ASTM D6655-01

(Terminology)Standard Terminology Relating to Mechanical Pump Dispensers

Standard Terminology Relating to Mechanical Pump Dispensers

SCOPE

1.1 The terms found in this terminology relate to the nomenclature used in the packaging industry.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

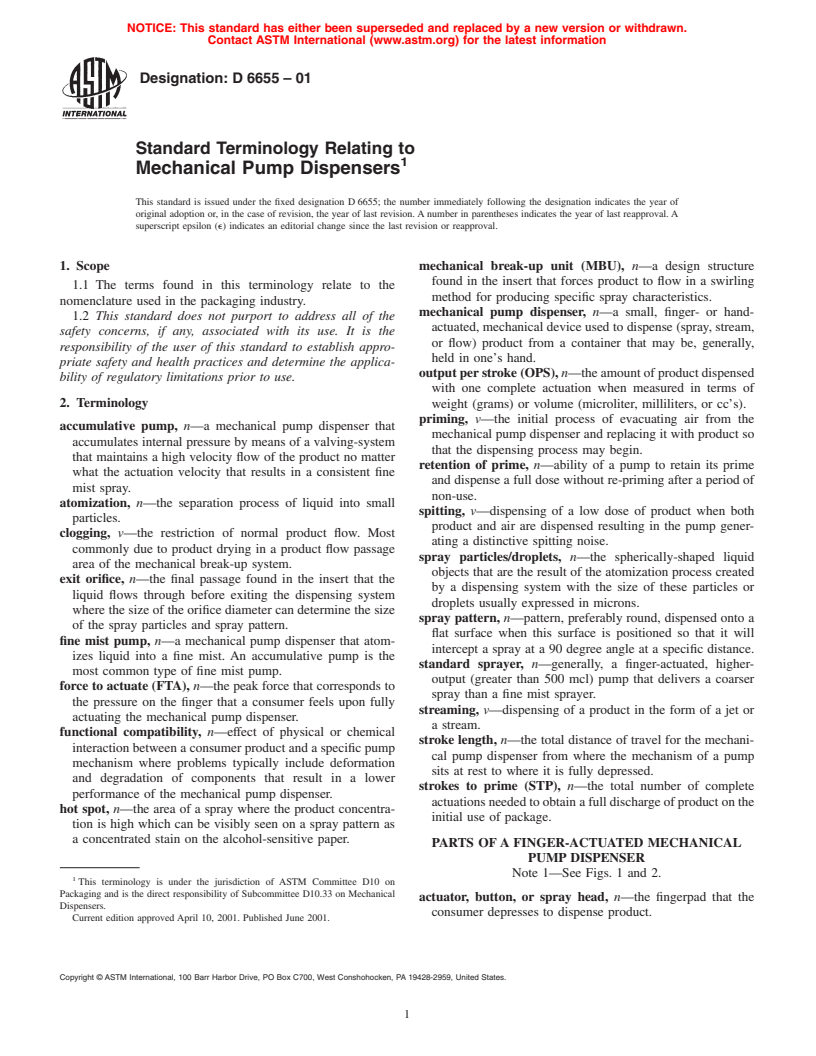

Designation:D6655–01

Standard Terminology Relating to

Mechanical Pump Dispensers

This standard is issued under the fixed designation D 6655; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope mechanical break-up unit (MBU), n—a design structure

found in the insert that forces product to flow in a swirling

1.1 The terms found in this terminology relate to the

method for producing specific spray characteristics.

nomenclature used in the packaging industry.

mechanical pump dispenser, n—a small, finger- or hand-

1.2 This standard does not purport to address all of the

actuated, mechanical device used to dispense (spray, stream,

safety concerns, if any, associated with its use. It is the

or flow) product from a container that may be, generally,

responsibility of the user of this standard to establish appro-

held in one’s hand.

priate safety and health practices and determine the applica-

outputperstroke(OPS), n—the amount of product dispensed

bility of regulatory limitations prior to use.

with one complete actuation when measured in terms of

2. Terminology weight (grams) or volume (microliter, milliliters, or cc’s).

priming, v—the initial process of evacuating air from the

accumulative pump, n—a mechanical pump dispenser that

mechanical pump dispenser and replacing it with product so

accumulates internal pressure by means of a valving-system

that the dispensing process may begin.

that maintains a high velocity flow of the product no matter

retention of prime, n—ability of a pump to retain its prime

what the actuation velocity that results in a consistent fine

and dispense a full dose without re-priming after a period of

mist spray.

non-use.

atomization, n—the separation process of liquid into small

spitting, v—dispensing of a low dose of product when both

particles.

product and air are dispensed resulting in the pump gener-

clogging, v—the restriction of normal product flow. Most

ating a distinctive spitting noise.

commonly due to product drying in a product flow passage

spray particles/droplets, n—the spherically-shaped liquid

area of the mechanical break-up system.

objects that are the result of the atomization process created

exit orifice, n—the final passage found in the insert that the

by a dispensing system with the size of these particles or

liquid flows through before exiting the dispensing system

droplets usually expressed in microns.

where the size of the orifice diameter can determine the size

spray pattern, n—pattern, preferably round, dispensed onto a

of the spray particles and spray pattern.

flat surface when this surface is positioned so that it will

fine mist pump, n—a mechanical pump dispenser that atom-

intercept a spray at a 90 degree angle at a specific distance.

izes liquid into a fine mist. An accumulative pump is the

standard sprayer, n—generally, a finger-actuated, higher-

most common type of fine mist pump.

output (greater than 500 mcl) pump that delivers a coarser

force to actuate (FTA), n—the peak force that corresponds to

spray than a fine mist sprayer.

the pressure on the finger that a consumer feels upon fully

streaming, v—dispensing of a product in the form of a jet or

actuating the mechanical pump dispenser.

a stream.

functional compatibility, n—effect of physical or chemical

stroke length, n—the total distance of travel for the mechani-

interaction between a consumer product and a specific pump

cal pump dispenser from where the mechanism of a pump

mechanism where problems typically include deformation

sits at rest to w

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.