ASTM D968-93(2001)

(Test Method)Standard Test Methods for Abrasion Resistance of Organic Coatings by Falling Abrasive

Standard Test Methods for Abrasion Resistance of Organic Coatings by Falling Abrasive

SCOPE

1.1 These test methods cover the determination of the resistance of organic coatings to abrasion produced by abrasive falling onto coatings applied to a plane rigid surface, such as a metal or glass panel.

1.2 Two test methods based on different abrasives are covered as follows: SectionsMethod A--Falling Sand Abrasion Test1-12Method B--Falling Silicon Carbide Abrasion Test13-19

1.3 These methods should be restricted to testing in only one laboratory when numerical values are used because of the poor reproducibility of the methods (see 13.1.2 and 21.1.2 ). Interlaboratory agreement is improved significantly when ranking is used in place of numerical values.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D968–93 (Reapproved 2001)

Standard Test Methods for

Abrasion Resistance of Organic Coatings by Falling

Abrasive

This standard is issued under the fixed designation D 968; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope DryFilmThicknessofNonconductiveCoatingsAppliedto

a Nonferrous Metal Base

1.1 These test methods cover the determination of the

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

resistance of organic coatings to abrasion produced by abrasive

poses

falling onto coatings applied to a plane rigid surface, such as a

metal or glass panel.

3. Terminology

1.2 Two test methods based on different abrasives are

3.1 Description of Term Specific to This Standard:

covered as follows:

3.1.1 abrasion resistance—the amount of abrasive required

Sections

to wear through a unit film thickness of the coating.

Method A—Falling Sand Abrasion Test 1-12

Method B—Falling Silicon Carbide Abrasion Test 13-19

4. Summary of Test Methods

1.3 These methods should be restricted to testing in only

4.1 Abrasive is allowed to fall from a specified height

one laboratory when numerical values are used because of the

through a guide tube onto a coated panel until the substrate

poor reproducibility of the methods (see 13.1.2 and 21.1.2).

becomes visible. The amount of abrasive per unit film thick-

Interlaboratoryagreementisimprovedsignificantlywhenrank-

ness is reported as the abrasion resistance of the coating on the

ing is used in place of numerical values.

panel. Silica sand or silicon carbide may be used, as specified.

1.4 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

5. Significance and Use

only.

5.1 Silica sand produces a slower rate of abrasion for

1.5 This standard does not purport to address the safety

organic coatings than provided by silicon carbide but, for some

concerns, if any, associated with its use. It is the responsibility

types of coatings, it provides greater discrimination.

of the user of this standard to establish appropriate safety and

5.2 The abrasion resistance scales produced by the two

health practices and determine the applicability of regulatory

methods differ, but the methods provide approximately the

limitations prior to use.

same rankings of coatings for abrasion resistance.

2. Referenced Documents 5.3 Each of the methods has been found useful for rating the

abrasion resistance of specific types of coatings. For example

2.1 ASTM Standards:

MethodA(falling sand) has been used for rating floor coatings

D 823 Practices for Producing Films of Uniform Thickness

2 while Method B (falling silicon carbide) has been used for

of Paint, Varnish, and Related Products on Test Panels

rating coatings for ship decks.

D 1005 Test Method for Measurement of Dry-Film Thick-

ness of Organic Coatings Using Micrometers

METHOD A—FALLING SAND ABRASION TEST

D 1186 Test Methods for Nondestructive Measurement of

Dry Film Thickness of Nonmagnetic Coatings Applied to

6. Apparatus and Materials

a Ferrous Base

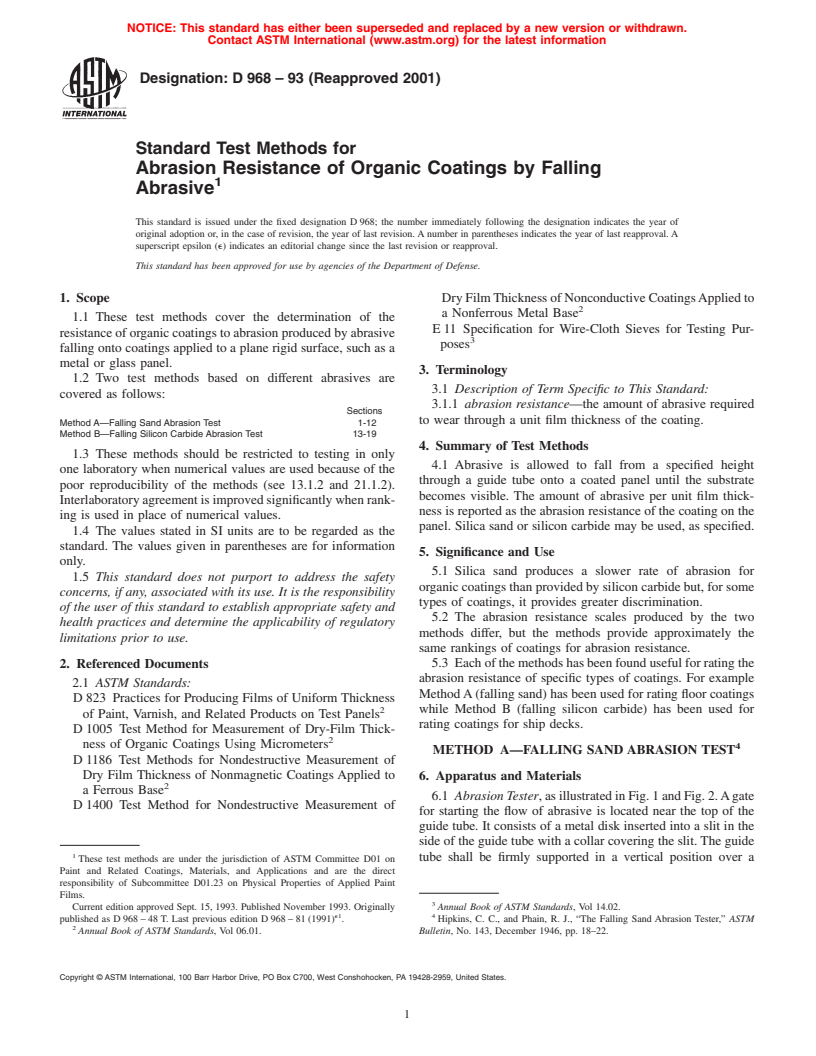

6.1 Abrasion Tester,asillustratedinFig.1andFig.2.Agate

D 1400 Test Method for Nondestructive Measurement of

for starting the flow of abrasive is located near the top of the

guide tube. It consists of a metal disk inserted into a slit in the

side of the guide tube with a collar covering the slit. The guide

tube shall be firmly supported in a vertical position over a

These test methods are under the jurisdiction of ASTM Committee D01 on

Paint and Related Coatings, Materials, and Applications and are the direct

responsibility of Subcommittee D01.23 on Physical Properties of Applied Paint

Films.

Current edition approved Sept. 15, 1993. Published November 1993. Originally Annual Book of ASTM Standards, Vol 14.02.

e1 4

published as D 968 – 48 T. Last previous edition D 968 – 81 (1991) . Hipkins, C. C., and Phain, R. J., “The Falling Sand Abrasion Tester,” ASTM

Annual Book of ASTM Standards, Vol 06.01. Bulletin, No. 143, December 1946, pp. 18–22.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D968

opening of the tube is directly above the area to be abraded and

the distance from the tube to the coated surface face at the

nearest point is 25 mm (1 in.) when measured in the vertical

direction. The base of the apparatus shall be fitted with

adjusting screws for properly aligning the equipment.

6.2 Standard Abrasive—Natural silica sand from the St.

Peters or Jordan sandstone deposits (located in the central

UnitedStates)shallbeconsideredstandardwhennotmorethan

15 % of the grains in a sample are retained on a No. 20 (850

µm) sieve and not more than 5% of the grains pass a No. 30

(600 µm) sieve after 5 min of continuous sieving. The sand is

characterized by its roundness of grains and its exceptionally

high silicon dioxide content. Use the sieves described in

Specification E 11.

NOTE 1—Theabradingqualitiesofsandobtainedfromdifferentsources

may differ slightly even though the sand meets the sieve requirements.

Therefore, for maximum precision of test results, purchaser and seller

should use sand from the same source.

7. Test Specimens

7.1 Apply uniform coatings of the material to be tested to a

plane, rigid surface such as a metal or glass panel. Prepare a

minimum of two coated panels for the material.

7.2 Cure the coated panels under the conditions of humidity

and temperature agreed upon between the purchaser and seller.

NOTE 2—The coatings should be applied in accordance with Practices

D 823, or as agreed upon between the purchaser and the seller.

FIG. 1 Apparatus for Falling Sand Abrasion Test

NOTE 3—The thickness of the dry coatings should be measured in

accordance with Test Methods D 1005, D 1186 or D 1400.

8. Standardization

8.1 Pour a quantity of standard sand into the funnel.

Examine the sand stream falling from the lower end of the

guide tube and align the apparatus by means of the adjusting

screws in the base until the inner concentrated core of the sand

stream falls in the center of the flow when viewed at two

positions at 90° to each other. Introduce a measured volume of

sand (2000 6 10 mL is a convenient amount) and determine

the time of efflux. The rate of flow shall be 2 L of sand in 21

to 23.5 s.

8.2 Secure a trial panel in the testing position, as described

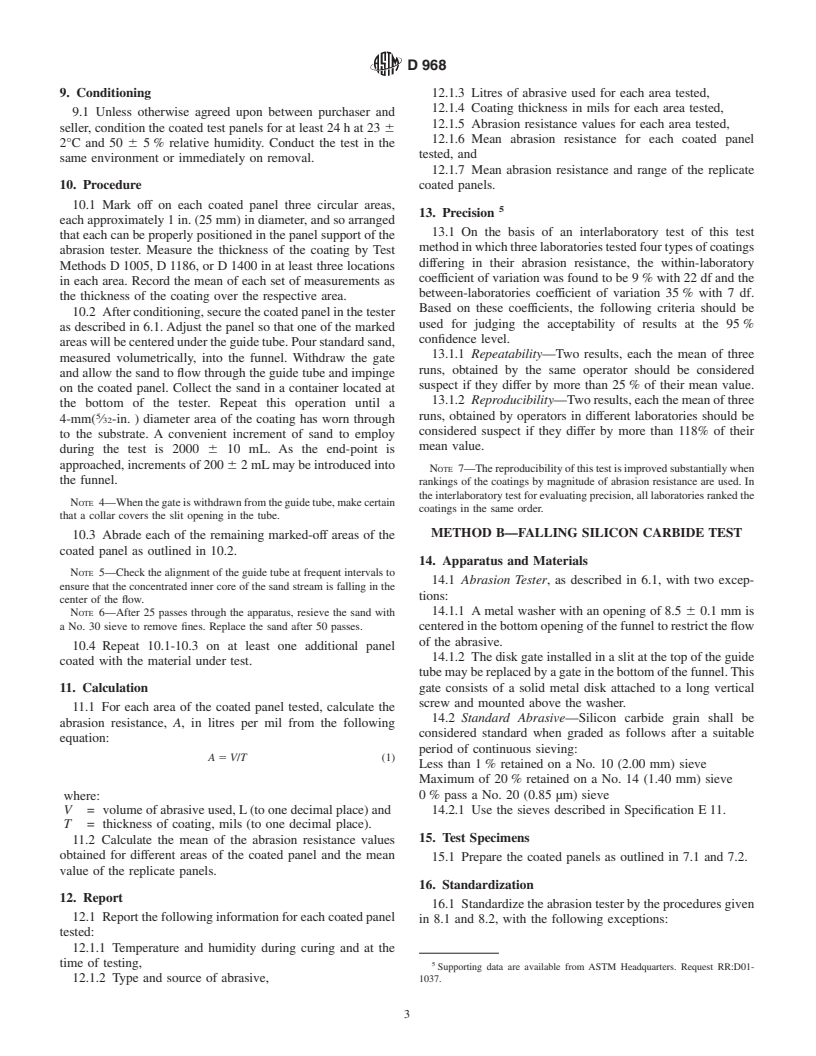

in 6.1, and introduce the sand in increments until a spot 4 mm

( ⁄32 in. ) in diameter is worn through to the base material. The

overall abraded area shall be elliptical in shape, about 1 in. (25

mm) in width and 30 mm (1 ⁄4 in.) in length. The center of the

area of maximum abrasion shall be on the center line through

the longer axis of the abraded pattern and within 14 to 17 mm

9 11

( ⁄16to ⁄16 in.) of the top edge. Slight final adjustment of the

instrument may be required to center the abrasion spot in the

pattern.Afinal check on alignment is made by determining the

amount of sand that passes through a 4-mm ( ⁄32-in. ) hole in a

metal panel placed directly under the tube. Place a container

undertheholeinthepanelandallowaweighedamountofsand

NOTE 1—All dimensions are given in inches. 1 in. = 25.4 mm.

to pass through the tube onto the panel. Weigh the amount of

FIG. 2 Design Details of Abrasion Test Apparatus

sand that passed through the hole into the container. The

apparatus can be considered to be in calibration if the amount

suitable receptacle, which shall contain a support for holding of sand that passed through the hole is 90 to 93 % of the

the coated panel at an angle of 45° to the vertical, so that the amount of sand that impinged on the panel.

D968

9. Conditioning 12.1.3 Litres of abrasive used for each area tested,

12.1.4 Coating thickness in mils for each area tested,

9.1 Unless otherwise agreed upon between purchaser and

12.1.5 Abrasion resistance values for each area tested,

seller, condition the coated test panels for at least 24 h at 23 6

12.1.6 Mean abrasion resistance for each coated panel

2°C and 50 6 5 % relative humidity. Conduct the test in the

tested, and

same environment or immediately on removal.

12.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.