specimen mass, mg (round to closest whole mg.)

capabilities. The TGA manufacturer typically provides them

s

ID = Nominal inside diameter of specimen pan, cm (see

and describes their use in the operating manual for the

9.1.1).

instrument.

9.2 Air Flowrate—Set air flowrate to that recommended by

7.2 Compressed air at a pressure suitable for operation of

the TGA manufacturer or higher if during the initial tests with

the TGA instrument. Reagent grade air is not necessary but

the Noack reference oil there appears to be condensation on

may be used if there are concerns over possible contamination

of the internal parts of the TGA. any part of the TGA balance mechanism or furnace lining.

Repeat 8.1 with the new flow rate.

7.3 Noack Reference Oil—Oil having a known Noack

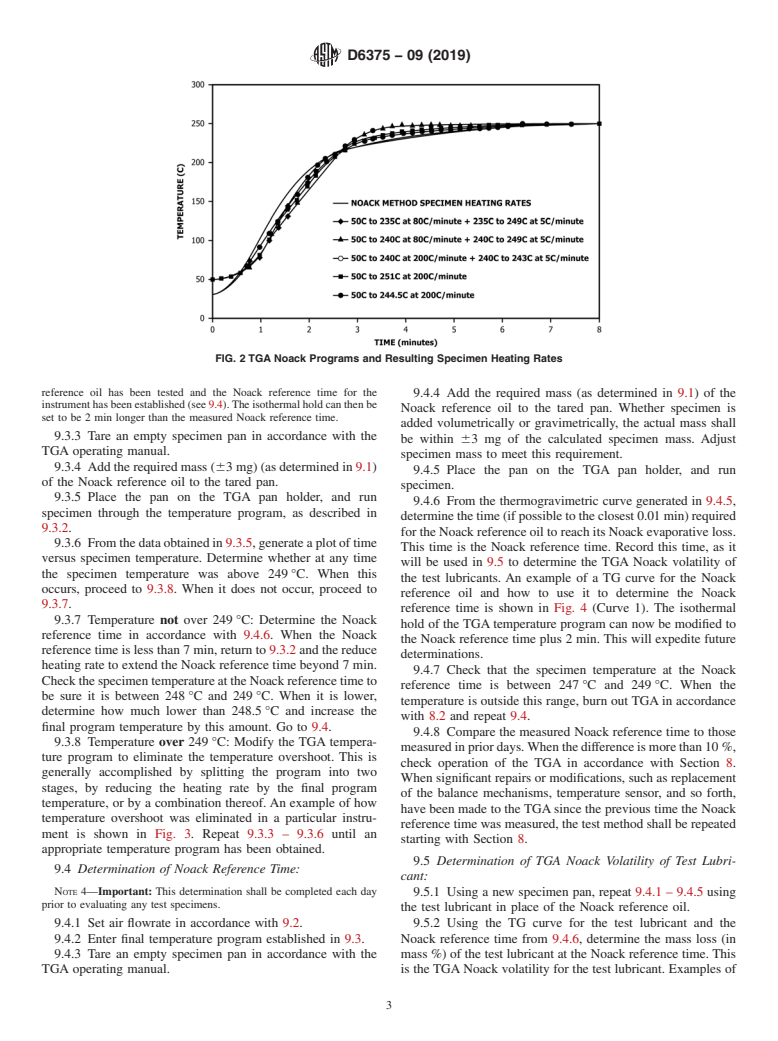

9.3 Temperature Program (see Note 2):

evaporative loss, the value of which is provided by the

manufacturer.

NOTE 2—This section only needs to be done during the initial set up of

the method in the TGA.

8. TGA Preparation and Calibration (see Note 1)

9.3.1 Using the correlation from 8.1, determine the final

NOTE 1—This section only needs to be done if TGA has been idle for

an extended period of time, has had significant repairs made to it, or has program temperature required to obtain a final specimen

been mishandled or its location changed.

temperature of 249 °C.

9.3.2 Program the TGAto heat the specimen from 50 °C to

8.1 Check the temperature correlation between the speci-

the final program temperature determined in 9.3.1 at heating

men and control temperatures in accordance with TGA manu-

rate(s) that will simulate the specimen heating rate of the

facturer’s recommendations or Practice E1582. Use calibration

standard Noack methods (;100 °C⁄min to 220 °C and

standards that will bracket 250°C.When necessary, recalibrate,

10 °C⁄min from 220 °C to 249 °C). Some guidance on how to

and regenerate correlation.

achieve acceptable heating rates can be obtained from the

8.2 When necessary, burn out the TGA to remove any

examples shown in Fig. 2. Maintain the final program tempera-

condensed liquids or deposits, which may have formed on its

ture for 30 min (see Note 3).

inside surfaces. Generally, burn out is accomplished by raising

the temperature of the TGA to a minimum of 800 °C with an NOTE 3—The 30 min isothermal hold may be adjusted after the Noack

D6375 − 09 (2019)

FIG. 2 TGA Noack Programs and Resulting Specimen Heating Rates

reference oil has been tested and the Noack reference time for the

9.4.4 Add the required mass (as determined in 9.1)ofthe

instrument has been established (see 9.4).The isothermal hold can then be

Noack reference oil to the tared pan. Whether specimen is

set to be 2 min longer than the measured Noack reference time.

added volumetrically or gravimetrically, the actual mass shall

9.3.3 Tare an empty specimen pan in accordance with the

be within 63 mg of the calculated specimen mass. Adjust

TGA operating manual.

specimen mass to meet this requirement.

9.3.4 A

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.