ASTM E476-87(1993)

(Test Method)Standard Test Method for Thermal Instability of Confined Condensed Phase Systems (Confinement Test)

Standard Test Method for Thermal Instability of Confined Condensed Phase Systems (Confinement Test)

SCOPE

1.1 This test method is designed to determine the temperature at which a chemical or mixture of chemicals, confined initially as a solid or liquid in air or other controlled atmosphere under normal laboratory conditions, will start a reaction, generating appreciable heat when subjected to a programmed temperature increase. This test method is also designed to measure the magnitude and rate of heat generation.

1.2 This test method is for use with condensed phases.

1.3 This test method can be used over a temperature range from 0 to 500oC, and a pressure range of 0 to 5000 psi.

1.4 As with any thermal stability test, proper safety precautions should be instituted to protect personnel. See also Section 6.

1.5 Limitations

1.5.1 The threshold temperature determined by this method may be higher than one determined by heating at a lesser rate.

1.5.2 Samples of the same material having different thermal histories may have different threshold temperatures.

1.6 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 476 – 87 (Reapproved 1993)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Thermal Instability of Confined Condensed Phase Systems

(Confinement Test)

This standard is issued under the fixed designation E 476; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test method is one of several methods developed by Committee E-27 for determining the

hazards of chemicals. This test method is to be used in conjunction with other tests to characterize the

hazard potential of chemicals.

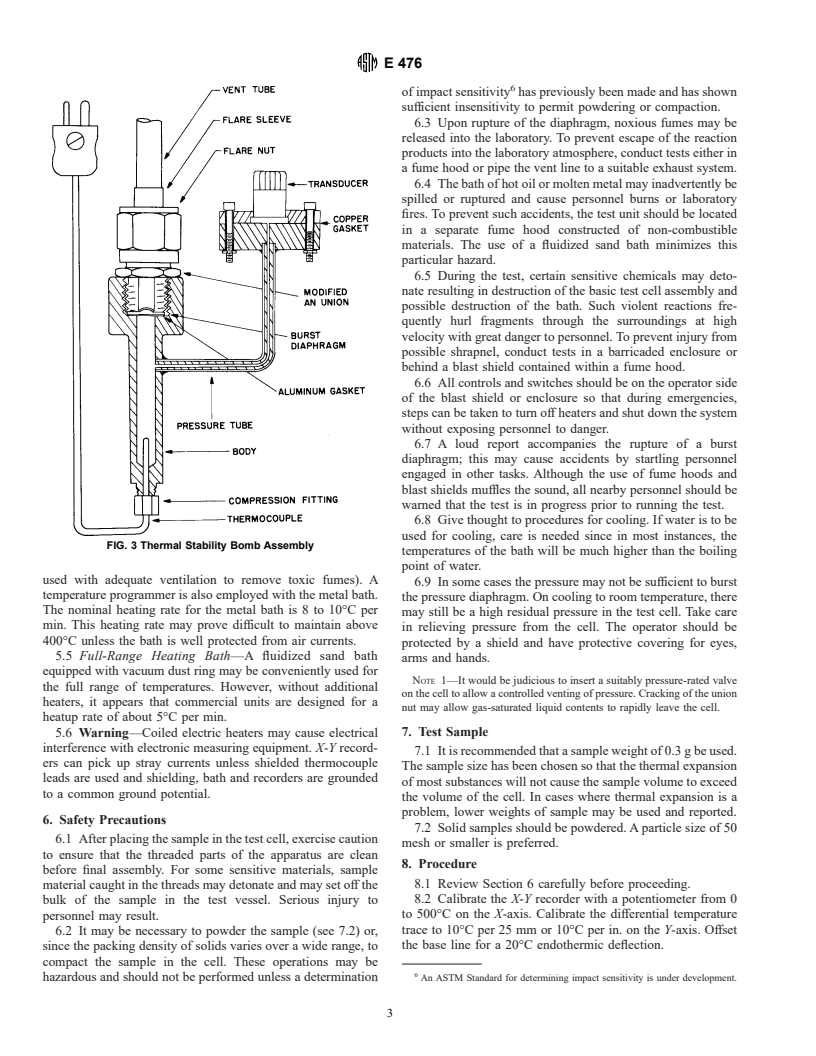

1. Scope curve (see Fig. 2) where the slope changes in the direction

indicating an exothermic reaction, that is, the sample is

1.1 This test method is designed to determine the tempera-

beginning to self-heat.

ture at which a chemical or mixture of chemicals, confined

initially as a solid or liquid in air or other controlled atmo-

3. Summary of Method

sphere under normal laboratory conditions, will start a reaction,

3.1 The sample is confined in a specially designed vessel

generating appreciable heat when subjected to a programmed

equipped with a shielded thermocouple. The test assembly is

temperature increase. This test method is also designed to

put into a bath and equilibrated, usually at room temperature.

measure the magnitude and rate of heat generation.

The bath is then heated at a constant temperature rise rate. The

1.2 This test method is for use with condensed phases.

differential temperature (sample temperature minus bath tem-

1.3 This test method can be used over a temperature range

perature) in the vessel is recorded versus bath temperature.

from 0 to 500°C, and a pressure range of 0 to 5000 psi.

Heating is continued until the diaphragm bursts or the upper

1.4 As with any thermal stability test, proper safety precau-

temperature limit is reached. The differential temperature curve

tions should be instituted to protect personnel. See also Section

is then analyzed to determine the threshold temperature for

6.

initiation of measurable reaction as indicated by an exothermic

1.5 Limitations:

temperature rise.

1.5.1 The threshold temperature determined by this method

may be higher than one determined by heating at a lesser rate.

4. Significance and Use

1.5.2 Samples of the same material having different thermal

4.1 The threshold temperature measured by this test method

histories may have different threshold temperatures.

is an indication of the thermal instability of a chemical or

1.6 This standard may involve hazardous materials, opera-

mixture of chemicals, qualitatively expressed by the tempera-

tions, and equipment. This standard does not purport to

ture rise. There is a potential hazard whenever the temperature

address all of the safety problems associated with its use. It is

of the chemical exceeds the threshold temperature unless

the responsibility of the user of this standard to establish

proper design safeguards are utilized. This does not imply that

appropriate safety and health practices and determine the

temperatures lower than the threshold temperature are safe.

applicability of regulatory limitations prior to use.

Since this test is not an adiabatic type and does not indicate the

2. Terminology effect of mass or time, other testing would be needed to

characterize the use or storage of the chemical at lower

2.1 threshold temperature—temperature on the DT versus T

temperatures.

4.2 Because of rate and mass dependent factors, failure to

find evidence of an exothermic reaction does not ensure

This test method is under the jurisdiction of Committee E-27 on Hazard

Potential of Chemicals and is the direct responsibility of Subcommittee E 27.02 on

thermal stability unless substantiated by other test methods.

Thermal Stability.

Current edition approved Sept. 25, 1987. Published November 1987. Originally

5. Apparatus

e2

published as E 476 – 73. Last previous edition E 476 – 73 (1979) .

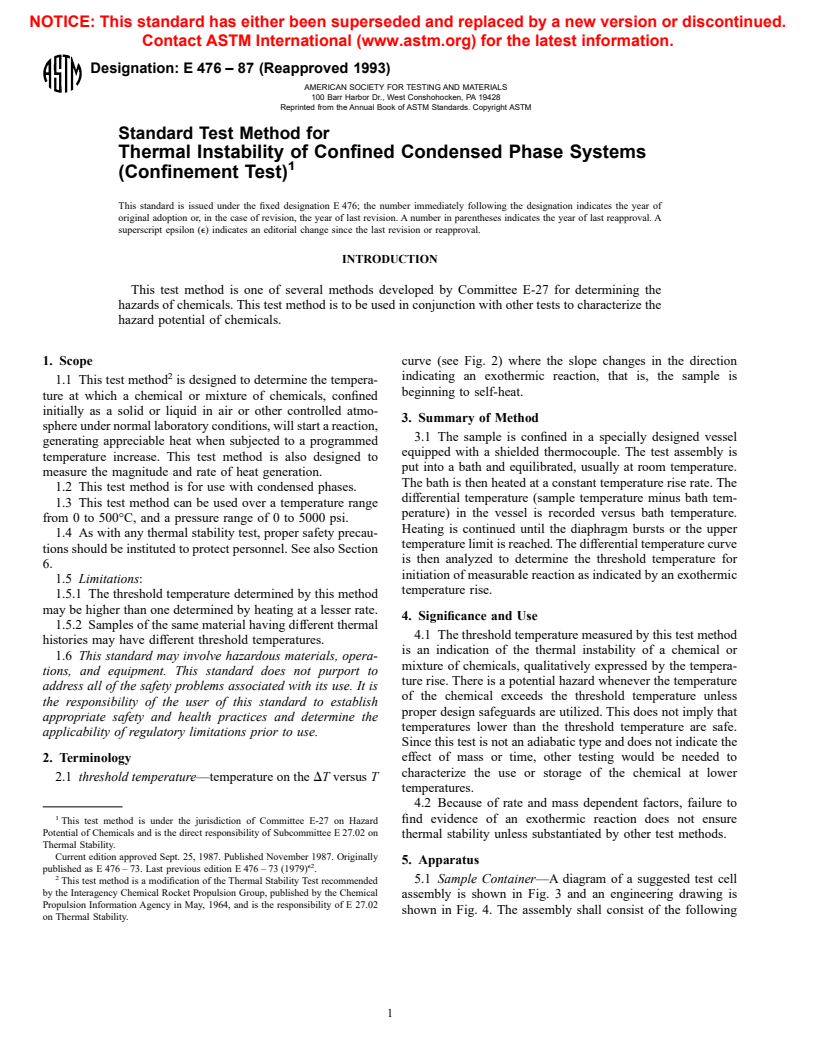

This test method is a modification of the Thermal Stability Test recommended 5.1 Sample Container—A diagram of a suggested test cell

by the Interagency Chemical Rocket Propulsion Group, published by the Chemical

assembly is shown in Fig. 3 and an engineering drawing is

Propulsion Information Agency in May, 1964, and is the responsibility of E 27.02

shown in Fig. 4. The assembly shall consist of the following

on Thermal Stability.

E 476

FIG. 1 Connector, Gasket, and Burst Diaphragm

function of bath temperature. A suitable recorder for this test is

a standard 8.5 by 11 in. X-Y plotter. Two recorders are required

if pressure versus bath temperature is monitored. Dual-pen

plotters are suitable, provided the temperature pens do not

interact at any critical junction of the reaction.

5.2.2 The maximum reaction rates that can be followed

using the recommended instrumentation are limited by the

writing speeds of the mechanical writing recorders. When

these are calibrated as described in Section 8, rates of reaction

producing temperature changes of 5°C per s can be determined.

Certain reactions may cause temperature changes in excess of

FIG. 2 Idealized Thermogram these. If more exact resolution for rapid reactions is desired, it

is necessary to use a recording oscillograph in place of the: X-Y

recorder.

parts: basic test cell, sample thermocouple, compression fitting,

5.3 Low-Range Heating Bath—For temperatures from 0 to

sealing ring, burst diaphragm, modified Army-Navy specifica-

370°C the bath may be a conventional 2-L silicon oil unit with

tion union (AN union), vent tube and flare fitting. Detailed

heaters (1800 W), stirring motor, and temperature programmer.

dimensions of all parts are given in Fig. 4 with the exception of

The bath container shall be metal with strip heaters on the

those parts readily available from manufacturers. The parts are

outside. The bath shall be well insulated. A cooling coil shall be

listed in Table 1. The internal volume ofthe assembled test cell

wrapped around the container to reduce the time lost between

3,4

is approximately 1.1 mL.

tests (optional). The coolant shall be tap water. The nominal

5.2 Instrumentation:

heating rate for the bath shall be 8 to 10°C per min.

5.2.1 One recorder is used for recording the difference

5.4 High-Range Heating Bath—For temperatures between

between the sample temperature and the bath temperature as a

100 and 500°C a bath of a low-melting alloy may be employed.

The bath medium may be cerrobend/Alloys or Woods’ metal

(Caution. Woods’ metal may contain cadmium and should be

Apparatus of similar designs with a total volume of 1 to 10 mL can be used.

This revised test method, when used with its provision for optional pressure

measurement, is essentially similar to earlier versions of this in which pressure

measurement was an integral part. Dow Corning 710 has been found satisfactory for this purpose.

E 476

of impact sensitivity has previously been made and has shown

sufficient insensitivity to permit powdering or compaction.

6.3 Upon rupture of the diaphragm, noxious fumes may be

released into the laboratory. To prevent escape of the reaction

products into the laboratory atmosphere, conduct tests either in

a fume hood or pipe the vent line to a suitable exhaust system.

6.4 The bath of hot oil or molten metal may inadvertently be

spilled or ruptured and cause personnel burns or laboratory

fires. To prevent such accidents, the test unit should be located

in a separate fume hood constructed of non-combustible

materials. The use of a fluidized sand bath minimizes this

particular hazard.

6.5 During the test, certain sensitive chemicals may deto-

nate resulting in destruction of the basic test cell assembly and

possible destruction of the bath. Such violent reactions fre-

quently hurl fragments through the surroundings at high

velocity with great danger to personnel. To prevent injury from

possible shrapnel, conduct tests in a barricaded enclosure or

behind a blast shield contained within a fume hood.

6.6 All controls and switches should be on the operator side

of the blast shield or enclosure so that during emergencies,

steps can be taken to turn off heaters and shut down the system

without exposing personnel to danger.

6.7 A loud report accompanies the rupture of a burst

diaphragm; this may cause accidents by startling personnel

engaged in other tasks. Although the use of fume hoods and

blast shields muffles the sound, all nearby personnel should be

warned that the test is in progress prior to running the test.

6.8 Give thought to procedures for cooling. If water is to be

used for cooling, care is needed since in most instances, the

FIG. 3 Thermal Stability Bomb Assembly

temperatures of the bath will be much higher than the boiling

point of water.

used with adequate ventilation to remove toxic fumes). A

6.9 In some cases the pressure may not be sufficient to burst

temperature programmer is also employed with the metal bath.

the pressure diaphragm. On cooling to room temperature, there

The nominal heating rate for the metal bath is 8 to 10°C per

may still be a high residual pressure in the test cell. Take care

min. This heating rate may prove difficult to maintain above

in relieving pressure from the cell. The operator should be

400°C unless the bath is well protected from air currents.

protected by a shield and have protective covering for eyes,

5.5 Full-Range Heating Bath—A fluidized sand bath

arms and hands.

equipped with vacuum dust ring may be conveniently used for

NOTE 1—It would be jud

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.