ASTM D5800-14e1

(Test Method)Standard Test Method for Evaporation Loss of Lubricating Oils by the Noack Method

Standard Test Method for Evaporation Loss of Lubricating Oils by the Noack Method

SIGNIFICANCE AND USE

5.1 The evaporation loss is of particular importance in engine lubrication. Where high temperatures occur, portions of an oil can evaporate.

5.2 Evaporation may contribute to oil consumption in an engine and can lead to a change in the properties of an oil.

5.3 Many engine manufacturers specify a maximum allowable evaporation loss.

5.4 Some engine manufacturers, when specifying a maximum allowable evaporation loss, quote this test method along with the specifications.

5.5 Procedure C, using the Selby-Noack apparatus, also permits collection of the volatile oil vapors for determination of their physical and chemical properties. Elemental analysis of the collected volatiles may be helpful in identifying components such as phosphorous, which has been linked to premature degradation of the emission system catalyst.

SCOPE

1.1 This test method covers three procedures for determining the evaporation loss of lubricating oils (particularly engine oils). Procedure A uses the Noack evaporative tester equipment; Procedure B uses the automated non-Woods metal Noack evaporative apparatus; and Procedure C uses Selby-Noack volatility test equipment. The test method relates to one set of operating conditions but may be readily adapted to other conditions when required.

1.2 Noack results determined using Procedures A and B show consistent differences. Procedure A gives slightly lower results versus Procedure B on formulated engine oils, while Procedure A gives higher results versus Procedure B on basestocks.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D5800 − 14

StandardTest Method for

Evaporation Loss of Lubricating Oils by the Noack Method

This standard is issued under the fixed designation D5800; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Eq 11 was corrected editorially in January 2015.

1. Scope* Measurement System Performance

D6300Practice for Determination of Precision and Bias

1.1 This test method covers three procedures for determin-

Data for Use in Test Methods for Petroleum Products and

ing the evaporation loss of lubricating oils (particularly engine

Lubricants

oils). Procedure A uses the Noack evaporative tester equip-

2.2 DIN Standards:

ment; Procedure B uses the automated non-Woods metal

DIN 1725Specification for Aluminum Alloys

Noack evaporative apparatus; and Procedure C uses Selby-

DIN 12785Specifications for Glass Thermometers

Noack volatility test equipment.The test method relates to one

set of operating conditions but may be readily adapted to other

3. Terminology

conditions when required.

3.1 Definitions of Terms Specific to This Standard:

1.2 Noack results determined using Procedures A and B

3.1.1 evaporation loss—of a lubricating oil by the Noack

show consistent differences. Procedure A gives slightly lower

method, that mass of volatile oil vapors lost when the oil is

results versus Procedure B on formulated engine oils, while

heatedinatestcruciblethroughwhichaconstantflowofairis

Procedure A gives higher results versus Procedure B on

drawn.

basestocks.

3.1.2 volatility, n—the tendency of a liquid to form a vapor.

1.3 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

4. Summary of Test Method

standard.

4.1 A measured quantity of sample is placed in an evapo-

1.4 This standard does not purport to address all of the

ration crucible or reaction flask that is then heated to 250°C

safety concerns, if any, associated with its use. It is the

with a constant flow of air drawn through it for 60 min. The

responsibility of the user of this standard to establish appro-

loss in mass of the oil is determined.

priate safety and health practices and determine the applica-

4.2 Interlaboratory tests have shown that Procedure A,

bility of regulatory limitations prior to use.

Procedure B, and Procedure C yield essentially equivalent

results, with a correlation coefficient of R = 0.996. See the

2. Referenced Documents

research report for the Selby-Noack interlaboratory study.

2.1 ASTM Standards:

D4057Practice for Manual Sampling of Petroleum and

5. Significance and Use

Petroleum Products

5.1 The evaporation loss is of particular importance in

D4177Practice for Automatic Sampling of Petroleum and

engine lubrication.Where high temperatures occur, portions of

Petroleum Products

an oil can evaporate.

D6299Practice for Applying Statistical Quality Assurance

5.2 Evaporation may contribute to oil consumption in an

and Control Charting Techniques to Evaluate Analytical

engine and can lead to a change in the properties of an oil.

5.3 Many engine manufacturers specify a maximum allow-

This test method is under the jurisdiction of ASTM Committee D02 on

able evaporation loss.

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.06 on Analysis of Liquid Fuels and Lubricants.

5.4 Some engine manufacturers, when specifying a maxi-

Current edition approved Oct. 1, 2014. Published October 2014. Originally

mum allowable evaporation loss, quote this test method along

approved in 1995. Last previous edition approved in 2008 as D5800–10. DOI:

with the specifications.

10.1520/D5800-14E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Deutsches Institut für Normunge, Beuth Verlag GmbH, Burg-

the ASTM website. grafen Strasse 6, 1000 Berlin 30, Germany.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D5800 − 14

5.5 Procedure C, using the Selby-Noack apparatus, also 6.10 Two Glass Bottles, approximately 2-L capacity, fitted

permits collection of the volatile oil vapors for determination with rubber bungs bored to receive inlet and outlet tubes (see

oftheirphysicalandchemicalproperties.Elementalanalysisof Fig. 4).

the collected volatiles may be helpful in identifying compo-

6.11 Manometer, inclined form, water-filled, precision 0.2

nentssuchasphosphorous,whichhasbeenlinkedtopremature

mm H O or suitable pressure sensor capable of measuring 20

degradation of the emission system catalyst.

6 0.2 mm of H O (a 0 to 50-mm H O pressure transducer has

2 2

been found to be satisfactory).

Procedure A

NOTE1—Somemanometersusewaterasthereferencefluid,othersmay

use a lower density fluid correlated to read in millimetres of water. Users

should ensure that the manometer is filled with the correct density

6. Apparatus

reference fluid.

6.1 Noack Evaporative Tester, comprising the following:

6.12 Glass T-Piece, with bleed valve attached.

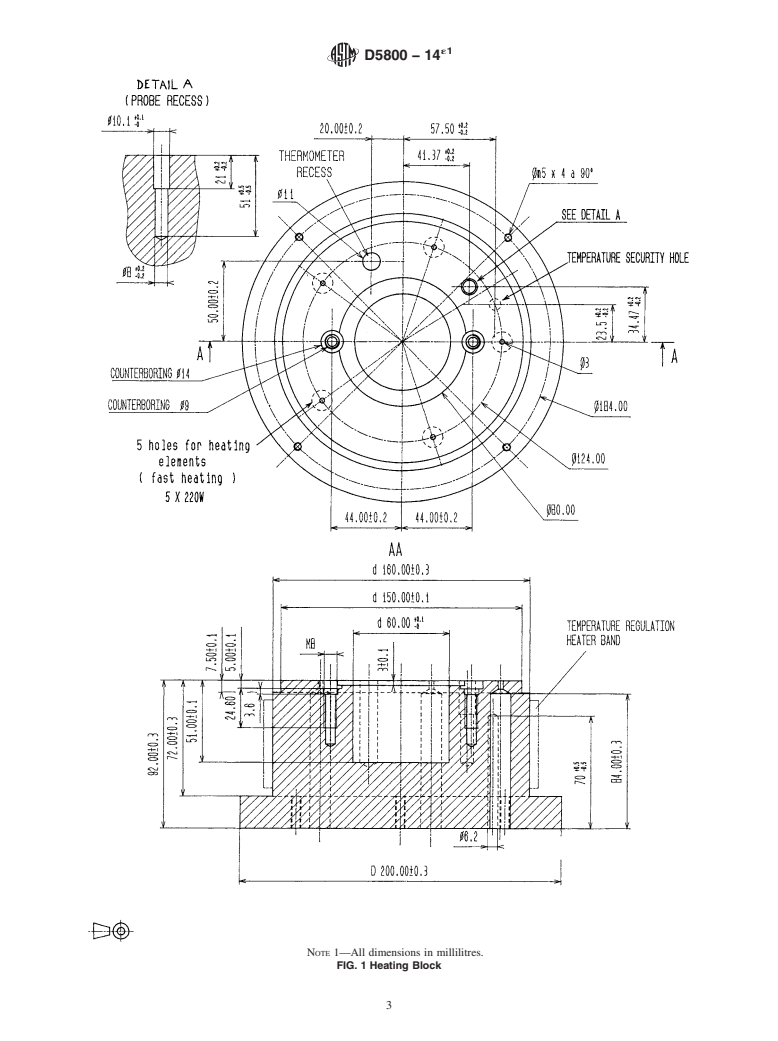

6.1.1 Electrically Heated Block Unit, made from a mal-

6.13 Vacuum Pump.

leablealuminumalloy(seeDIN1725,Sheet1),insulatedatthe

jacket and base against loss of heat. (Warning—This block is

6.14 Timer, with accuracy of 0.2 s.

heatedto250°C.)Theblockisheatedelectricallybyabaseand

6.15 Silicone Rubber Tubing, cut to size, with an internal

jacketheater,havingatotalpowerconsumptionof1to1.2kW.

diameter of 4 mm.

In this respect the difference between both individual power

6.15.1 40-mm long; three pieces required,

consumption should not exceed 0.15 kW. In the center of the

6.15.2 300-mm long, and

heatingblock,thereisacircularrecesstoinserttheevaporating

6.15.3 100-mm long.

crucible,thespacebetweenblockandcruciblebeingfilledwith

NOTE 2—The use of automated equipment is permissible as long as it

Woodsalloyorasuitableequivalent.Twocatchesontheblock

gives equivalent results specified in this test method. All hardware

prevent the crucible from rising in the liquid metal bath. Two

dimensions, make-up of the block, crucible, heat capacity, and so forth,

additionalcircularrecessesatequalintervalsfromthecenterof

and glassware must conform to the specifications given in this test

the block are provided for the thermometers (see Fig. 1).

method.

6.1.2 Evaporating Crucible, with screw cover. The crucible

7. Reagents and Materials

is made of stainless steel (see Fig. 2). Above the support ring

is the thread for the cover. The nickel-plated brass cover is

7.1 Cleaning Solvent—Amixture of naphtha and toluene is

hermetically sealed to the crucible by an internal conical

recommended for the cleaning of the crucible. (Warning—

sealing surface (see Fig. 3). Three nozzles of hardened steel

Flammable, vapor harmful.) Overnight soaking may be neces-

permit the air stream to pass through the cover. The extraction

sary.

tube,whichslopesdownward,leadsfromathreadedandsealed

7.2 Oils having a known evaporative loss, the value of

connection in the center of the cover.

which is provided by the oil supplier. Some examples of such

6.2 Balance, capable of weighing at least 200 g to the

oils include RL-N, RL 172, and RL 223, supplied by CEC.

nearest 0.01 g.

Other oils supplied by other vendors may also be used.

6.3 Crucible Clamp and Spanner. 7.3 Insulated Gloves.

7.4 Paint Brush,suchasatinnerpsacidbrush(15to25-mm

6.4 Reamer, 2-mm diameter.

width).

6.5 Ball Bearing, 3.5-mm diameter.

7.5 Woods Metal or Suitable Heat Transfer Material—

6.6 Thermometer, M260 (see DIN 12785) or temperature

(Warning—Woods metal contains lead (25 %), bismuth

sensing device capable of reading temperature to 0.1°C. The

(50%),antimony(12.5%),andcadmium(12.5%);thesehave

thermometer should be calibrated with appropriate procedure

been found to be health hazardous.Avoid contact with skin at

at appropriate frequency (generally every six months).

all times.)

6.7 Contact Type Control Thermometer (for manual).

8. Hazards

6.8 GlassY-piece,aninternaldiameterof4mm.Theupright

8.1 Safety Hazards—It is assumed that anyone using this

arms,each45-mmlong,shouldformananglesuchthatthearm

test method will either be fully trained and familiar with all

connected to the crucible extraction tube and theY-piece form

normal laboratory practices, or will be under the direct super-

a straight line. The vertical arm is 60-mm long and beveled at

vision of such a person. It is the responsibility of the operator

45°.

to ensure that all local legislative and statutory requirements

6.9 Glass Delivery Tubes, an internal diameter of 4 mm,

are met.

each arm length 100 mm, beveled at 45° at ends entering and

leaving the bottles.

6.9.1 Bent at an angle of approximately 80°. The sole source of supply ofWoods metal known to the committee at this time

is Sigma-Aldrich, Customer Support, P.O. Box 14508, St. Louis, MO 63178. If you

6.9.2 Bent at an angle of approximately 100°, length to 20

are aware of alternative suppliers, please provide this information to ASTM

mm of bottle base.

International Headquarters. Your comments will receive careful consideration at a

6.9.3 Bent at an angle of approximately 90°. meeting of the responsible technical committee, which you may attend.

´1

D5800 − 14

NOTE 1—All dimensions in millilitres.

FIG. 1 Heating Block

´1

D5800 − 14

NOTE 1—All dimensions in millilitres.

NOTE 1—All dimensions in millilitres.

FIG. 2 Crucible

FIG. 3 Cover

8.2 (Warning—Though the test method calls for a draft-

–free area, the exhaust fumes from the evaporating oil must be

supplied to the heating block so that the temperature can be

ventilated to an outside source. Precaution shall be taken to

maintained at 250 6 0.5°C.

avoid any possibility of fire or explosion.)

NOTE 3—One way to achieve a draft–free environment and greater

9.4 Assemble the remaining apparatus, less the crucible, as

safetyinoperationfortheinstrumentsusedinthistestmethodisdescribed

shown in Fig. 5.

in Appendix X3.

9.5 Place an empty crucible in the heating block, securing

8.3 An alternate means for preventing draft described in

the flange under the screw heads against the buoyancy of the

Appendix X3 was not used in the development of the test

Woodsmetal.Thelevelofthemoltenmetalshouldbesuchthat

method precision statement.

atraceofitcanbeseenattheflangeofthecrucibleandthetop

9. Preparation of Apparatus of the heating block.

9.1 AstandardassemblyoftheapparatusisshowninFig.5.

9.6 Check that the readings can be obtained on the manom-

To avoid disturbing the thermal equilibrium, the apparatus

eter scale, or other measuring device, by connecting the

shall be assembled in a draft–free area and comply with Fig. 5

crucible to the assembled apparatus. A reading of 20.0 6 0.2

in dimensions and apparatus. (See 8.2.)

mm shall be obtained.

9.2 AddsufficientWoodsmetalorequivalentmaterialtothe

9.7 Disconnectandremovethecruciblefromtheassembled

recesses of the heating block so that, with the crucible and

apparatus.

thermometer in place, the remaining spaces will be filled with

9.8 Switch off the pump and the heating block and raise the

the molten metal.

crucible and the thermometers from the molten Woods metal.

9.3 Using the highest heating rate possible, raise the tem-

Using the brush, return any Woods metal clinging to the

perature of the heating block until the Woods metal is molten.

crucible to the heating block.

Insertthethermometerswiththeirbulbstouchingthebottomof

the recesses, and ensure that the contact thermometer is 9.9 Clean theY-piece and glass tubing to prevent a build up

plugged in the back of the heating block. Adjust the power of condensate.

´1

D5800 − 14

at the bottom of the heating block recess. The heating block and the

thermometerrecessesshouldbecleanedandtheWoodsmetalreplacedon

a regular basis to avoid the accumulation of slag. Oxidized Woods metal

will affect the heat transfer to the crucible and hence may have a

deleterious effect on the results obtained.

10.9 Adjust the control on the heating block to maintain the

block temperature approximately 5°C below the test tempera-

ture. Readjust the temperature control so that the test tempera-

ture is reestablished within 3 min of the start of the test.

NOTE 5—Temperature and pressure will be controlled automatically

when automated equipment is used.

10.10 Atthestartofthetest,constantattentionshallbepaid

to maintaining the correct pressure. Once this becomes steady,

usually within 10 to 15 min, check periodically that the

temperature and pressure differential remain constant through-

out the period of the test.

10.11 After 60 min 6 5 s, lift the crucible from the heating

block, remove any adhering alloy, and place the crucible in a

warm water bath to a depth of at least 30 mm.The time period

from the end of the test to immersion of the crucible shall not

exceed 60 s.

10.12 After30min,removethecruciblefromthewater,dry

FIG. 4 Glassware

the outside, and carefully remove the lid.

10.13 Reweigh the crucible without the lid to the nearest

10. Verification

0.01 g.

10.1 Switch on the pump and the heating block and ensure

10.14 Calculate to the nearest 0.1% mass/mass (M/M) the

that the apparatus is assembled, minus the crucible, as shown

evaporation loss of the reference oil.

in Fig. 5.

10.15 Compare the result obtained against the given value

10.2 Checkthatthecrucibleandcoverarefreefromlacquer.

for the reference oil. If the result is within 6% of the value,

10.2.1 After every test, clean the crucible and cover with

repeat the procedure from 11.1, using the test sample.

solvent and allow to dry. Stubborn lacquer can be cleaned by

abrasion from a glass beader under pressure.

10.16 If the result is not within 6% of the given value,

check that the apparatus complies with that shown in Fig. 5,

10.3 Passthereamerthrougheachofthethreenozzlesinthe

and that the procedure has been adhered to. Check the

covertoensurethattheyareclear.(Warning—Usingareamer

calibration of the thermometer and pressure sensing device.

withadiameterlargerthan2mmcanenlargethenozzles.This

can lead to higher losses because of increased air flow.)

10.17 Re-check the evaporation loss of the reference oil.

10.4 Run the ball bearing through the extraction tube to

NOTE6—Condensateshouldnotbeallowedto

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D5800 − 14 D5800 − 14

Standard Test Method for

Evaporation Loss of Lubricating Oils by the Noack Method

This standard is issued under the fixed designation D5800; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Eq 11 was corrected editorially in January 2015.

1. Scope*

1.1 This test method covers three procedures for determining the evaporation loss of lubricating oils (particularly engine oils).

Procedure A uses the Noack evaporative tester equipment; Procedure B uses the automated non-Woods metal Noack evaporative

apparatus; and Procedure C uses Selby-Noack volatility test equipment. The test method relates to one set of operating conditions

but may be readily adapted to other conditions when required.

1.2 Noack results determined using Procedures A and B show consistent differences. Procedure A gives slightly lower results

versus Procedure B on formulated engine oils, while Procedure A gives higher results versus Procedure B on basestocks.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measure-

ment System Performance

D6300 Practice for Determination of Precision and Bias Data for Use in Test Methods for Petroleum Products and Lubricants

2.2 DIN Standards:

DIN 1725 Specification for Aluminum Alloys

DIN 12785 Specifications for Glass Thermometers

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 evaporation loss—of a lubricating oil by the Noack method, that mass of volatile oil vapors lost when the oil is heated

in a test crucible through which a constant flow of air is drawn.

3.1.2 volatility, n—the tendency of a liquid to form a vapor.

4. Summary of Test Method

4.1 A measured quantity of sample is placed in an evaporation crucible or reaction flask that is then heated to 250°C with a

constant flow of air drawn through it for 60 min. The loss in mass of the oil is determined.

4.2 Interlaboratory tests have shown that Procedure A, Procedure B, and Procedure C yield essentially equivalent results, with

a correlation coefficient of R = 0.996. See the research report for the Selby-Noack interlaboratory study.

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.06 on Analysis of Liquid Fuels and Lubricants.

Current edition approved Oct. 1, 2014. Published October 2014. Originally approved in 1995. Last previous edition approved in 2008 as D5800 – 10. DOI:

10.1520/D5800-14.10.1520/D5800-14E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from Deutsches Institut für Normunge, Beuth Verlag GmbH, Burggrafen Strasse 6, 1000 Berlin 30, Germany.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D5800 − 14

5. Significance and Use

5.1 The evaporation loss is of particular importance in engine lubrication. Where high temperatures occur, portions of an oil can

evaporate.

5.2 Evaporation may contribute to oil consumption in an engine and can lead to a change in the properties of an oil.

5.3 Many engine manufacturers specify a maximum allowable evaporation loss.

5.4 Some engine manufacturers, when specifying a maximum allowable evaporation loss, quote this test method along with the

specifications.

5.5 Procedure C, using the Selby-Noack apparatus, also permits collection of the volatile oil vapors for determination of their

physical and chemical properties. Elemental analysis of the collected volatiles may be helpful in identifying components such as

phosphorous, which has been linked to premature degradation of the emission system catalyst.

Procedure A

6. Apparatus

6.1 Noack Evaporative Tester, comprising the following:

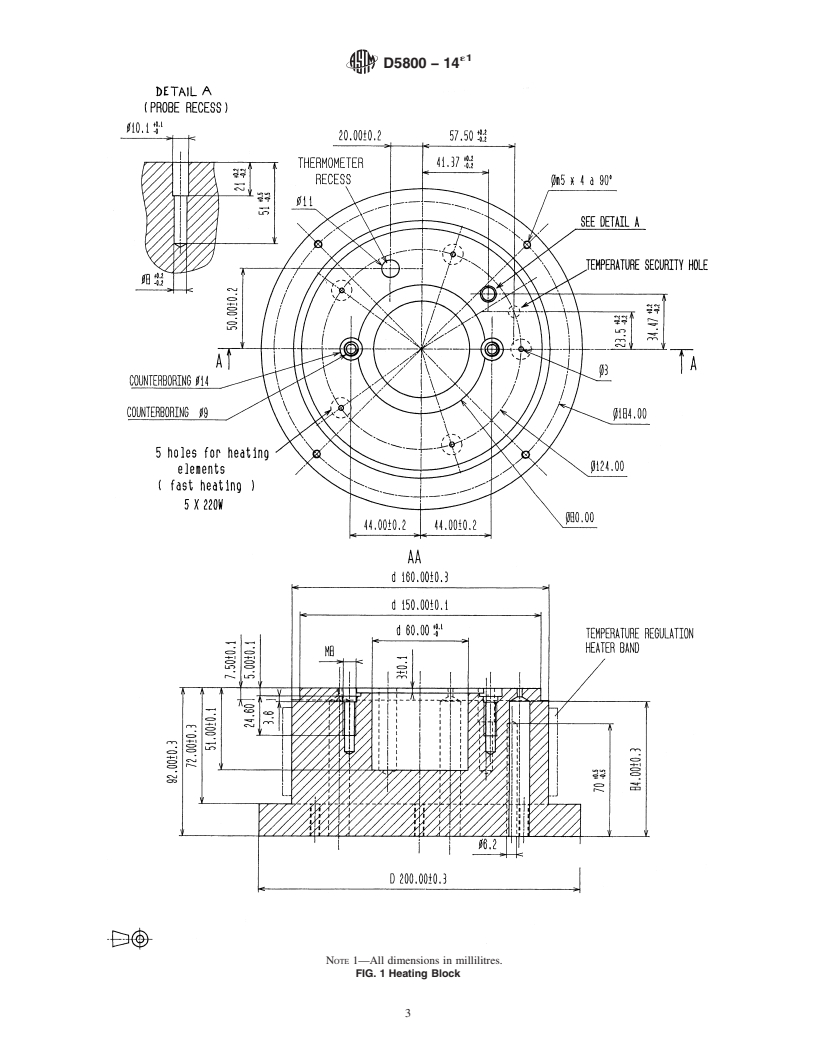

6.1.1 Electrically Heated Block Unit, made from a malleable aluminum alloy (see DIN 1725, Sheet 1), insulated at the jacket

and base against loss of heat. (Warning—This block is heated to 250°C.) The block is heated electrically by a base and jacket

heater, having a total power consumption of 1 to 1.2 kW. In this respect the difference between both individual power consumption

should not exceed 0.15 kW. In the center of the heating block, there is a circular recess to insert the evaporating crucible, the space

between block and crucible being filled with Woods alloy or a suitable equivalent. Two catches on the block prevent the crucible

from rising in the liquid metal bath. Two additional circular recesses at equal intervals from the center of the block are provided

for the thermometers (see Fig. 1).

6.1.2 Evaporating Crucible, with screw cover. The crucible is made of stainless steel (see Fig. 2). Above the support ring is the

thread for the cover. The nickel-plated brass cover is hermetically sealed to the crucible by an internal conical sealing surface (see

Fig. 3). Three nozzles of hardened steel permit the air stream to pass through the cover. The extraction tube, which slopes

downward, leads from a threaded and sealed connection in the center of the cover.

6.2 Balance, capable of weighing at least 200 g to the nearest 0.01 g.

6.3 Crucible Clamp and Spanner.

6.4 Reamer, 2-mm diameter.

6.5 Ball Bearing, 3.5-mm diameter.

6.6 Thermometer, M260 (see DIN 12785) or temperature sensing device capable of reading temperature to 0.1°C. The

thermometer should be calibrated with appropriate procedure at appropriate frequency (generally every six months).

6.7 Contact Type Control Thermometer (for manual).

6.8 Glass Y-piece, an internal diameter of 4 mm. The upright arms, each 45-mm long, should form an angle such that the arm

connected to the crucible extraction tube and the Y-piece form a straight line. The vertical arm is 60-mm long and beveled at 45°.

6.9 Glass Delivery Tubes, an internal diameter of 4 mm, each arm length 100 mm, beveled at 45° at ends entering and leaving

the bottles.

6.9.1 Bent at an angle of approximately 80°.

6.9.2 Bent at an angle of approximately 100°, length to 20 mm of bottle base.

6.9.3 Bent at an angle of approximately 90°.

6.10 Two Glass Bottles, approximately 2-L capacity, fitted with rubber bungs bored to receive inlet and outlet tubes (see Fig.

4).

6.11 Manometer, inclined form, water-filled, precision 0.2 mm H O or suitable pressure sensor capable of measuring 20 6 0.2

mm of H O (a 0 to 50-mm H O pressure transducer has been found to be satisfactory).

2 2

NOTE 1—Some manometers use water as the reference fluid, others may use a lower density fluid correlated to read in millimetres of water. Users

should ensure that the manometer is filled with the correct density reference fluid.

6.12 Glass T-Piece, with bleed valve attached.

6.13 Vacuum Pump.

6.14 Timer, with accuracy of 0.2 s.

6.15 Silicone Rubber Tubing, cut to size, with an internal diameter of 4 mm.

6.15.1 40-mm long; three pieces required,

´1

D5800 − 14

NOTE 1—All dimensions in millilitres.

FIG. 1 Heating Block

´1

D5800 − 14

NOTE 1—All dimensions in millilitres.

FIG. 2 Crucible

6.15.2 300-mm long, and

6.15.3 100-mm long.

NOTE 2—The use of automated equipment is permissible as long as it gives equivalent results specified in this test method. All hardware dimensions,

make-up of the block, crucible, heat capacity, and so forth, and glassware must conform to the specifications given in this test method.

7. Reagents and Materials

7.1 Cleaning Solvent—A mixture of naphtha and toluene is recommended for the cleaning of the crucible. (Warning—

Flammable, vapor harmful.) Overnight soaking may be necessary.

7.2 Oils having a known evaporative loss, the value of which is provided by the oil supplier. Some examples of such oils include

RL-N, RL 172, and RL 223, supplied by CEC. Other oils supplied by other vendors may also be used.

7.3 Insulated Gloves.

7.4 Paint Brush, such as a tinnerps acid brush (15 to 25-mm width).

7.5 Woods Metal or Suitable Heat Transfer Material—(Warning—Woods metal contains lead (25 %), bismuth (50 %),

antimony (12.5 %), and cadmium (12.5 %); these have been found to be health hazardous. Avoid contact with skin at all times.)

8. Hazards

8.1 Safety Hazards—It is assumed that anyone using this test method will either be fully trained and familiar with all normal

laboratory practices, or will be under the direct supervision of such a person. It is the responsibility of the operator to ensure that

all local legislative and statutory requirements are met.

The sole source of supply of Woods metal known to the committee at this time is Sigma-Aldrich, Customer Support, P.O. Box 14508, St. Louis, MO 63178. If you are

aware of alternative suppliers, please provide this information to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend.

´1

D5800 − 14

NOTE 1—All dimensions in millilitres.

FIG. 3 Cover

FIG. 4 Glassware

´1

D5800 − 14

FIG. 5 Test Apparatus

8.2 (Warning—Though the test method calls for a draft–free area, the exhaust fumes from the evaporating oil must be

ventilated to an outside source. Precaution shall be taken to avoid any possibility of fire or explosion.)

NOTE 3—One way to achieve a draft–free environment and greater safety in operation for the instruments used in this test method is described in

Appendix X3.

8.3 An alternate means for preventing draft described in Appendix X3 was not used in the development of the test method

precision statement.

9. Preparation of Apparatus

9.1 A standard assembly of the apparatus is shown in Fig. 5. To avoid disturbing the thermal equilibrium, the apparatus shall

be assembled in a draft–free area and comply with Fig. 5 in dimensions and apparatus. (See 8.2.)

9.2 Add sufficient Woods metal or equivalent material to the recesses of the heating block so that, with the crucible and

thermometer in place, the remaining spaces will be filled with the molten metal.

9.3 Using the highest heating rate possible, raise the temperature of the heating block until the Woods metal is molten. Insert

the thermometers with their bulbs touching the bottom of the recesses, and ensure that the contact thermometer is plugged in the

back of the heating block. Adjust the power supplied to the heating block so that the temperature can be maintained at 250 6 0.5°C.

9.4 Assemble the remaining apparatus, less the crucible, as shown in Fig. 5.

9.5 Place an empty crucible in the heating block, securing the flange under the screw heads against the buoyancy of the Woods

metal. The level of the molten metal should be such that a trace of it can be seen at the flange of the crucible and the top of the

heating block.

9.6 Check that the readings can be obtained on the manometer scale, or other measuring device, by connecting the crucible to

the assembled apparatus. A reading of 20.0 6 0.2 mm shall be obtained.

9.7 Disconnect and remove the crucible from the assembled apparatus.

9.8 Switch off the pump and the heating block and raise the crucible and the thermometers from the molten Woods metal. Using

the brush, return any Woods metal clinging to the crucible to the heating block.

9.9 Clean the Y-piece and glass tubing to prevent a build up of condensate.

´1

D5800 − 14

10. Verification

10.1 Switch on the pump and the heating block and ensure that the apparatus is assembled, minus the crucible, as shown in Fig.

5.

10.2 Check that the crucible and cover are free from lacquer.

10.2.1 After every test, clean the crucible and cover with solvent and allow to dry. Stubborn lacquer can be cleaned by abrasion

from a glass beader under pressure.

10.3 Pass the reamer through each of the three nozzles in the cover to ensure that they are clear. (Warning—Using a reamer

with a diameter larger than 2 mm can enlarge the nozzles. This can lead to higher losses because of increased air flow.)

10.4 Run the ball bearing through the extraction tube to ensure that it is clear of dirt.

10.5 Weigh the empty crucible without its cover to the nearest 0.01 g.

10.6 Weigh into the crucible 65.0 6 0.1 g of the Reference Oil.

10.7 Screw on the cover using the clamp and spanner.

10.8 Ensure the temperature of the heating block is at 250 6 0.5°C. Place the crucible in its recess in the heating block, securing

the flange under the screw heads against the buoyancy of the Woods metal. Switch the control of the heating block to compensate

for the heat capacity of the crucible. Immediately (in less than 5 s), connect the extraction tube of the crucible to the arm of the

glass Y-piece, making a butt joint. Simultaneously, start the pump and the stopwatch and adjust the bleed valve to give a pressure

differential of 20 6 0.2 mm.

NOTE 4—When the crucible is in the test position, its flange should be flush with the top of the heating block. Any protrusion of the crucible flange

above the heating block may suggest a buildup of Woods metal slag at the bottom of the heating block recess. The heating block and the thermometer

recesses should be cleaned and the Woods metal replaced on a regular basis to avoid the accumulation of slag. Oxidized Woods metal will affect

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.