ASTM E296-70(2004)

(Practice)Standard Practice for Ionization Gage Application to Space Simulators

Standard Practice for Ionization Gage Application to Space Simulators

ABSTRACT

This practice provides application criteria, definitions, and supplemental information to assist the user in obtaining meaningful vacuum ionization gage measurements in space-simulation facilities. Acceptable vacuum-measuring equipment shall consist of those items in which performance is compatible with obtaining meaningful measurements. The gage mounting, gage orientation, gage operational error, and gage correction for gas composition are presented in details. The gas composition determination, operating criteria, heavy molecular weight contamination effects, apparent X-ray limit for hot-cathode gages, and cold cathode gages are presented in details.

SCOPE

1.1 This practice provides application criteria, definitions, and supplemental information to assist the user in obtaining meaningful vacuum ionization gage measurements below 101 N/m2 (10 3 torr) in space-simulation facilities. Since a variety of influences can alter observed vacuum measurements, means of identifying and assessing potential problem areas receive considerable attention. This practice must be considered informational, for it is impossible to specify a means of applying the vacuum-measuring equipment to guarantee accuracy of the observed vacuum measurement. Therefore, the user's judgment is essential so that if a problem area is identified, suitable steps can be taken to either minimize the effect, correct the observed readings as appropriate, or note the possible error in the observation.

1.2 While much of the discussion is concerned with the application of hot-cathode ionization gages, no exclusion is made of cold-cathode designs. Since a great deal more experience with hot-cathode gages is available and hot-cathode devices are used in the majority of applications, the present emphasis is fully warranted.

1.3 The values stated in inch-pound units are to be regarded as the standard. The metric equivalents of inch-pound units may be approximate.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:E296–70 (Reapproved 2004)

Standard Practice for

Ionization Gage Application to Space Simulators

This standard is issued under the fixed designation E296; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope vacuum-measurement devices and are useful in differentiating

between pressure, density, and flux measuring devices for

1.1 This practice provides application criteria, definitions,

proper application and interpretation of low-density molecular

and supplemental information to assist the user in obtaining

−1

measurements.

meaningful vacuum ionization gage measurements below 10

2 −3

3.1.1 Blears effect—the reduction of the partial pressure of

N/m (10 torr) in space-simulation facilities. Since a variety

organic vapors within the envelope of a tubulated ionization

of influences can alter observed vacuum measurements, means

gage below the partial pressure that would prevail in the

of identifying and assessing potential problem areas receive

envelope with a tubulation having infinite conductance.

considerable attention. This practice must be considered infor-

3.1.2 controlled-temperature enclosed gage—an enclosed

mational,foritisimpossibletospecifyameansofapplyingthe

gage in which the envelope is maintained at nearly uniform

vacuum-measuring equipment to guarantee accuracy of the

constant temperature by suitable means.

observed vacuum measurement. Therefore, the user’s judg-

3.1.3 enclosed ionization gage—an ionization gage for

mentisessentialsothatifaproblemareaisidentified,suitable

which the ion source region is enclosed over at least 0.95 34

steps can be taken to either minimize the effect, correct the

p steradians about the center of the region by an envelope at a

observed readings as appropriate, or note the possible error in

known temperature with only a single opening such that all

the observation.

molecules entering the ion source region must have crossed a

1.2 While much of the discussion is concerned with the

plane located outside this region.

application of hot-cathode ionization gages, no exclusion is

3.1.4 equivalent nitrogen concentration—the quantity ob-

made of cold-cathode designs. Since a great deal more expe-

tained when the ion-collector current of a nude gage (in

rience with hot-cathode gages is available and hot-cathode

amperes) for the gas in the system is divided by the concen-

devices are used in the majority of applications, the present

tration sensitivity of the gage for nitrogen. This sensitivity is

emphasis is fully warranted.

defined as the ratio of gage ion collector current in amperes to

1.3 Thevaluesstatedininch-poundunitsaretoberegarded

molecular concentration in molecules per cubic metre of

as the standard. The metric equivalents of inch-pound units

nitrogen under specified operating conditions.

may be approximate.

3.1.5 equivalent nitrogen flux density—the quotient of the

2. Referenced Documents

current output of an enclosed vacuum gage operating under

specified conditions divided by the molecular flux sensitivity

2.1 ASTM Standards:

for nitrogen.

E297 Methods for Calibrating Ionization Vacuum Gage

3.1.6 equivalent nitrogen pressure:

Tubes

3.1.6.1 For a nude gage, equivalent nitrogen pressure is

3. Terminology

obtained by multiplying the equivalent nitrogen concentration

bykT where k is the Boltzmann constant and T is the mean

3.1 Definitions—The following definitions are necessary to

absolute temperature of the walls from which the gas mol-

understanding meaningful application of ionization-type

ecules travel to the ionizing region of the gage, averaged as

nearly as possible on the basis of relative molecular flux.

This practice is under the jurisdiction of ASTM Committee E21 on Space

3.1.6.2 standard equivalent nitrogen pressure—for a nude

Simulation and Applications of Space Technology and are the direct responsibility

gage, the value of the equivalent nitrogen pressure is obtained

of Subcommittee E21.04 on Space Simulation Test Methods.

Current edition approved Sept. 1, 2004. Published September 2004. Originally when T=296K (or standard ambient temperature) is used in

approved in 1966. Last previous edition approved in 1999 as E296–70 (1999).

the factorkT.

DOI: 10.1520/E0296-70R04.

3.1.6.3 For a tubulated gage, the equivalent nitrogen

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

pressureinnewtonpersquaremetreisobtainedbydividingthe

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on ioncollectorcurrentinamperesforagivengasbythepressure

the ASTM website.

Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E296–70 (2004)

sensitivity of the gage in amperes per newton per square metre indications not more than 105% or less than 95% of the final

for pure nitrogen under specified operating conditions. average steady-state value after a sudden change in the

3.1.7 gage background—the part of the indicated ion col- operatingconditionsofthegagewithoutappreciablechangein

lector current produced by phenomena other than ions formed the gas pressure in the vacuum chamber. Pressure changes less

in the gas phase arriving at the collector. than 5% of the initial value shall be regarded as within the

3.1.8 gage limit—a pressure or concentration indication normal fluctuations of pressure indication.

four times the background.

3.1.17 response time—the time required for the change in

3.1.9 ionization gage—a vacuum gage comprising a means pressure indication as a result of a specified gas (or vapor)

of ionizing the gas molecules and a means of correlating the

withinagagetubetoreach(1−1/e)(or63%)ofthechangein

number and type of ions produced with the pressure or steady-state pressure after a relatively instantaneous change of

concentration of the gas. Various types of ionization gages are the pressure of that gas in the vacuum chamber. The response

distinguished according to the method of producing the ion- time may depend on the time of adsorption of the gas (or

ization. vapor)onthewallsofthegagetubeaswellasthegeometryof

3.1.9.1 cold-cathode ionization gage—anionizationgagein the tube (including the connecting line to the vacuum cham-

which the ions are produced by a cold-cathode gas discharge, ber).

usually in the presence of a magnetic field.

3.1.18 tubulated ionization gage—an enclosed ionization

3.1.9.2 hot-cathode ionization gage—an ionization gage in

gage for which the opening in the envelope is determined by a

which ion production is initiated and sustained by electrons

tubulation of diameter equal to or less than the minimum

emitted from a hot cathode.

diameter of the part of the envelope adjacent to the ion source

3.1.10 molecular flux density—the number of molecules

region and of length at least equal to the diameter of the

incident on a real or imaginary surface per unit area per unit

tubulation.

time. The unit is molecules per second per square centimetre.

3.1.19 vacuum gas analyzer—adevicecapableofindicating

3.1.11 molecular flux sensitivity—the output current of an

the relative composition of a gas mixture at low pressures.

enclosed vacuum gage per unit molecular flux density under

specified gage operating conditions and random particle mo-

4. Apparatus

tion.

4.1 Equipment—Acceptable vacuum-measuring equipment

3.1.12 nude ionization gage—an ionization gage for which

shallconsistofthoseitemsinwhichperformanceiscompatible

the center of the ion source region is exposed to direct

with obtaining meaningful measurements. The basic elements

molecular flux (from surfaces not forming part of the gage) in

consistofapowersupply,readout,andsensingelement.These

all directions except for a solid angle less than 0.05 34 p

items must be acceptable for applying the proper calibrations

steradians (determined by the parts of the gage head). No

described in Methods E297. The electronic power supply and

structures shall be within one sensing element diameter of any

readout shall have been calibrated either separately or in

partofthesensingelementunlesssimilarstructuresarepresent

conjunction with the test stand calibration of the gage sensor.

during calibration.

Special attention must be given to cabling, especially where

NOTE 1—The solid angle subtended by a circular disk of radius r with

cablingrunsarelong(asinlargevacuumsystems)inorderthat

axispassingthroughthecenterpointofthesolidangleatadistance yfrom

impedance or resistance errors are properly accounted for in

the disk is given as follows:

the calibration activities.

2 2 1 2

4.2 Calibration—These practices are not concerned with

/

v52 p[1 2 y/~y 1 r ! # (1)

gage calibration criteria except as applicable during test. Test

stand calibration criteria is provided by Methods E297. Re-

For v=0.05 34p,thedistance ymustequal2.07 r,avalue

cycle of the vacuum-measuring equipment to the calibration

which should be easily attainable for typical ionization gage

test stand should not be programmed only on a calendar basis.

electrodes mounted on a circular base of radius r.

Periodic recycle can best be determined by the individual

3.1.13 orifice ionization gage—anenclosedgagecontaining

operators compatible with usage requirements. Upon any

a single orifice or port having a length less than 0.15 of its

strong indication that usage in test may have produced an

diameter such that molecules from the chamber can enter the

alteration in gage factor, suspect elements shall be returned to

envelope directly from within a solid angle nearly equal to 2 p

the test stand. Alternatively, calibration before and after test

steradians.

may be incorporated as part of major test programs.

3.1.14 partial pressure gage—an ionization gage that indi-

catesthepartialpressureofanygasinamixtureirrespectiveof

5. Gage Mounting

the partial pressure of other gases in the mixture.

5.1 Flanges and Couplings—Flanging and connections are

3.1.15 partially enclosed ionization gage—a gage in which

the ion formation region is enclosed over less than 0.95 34 p specified in this section both for dimensions and material

between ionization gages and the external walls of high-

steradiansbutmorethan0.05 34 psteradiansaboutcenterby

an envelope which has one or more openings such that not all vacuumsystemstoproduceageometricallystandardmounting

method (compatible with the calibration test stand) which is a

molecules entering the ion formation region must first cross a

plane located outside this region. clean assembly free of interfering contamination such as that

produced by organic or high vapor-pressure sealing materials.

3.1.16 recovery time—the time required for the pressure

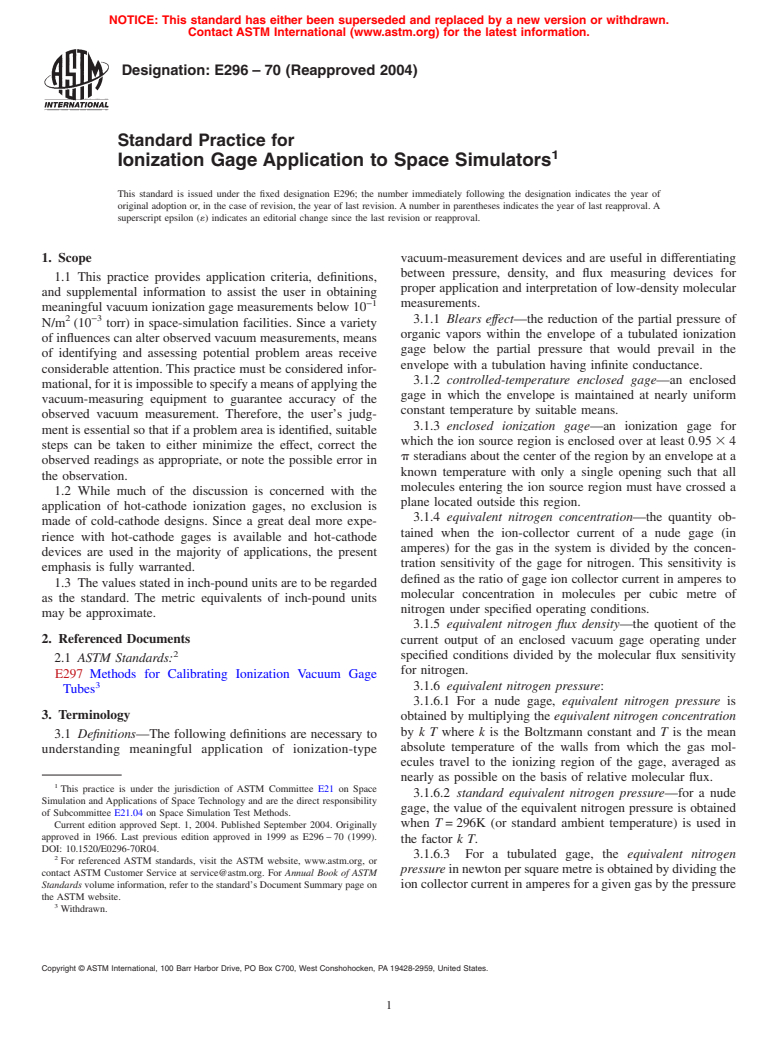

indication of a gage to reach and remain within pressure 5.1.1 Tubulated Ionization Gage (Fig. 1):

E296–70 (2004)

FIG. 3 Nude Ion Gage (Probe) Mounted Clear of Walls and

Structures

5.2 Internally Mounted Ionization Gages—Limitations for

mounting ionization gages internally are specified in this

FIG. 1 Tubulated Ionization Gage

section to provide mounting considerations applicable to plac-

ing any vacuum-ionization gage within the vacuum volume.

5.1.1.1 The flange material shall be stainless steel with a Measurement considerations are provided in Section 6.

glass-to-metal seal connecting the gage to the flange stub. The

5.2.1 Tubulated Ionization Gages:

flanges shall be welded or high-temperature brazed with 5.2.1.1 Mechanical—The mechanical support and position-

appropriate cleaning to remove residual flux. Gasket material

ing of internally mounted tubulated gages must not influence

shall be metallic: copper, aluminum, indium, and so forth. the distribution of molecules across the tubulation.

5.1.1.2 The gage may be attached directly to chamber

5.2.1.2 Thermal—Since internally mounted tubulated gages

eliminating flanges and gasketing providing limiting dimen- will experience significantly different heat transfer conditions

sions are adhered to.

from the envelope, care should be taken to provide means in

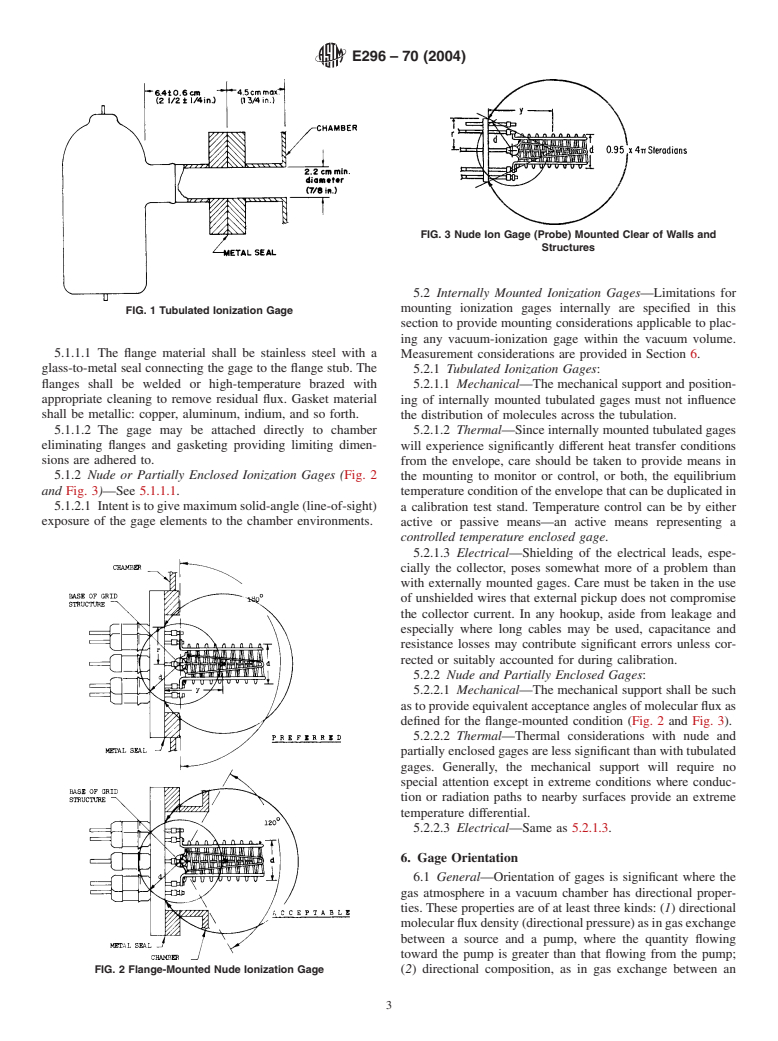

5.1.2 Nude or Partially Enclosed Ionization Gages (Fig. 2 the mounting to monitor or control, or both, the equilibrium

and Fig. 3)—See 5.1.1.1.

temperatureconditionoftheenvelopethatcanbeduplicatedin

5.1.2.1 Intentistogivemaximumsolid-angle(line-of-sight)

a calibration test stand. Temperature control can be by either

exposure of the gage elements to the chamber environments.

active or passive means—an active means representing a

controlled temperature enclosed gage.

5.2.1.3 Electrical—Shielding of the electrical leads, espe-

cially the collector, poses somewhat more of a problem than

with externally mounted gages. Care must be taken in the use

of unshielded wires that external pickup does not compromise

the collector current. In any hookup, aside from leakage and

especially where long cables may be used, capacitance and

resistance losses may contribute significant errors unless cor-

rected or suitably accounted for during calibration.

5.2.2 Nude and Partially Enclosed Gages:

5.2.2.1 Mechanical—The mechanical support shall be such

astoprovideequivalentacceptanceanglesofmolecularfluxas

defined for the flange-mounted condition (Fig. 2 and Fig. 3).

5.2.2.2 Thermal—Thermal considerations with nude and

partiallyenclosedgagesarelesssignificantthanwithtubulated

gages. Generally, the mechanical support will require no

special attention except in extreme conditions where conduc-

tion or radiation paths to nearby surfaces provide an extreme

temperature differential.

5.2.2.3 Electrical—Same as 5.2.1.3.

6. Gage Orientation

6.1 General—Orientation of gages is significant where the

gas atmosphere in a vacuum chamber has directional proper-

ties.These properties are of at least three kinds: (1) directional

molecularfluxdensity(directionalpressure)asingasexchange

between a source and a pump, where the quantity flowing

toward the pump is greater than that flowing from the pump;

FIG. 2 Flange-Mounted Nude Ionization Gage (2) directional composition, as in gas exchange between an

E296–70 (2004)

outgassing body and a cryopump, where the outgassing mate- 7.1.1.2 Radioactive sources emitting nuclear radiations,

rial is mainly condensible and the material flowing from the

7.1.1.3 Other sources of electromagnetic radiation or par-

cryopump is mainly noncondensible; (3) directional tempera-

ticle radiation being used to simulate the solar spectrum or the

ture,asingasexchangebetweenawarmandcol

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.