ASTM D1879-99

(Practice)Standard Practice for Exposure of Adhesive Specimens to High-Energy Radiation

Standard Practice for Exposure of Adhesive Specimens to High-Energy Radiation

SCOPE

1.1 The purpose of this practice is to define conditions for the exposure of polymeric adhesives in bonded specimens to high-energy radiation prior to determination of radiation-induced changes in physical or chemical properties. This recommended practice specifically covers the following kinds of radiation: gamma or X-ray radiation, electron or beta radiation, neutrons, and mixtures of these such as reactor radiation.

1.2 This practice specifies only the conditions of irradiation but does not cover the preparation of test specimens, testing conditions, or the evaluation of test. These are covered in the various ASTM methods or specifications for specific materials.

1.3 This practice covers procedures for the following five types of exposure: Procedure A -Exposure at ambient conditions. Procedure B -Exposure at controlled temperature. Procedure C -Exposure in a medium other than air. Procedure D- Exposure under load. Procedure E- Exposure combining two or more of the variables listed in Procedures A to D. Note 1-The problems of measuring the properties of materials during irradiation involve shielding and remote control facilities and are, therefore, not considered in this practice.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1879 –99

Standard Practice for

Exposure of Adhesive Specimens to High-Energy Radiation

This standard is issued under the fixed designation D1879; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope cannot and will not substitute for a practical knowledge of the

instrument used for a particular procedure.

1.1 The purpose of this practice is to define conditions for

1.5.2 RadioFrequency: Warning—Personswithpacemak-

the exposure of polymeric adhesives in bonded specimens to

ers may be affected by the radio frequency.

high-energy radiation prior to determination of radiation-

induced changes in physical or chemical properties. This

2. Referenced Documents

recommended practice specifically covers the following kinds

2.1 ASTM Standards:

of radiation: gamma or X-ray radiation, electron or beta

D618 Practice for Conditioning Plastics and Electrical

radiation, neutrons, and mixtures of these such as reactor

Insulating Materials for Testing

radiation.

D907 Terminology of Adhesives

1.2 This practice specifies only the conditions of irradiation

D1671 Test Method forAbsorbed Gamma Radiation Dose

but does not cover the preparation of test specimens, testing

in the Fricke Dosimeter

conditions, or the evaluation of test. These are covered in the

D1672 Practice for Exposure of Polymeric Materials to

variousASTMmethodsorspecificationsforspecificmaterials.

High-Energy Radiation

1.3 This practice covers procedures for the following five

D2953 Classification System for Polymeric Materials for

types of exposure:

Service in Ionizing Radiation

Procedure A—Exposure at ambient conditions.

2.2 ANSI Document:

Procedure B—Exposure at controlled temperature.

N1.1 Glossary of Terms in Nuclear Science and Technol-

Procedure C—Exposure in a medium other than air.

ogy

Procedure D—Exposure under load.

2.3 IEEE Documents:

Procedure E—Exposure combining two or more of the

278 Classifying Electrical Insulating Materials Exposed to

variables listed in Procedures A to D.

Neutron and Gamma Radiation

NOTE 1—Theproblemsofmeasuringthepropertiesofmaterialsduring

323 Qualifying Class 1E Equipment for Nuclear Power

irradiation involve shielding and remote control facilities and are, there-

Generating Stations

fore, not considered in this practice.

3. Terminology

1.4 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are provided for

3.1 Many terms in this practice are defined in Terminology

information purposes only.

D907.

1.5 This standard does not purport to address all of the

3.2 gray, n—the unit of absorbed dose when the energy per

safety concerns, if any, associated with its use. It is the

unit mass imparted to matter by radiation is one joule per

responsibility of the user of this standard to establish appro-

kilogram.

priate safety and health practices and determine the applica-

3.3 rad, n—the unit of absorbed dose when the energy per

bility of regulatory limitations prior to use.

unitmassimpartedtomatterbyradiationis100ergspergram.

1.5.1 Electrical Hazard: Warning—Theusersofthisprac-

–2

NOTE 2—To convert from rad to gray (Gy), multiply by 1.00 3 10 .

tice must be aware that there are inherent dangers associated

with the use of electrical instrumentation and that this practice

Annual Book of ASTM Standards, Vol 08.01.

Annual Book of ASTM Standards, Vol 15.06.

Discontinued; see 1984 Annual Book of ASTM Standards, Vol 12.02.

1 5

This practice is under the jurisdiction ofASTM Committee D-14 onAdhesives Discontinued; see 1985 Annual Book of ASTM Standards, Vol 12.02.

and is the direct responsibility of Subcommittee D14.80 on Metal Bonding Available from American National Standards Institute, 11 W. 42nd St., 13th

Adhesives. Floor, New York, NY 10036.

Current edition approved Oct. 10, 1999. Published December 1999. Originally Available from Institute of Electrical and Electronics Engineers, 345 E. 47th

published as D1879–61. Last previous edition D1879–70 (1994). St., New York, NY 10017.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1879

4. Significance and Use which the specimen has been exposed be reported as well as

the irradiation dose in energy absorbed units.

4.1 The procedures outlined in this practice are designed to

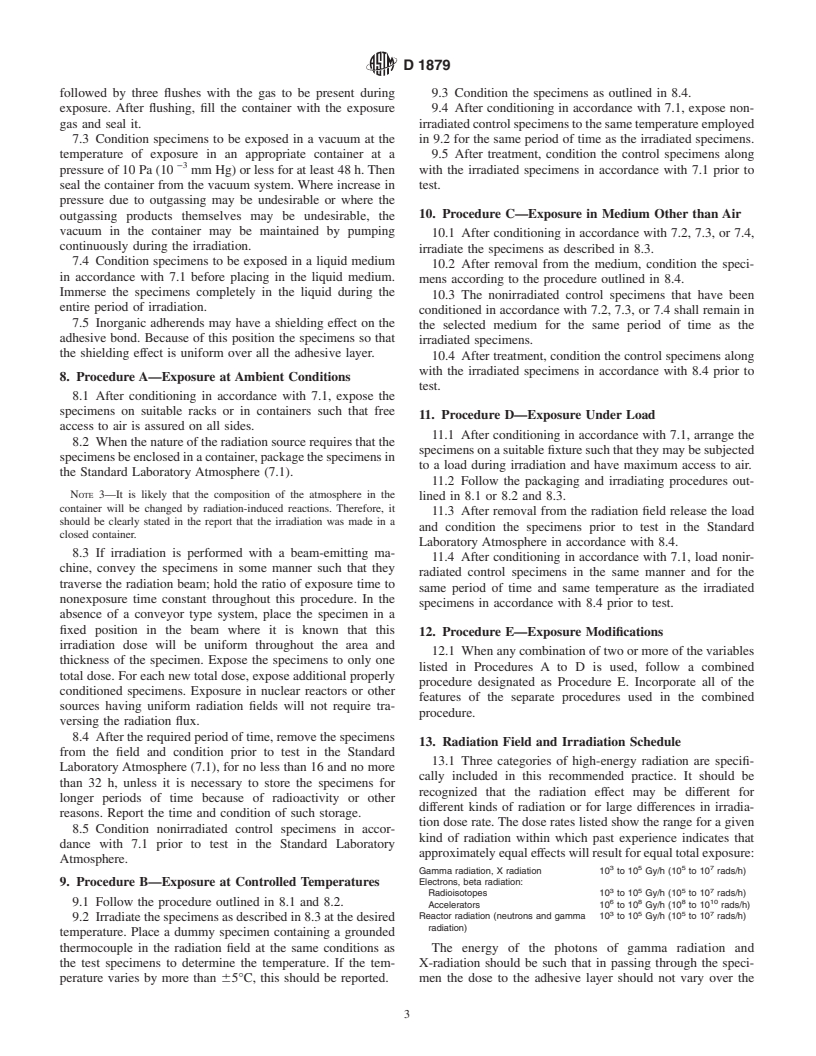

5.6 Awide variation in the stability of the various chemical

standardizetheexposureofadhesive-bondedspecimensforthe

structures on exposure to radiation makes it difficult to select

purpose of studying the effects of high-energy radiation, but

specific exposure levels for testing. Polystyrene requires the

have been made flexible enough so that a large variety of

absorption of about 50 times as much radiation energy for the

conditions may be met within the scope of this one irradiation

formation of one crosslink as does polyethylene. At the other

method. Because of this flexibility in the procedures it is

end of the scale, poly(methylmethacrylate) and polytetrafluo-

important that the experimenter have some idea of the kind of

roethyleneshowchangesinengineeringpropertiesatabout ⁄20

changes that will occur, and of the conditions that will affect

theexposurerequiredforchangesinpolyethylene.Anaromatic

these changes.

ringattachedtothemainchainatfrequentregularintervalshas

been found to confer marked stability toward radiation, while

5. Effects of Irradiation

a quaternary carbon atom in the polymer chain leads to

5.1 Exposuretoradiationresultsinextensivechangesinthe

cleavage under radiation and a loss of strength at fairly low

nature of high polymers, which owe their unique properties to

exposures. The exposure levels should therefore be those

chemicallinkinginto giant molecules of chain or netstructure.

which will produce significant changes in a stipulated property

These chain or net structures may be cross-linked by radiation

rather than a specified fixed irradiation dose. Furthermore, the

into a rigid, three-dimensional network or in other cases, may

change in property may progress at different rates, with some

be cleaved into smaller molecules to produce a weaker

materials changing rapidly once a change has been initiated,

material. Both may occur at the same time. In all cases some

while others may change quite slowly. It is necessary therefore

low molecular weight fragments are produced and, if expo-

to irradiate to several fixed levels of property change in order

sures are large enough, general decomposition results.

to establish the rate of change (see 13.2).

5.2 The first result of the reaction of high-energy radiation

5.7 Materials that have been exposed to reactor radiation

with polymers is the formation of free radicals or excited

willbecomeradioactive.Forpurehydrocarbons,theamountof

molecular fragments. The rate at which these molecular frag-

induced radioactivity is not large, but metallic and other

ments are formed may be much greater than their annihilation

inorganicadherendsandfillersandsmallamountsofimpurities

rate, and this leads to the accumulation of reactive species

may become highly radioactive and thus create a handling

within the irradiated material and to the possibility of continu-

problem. The other common radiation sources to which poly-

ing reactions for days or weeks after the specimen has been

meric materials will be exposed will not normally produce

removed from the radiation field. Because of these post-

significant amounts of induced radioactivity. The obvious

irradiation reactions it has been necessary to standardize the

solution would be to expose adhesive-bonded metallic speci-

times and conditions of storage between irradiation and testing

mens in non-neutron environments only. Unfortunately it is

of specimens.

very difficult to calculate for a given reactor spectrum the

5.3 The resultant changes in the molecular structure of

equivalent dosage in a gamma source. For exact work, where

polymeric materials by exposure to radiation are dependent on

the reactor spectrum is being studied, exposure in a reactor

therespectiveratesofrecombination,crosslinking,orcleavage

would give the only accurate results.

of the molecular fragments. These rates are affected by the

5.8 Metallic adherends such as cadmium will produce large

mobility of the molecular fragments (which is strongly influ-

sources of secondary radiation, which will significantly add to

enced by temperature) and by the concentration of the reac-

the absorbed dose of the adhesive.

tants.

5.4 The concentration of reactive species will vary with the

6. Test Specimens

rate of absorption of radiation. Either radiation intensity or

6.1 Wherever possible, use the type of specimens in accor-

dose rate is therefore specified in reporting the results of tests,

dance with the ASTM test methods for the specific properties

even though a dose rate effect is not often observed.The effect

to be measured.

of dose rate and specimen thickness is observed when irradia-

6.2 Where it is not possible to utilize standard test speci-

tions are carried out in the presence of oxygen, where oxygen

mens,makeirradiatedandnonirradiatedspecimensofthesame

reacts with radicals produced in the irradiated material. This

size and shape.

oxygen reaction will be diffusion controlled. The reactivity of

6.3 Sinceorganicadherendswouldbesensitivetoradiation,

irradiated specimens toward oxygen makes it necessary to

they should be tested independently of the adhesive assembly

specify whether irradiations are carried out in air. The acces-

under the same conditions, using irradiated and nonirradiated

sibilitytoanairsupplyundepletedinoxygenshouldbeassured

adherend specimens.

if possible.

5.5 The localized concentration of reactive species during

7. Conditioning

irradiation will vary, depending on the type of radiation

employed. The proton and carbon recoils from neutron bom- 7.1 Condition specimens to be exposed in air in accordance

with Procedure A of Practice D618.

bardment produce densely ionized tracks in the specimen

compared to the diffuse ionization in the wake of protons or 7.2 Condition specimens to be exposed in a gas other than

electrons. The effect of different types of radiation may air at the temperature of exposure in an appropriate container

−3

thereforebedifferent.Itisrequiredthatthetypeofradiationto at a pressure of 10 Pa (10 mm Hg) or less for at least 8 h

D1879

followed by three flushes with the gas to be present during 9.3 Condition the specimens as outlined in 8.4.

exposure. After flushing, fill the container with the exposure 9.4 After conditioning in accordance with 7.1,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.