ASTM C1088-09

(Specification)Standard Specification for Thin Veneer Brick Units Made From Clay or Shale

Standard Specification for Thin Veneer Brick Units Made From Clay or Shale

ABSTRACT

This specification covers thin veneer brick units made from clay, shale, fire clay, sand, or mixtures thereof, and fired to incipient fusion for use in adhered or fastened veneer applications. The brick units shall be available in both Grades Interior and Exterior of the following types: Type TBS (Standard), which are for general masonry use; Type TBX (Select), which are produced with higher degree of precision; and Type TBA (Architectural), which are selected to produce characteristic architectural effects resulting from nonuniformity in size and texture of the individual units. Materials shall undergo durability, and freezing and thawing tests and should adhere to physical property requirements such as maximum water absorption, maximum saturation coefficient, maximum water loss, breakage, cracking, and weathering index. Bricks should also conform to specified characteristics as to face finish, color and texture, size and dimensions, and warpage.

SCOPE

1.1 This specification covers thin veneer brick units made from clay, shale, fire clay, sand, or mixtures thereof, and fired to incipient fusion for use in adhered or fastened veneer applications. Three types of thin veneer brick units in each of two grades are covered. In this specification, the term thin veneer brick shall be understood to mean clay masonry unit with a maximum thickness of 1¾ in. (44.45 mm).

Note 1—Brick intended for paving should be specified under Specification C 902.

1.2 The property requirements of this specification apply at the time of purchase. The use of results from testing of brick extracted from masonry structures for determining conformance or nonconformance to the property requirements (Section 5) of this specification is beyond the scope of this specification.

1.3 Brick covered by this specification are manufactured from clay, shale, or similar naturally occurring substances and subjected to a heat treatment at elevated temperatures (firing). The heat treatment must develop sufficient fired bond between the particulate constituents to provide the strength and durability requirements of the specification. (See “firing” and “fired bond” in Terminology C 43.)

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 The text of this specification references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.:

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C1088 – 09

Standard Specification for

1

Thin Veneer Brick Units Made From Clay or Shale

This standard is issued under the fixed designation C1088; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

1.1 This specification covers thin veneer brick units made 2.1 ASTM Standards:

3

from clay, shale, fire clay, sand, or mixtures thereof, and fired C43 Terminology of Structural Clay Products

to incipient fusion for use in adhered or fastened veneer C67 Test Methods for Sampling and Testing Brick and

applications. Three types of thin veneer brick units in each of Structural Clay Tile

two grades are covered. In this specification, the term thin C902 Specification for Pedestrian and Light Traffic Paving

veneer brick shall be understood to mean clay masonry unit Brick

3

with a maximum thickness of 1 ⁄4 in. (44.45 mm). E835/E835M Guide for Modular Coordination of Clay and

Concrete Masonry Units

NOTE 1—Brick intended for paving should be specified under Specifi-

cation C902.

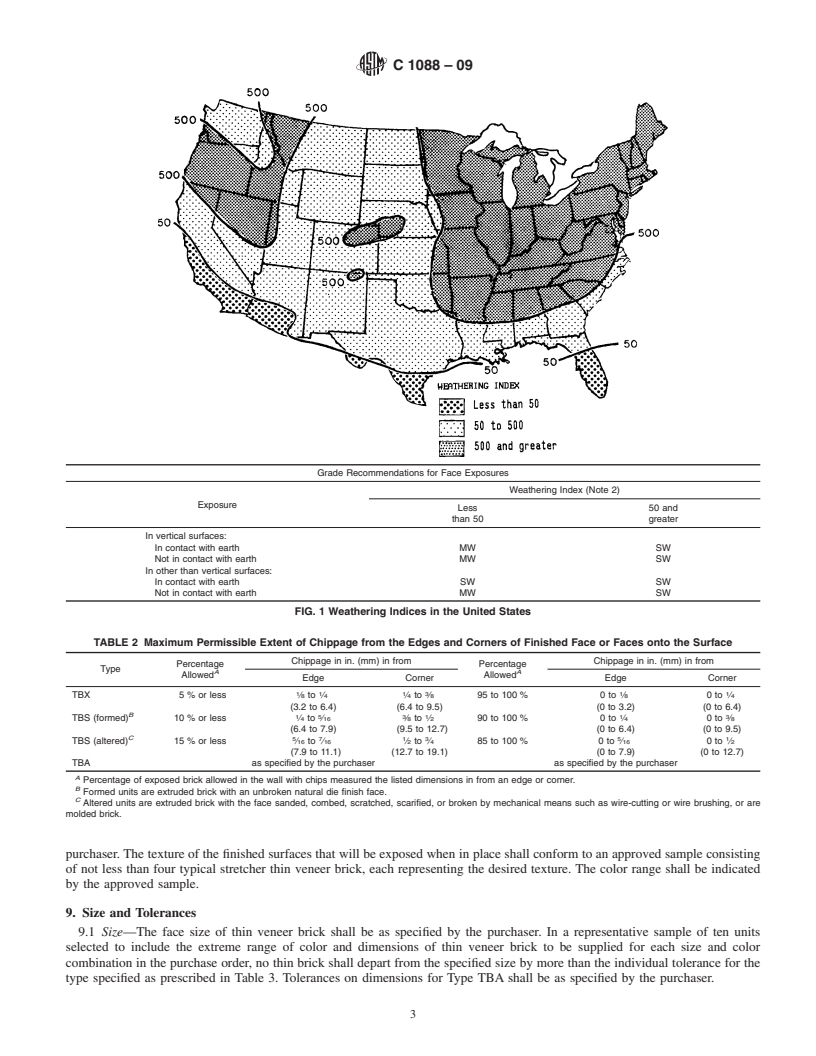

3. Grades

1.2 The property requirements of this specification apply at

3.1 Two grades of thin veneer brick units are covered for

the time of purchase. The use of results from testing of brick

exposure conditions to weather and are defined in Table 1 as

extracted from masonry structures for determining conform-

Interior and Exterior.

ance or nonconformance to the property requirements (Section

5) of this specification is beyond the scope of this specification. 4. Types

1.3 Brick covered by this specification are manufactured

4.1 Three types of thin veneer brick units are covered as

from clay, shale, or similar naturally occurring substances and

follows:

subjected to a heat treatment at elevated temperatures (firing).

4.1.1 Type TBS (Standard)—Thin veneer brick for general

The heat treatment must develop sufficient fired bond between

use in masonry.

the particulate constituents to provide the strength and dura-

4.1.2 Type TBX (Select)—Thin veneer brick for general use

bility requirements of the specification. (See “firing” and “fired

in masonry where a higher degree of precision and lower

bond” in Terminology C43.)

permissible variation in size than permitted for Type TBS is

1.4 The values stated in inch-pound units are to be regarded

required.

as standard. The values given in parentheses are mathematical

4.1.3 Type TBA(Architectural)—Thin veneer brick for gen-

conversions to SI units that are provided for information only

eral use in masonry selected to produce characteristic architec-

and are not considered standard.

tural effects resulting from nonuniformity in size and texture of

1.5 The text of this specification references notes and

the individual units.

footnotes which provide explanatory material. These notes and

4.2 When the type is not specified, the requirements for

footnotes (excluding those in tables and figures) shall not be

Type TBS will govern.

considered as requirements of the standard.

1 2

This specification is under the jurisdiction of ASTM Committee C15 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Manufactured Masonry Units and is the direct responsibility of Subcommittee contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

C15.02 on Brick and Structural Clay Tile. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Jan. 1, 2009. Published January 2009. Originally the ASTM website.

3

approved in 1988. Last previous edition approved in 2007 as C1088 – 07a. DOI: Withdrawn. The last approved version of this historical standard is referenced

10.1520/C1088-09. on www.astm.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

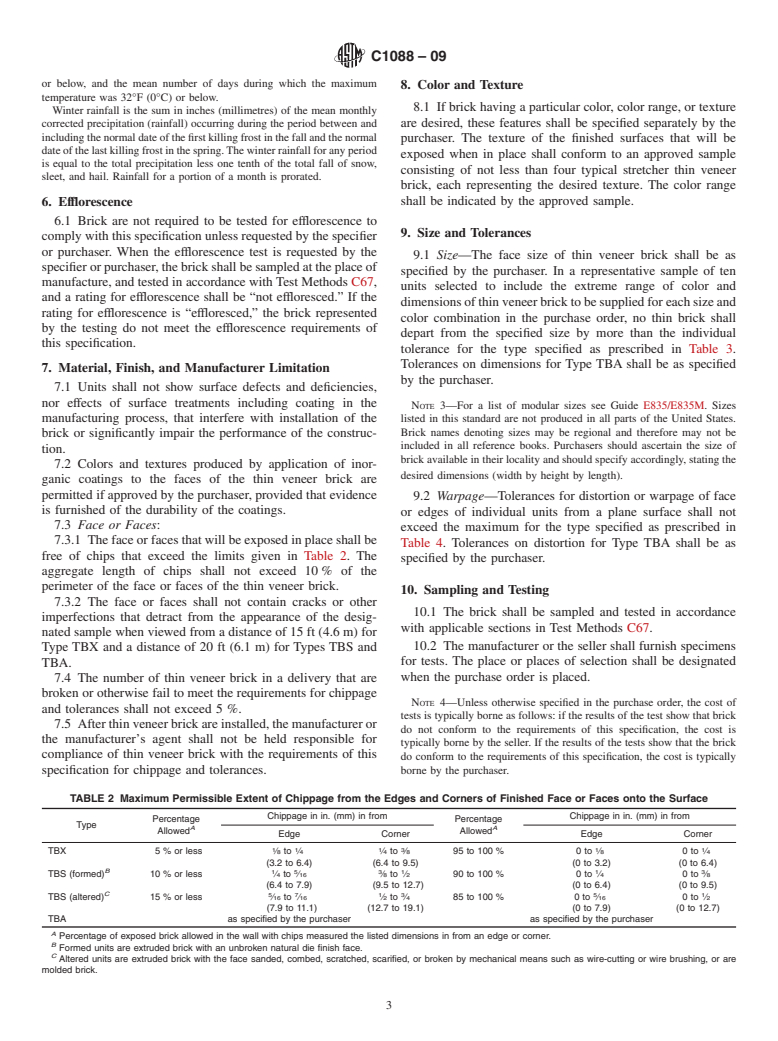

C1088 – 09

TABLE 1 Physical Requirements

thin veneer brick, meeting all other requirements, complies

Maximum Water Maximum withthefollowingrequirementswhensubjectedto50cyclesof

Absorption by 5-h Saturation

the freezing-and-thawing test:

A

Designation Boiling, % Coefficient

5.2.1 Grade Exterior: Breakage and Weight Loss

Average Average

Individual Individual

of 5 units of 5 units Requirement—No individual unit separates or disintegrates

Grade Exterior 17.0 20.0 0.78 0.80

resulting in a weight loss greater than 0.5 % of its original dry

Grade Interior 22.0 25.0 0.88 0.90

weight.

A

The saturation coefficient is the ratio of absorption by 24-h submersion in cold

5.2.2 Grade Exterior: Cracking

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1088–07a Designation: C 1088 – 09

Standard Specification for

1

Thin Veneer Brick Units Made From Clay or Shale

This standard is issued under the fixed designation C 1088; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers thin veneer brick units made from clay, shale, fire clay, sand, or mixtures thereof, and fired to

incipient fusion for use in adhered or fastened veneer applications. Three types of thin veneer brick units in each of two grades

are covered. In this specification, the term thin veneer brick shall be understood to mean clay masonry unit with a maximum

3

thickness of 1 ⁄4 in. (44.45 mm).

NOTE 1—Brick intended for paving should be specified under Specification C 902.

1.2 The property requirements of this specification apply at the time of purchase. The use of results from testing of brick

extracted from masonry structures for determining conformance or nonconformance to the property requirements (Section 5) of

this specification is beyond the scope of this specification.

1.3 Brick covered by this specification are manufactured from clay, shale, or similar naturally occurring substances and

subjected to a heat treatment at elevated temperatures (firing). The heat treatment must develop sufficient fired bond between the

particulate constituents to provide the strength and durability requirements of the specification. (See “firing” and “fired bond” in

Terminology C 43.)

1.4The values stated in inch-pound units are to be regarded as standard. The metric equivalents may be approximate.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.5 The text of this specification references notes and footnotes which provide explanatory material. These notes and footnotes

(excluding those in tables and figures) shall not be considered as requirements of the standard.

2. Referenced Documents

2

2.1 ASTM Standards:

C43 Terminology of Structural Clay Products

C67 Test Methods for Sampling and Testing Brick and Structural Clay Tile

C 902 Specification for Pedestrian and Light Traffic Paving Brick

E 835/E 835M Guide for Modular Coordination of Clay and Concrete Masonry Units

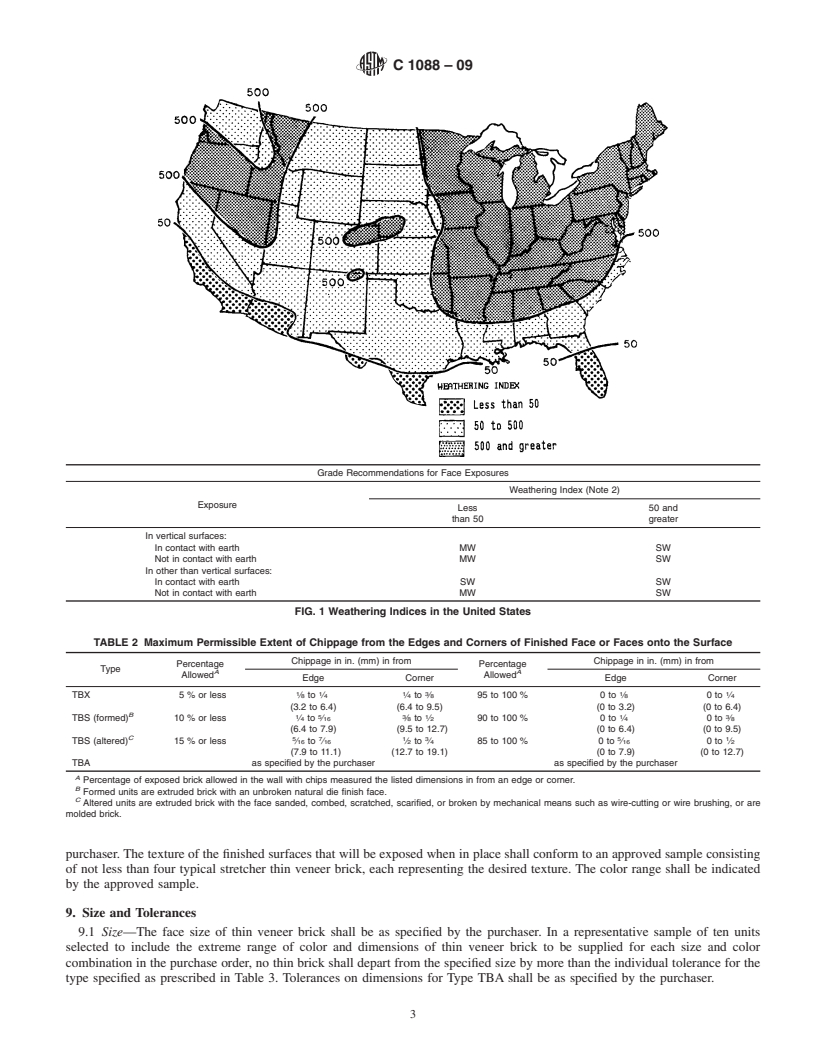

3. Grades

3.1 Two grades of thin veneer brick units are covered for exposure conditions to weather and are defined in Table 1 as Interior

and Exterior.

4. Types

4.1 Three types of thin veneer brick units are covered as follows:

4.1.1 Type TBS (Standard)—Thin veneer brick for general use in masonry.

4.1.2 Type TBX (Select)—Thin veneer brick for general use in masonry where a higher degree of precision and lower

permissible variation in size than permitted for Type TBS is required.

4.1.3 Type TBA (Architectural)—Thin veneer brick for general use in masonry selected to produce characteristic architectural

effects resulting from nonuniformity in size and texture of the individual units.

4.2 When the type is not specified, the requirements for Type TBS will govern.

1

This specification is under the jurisdiction ofASTM Committee C15 on Manufactured Masonry Units and is the direct responsibility of Subcommittee C15.02 on Brick

and Structural Clay Tile.

Current edition approved JuneJan. 1, 2007.2009. Published June 2007.January 2009. Originally approved in 1988. Last previous edition approved in 2007 as C 1088 – 07a.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C1088–09

TABLE 1 Physical Requirements

Maximum Water Maximum

Absorption by 5-h Saturation

A

Designation Boiling, % Coefficient

Average Average

Individual Individual

of 5 units of 5 units

Grade Exterior 17.0 20.0 0.78 0.80

Grade Interior 22.0 25.0 0.88 0.90

A

The saturation coefficient is the ratio of absorption by 24-h submersion in cold

water to that after 5-h submersion in boiling water.

5.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1088–07a Designation: C 1088 – 09

Standard Specification for

1

Thin Veneer Brick Units Made From Clay or Shale

This standard is issued under the fixed designation C 1088; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers thin veneer brick units made from clay, shale, fire clay, sand, or mixtures thereof, and fired to

incipient fusion for use in adhered or fastened veneer applications. Three types of thin veneer brick units in each of two grades

are covered. In this specification, the term thin veneer brick shall be understood to mean clay masonry unit with a maximum

3

thickness of 1 ⁄4 in. (44.45 mm).

NOTE 1—Brick intended for paving should be specified under Specification C 902.

1.2 The property requirements of this specification apply at the time of purchase. The use of results from testing of brick

extracted from masonry structures for determining conformance or nonconformance to the property requirements (Section 5) of

this specification is beyond the scope of this specification.

1.3 Brick covered by this specification are manufactured from clay, shale, or similar naturally occurring substances and

subjected to a heat treatment at elevated temperatures (firing). The heat treatment must develop sufficient fired bond between the

particulate constituents to provide the strength and durability requirements of the specification. (See “firing” and “fired bond” in

Terminology C 43.)

1.4The values stated in inch-pound units are to be regarded as standard. The metric equivalents may be approximate.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.5 The text of this specification references notes and footnotes which provide explanatory material. These notes and footnotes

(excluding those in tables and figures) shall not be considered as requirements of the standard.

2. Referenced Documents

2

2.1 ASTM Standards:

C43 Terminology of Structural Clay Products

C67 Test Methods for Sampling and Testing Brick and Structural Clay Tile

C 902 Specification for Pedestrian and Light Traffic Paving Brick

E 835/E 835M Guide for Modular Coordination of Clay and Concrete Masonry Units

3. Grades

3.1 Two grades of thin veneer brick units are covered for exposure conditions to weather and are defined in Table 1 as Interior

and Exterior.

4. Types

4.1 Three types of thin veneer brick units are covered as follows:

4.1.1 Type TBS (Standard)—Thin veneer brick for general use in masonry.

4.1.2 Type TBX (Select)—Thin veneer brick for general use in masonry where a higher degree of precision and lower

permissible variation in size than permitted for Type TBS is required.

4.1.3 Type TBA (Architectural)—Thin veneer brick for general use in masonry selected to produce characteristic architectural

effects resulting from nonuniformity in size and texture of the individual units.

4.2 When the type is not specified, the requirements for Type TBS will govern.

1

This specification is under the jurisdiction ofASTM Committee C15 on Manufactured Masonry Units and is the direct responsibility of Subcommittee C15.02 on Brick

and Structural Clay Tile.

Current edition approved JuneJan. 1, 2007.2009. Published June 2007.January 2009. Originally approved in 1988. Last previous edition approved in 2007 as C 1088 – 07a.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C1088–09

TABLE 1 Physical Requirements

Maximum Water Maximum

Absorption by 5-h Saturation

A

Designation Boiling, % Coefficient

Average Average

Individual Individual

of 5 units of 5 units

Grade Exterior 17.0 20.0 0.78 0.80

Grade Interior 22.0 25.0 0.88 0.90

A

The saturation coefficient is the ratio of absorption by 24-h submersion in cold

water to that after 5-h submersion in boiling water.

5.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.