ASTM D1941-91(2007)

(Test Method)Standard Test Method for Open Channel Flow Measurement of Water with the Parshall Flume

Standard Test Method for Open Channel Flow Measurement of Water with the Parshall Flume

SIGNIFICANCE AND USE

Flume designs are available for throat sizes of 1 in. (2.54 cm) to 50 ft (15.2 m) which cover maximum flows of 0.2 to 3000 ft3/s (0.0057 to 85 m3/s) (1) and (2)4 . They can therefore be applied to a wide range of flows, with head losses that are moderate.

The flume is self-cleansing for moderate solids transport and therefore is suited for wastewater and flows with sediment.

SCOPE

1.1 This test method covers measurement of the volumetric flowrate of water and wastewater in open channels with the Parshall flume.

1.1.1 Information related to this test method can be found in ISO 1438 and ISO 4359.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1941 − 91 (Reapproved2007)

Standard Test Method for

Open Channel Flow Measurement of Water with the Parshall

Flume

This standard is issued under the fixed designation D1941; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Definitions of Terms Specific to This Standard:

3.2.1 free flow—a condition where the flowrate is governed

1.1 This test method covers measurement of the volumetric

by the state of flow at the crest overfall and hence can be

flowrate of water and wastewater in open channels with the

determined from a single upstream depth measurement.

Parshall flume.

1.1.1 Information related to this test method can be found in

3.2.2 head—the height of a liquid above a specified point;

ISO 1438 and ISO 4359.

that is, the flume crest.

1.2 This standard does not purport to address all of the

3.2.3 hydraulic jump—an abrupt transition from supercriti-

safety concerns, if any, associated with its use. It is the

caltosubcriticalflow,accompaniedbyconsiderableturbulence

responsibility of the user of this standard to establish appro-

or gravity waves, or both.

priate safety and health practices and determine the applica-

3.2.4 normal depth—the uniform depth of flow for a given

bility of regulatory limitations prior to use.

flowrate in a long open channel of specific shape, roughness,

and slope.

2. Referenced Documents

3.2.5 primary instrument—the device (in this case, the

2.1 ASTM Standards:

flume) that creates a hydrodynamic condition that can be

D1129 Terminology Relating to Water

sensed by the secondary instrument.

D2777 Practice for Determination of Precision and Bias of

Applicable Test Methods of Committee D19 on Water

3.2.6 scow float—an in-stream flat for depth sensing usually

D3858 Test Method for Open-Channel Flow Measurement

mounted on a hinged cantilever.

of Water by Velocity-Area Method

3.2.7 secondary instrument—in this case, a device which

2.2 ISO Standards:

measures the depth of flow at an appropriate location in the

ISO 555 Liquid Flow Measurements in Open Channels—

flume. The secondary instrument may also convert the mea-

Dilution Methods for Measurement of Steady Flow—

sured depth to an indicated flow rate.

Constant Rate Injection Method

3.2.8 stilling well—a small reservoir connected through a

ISO 1438 Liquid Flow Measurement in Open Channels

constricted passage to the main channel, that is, the flume, so

Using Thin-Plate Weirs and Venturi Flumes

that a depth measurement can be made under quiescent

ISO 4359 Liquid Flow Measurement in Open Channels—

conditions.

Rectangular Trapezoidal and U-shaped Flumes

3.2.9 subcritical flow—open channel flow at a velocity less

3. Terminology

than the velocity of gravity waves in the same depth of water.

3.1 Definitions: For definitions of terms used in this test

Subcritical flow is affected by downstream conditions, since

method, refer to Terminology D1129. disturbances are able to travel upstream.

3.2.10 submerged flow—a condition where the water stage

downstream of the flume is sufficiently high to affect the flow

This test method is under the jurisdiction of ASTM Committee D19 on Water

and is the direct responsibility of Subcommittee D19.07 on Sediments,

over the flume crest and hence the free-flow depth-discharge

Geomorphology, and Open-Channel Flow.

relation no longer applies and discharge depends on two head

Current edition approved June 15, 2007. Published June 2007. Originally

measurements.

approved in 1962. Last previous edition approved in 2001 as D1941 – 91 (2001).

DOI: 10.1520/D1941-91R07.

3.2.11 supercritical flow—open channel flow at a velocity

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

greater than that of gravity waves in the same depth, so

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on disturbances cannot travel upstream, and downstream condi-

the ASTM website.

tions do not affect the flow.

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. 3.2.12 throat—the constriction in a flume.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1941 − 91 (2007)

4. Summary of Test Method

4.1 Parshall flumes are measuring flumes of specified ge-

ometries for which empirical relations of the form

n

Q5CH (1)

a

have been established so that the flowrate, Q, can be

determined from a single depth measurement, H , in free flow.

a

If the flow is submerged, an addition downstream depth, H ,

b

must be measured and suitable adjustments made.

5. Significance and Use

5.1 Flumedesignsareavailableforthroatsizesof1in.(2.54

cm) to 50 ft (15.2 m) which cover maximum flows of 0.2 to

3 3 4

3000 ft /s (0.0057 to 85 m /s) (1) and (2) . They can therefore

be applied to a wide range of flows, with head losses that are

moderate.

5.2 Theflumeisself-cleansingformoderatesolidstransport

and therefore is suited for wastewater and flows with sediment.

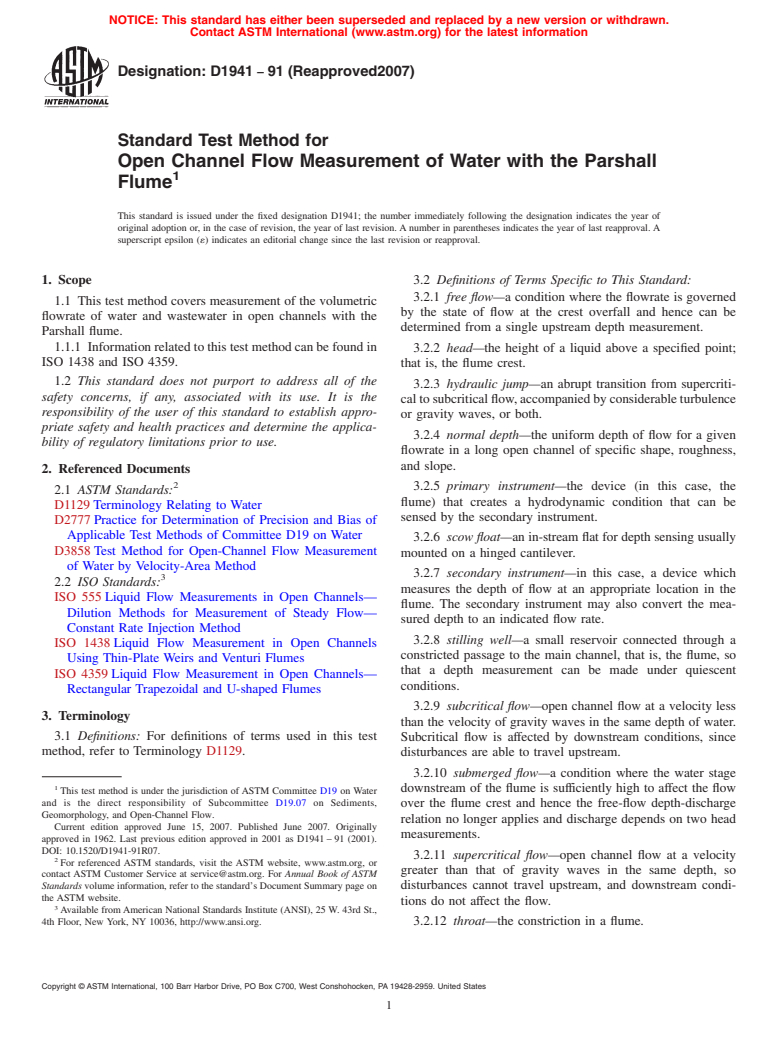

FIG. 1 Parshall Flume

6. Interferences

6.1 Theflumeisapplicableonlytoopenchannelflowandis

inoperative under full-pipe flow conditions.

7.3.2 The lateral area of the stilling well is governed in part

6.2 Although the flume has substantial self-cleansing capac- by the requirements of the depth sensor. For example, the

ity, it can be clogged by debris or affected by accumulation of clearancebetweenafloatandthestilling-wellwallshouldbeat

aquatic growth and cleaning or debris removal may be re- least 0.1 ft (3 cm) and should be increased to 0.25 ft (7.6 cm)

quired. ifthewellismadeofconcreteorotherroughmaterial,thefloat

diameteritselfbeingdeterminedinpartbypermissiblefloatlag

7. Apparatus

error (see 11.4.2). Other types of depth sensors may also

7.1 AParshallflumemeasuringsystemconsistsoftheflume

impose size requirements on the stilling well, and the maxi-

itself(primary)andadepth-measuringdevice(secondary).The

mum size may be limited by response lag.

secondary device can range from a simple scale for manual

7.3.3 Provision should be made for cleaning and flushing

readings to an instrument which continuously senses the depth,

the stilling well to remove accumulated solids. It may be

converts it to flowrate, and provides a readout or record of

necessary to add a small purge flow of tap water to help keep

instantaneous flowrate or totalized flow, or both.

thewellandanyconnectorpipeandthesensorpartsclean.This

flow should be small enough for any depth increase in the

7.2 The Flume:

stilling well to be imperceptible.

7.2.1 Parshall flumes are characterized by throat width;

7.3.4 The opening in the flume sidewall connecting to the

dimensions and flowrates for each size are given in Fig. 1 and

stilling well either directly or through a short perpendicular

Table 1, respectively. The dimensions must be maintained

pipe must have a burr-free junction with the wall. The hole or

within 2 %, because the flume is an empirical device and

pipe must be small enough to dampen surface disturbances; an

corrections for non-standard geometry are only estimates. The

area of about 1/1000th of the stilling-well area is considered

inside surface of the flume should be at least as smooth as a

adequateforthispurpose.However,thediametershouldnotbe

good quality concrete finish.

so small (or the pipe so long) that it is difficult to keep open or

7.2.2 The measurement location for depth H is shown in

a

a lag is introduced in the response to changing flows (3); hole

Fig. 1. In submerged flow a second depth, H , must be

b

and pipe diameters of about ⁄2 in. (1.3 cm) should be

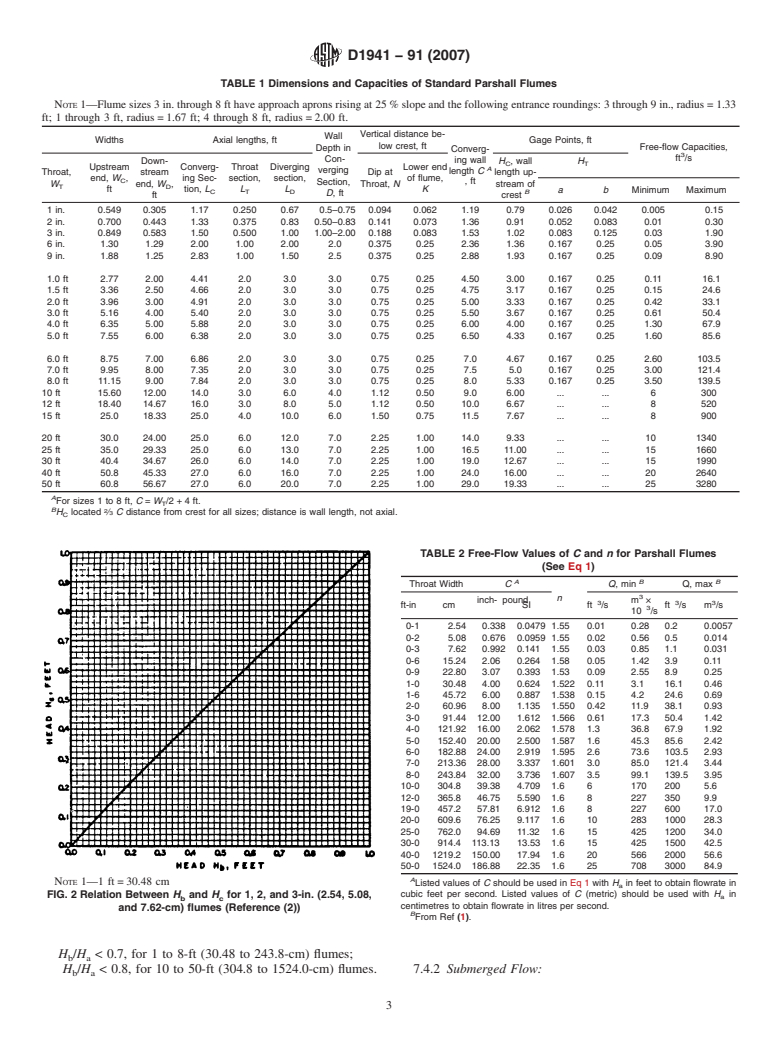

measured in the throat as indicated. However, in the 1, 2, and

considered a minimum. If changes are made in pipe sizes, they

3-in. (2.54, 5.08, and 7.62-cm) flumes, this measurement is

should be done sufficiently removed from the flume wall that

made at H instead, because disturbances have been observed

c

no drawdown will occur. The intake dimensions cited in this

at the H location in these sizes ((1) and (2)). See Fig. 2 for the

b

paragraph should be regarded as suggestions only.

relation between H and H .

b c

7.4 Depth-Discharge Relations:

7.3 Stilling Well and Connector :

7.4.1 Free Flow—The values of C and n for use with Eq 1

7.3.1 Stilling wells are recommended for accurate depth

are given in Table 2, along with approximate limiting flow-

measurements; they are required when wire- or tape-supported

rates.Themaximumsubmergenceratios, H /H ,forwhichfree

b a

cylindrical floats are used or when the liquid surface is

flow will occur are:

fluctuating.

H /H < 0.5, for 1, 2, and 3-in. (2.54, 5.08, and

b a

7.62-cm) flumes;

The boldface numbers in parentheses refer to a list of references at the end of

this test method. H /H < 0.6, for 6 and 9-in. (15.24 and 22.86-cm) flumes;

b a

D1941 − 91 (2007)

TABLE 1 Dimensions and Capacities of Standard Parshall Flumes

NOTE 1—Flume sizes 3 in. through 8 ft have approach aprons rising at 25 % slope and the following entrance roundings: 3 through 9 in., radius = 1.33

ft; 1 through 3 ft, radius = 1.67 ft; 4 through 8 ft, radius = 2.00 ft.

Vertical distance be-

Wall

Widths Axial lengths, ft Gage Points, ft

low crest, ft

Free-flow Capacities,

Depth in

Converg-

ft /s

Con-

ing wall

Down- H , wall H

C T

Upstream Converg- Throat Diverging Lower end

A

verging length C

Throat, stream Dip at length up-

end, W , ing Sec- section, section, of flume,

C ,ft

Section,

W end, W , Throat, N stream of

T D

ft tion, L L L K

C T D B ab Minimum Maximum

D,ft

ft crest

1 in. 0.549 0.305 1.17 0.250 0.67 0.5–0.75 0.094 0.062 1.19 0.79 0.026 0.042 0.005 0.15

2 in. 0.700 0.443 1.33 0.375 0.83 0.50–0.83 0.141 0.073 1.36 0.91 0.052 0.083 0.01 0.30

3 in. 0.849 0.583 1.50 0.500 1.00 1.00–2.00 0.188 0.083 1.53 1.02 0.083 0.125 0.03 1.90

6 in. 1.30 1.29 2.00 1.00 2.00 2.0 0.375 0.25 2.36 1.36 0.167 0.25 0.05 3.90

9 in. 1.88 1.25 2.83 1.00 1.50 2.5 0.375 0.25 2.88 1.93 0.167 0.25 0.09 8.90

1.0 ft 2.77 2.00 4.41 2.0 3.0 3.0 0.75 0.25 4.50 3.00 0.167 0.25 0.11 16.1

1.5 ft 3.36 2.50 4.66 2.0 3.0 3.0 0.75 0.25 4.75 3.17 0.167 0.25 0.15 24.6

2.0 ft 3.96 3.00 4.91 2.0 3.0 3.0 0.75 0.25 5.00 3.33 0.167 0.25 0.42 33.1

3.0 ft 5.16 4.00 5.40 2.0 3.0 3.0 0.75 0.25 5.50 3.67 0.167 0.25 0.61 50.4

4.0 ft 6.35 5.00 5.88 2.0 3.0 3.0 0.75 0.25 6.00 4.00 0.167 0.25 1.30 67.9

5.0 ft 7.55 6.00 6.38 2.0 3.0 3.0 0.75 0.25 6.50 4.33 0.167 0.25 1.60 85.6

6.0 ft 8.75 7.00 6.86 2.0 3.0 3.0 0.75 0.25 7.0 4.67 0.167 0.25 2.60 103.5

7.0 ft 9.95 8.00 7.35 2.0 3.0 3.0 0.75 0.25 7.5 5.0 0.167 0.25 3.00 121.4

8.0 ft 11.15 9.00 7.84 2.0 3.0 3.0 0.75 0.25 8.0 5.33 0.167 0.25 3.50 139.5

10 ft 15.60 12.00 14.0 3.0 6.0 4.0 1.12 0.50 9.0 6.00 . . 6 300

12 ft 18.40 14.67 16.0 3.0 8.0 5.0 1.12 0.50 10.0 6.67 . . 8 520

15 ft 25.0 18.33 25.0 4.0 10.0 6.0 1.50 0.75 11.5 7.67 . . 8 900

20 ft 30.0 24.00 25.0 6.0 12.0 7.0 2.25 1.00 14.0 9.33 . . 10 1340

25 ft 35.0 29.33 25.0 6.0 13.0 7.0 2.25 1.00 16.5 11.00 . . 15 1660

30 ft 40.4 34.67 26.0 6.0 14.0 7.0 2.25 1.00 19.0 12.67 . . 15 1990

40 ft 50.8 45.33 27.0 6.0 16.0 7.0 2.25 1.00 24.0 16.00 . . 20 2640

50 ft 60.8 56.67 27.0 6.0 20.0 7.0 2.25 1.00 29.0 19.33 . . 25 3280

A

For sizes 1 to 8 ft, C = W /2 + 4 ft.

T

B

H located ⁄3 C distance from crest for all sizes; distance is wall length, not axial.

C

TABLE 2 Free-Flow Values ofC andn for Parshall Flumes

(See Eq 1)

A B B

Throat Width C Q,min Q, max

n

inch- pound m ×

3 3 3

ft-in cm SI ft /s ft /s m /s

10 /s

0-1 2.54 0.338 0.0479 1.55 0.01 0.28 0.2 0.0057

0-2 5.08 0.676 0.0959 1.55 0.02 0.56 0.5 0.014

0-3 7.62 0.992 0.141 1.55 0.03 0.85 1.1 0.031

0-6 15.24 2.06 0.264 1.58 0.05 1.42 3.9 0.11

0-9 22.80 3.07 0.393 1.53 0.09 2.55 8.9 0.25

1-0 30.48 4.00 0.624 1.522 0.11 3.1 16.1 0.46

1-6 45.72 6.00 0.887 1.538 0.15 4.2 24.6 0.69

2-0 60.96 8.00 1.135 1.550 0.42 11.9 38.1 0.93

3-0 91.44 12.00 1.612 1.566 0.61 17.3 50.4 1.42

4-0 121.92 16.00 2.062 1.578 1.3 36.8 67.9 1.92

5-0 152.40 20.00 2.500 1.587 1.6 45.3 85.6 2.42

6-0 182.88 24.00 2.919 1.595 2.6 73.6 103.5 2.93

7-0 213.36 28.00 3.337 1.601 3.0 85.0 121.4 3.44

8-0 243.84 32.00 3.736 1.607 3.5 99.1 139.5 3.95

10-0 304.8 39.38 4.709 1.6 6 170 200 5.6

12-0 365.8 46.75 5.590 1.6 8 227 350 9.9

19-0 457.2 57.81 6.912 1.6 8 227 600 17.0

20-0 609.6 76.25 9.117 1.6 10 283 1000 28.3

25-0 762.0 94.69 11.32 1.6 15 425 1200 34.0

30-0 914.4 113.13 13.53 1.6 15 425 1500 42.5

40-0 1219.2 150.00 17.94 1.6 20 566 2000 56.6

50-0 1524.0 186.88 22.35 1.6 25 708 3000 84.9

A

NOTE 1—1 ft = 30.48 cm

Listed values of C should be used in Eq 1 with H in feet to obtain flowrate in

a

cubic feet per second. Listed values of C (metric) should be used with H in

FIG. 2 Relation BetweenH andH for 1, 2, and 3-in. (2.54, 5.08,

a

b c

centimetres to obtain flowrate in litres per second.

and 7.62-cm) flumes (Reference (2))

B

From Ref (1).

H /H < 0.7, for 1 to 8-ft (30.48 to 243.8-cm) flumes;

b a

H /H < 0.8, for 10 to 50-ft (304.8 to 1524.0-cm) flumes. 7.4.2 Submerged Flow:

b a

D1941 − 91 (2007)

7.4.2.1 Discharge rates for submerged-flow conditions are 7.6.1 A minimal secondary system for continuous monitor-

given for 1, 2, 3, 6, and 9-in. (2.54, 5.08, 7.62, 15.24, and ing would contain a depth-sensing device and a depth indicator

22.86-cm) flumes in Table 3, Table 4, Table 5, Table 6, and or recorder from which the user could determine flowrates

Table 7 (Table 8, Table 9, Table 10, Table 11, and Table 12), from the depth-discharge relations. Optionally, the secondary

which were compiled from published curves (2). system could convert the measured depth to an indicated or

7.4.2.2 Foralllargerflumes,thatis,1to50ft(30.48to1524 recordedflowrate,orboth,andtotalizedflow,andfurthercould

cm) throat widths, flowrates under submerged-flow conditions transmit the information electrically or pneumatically to a

are given as corrections to be subtracted from the free-flow central location.

discharge at the same H . These corrections are found in Table 7.6.2 Continuous depth measurements can be made with

a

13, Table 14, Table 15, and Table 16 (Table 17, Table 14, Table several types of sensors including, but not restricted to, the

18, and Table 16), which were compiled from published curves following:

(2). 7.6.2.1 Floats, such as, cylindrical (3) and scow types;

7.4.2.3 It is recommended that submergence be avoided if 7.6.2.2 Pressure sensors, such as, bubble types (3) and (4) ,

possible and that ratios not be allowed to ex

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.