ASTM C610-11

(Specification)Standard Specification for Molded Expanded Perlite Block and Pipe Thermal Insulation

Standard Specification for Molded Expanded Perlite Block and Pipe Thermal Insulation

ABSTRACT

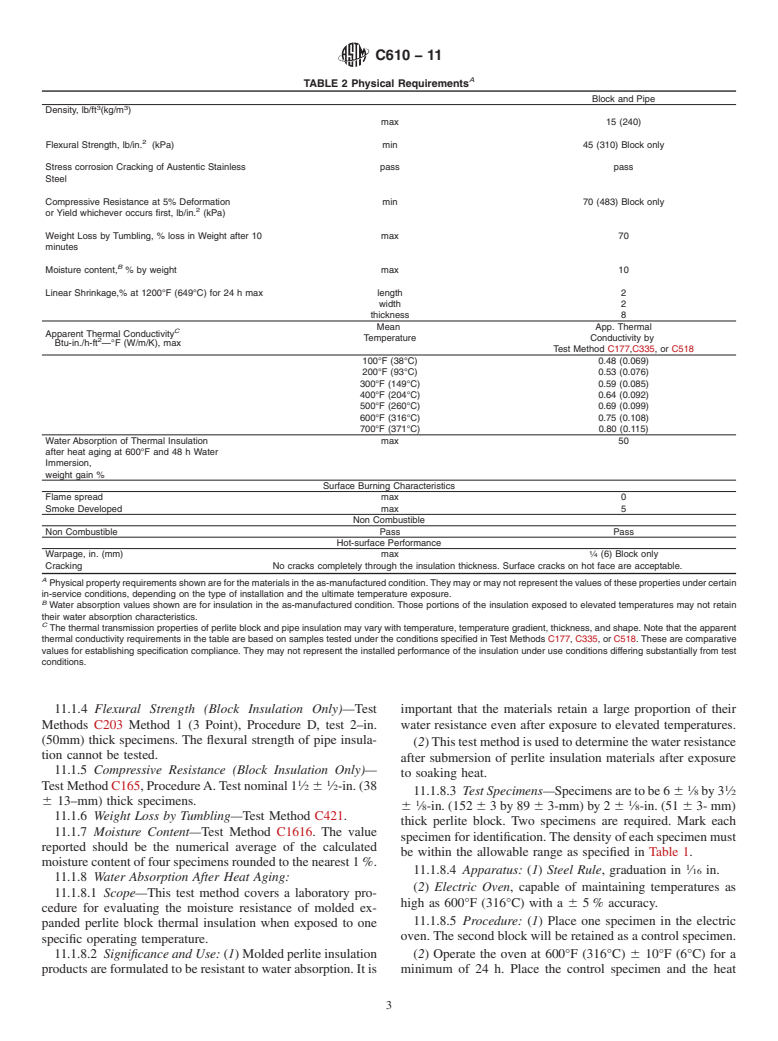

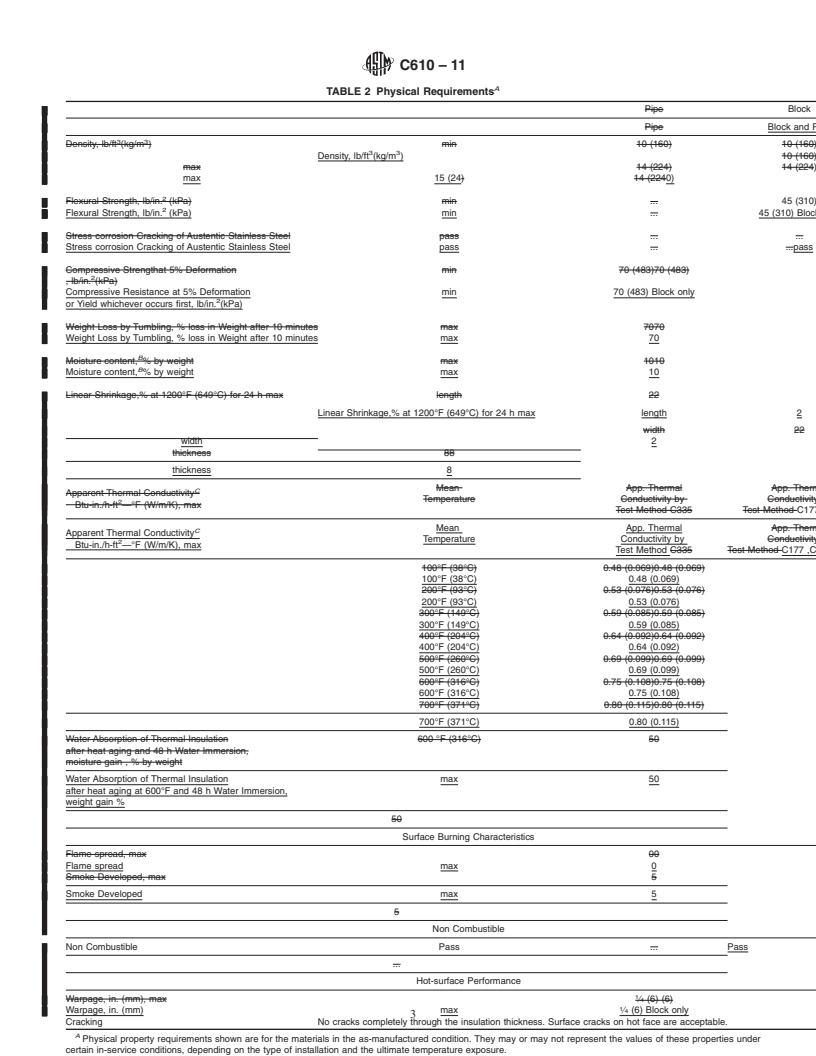

This specification covers molded expanded perlite block, fittings, and pipe thermal insulation intended for use on surfaces with temperatures of certain range. The insulation shall not have visible defects that will adversely affect its service qualities. Different test methods shall be performed in order to determine the properties of the block, fitting, and pipe insulations: density, apparent thermal conductivity, linear shrinkage after heat soaking, flexural strength, compressive strength, weight loss by tumbling, moisture content, water absorption after heat aging, surface bearing characteristics, hot-surface performance, and stress corrosion cracking of austenitic stainless steel.

SCOPE

1.1 This specification covers molded expanded perlite block, fittings, and pipe thermal insulation intended for use on surfaces with temperatures between 80 to 1200°F (27 to 649°C).

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 When the installation or use of thermal insulation materials, accessories, and systems may pose safety or health problems, the manufacturer shall provide the user appropriate current information regarding any known problems associated with the recommended use of the company's products and shall also recommend protective measures to be employed in their safe utilization. The following safety caveat applies only to the test methods portion of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

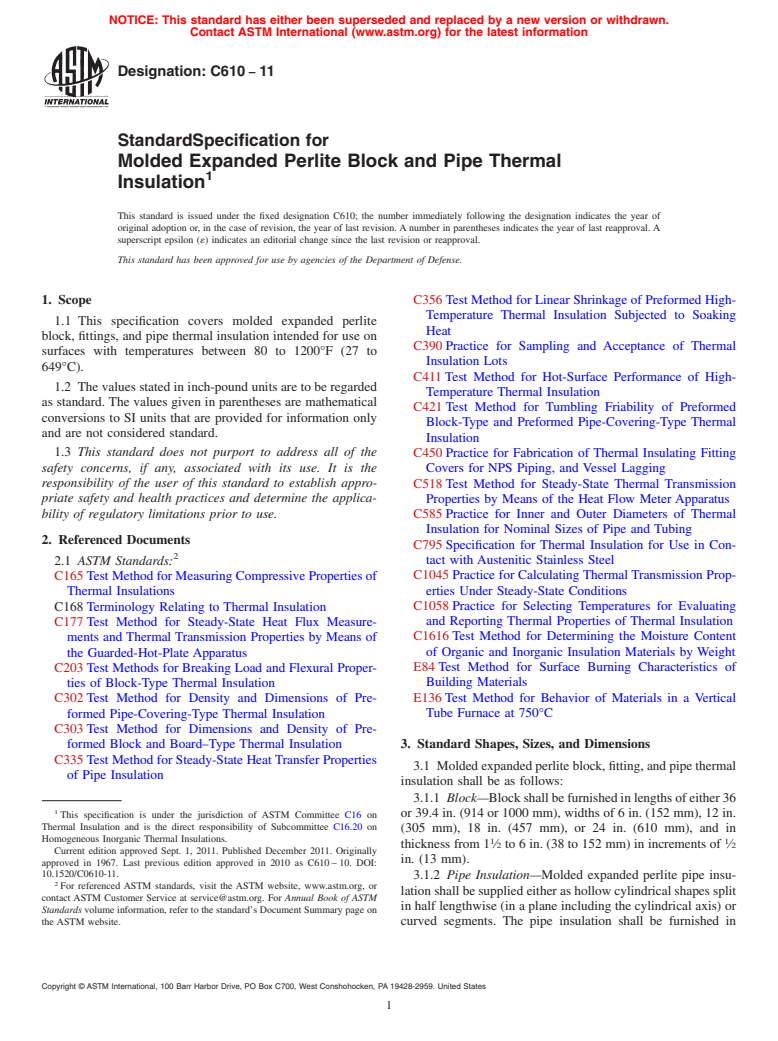

Designation:C610 −11

StandardSpecification for

Molded Expanded Perlite Block and Pipe Thermal

1

Insulation

This standard is issued under the fixed designation C610; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope C356 Test Method for Linear Shrinkage of Preformed High-

Temperature Thermal Insulation Subjected to Soaking

1.1 This specification covers molded expanded perlite

Heat

block, fittings, and pipe thermal insulation intended for use on

C390 Practice for Sampling and Acceptance of Thermal

surfaces with temperatures between 80 to 1200°F (27 to

Insulation Lots

649°C).

C411 Test Method for Hot-Surface Performance of High-

1.2 The values stated in inch-pound units are to be regarded

Temperature Thermal Insulation

as standard. The values given in parentheses are mathematical

C421 Test Method for Tumbling Friability of Preformed

conversions to SI units that are provided for information only

Block-Type and Preformed Pipe-Covering-Type Thermal

and are not considered standard.

Insulation

1.3 This standard does not purport to address all of the

C450 Practice for Fabrication of Thermal Insulating Fitting

safety concerns, if any, associated with its use. It is the Covers for NPS Piping, and Vessel Lagging

responsibility of the user of this standard to establish appro-

C518 Test Method for Steady-State Thermal Transmission

priate safety and health practices and determine the applica- Properties by Means of the Heat Flow Meter Apparatus

bility of regulatory limitations prior to use.

C585 Practice for Inner and Outer Diameters of Thermal

Insulation for Nominal Sizes of Pipe and Tubing

2. Referenced Documents

C795 Specification for Thermal Insulation for Use in Con-

2

tact with Austenitic Stainless Steel

2.1 ASTM Standards:

C165 Test Method for Measuring Compressive Properties of C1045 Practice for Calculating Thermal Transmission Prop-

erties Under Steady-State Conditions

Thermal Insulations

C1058 Practice for Selecting Temperatures for Evaluating

C168 Terminology Relating to Thermal Insulation

and Reporting Thermal Properties of Thermal Insulation

C177 Test Method for Steady-State Heat Flux Measure-

C1616 Test Method for Determining the Moisture Content

ments and Thermal Transmission Properties by Means of

the Guarded-Hot-Plate Apparatus of Organic and Inorganic Insulation Materials by Weight

E84 Test Method for Surface Burning Characteristics of

C203 Test Methods for Breaking Load and Flexural Proper-

ties of Block-Type Thermal Insulation Building Materials

E136 Test Method for Behavior of Materials in a Vertical

C302 Test Method for Density and Dimensions of Pre-

formed Pipe-Covering-Type Thermal Insulation Tube Furnace at 750°C

C303 Test Method for Dimensions and Density of Pre-

formed Block and Board–Type Thermal Insulation 3. Standard Shapes, Sizes, and Dimensions

C335 Test Method for Steady-State Heat Transfer Properties

3.1 Molded expanded perlite block, fitting, and pipe thermal

of Pipe Insulation

insulation shall be as follows:

3.1.1 Block—Blockshallbefurnishedinlengthsofeither36

1

This specification is under the jurisdiction of ASTM Committee C16 on or 39.4 in. (914 or 1000 mm), widths of 6 in. (152 mm), 12 in.

Thermal Insulation and is the direct responsibility of Subcommittee C16.20 on

(305 mm), 18 in. (457 mm), or 24 in. (610 mm), and in

Homogeneous Inorganic Thermal Insulations.

1 1

thickness from 1 ⁄2 to 6 in. (38 to 152 mm) in increments of ⁄2

Current edition approved Sept. 1, 2011. Published December 2011. Originally

in. (13 mm).

approved in 1967. Last previous edition approved in 2010 as C610 – 10. DOI:

10.1520/C0610-11.

3.1.2 Pipe Insulation—Molded expanded perlite pipe insu-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

lation shall be supplied either as hollow cylindrical shapes split

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in half lengthwise (in a plane including the cylindrical axis) or

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. curved segments. The pipe insulation shall be furnished in

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C610−11

sections or segments in lengths of either 36 or 39.4 in. (914 or 8. Sampling

1000 mm) to fit standard sizes of pipe and tubing, and in

8.1 The insulation shall be sampled in accordance with

1

nominal thickness from 1 to 4 in

...

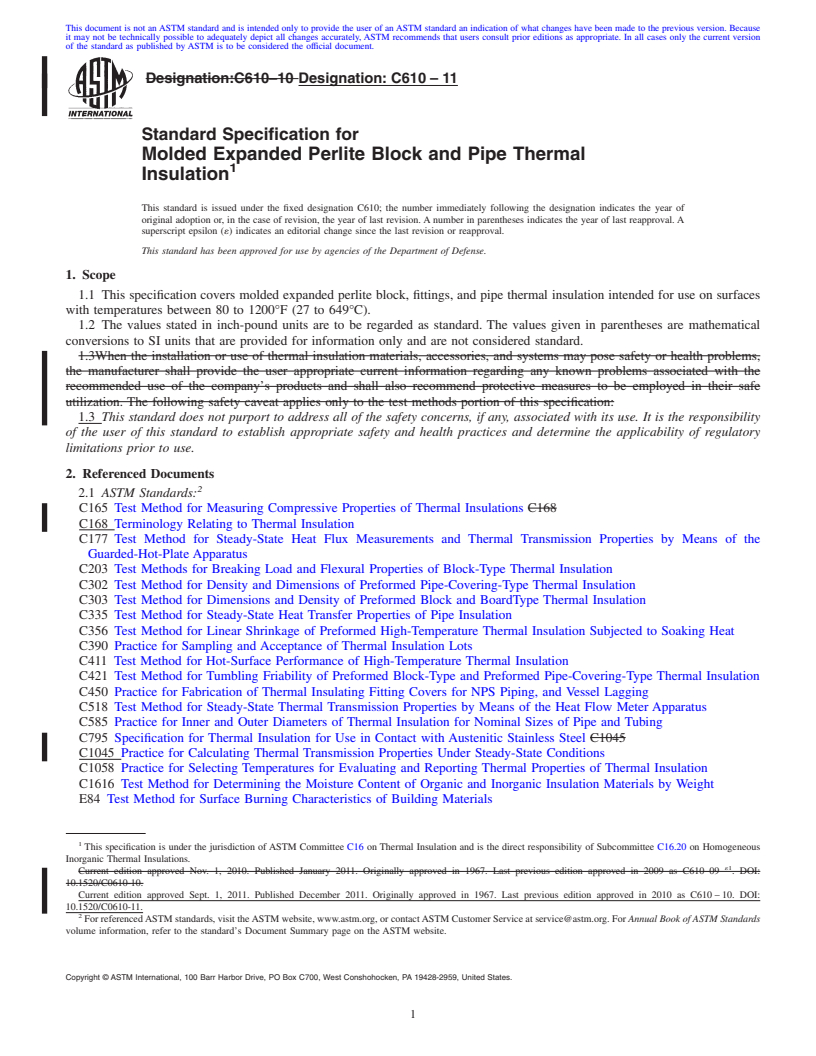

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C610–10 Designation: C610 – 11

Standard Specification for

Molded Expanded Perlite Block and Pipe Thermal

1

Insulation

This standard is issued under the fixed designation C610; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers molded expanded perlite block, fittings, and pipe thermal insulation intended for use on surfaces

with temperatures between 80 to 1200°F (27 to 649°C).

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3When the installation or use of thermal insulation materials, accessories, and systems may pose safety or health problems,

the manufacturer shall provide the user appropriate current information regarding any known problems associated with the

recommended use of the company’s products and shall also recommend protective measures to be employed in their safe

utilization. The following safety caveat applies only to the test methods portion of this specification:

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C165 Test Method for Measuring Compressive Properties of Thermal Insulations C168

C168 Terminology Relating to Thermal Insulation

C177 Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the

Guarded-Hot-Plate Apparatus

C203 Test Methods for Breaking Load and Flexural Properties of Block-Type Thermal Insulation

C302 Test Method for Density and Dimensions of Preformed Pipe-Covering-Type Thermal Insulation

C303 Test Method for Dimensions and Density of Preformed Block and BoardType Thermal Insulation

C335 Test Method for Steady-State Heat Transfer Properties of Pipe Insulation

C356 Test Method for Linear Shrinkage of Preformed High-Temperature Thermal Insulation Subjected to Soaking Heat

C390 Practice for Sampling and Acceptance of Thermal Insulation Lots

C411 Test Method for Hot-Surface Performance of High-Temperature Thermal Insulation

C421 Test Method for Tumbling Friability of Preformed Block-Type and Preformed Pipe-Covering-Type Thermal Insulation

C450 Practice for Fabrication of Thermal Insulating Fitting Covers for NPS Piping, and Vessel Lagging

C518 Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus

C585 Practice for Inner and Outer Diameters of Thermal Insulation for Nominal Sizes of Pipe and Tubing

C795 Specification for Thermal Insulation for Use in Contact with Austenitic Stainless Steel C1045

C1045 Practice for Calculating Thermal Transmission Properties Under Steady-State Conditions

C1058 Practice for Selecting Temperatures for Evaluating and Reporting Thermal Properties of Thermal Insulation

C1616 Test Method for Determining the Moisture Content of Organic and Inorganic Insulation Materials by Weight

E84 Test Method for Surface Burning Characteristics of Building Materials

1

This specification is under the jurisdiction of ASTM Committee C16 on Thermal Insulation and is the direct responsibility of Subcommittee C16.20 on Homogeneous

Inorganic Thermal Insulations.

´1

Current edition approved Nov. 1, 2010. Published January 2011. Originally approved in 1967. Last previous edition approved in 2009 as C610–09 . DOI:

10.1520/C0610-10.

Current edition approved Sept. 1, 2011. Published December 2011. Originally approved in 1967. Last previous edition approved in 2010 as C610 – 10. DOI:

10.1520/C0610-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C610 – 11

E136

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.