ASTM D1152-97

(Specification)Standard Specification for Methanol (Methyl Alcohol)

Standard Specification for Methanol (Methyl Alcohol)

SCOPE

1.1 This specification covers methanol (99.85% grade).

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 For specific hazard information and guidance, see the supplier's Material Safety Data Sheet for materials listed in this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: D 1152 – 97

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

1

Methanol (Methyl Alcohol)

This standard is issued under the fixed designation D 1152; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

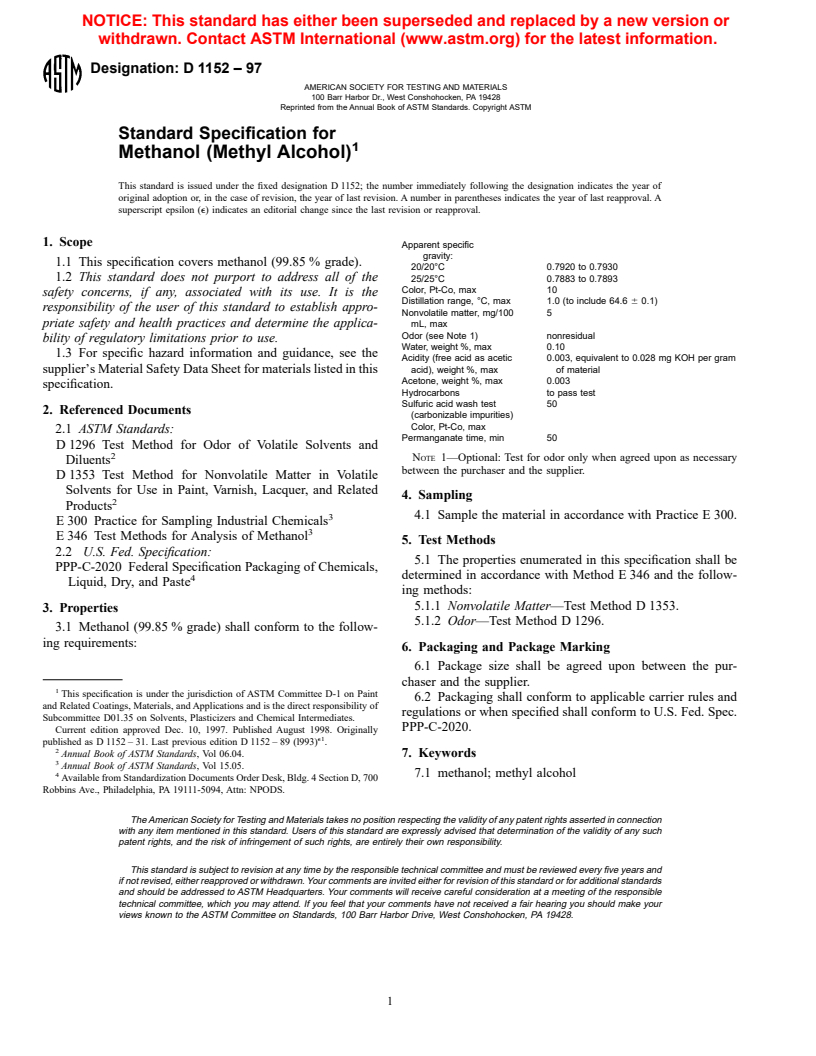

1. Scope

Apparent specific

gravity:

1.1 This specification covers methanol (99.85 % grade).

20/20°C 0.7920 to 0.7930

1.2 This standard does not purport to address all of the

25/25°C 0.7883 to 0.7893

Color, Pt-Co, max 10

safety concerns, if any, associated with its use. It is the

Distillation range, °C, max 1.0 (to include 64.6 6 0.1)

responsibility of the user of this standard to establish appro-

Nonvolatile matter, mg/100 5

priate safety and health practices and determine the applica- mL, max

Odor (see Note 1) nonresidual

bility of regulatory limitations prior to use.

Water, weight %, max 0.10

1.3 For specific hazard information and guidance, see the

Acidity (free acid as acetic 0.003, equivalent to 0.028 mg KOH per gram

supplier’s Material Safety Data Sheet for materials listed in this acid), weight %, max of material

Acetone, weight %, max 0.003

specification.

Hydrocarbons to pass test

Sulfuric acid wash test 50

2. Referenced Documents

(carbonizable impurities)

Color, Pt-Co, max

2.1 ASTM Standards:

Permanganate time, min 50

D 1296 Test Method for Odor of Volatile Solvents and

2

NOTE 1—Optional: Test for odor only when agreed upon as necessary

Diluents

between the purchaser and the supplier.

D 1353 Test Method for Nonvolatile Matter in Volatile

Solvents for Use in Paint, Varnish, Lacquer, and Related

4. Sampling

2

Products

4.1 Sample the material in accordance with Practice E 300.

3

E 300 Practice for Sampling Industrial Chemicals

3

E 346 Test Methods for Analysis of Methanol

5. Test Methods

2.2 U.S. Fed. Specification:

5.1 The

...

This May Also Interest You

SIGNIFICANCE AND USE

3.1 This guide is meant to aid response teams who may use it during spill response planning and spill events.

3.2 This guide should be adapted to site specific circumstance.

SCOPE

1.1 This guide covers the use of oil spill dispersants to assist in the control of oil spills. The guide is written with the goal of minimizing the environmental impacts of oil spills; this goal is the basis on which the recommendations are made. Aesthetic and socioeconomic factors are not considered, although these and other factors are often important in spill response.

1.2 Spill responders have available several means to control or clean up spilled oil. Chemical dispersants should be given equal consideration with other spill countermeasures.

1.3 This is a general guide only. Oil, as used in this guide, includes crude oils and refined petroleum products. Differences between individual dispersants or between different oil products are not considered. The dispersibility of the oil with the chosen dispersant should be evaluated.

1.4 The guide is organized by habitat type, for example, small ponds and lakes, rivers and streams, and land. It considers the use of dispersants primarily to protect habitats from impact (or to minimize impacts).

1.5 This guide applies only to freshwater and other inland environments. It does not consider the direct application of dispersants to subsurface waters.

1.6 In making dispersant use decisions, appropriate government authorities should be consulted as required by law.

1.7 This guide does not address getting regulatory approval.

1.8 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.10 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Guide3 pagesEnglish languagesale 15% off

- Guide3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 This test method establishes a selected set of conditions of temperature, relative humidity and rate of evaporation of the environment to which a mortar specimen of stated composition shall be subjected for a specified period of time during which its change in length is determined and designated “drying shrinkage.”

4.2 The drying shrinkage of mortar as determined by this test method has a linear relation to the drying shrinkage of concrete made with the same cement and exposed to the same drying conditions.4 Hence this test method may be used when it is desired to develop data on the effect of a hydraulic cement on the drying shrinkage of concrete made with that cement.

SCOPE

1.1 This test method determines the change in length on drying of mortar bars containing hydraulic cement and graded standard sand.

1.2 The values stated in SI units are to be regarded as standard. When combined standards are referenced, the selection of measurement system is at the user’s discretion subject to the requirements of the referenced standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Warning—Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and tissue upon prolonged exposure).2

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard4 pagesEnglish languagesale 15% off

- Standard4 pagesEnglish languagesale 15% off

SCOPE

1.1 This specification covers preformed expansion joint filler having relatively little extrusion and substantial recovery after release from compression.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

Note 1: Attention is called to Specifications D1752 and D994/D994M.

1.3 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification2 pagesEnglish languagesale 15% off

- Technical specification2 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers hot- and cold-worked precipitation-hardenable nickel alloy rod, bar, forgings, and forging stock for high-temperature service. Chemical analysis shall be performed on the alloy and shall conform to the chemical composition requirement in carbon, manganese, silicon, phosphorus, sulfur, chromium, cobalt, molybdenum, columbium, tantalum, titanium, aluminum, zirconium, boron, iron, copper, and nickel. The material shall follow recommended annealing treatment, solution treatment, stabilizing treatment, and precipitation hardening treatment. Tension testing, hardness testing and stress-rupture testing shall be performed on the material and shall comply to the required tensile strength, yield strength, elongation, reduction in area, and Brinell hardness.

SCOPE

1.1 This specification2 covers hot- and cold-worked precipitation-hardenable nickel alloy rod, bar, forgings, and forging stock for moderate or high temperature service (Table 1).

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Safety Data Sheet (SDS) for this product/material as provided by the manufacturer, to establish appropriate safety, health, and environmental practices, and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification7 pagesEnglish languagesale 15% off

- Technical specification7 pagesEnglish languagesale 15% off

SCOPE

1.1 This specification covers preformed expansion joint fillers made from closed-cell polypropylene foam materials having suitable compressibility, recovery from compression, nonextruding, and weather-resistant characteristics.

1.1.1 Type I, closed-cell polypropylene foam.

1.2 These joint fillers are intended for use in concrete pavements in full-depth joints. There are several variations in size with typical thicknesses of 1/2 in. (12.7 mm), 3/4 in. (19.05 mm), and 1 in. (25.4 mm); typical widths of 31/2 in. (88.9 mm), 4 in. (101.6 mm), 5 in. (127 mm), 6 in. (152.5 mm), 7 in. (177.8 mm), 8 in. (203.2 mm), or 48 in. (1.2 m) sheet; and typical lengths of 5 ft (1.52 m) and 10 ft (3.05 m).

1.3 The values stated in inch-pound units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification2 pagesEnglish languagesale 15% off

- Technical specification2 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 A standard procedure is necessary to establish property changes for spilled oils or petroleum products at different oil weathering stages.

5.2 This procedure employs standardized equipment, and test procedures.

5.3 This procedure should be performed at the stages of weathering corresponding to the spill conditions of interest.

SCOPE

1.1 This guide summarizes methods to fractionate oil by evaporative weathering and then measure the properties and behavior of the weathered oil. The results of this guide can provide oil behavior data for input into oil spill models and response method selection.

1.2 This guide covers general procedures for oil weathering and behavior and does not cover all possible procedures which may be applicable to this topic.

1.3 The results obtained using this guide are intended to provide baseline data for the behavior of oil and petroleum products when spilled and input to oil spill models.

1.4 The results obtained using this guide can be used directly to predict certain facets of oil spill behavior or as input to oil spill models.

1.5 The accuracy of the guide depends very much on the representative nature of the oil sample used. Certain oils can have different properties depending on their chemical contents at the moment a sample is taken.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Guide4 pagesEnglish languagesale 15% off

- Guide4 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 This test method can be used to determine whether the amount of draindown measured for a given asphalt mixture is within specified acceptable levels. The test provides an evaluation of the draindown potential of an asphalt mixture during mixture design and/or during field production. This test is primarily used for mixtures with high coarse aggregate content such as porous asphalt (open-graded friction course) and stone matrix asphalt (SMA).

Note 1: The quality of the results produced by this standard are dependent on the competence of the personnel performing the procedure and the capability, calibration, and maintenance of the equipment used. Agencies that meet the criteria of Specification D3666 are generally considered capable of competent and objective testing, sampling, inspection, etc. Users of this standard are cautioned that compliance with Specification D3666 alone does not completely ensure reliable results. Reliable results depend on many factors; following the suggestions of Specification D3666 or some similar acceptable guideline provides a means of evaluating and controlling some of those factors.

SCOPE

1.1 This test method covers the determination of the amount of draindown in an uncompacted asphalt mixture sample when the sample is held at elevated temperatures comparable to those encountered during the production, storage, transport, and placement of the mixture. The test is particularly applicable to mixtures such as porous asphalt (open-graded friction course) and stone matrix asphalt (SMA).

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

- Standard3 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers UNS N06002, UNS N06030, UNS N06035, UNS N06022, UNS N06200, UNS N06230, UNS N06600, UNS N06617, UNS N06625, UNS N08020, UNS N08026, UNS N08024, UNS N08120, UNS N08926, UNS N08367, UNS N10242, UNS N10276, UNS N10665, UNS N10675, UNS N12160, UNS R20033, UNS N06059, UNS N06686, UNS N10629, UNS N08031, UNS N06045, UNS N06025, and UNS R30556 nickel alloy billets and bars for reforging. The products shall be hot worked from ingots by rolling, forging, extruding, hammering, or pressing. The material shall conform to the chemical composition requirements prescribed by the reference material. The chemical composition of the material shall be determined by chemical analysis in accordance with test method E1473.

SCOPE

1.1 This specification covers UNS N06002, UNS N06030, UNS N06035, UNS N06022, UNS N06200, UNS N10362, UNS N06230, UNS N06600, UNS N06617, UNS N06625, UNS N08020, UNS N08026, UNS N08024, UNS N08120, UNS N08926, UNS N08367, UNS N10242, UNS N10276, UNS N10665, UNS N10675, UNS N12160, UNS R20033, UNS N06059, UNS N06686, UNS N10629, UNS N08031, UNS N06045, UNS N06025, UNS N06699, and UNS R305562 billets and bars for reforging.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Safety Data Sheet (SDS) for this product/material as provided by the manufacturer, to establish appropriate safety, health, and environmental practices, and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification5 pagesEnglish languagesale 15% off

- Technical specification5 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 The compression resistance perpendicular to the faces, the resistance to the extrusion during compression, and the ability to recover after release of the load are indicative of a joint filler's ability to continuously fill a concrete expansion joint and thereby prevent damage that might otherwise occur during thermal expansion. The asphalt content is a measure of the fiber-type joint filler's durability and life expectancy. In the case of cork-type fillers, the resistance to water absorption and resistance to boiling hydrochloric acid are relative measures of durability and life expectancy.

Note 2: The quality of the results produced by this standard are dependent on the competence of the personnel performing the procedure and the capability, calibration, and maintenance of the equipment used. Agencies that meet the criteria of Specification D3666 are generally considered capable of competent and objective testing, sampling, inspection, etc. Users of this standard are cautioned that compliance with Specification D3666 alone does not completely ensure reliable results. Reliable results depend on many factors; following the suggestions of Specification D3666 or some similar acceptable guideline provides a means of evaluating and controlling some of those factors.

SCOPE

1.1 These test methods cover the physical properties associated with preformed expansion joint fillers. The test methods include:

Property

Section

Expansion in Boiling Water

7.1

Recovery and Compression

7.2

Extrusion

7.3

Boiling in Hydrochloric Acid

7.4

Asphalt Content

7.5

Water Absorption

7.6

Density

7.7

Note 1: Specific test methods are applicable only to certain types of joint fillers, as stated herein.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard7 pagesEnglish languagesale 15% off

- Standard7 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers asphalt plank used for bridge decks as well as for industrial floors. Asphalt planks shall be classified according to usage: Type Ia; Type Ib; and Type II. Asphalt plank shall be formed from a mixture of asphalt, fibers, modifiers, or a combination thereof, and mineral filler in such a manner as to produce a uniformly dense mass. The following test methods shall be intended to measure those attributes necessary to measure the ability of asphalt plank to provide a reasonably long and satisfactory service: absorption; brittleness; dimensions; and hardness.

SCOPE

1.1 This specification covers asphalt plank used for bridge decks as well as for industrial floors.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification3 pagesEnglish languagesale 15% off

- Technical specification3 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.